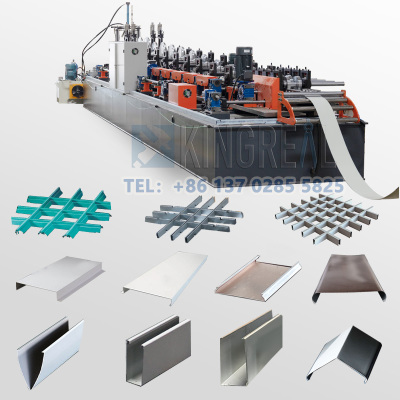

Facade Panel Roll Forming Machine

The facade panel roll forming machine is specifically designed for producing facade panels of various sizes, widely used in the exterior walls of modern buildings, commercial buildings, and industrial cladding systems. It provides excellent thermal insulation, sound insulation, load-bearing capacity, and decorative effects for buildings.

- KINGREAL CEILING MACHINERY

Details

◀ Video About Facade Panel Roll Forming Machine

◀ Brief Introduction to Facade Panel Roll Forming Machine

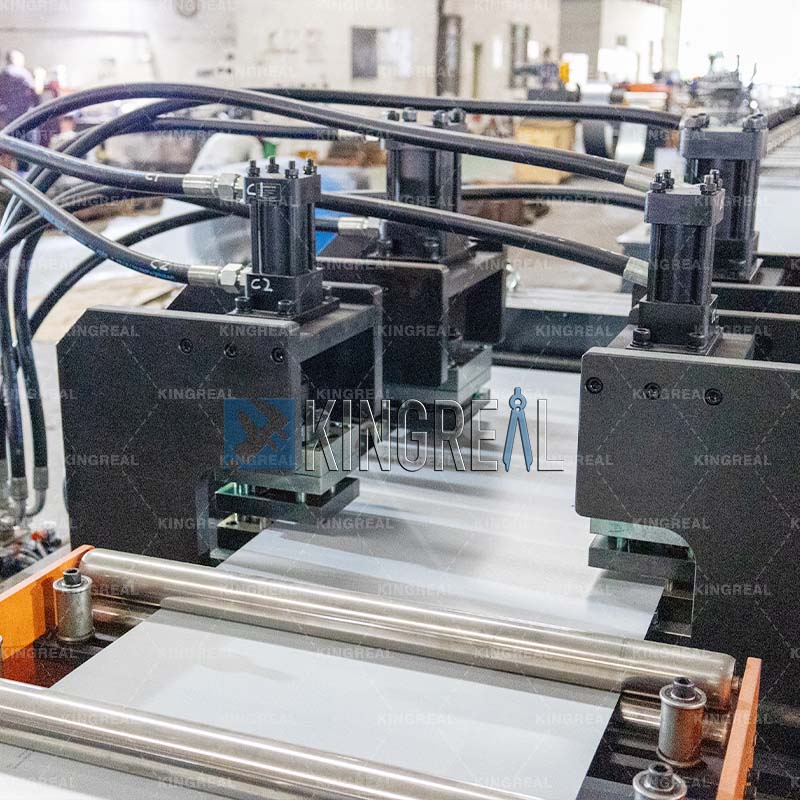

The facade panel roll forming machine is specifically designed for producing facade panels of various sizes, widely used in the exterior walls of modern buildings, commercial buildings, and industrial cladding systems. It provides excellent thermal insulation, sound insulation, load-bearing capacity, and decorative effects for buildings. The facade panel making machine enables continuous uncoiling, leveling, punching, roll forming, and fixed-length cutting. The entire production line adopts an advanced PLC control system to ensure fully automated operation. Furthermore, the facade panel roll forming machine can be customized according to the customer's specific project requirements, allowing for flexible and efficient production of facade panels in different sizes and styles, while guaranteeing high-quality surface finish. |  |

◀ Working Process of Facade Panel Roll Forming Machine

Decoiler -- Metal Leveling Machine -- Metal Punching Station -- Roll Forming Machine -- Cutting Station -- Output

◀ Technical Specification of Facade Panel Roll Forming Machine

| No | Item | Parameter | Remark | |

1 | Suitable Material | Type | PPGI, Steel | |

| Width(mm) | 312/416/500/Customize | |||

| Thickness(mm) | 0.6-1.0 | |||

| Yield Strength(Mpa) | 230-300 | customize | ||

| 2 | Forming Speed(m/min) | 20 | customize | |

| 3 | Roller Material | No.45 steel with Chrome plate | Up to buyer | |

| 4 | Roller Shaft Diameter | 70 | customize | |

| 5 | Cutting Model | Hydraulic/Electric Cutting | ||

6 | Power source | Type | 380V/3PH/50HZ | Up to buyer |

| Total Power | According to actual design | |||

◀ Advantages of Facade Panel Roll Forming Machine

1/Integrated Manufacturing

The facade panel making machine achieves integrated forming through the effective collaboration of various components, including the decoiler, leveling machine, punching station, roll forming machine, and cutting station. This results in wall panels with multiple advantages, including load-bearing capacity, thermal insulation, and sound insulation, ensuring the stability and reliability of the wall.

