- Home

- >

- Products

- >

- Coil Processing Line

- >

Products Lists

1/ Coil Processing Lines from KINGREAL CEILING MACHINERY

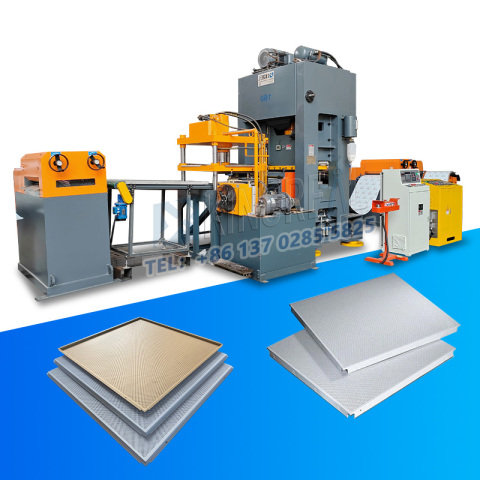

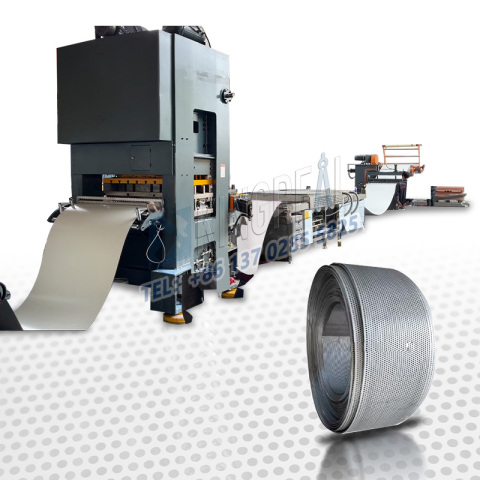

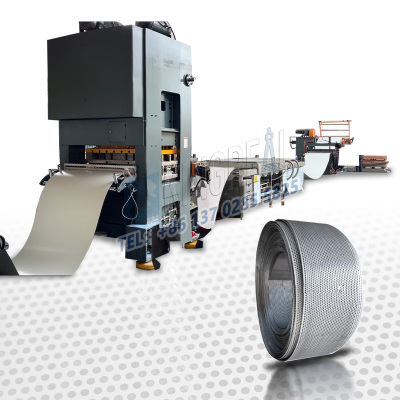

KINGREAL CEILING MACHINERY coil processing lines cover a wide range of applications, playing a crucial role in metal material processing. The metal perforated machine is specifically designed to punch various patterns into metal materials to meet the needs of different industries. Through the metal stamping making machine, metal materials can be processed using progressive dies for various operations such as punching, blanking, embossing, forming, and bending, ultimately producing metal parts of specific shapes. The metal sheet leveling machine functions to flatten the surface of the material, ensuring the flatness of the processed material. In addition, KINGREAL CEILING MACHINERY feeding device, driven by power, can continuously and smoothly feed materials into the processing equipment. This process is usually achieved through mechanical actions, such as the rotation of rollers or the clamping of plates, to achieve continuous step-by-step conveying of coiled or strip materials. Combining these coil processing lines with other roll forming machines can achieve more efficient production operations.

2/ What are the Features of Coil Processing Line?

(1) Customized Service: Each coil processing line provided by KINGREAL CEILING MACHINERY is customized according to the specific needs of the customer, rather than being a simple standardized product. During the design process, engineers consider multiple factors, including metal material, thickness, width, material weight, and precision requirements, ensuring that the coil processing line can be seamlessly integrated into the customer's production process. At the same time, personalized design means that customers can obtain unique performance specifications, thereby improving production efficiency.

(2)Ultra-precision Processing: KINGREAL CEILING MACHINERY coil processing lines are widely praised by customers for their high precision. This is due to the rigorous manufacturing process of the equipment, including material selection, every aspect of the production process, and final machine debugging, ensuring the accuracy of material processing. At the same time, KINGREAL CEILING MACHINERY coil processing line also boasts high performance and durability, maintaining stable performance during long periods of operation.

