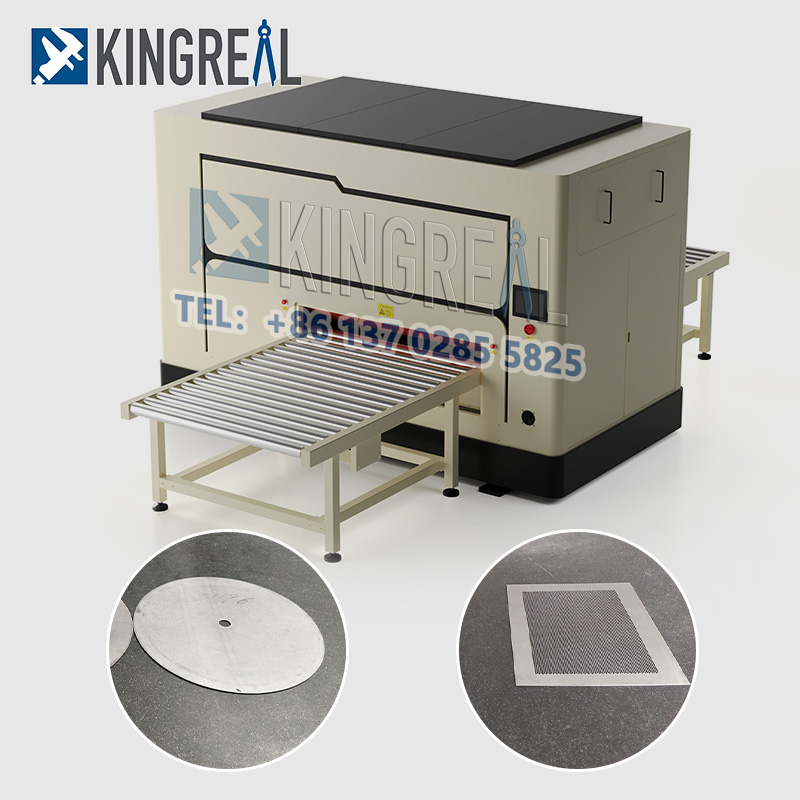

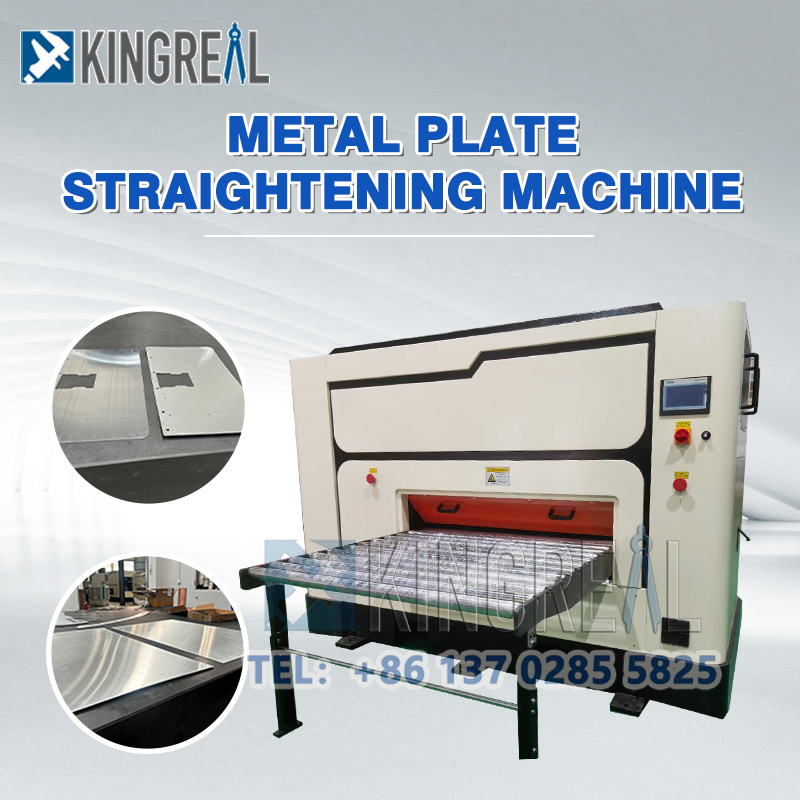

Metal Sheet Leveling Machine: An Efficient Solution for Sheet Metal Processing

2025-12-23 17:00

Metal sheet leveling machines are primarily used for straightening metal sheets, coils, perforated metal sheets, and various metal parts. Achieving a smooth, consistent surface and high-precision machining outcomes, sheet metal flattening machine play a critical role in contemporary production by removing any material deformation or warping. Hence, enhancing product quality depends on selecting a good metal sheet leveling machine.

Advanced Features of KINGREAL CEILING MACHINERY Metal Sheet Leveling Machine

--------------------------------------------------------------------------------------

KINGREAL CEILING MACHINERY sheet metal flattening machines provide an efficient solution for the processing industry. With its cutting-edge technology and high-efficiency functions, this metal sheet leveling machine delivers precise and consistent leveling results, even with the most challenging materials, ensuring that every customer's needs are met.

