Video Display

Video Display

KINGREAL Metal Ceiling Tile Production Line Description

KINGREAL Metal Ceiling Tile Production Line Description

KINGREAL 600x1200mm Full-Automatic Metal Ceiling Tiles Production Line is one of our most featuring products, it can produce both plain and perforated metal ceiling tiles according to customers‘ needs.

Producing suspended ceiling tiles by Kingreal 60*120cm Dropped Ceiling Tiles Production Line, the ceiling tile surface is flat, the splicing is neat, the thick and thin materials can be adjusted, the equipment process is simple, and the operation is easy.

We euipped this production line with 3 presses for perforation, notching and bend forming. Each press comes with quality hydraulic system.

They provide precise perforation and corner cutting, final bending forming as per requirements. Clients can buy more molds for different types of ceiling tiles such as Clip-in, Lay-in and tegular.

The automatic cleaning machine can remove oil and rust on the surface of tiles, automatic turn-over machine and mechanical arm to transform ceiling tiles to final bend forming.

All steps are done fully automatically, which can save labor costs and avoid unnecessary injuries.

All steps are done fully automatically, which can save labor costs and avoid unnecessary injuries.

Main Components

Main ComponentsDecoiler - Straightener -- Servo Feeder -- Perforation Press -- Notching & Shearing Press Machine -- Bending Forming Press -- Products Stacking System

|

|

|

| Decoiler | Punching Press | Notching & Shearing Press Machine |

Optional:

Automatic Cleaning Machine -- Fleece Gluing Machine --

|

|

|

| Degreaser Cleaning Machine | Acoustic Ceiling Tile Fleece Gluing Machine | Automatic Turn-over Machine |

Specification

Specification

|

Leveler Machine

Thickness of material : 0.3 - 2.2 mm

Feeding speed : 25m / min Upper rollers : 9 Lower rollers : 10 |

|

Punching Press Machine

Output pressure force : 125 tons

Punching stroke : 20 mm Aperture of holes : Φ 2.5 Adjustable thickness : 10mm |

|

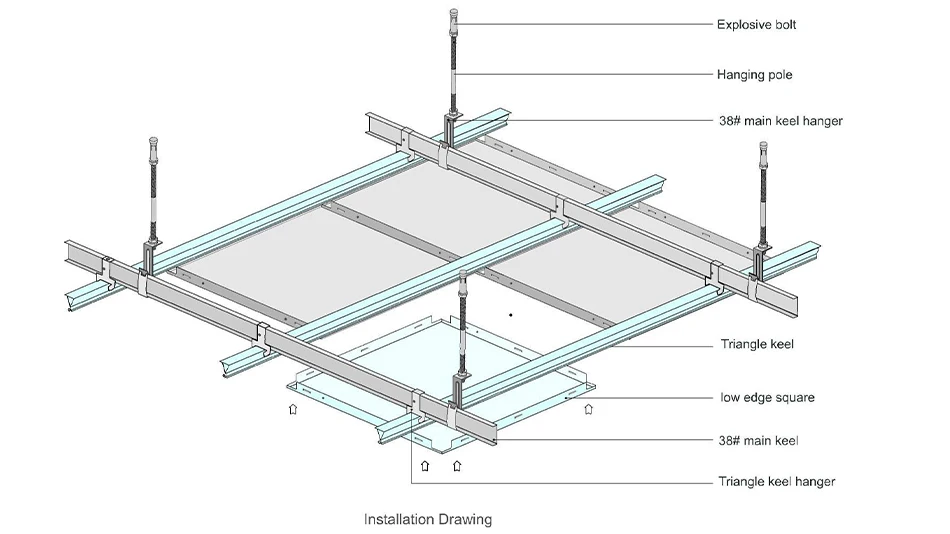

Installation Drawing

Installation Drawing

Different Size Products On Your Choice

Different Size Products On Your Choice

Related Local Installation Cases

Related Local Installation CasesKINGREAL Technical Team in Turkey

KINGREAL Technical Team in Saudi Arabia

Customer Visit

Customer VisitIt is such a delight to have friends coming from afar. KINGREAL is warmly welcome customers to visit our factory and communicate with us!

Iranian customers in KINGREAL factory