(3) Automation and Safety: In KINGREAL CEILING MACHINERY metal perforated machine and metal stamping making machine, the application of intelligent control systems aims to reduce downtime and improve production efficiency. These systems can achieve functions such as automatic parameter adjustment, fault alarms, and quality inspection. Furthermore, when designing these coil processing lines, KINGREAL CEILING MACHINERY prioritizes operator safety, incorporating various safety protection devices to ensure safety during operation.

3/ KINGREAL CEILING MACHINERY Coil Processing Solutions

(1) Metal Perforated Machine Solutions: KINGREAL CEILING MACHINERY provides customers with a variety of metal perforated machine solutions, including metal sheet perforated machine, coil to coil perforation line, and metal ceiling tile perforation line. Through continuous research and development and technological innovation, KINGREAL CEILING MACHINERY is now able to manufacture metal perforated machines capable of punching micro-holes with diameters of 1.0mm and 1.5mm. These high-precision metal perforated machines are already operating stably in customer factories in Brazil, Morocco, Greece, Bangladesh, and other countries, greatly meeting customers' needs for high production efficiency and precision.

(2) Metal Stamping Making Machine Solutions: KINGREAL CEILING MACHINERY metal stamping making machines have multiple processing capabilities and can be used in conjunction with various roll forming machines to form a complete and efficient production system. In the steel structure industry, metal parts produced by metal stamping making machines often need to be joined with profiles produced by forming machines to provide support, connection, and fixation.

(3) Metal Sheet Leveling Machine Solutions: KINGREAL CEILING MACHINERY provides metal sheet leveling machine solutions for different types of metal materials, covering metal sheets, metal strips, perforated mesh, and components. Based on the thickness and characteristics of the materials, KINGREAL CEILING MACHINERY has launched various models of metal sheet leveling machines to meet the leveling needs of thin, medium, and thick materials. In addition, KINGREAL CEILING MACHINERY has also designed high-speed metal sheet leveling machines specifically to meet the wide-ranging needs of the automotive manufacturing, construction, metal processing, and electronics industries.

(4) Feeding System Solutions: In modern industry, feeding device is widely used in metal processing, automotive manufacturing, precision engineering, and electronics industries. These feeding devices can work in conjunction with other equipment such as punch presses, roll forming machines, or hydraulic presses to achieve continuity and automation of the production line. Efficient feeding system not only increases production speed but also reduces the labor intensity of operators, greatly improving overall production efficiency.

KINGREAL CEILING MACHINERY coil processing lines cover a wide range of applications, playing a crucial role in metal material processing. The metal perforated machine is specifically designed to punch various patterns into metal materials to meet the needs of different industries. Through the metal stamping making machine, metal materials can be processed using progressive dies for various operations such as punching, blanking, embossing, forming, and bending, ultimately producing metal parts of specific shapes. The metal sheet leveling machine functions to flatten the surface of the material, ensuring the flatness of the processed material. In addition, KINGREAL CEILING MACHINERY feeding device, driven by power, can continuously and smoothly feed materials into the processing equipment. This process is usually achieved through mechanical actions, such as the rotation of rollers or the clamping of plates, to achieve continuous step-by-step conveying of coiled or strip materials. Combining these coil processing lines with other roll forming machines can achieve more efficient production operations.

2/ What are the Features of Coil Processing Line?

(1) Customized Service: Each coil processing line provided by KINGREAL CEILING MACHINERY is customized according to the specific needs of the customer, rather than being a simple standardized product. During the design process, engineers consider multiple factors, including metal material, thickness, width, material weight, and precision requirements, ensuring that the coil processing line can be seamlessly integrated into the customer's production process. At the same time, personalized design means that customers can obtain unique performance specifications, thereby improving production efficiency.