2/Precision Manufacturing

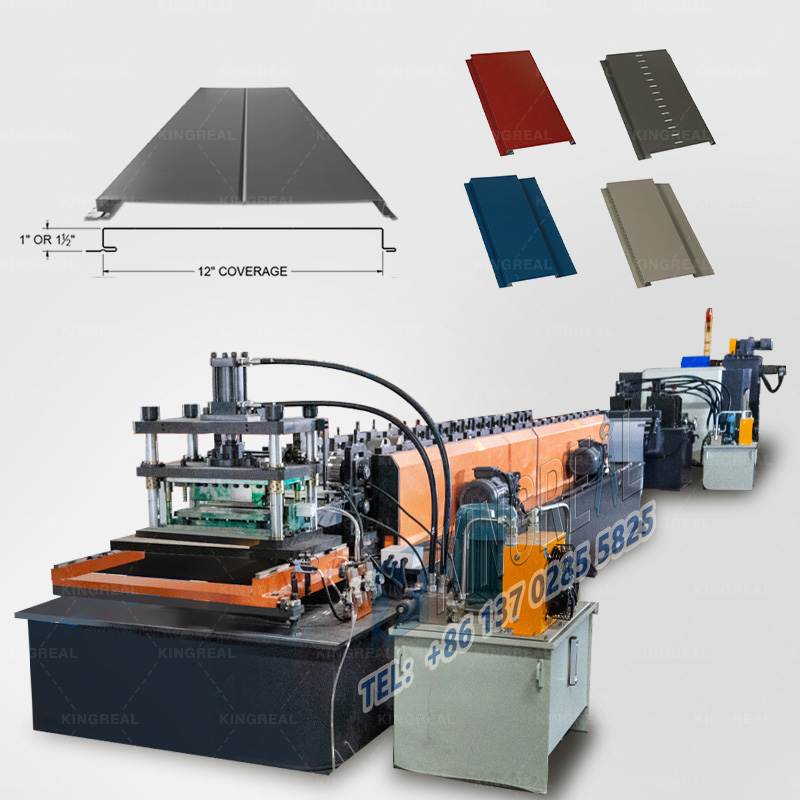

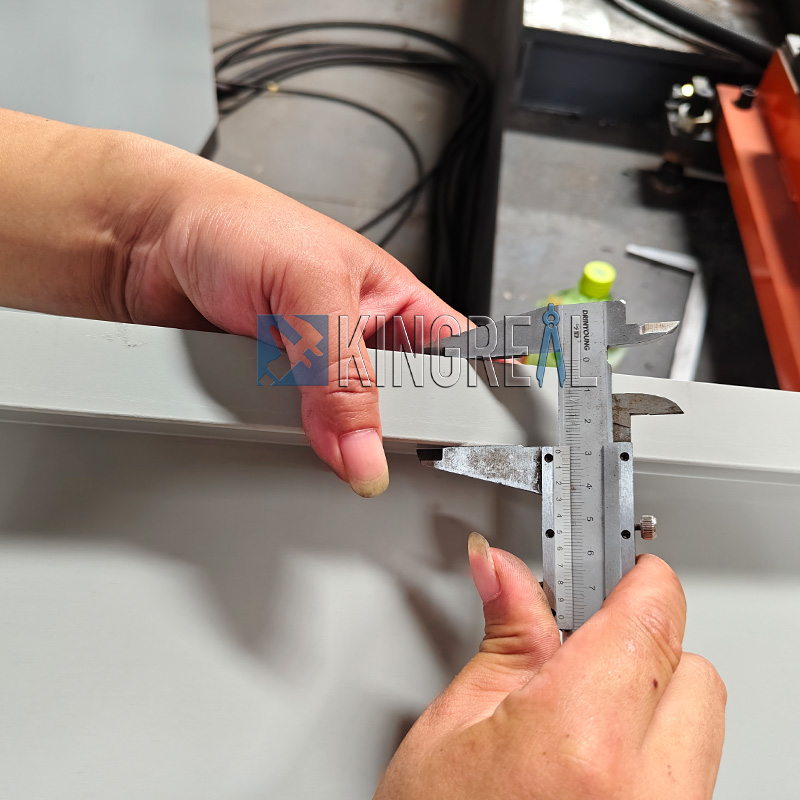

The soffit panels produced by this facade panel making machine can reach a depth of 400 mm, with a tolerance range of only ±0.3 mm. Equipped with CNC machined rollers, the facade panel making machine ensures tight seams during installation, preventing wind and rain intrusion. More importantly, the quad wall panels produced by the facade panel making machine have a scratch-resistant surface treatment, making them durable and visually appealing.

