Your Expert Partner in Metal Sheet Perforated Machine

2025-12-10 17:00

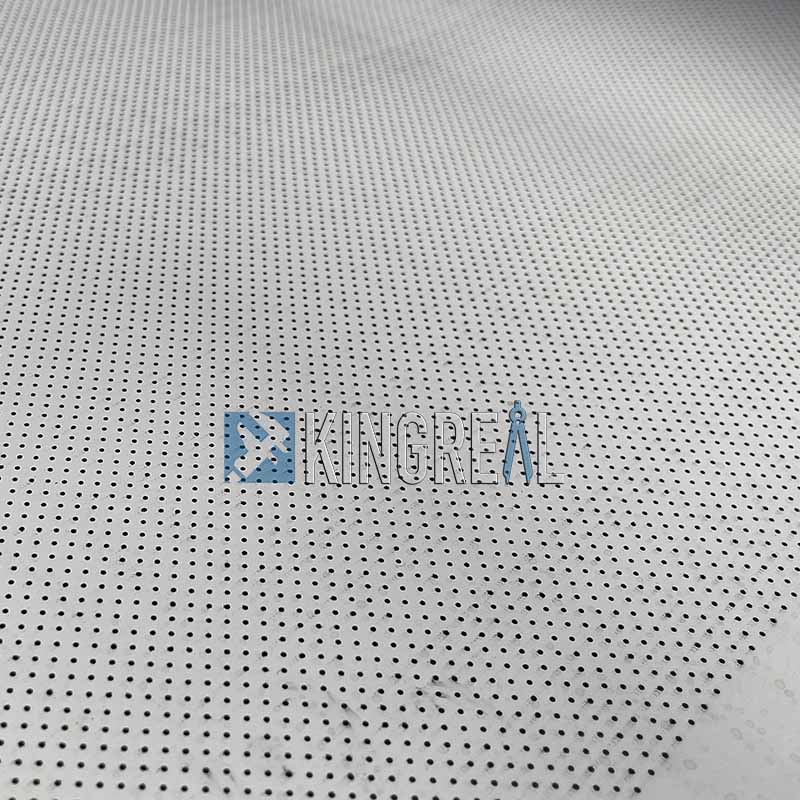

In the metal processing industry, metal sheet perforated machines are indispensable equipment, capable of punching various types of holes on the surface of metal coils of different materials. After subsequent secondary processing, they are manufactured into complete perforated profiles, widely used in industries that require perforated materials. As your trusted partner, KINGREAL CEILING MACHINERY will delve into the composition, advantages, and selection methods of metal sheet perforation production lines to help you make the most informed decision.

Introduction to Metal Sheet Perforated Machine

A metal sheet perforated machine is a highly precise piece of equipment, mainly composed of multiple units, including a perforated metal sheet feeding unit, a perforated sheet punching unit, a perforated metal sheet cutting unit, a punching machine stacking unit, and a punching machine winding unit. In this complete metal sheet perforation production line, the perforated metal sheet feeding system includes a decoiler, a loading trolley, a leveling machine, and a feeding machine, ensuring the feeding accuracy on the metal sheet perforated machine through servo control. This design ensures the high quality and precision of the final product. With KINGREAL CEILING MACHINERY extensive experience in the industry, KINGREAL CEILING MACHINERY provides customers with the best metal sheet perforation production line solutions and offers different punching dies according to customers' specific requirements. Using KINGREAL CEILING MACHINERY metal sheet perforated machines, customers can easily achieve perfect perforated metal sheet punching results. Based on market demand, these metal sheet perforation production lines can be configured for length cutting or winding of perforated sheets according to customer requirements. |  |

Punching Machines Equipped in Metal Sheet Perforated Machine

In the entire metal sheet perforation production line, the punching machine is the most critical component. Whether it's a coil to coil perforation line, a metal sheet perforated machine, or a metal ceiling tile perforation line, the punching machine is indispensable. KINGREAL CEILING MACHINERY customizes the parameters of the punching machine according to the customer's actual project needs. Common punching machine tonnages include 125 tons, 160 tons, and even 200 tons. The specific tonnage selection depends on factors such as hole type, material width, material type, and material thickness.