-Rugged and durable construction for sheet metal flattening machine

Designed to endure intensive usage, KINGREAL CEILING MACHINERY metal sheet leveling machines have a strong and long-lasting structural design. Even in the most demanding conditions, this design guarantees the sustained performance and dependability of the sheet metal flattening machine. Moreover, the metal sheet leveling machine goes through painstaking production methods to guarantee each component's stability throughout long-term usage, hence lowering failure rate.

-Easy-to-use user interface for sheet metal flattening machine

The user-friendly design of the metal sheet leveling machine helps operators to begin fast. Starting and modifying the sheet metal flattening machine is easy and uncomplicated thanks to the intuitive control interface and basic setup instructions. Whether you are a seasoned technician or a first-time operator, you may quickly change and so boost productivity.

-High-speed operation design for metal sheet leveling machine

This sheet metal flattening machine incorporates a high-speed operation design, significantly reducing processing time and increasing production efficiency. For high-volume production operations requiring fast and efficient processing, KINGREAL CEILING MACHINERY metal sheet leveling machines are undoubtedly the best choice. This is especially suitable for industries such as automotive, aerospace, and furniture manufacturing, where delivery time requirements are extremely tight.

-Advanced sensors and control systems for sheet metal flattening machine

KINGREAL CEILING MACHINERY metal sheet leveling machines are equipped with advanced sensors and a high-precision control system that can monitor and correct any deformation or warping in the material in real time. This technology increases product yield by making flat and consistent the final product free of blemishes or errors. Simultaneously, the sheet metal flattening machine serves several needs and has wide range, readily processing thin metals to hefty coils.

Wide Applications of Metal Sheet Leveling Machines

------------------------------------------------------

Metal sheet leveling machines play a vital role in numerous industries, including:

-Sheet metal flattening machine in automotive manufacturing

In the automotive industry, metal sheet leveling machines are primarily used to process components such as car bodies and chassis, ensuring their flatness and strength to improve the safety and performance of the entire vehicle.

-Sheet metal flattening machine in aerospace

In the aviation sector, material accuracy and quality come first. Reducing air resistance and increasing aircraft efficiency, metal sheet leveling machines guarantee the flawless surface of aviation components.

-Sheet metal flattening machine in electrical equipment

In the manufacturing process of electrical equipment, the leveling of metal casings and internal components not only improves the product's appearance but also ensures the precision of the fit of electrical components, reducing failure rates.

-Metal sheet leveling machine in household goods and furniture manufacturing

In the manufacturing of household products, sheet metal flattening machines produce flat and aesthetically pleasing metal components, such as furniture frames and appliance casings, enhancing the overall market competitiveness of the product.

Considerations for Choosing the Right Metal Sheet Leveling Machine

-----------------------------------------------------------------------

Selecting the right sheet metal flattening machine not only assures product quality but also streamlines manufacturing efficiency. One must take into account several elements during the selection process:

-Material Type and Thickness: Different material types and thicknesses place different requirements on the metal sheet leveling machine. Choosing the appropriate leveling model for different industries and product needs is crucial. For example, KINGREAL CEILING MACHINERY offers sheet metal flattening machines for thin plates (0.1-1mm) and thick plates (20mm), fully meeting diverse customer production needs.

-Production Efficiency and Stability: Production efficiency and machine stability are two important considerations when selecting a metal sheet leveling machine. A high-efficiency sheet metal flattening machine can complete more production tasks in a shorter time, creating greater economic benefits for the enterprise.

-Cost Considerations and Return on Investment: Although the initial investment for some high-end metal sheet leveling machines is relatively high, their high efficiency and stability during production will ultimately bring longer-term returns to the enterprise. Therefore, choosing a sheet metal flattening machine with a high cost-performance ratio is an important consideration when making investment decisions.

Importance of Metal Sheet Leveling Machine Maintenance and Upkeep

----------------------------------------------------------------------

Even the highest quality metal sheet leveling machines require regular maintenance and upkeep to ensure stable performance.

Routine Maintenance

Regularly inspect all sheet metal flattening machine components, keep the metal sheet leveling machine clean, and perform regular lubrication to effectively extend the sheet metal flattening machine's lifespan. Operators should also be trained in operating techniques to ensure efficient equipment operation.

Common Faults and Solutions

Metal sheet leveling machine faults are inevitable during use. Therefore, companies should have a professional technical support team to promptly resolve sheet metal flattening machine problems. In addition, an operation manual should be created to provide clear guidance to employees.

Importance of Maintenance and Regular Inspections

Regular checks of sensor and control systems are essential to quickly detect and fix any problems, hence guaranteeing consistent functioning of the sheet metal flattening machine.

Please call KINGREAL CEILING MACHINERY if you have any queries about their top-quality metal sheet leveling machine; KINGREAL CEILING MACHINERY will respond as soon possible.

Get the latest price? We'll respond as soon as possible(within 12 hours)