(2)Ultra-precision Processing: KINGREAL CEILING MACHINERY coil processing lines are widely praised by customers for their high precision. This is due to the rigorous manufacturing process of the equipment, including material selection, every aspect of the production process, and final machine debugging, ensuring the accuracy of material processing. At the same time, KINGREAL CEILING MACHINERY coil processing line also boasts high performance and durability, maintaining stable performance during long periods of operation.

(3) Automation and Safety: In KINGREAL CEILING MACHINERY metal perforated machine and metal stamping making machine, the application of intelligent control systems aims to reduce downtime and improve production efficiency. These systems can achieve functions such as automatic parameter adjustment, fault alarms, and quality inspection. Furthermore, when designing these coil processing lines, KINGREAL CEILING MACHINERY prioritizes operator safety, incorporating various safety protection devices to ensure safety during operation.

3/ KINGREAL CEILING MACHINERY Coil Processing Solutions

(1) Metal Perforated Machine Solutions: KINGREAL CEILING MACHINERY provides customers with a variety of metal perforated machine solutions, including metal sheet perforated machine, coil to coil perforation line, and metal ceiling tile perforation line. Through continuous research and development and technological innovation, KINGREAL CEILING MACHINERY is now able to manufacture metal perforated machines capable of punching micro-holes with diameters of 1.0mm and 1.5mm. These high-precision metal perforated machines are already operating stably in customer factories in Brazil, Morocco, Greece, Bangladesh, and other countries, greatly meeting customers' needs for high production efficiency and precision.

(2) Metal Stamping Making Machine Solutions: KINGREAL CEILING MACHINERY metal stamping making machines have multiple processing capabilities and can be used in conjunction with various roll forming machines to form a complete and efficient production system. In the steel structure industry, metal parts produced by metal stamping making machines often need to be joined with profiles produced by forming machines to provide support, connection, and fixation.

(3) Metal Sheet Leveling Machine Solutions: KINGREAL CEILING MACHINERY provides metal sheet leveling machine solutions for different types of metal materials, covering metal sheets, metal strips, perforated mesh, and components. Based on the thickness and characteristics of the materials, KINGREAL CEILING MACHINERY has launched various models of metal sheet leveling machines to meet the leveling needs of thin, medium, and thick materials. In addition, KINGREAL CEILING MACHINERY has also designed high-speed metal sheet leveling machines specifically to meet the wide-ranging needs of the automotive manufacturing, construction, metal processing, and electronics industries.

(4) Feeding System Solutions: In modern industry, feeding device is widely used in metal processing, automotive manufacturing, precision engineering, and electronics industries. These feeding devices can work in conjunction with other equipment such as punch presses, roll forming machines, or hydraulic presses to achieve continuity and automation of the production line. Efficient feeding system not only increases production speed but also reduces the labor intensity of operators, greatly improving overall production efficiency.

-

Catalogs:

-

![Perforated Metal Ceiling Panel Machine]()

Perforated Metal Ceiling Panel Machine

-

![Metal Sheet Perforation Production Line]()

Metal Sheet Perforation Production Line

-

![Steel Perforated Machine]()

Steel Perforated Machine

-

![Decoiler Straightener Feeder]()

Decoiler Straightener Feeder

-

![Metal Sheet Perforated Machine]()

Metal Sheet Perforated Machine

-

![Punch Press Decoiler Straightener Feeder]()

Punch Press Decoiler Straightener Feeder

-

![Perforated Metal Machine For Baguette Pan]()

Perforated Metal Machine For Baguette Pan

-

![NC Servo Feeder]()

NC Servo Feeder

-

![Perforated Machine For Metal Acoustic Wall Panel]()

Perforated Machine For Metal Acoustic Wall Panel

-

![High Precision Gantry Type Press Machine]()

High Precision Gantry Type Press Machine

-

![Metal Punching Machine For Metal Filter]()

Metal Punching Machine For Metal Filter

-

![Sheet Metal Decoilers]()

Sheet Metal Decoilers

Get the latest price? We'll respond as soon as possible(within 12 hours)