KINGREAL CEILING MACHINERY team uses specialized calculation formulas to ensure that the punching machine configured in the metal sheet perforation production line can accurately and precisely punch holes in the customer's materials. Through this customized service, KINGREAL CEILING MACHINERY strives to provide every customer with the best metal sheet perforation production line manufacturing solution.

Why Choose KINGREAL CEILING MACHINERY Metal Sheet Perforated Machine?

Quality Assurance KINGREAL CEILING MACHINERY always insists on providing customers with high-quality metal sheet perforated machines. Regardless of the equipment model or manufacturing complexity, the KINGREAL CEILING MACHINERY team manufactures to the same high standards. During the production process, KINGREAL CEILING MACHINERY selects high-quality materials and collaborates with well-known domestic and international electrical brands to ensure the high performance and reliability of every metal sheet perforation production line. Furthermore, through extensive testing, KINGREAL CEILING MACHINERY ensures that each metal sheet perforated machine fully meets customer needs, guaranteeing efficient and stable production for KINGREAL CEILING MACHINERY clients. |  |

Latest Punching Technology and Design To meet the ever-changing demands of the market, KINGREAL CEILING MACHINERY continuously improves and innovates metal sheet perforation production lines. To date, KINGREAL CEILING MACHINERY has successfully developed metal sheet perforated machines capable of punching small holes with diameters of 1.0mm and 1.5mm. Manufacturing these small-diameter punching dies is challenging and requires high precision. The small diameter demands extremely high processing accuracy; any minor error can lead to a defective final product. Furthermore, small-hole dies typically require harder materials to ensure wear resistance and lifespan. More importantly, manufacturing small-diameter dies requires more complex processing techniques and advanced technical support. In addition, KINGREAL CEILING MACHINERY metal sheet perforation production lines support various hole types, including circular, oval, square, triangular, hexagonal, and cross-shaped holes, meeting customers' needs for different hole patterns. |  |

Pre-sales Consultation and After-sales Service Whether before, during, or after the sale, the KINGREAL CEILING MACHINERY team maintains a high level of professionalism and enthusiasm. In the pre-sales stage, KINGREAL CEILING MACHINERY not only provides online consultation services but also accompanies customers to the KINGREAL CEILING MACHINERY factory for on-site inspections of the metal sheet perforated machines and more in-depth discussions. After the sale, KINGREAL CEILING MACHINERY professional engineers will promptly visit the customer's factory for metal sheet perforation production line installation and operation training, ensuring that customers can fully utilize the functions of the metal sheet perforated machine. When metal sheet perforation production line malfunctions occur, KINGREAL CEILING MACHINERY engineers will respond quickly, helping customers troubleshoot problems and providing effective solutions to minimize downtime. |  |

Customer Support KINGREAL CEILING MACHINERY has established friendly cooperative relationships with customers in several countries, including Iran, Bangladesh, Morocco, and Greece. Our customers have expressed satisfaction with the quality of KINGREAL CEILING MACHINERY metal sheet perforated machines and comprehensive services. KINGREAL CEILING MACHINERY goal is to earn customer trust and long-term cooperation through high-quality metal sheet perforated machines and services. |  |

How to Choose the Right Metal Sheet Perforated Machine?

When choosing a suitable metal sheet perforation production line, the following factors need to be fully considered:

1

Material type

Different metal materials require different punching forces and processes.

2

Hole diameter requirements

Select the appropriate hole diameter and shape according to production needs.

3

Production scale

The customer's production volume and cycle will affect the selection of the metal sheet perforated machine.

4

Budget constraints

Plan your investment reasonably based on your company's financial situation.

If you are unfamiliar with metal sheet perforated machine selection, please provide KINGREAL CEILING MACHINERY with detailed information. KINGREAL CEILING MACHINERY engineers will recommend the most suitable metal sheet perforation production line manufacturing solution based on your specific needs.

KINGREAL CEILING MACHINERY welcomes you to contact us and discuss your metal sheet perforated machine requirements with the KINGREAL CEILING MACHINERY team. Take the first step and contact KINGREAL CEILING MACHINERY! You can contact the KINGREAL CEILING MACHINERY team through our website, email, phone number, or company address. KINGREAL CEILING MACHINERY will be happy to assist you.

Get the latest price? We'll respond as soon as possible(within 12 hours)