3/High Production Efficiency

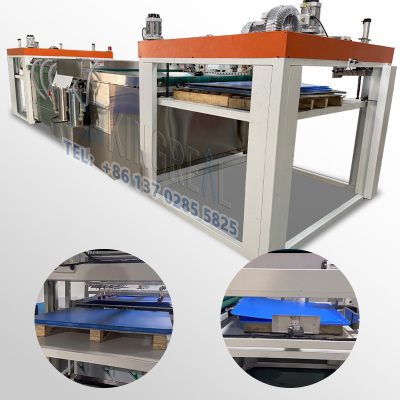

The facade panel roll forming machine boasts a high production speed of up to 20m/min, combined with automatic cutting accuracy of up to 0.5 mm (length tolerance ±1 mm), ensuring a fast and trouble-free production process and significantly improving overall production efficiency.

4/Flexible Switching and Intelligent Functions

The facade panel roll forming machine can quickly switch between the production of various wall cladding panels by changing molds, and it supports processing materials with a thickness of 0.6-1 mm, and can even process steel and color-coated steel sheets up to 1.5 mm thick.

◀ Facade Panel Roll Forming Machine Solution

KINGREAL CEILING MACHINERY facade panel making machine is an ideal choice for building facade cladding, widely used in the construction of exterior metal wall panels of residential and industrial buildings.

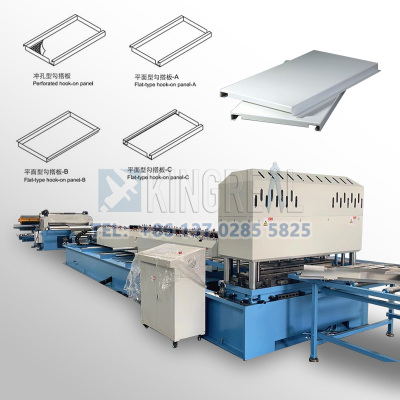

1/Automated facade panel making machine

This facade panel making machine is designed for fully automatic operation, equipped with a roller forming section, an automation system, and a cutting station at the exit. To meet different customer needs, the facade panel roll forming machine can also be optionally configured with a manual or automatic decoiler for efficient material unwinding.

2/Robust cassette panel output

The facade panel making machine forms multiple reinforcing ribs through 18 roll forming stages, allowing a single interior metal wall panel to withstand a load of up to 12 kPa, perfectly meeting the needs of large-span structures and lightweight requirements, providing stronger wall cladding panel support for buildings.

3/Flexible production facade panel making machine

To facilitate the processing of materials of different thicknesses, the facade panel making machine can automatically adjust the forming parameters through a PLC control system. In addition, the facade panel roll forming machine features an innovative quick mold change system with a modular design. Operators only need to remove and replace the molds to produce different types of wall panels, greatly improving production flexibility and efficiency.

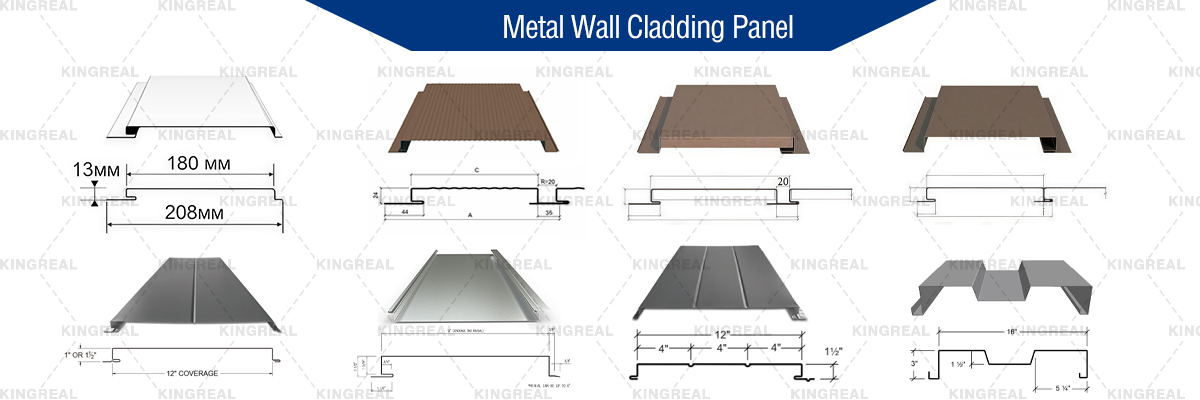

◀ Introduction to Facade Panel

The soffit panels produced by KINGREAL CEILING MACHINERY facade panel making machine are suitable for almost any building requiring steel wall panel, such as schools, hospitals, banks, sports facilities, office buildings, industrial buildings, and most other non-residential buildings, and even residential buildings. The facade panel making machine can flexibly produce wall cladding panels of various types, including corrugated, trapezoidal, micro-Rib, and flat lock, offering design flexibility and striking visual effects, while also being easy to install and cost-effective.

Notably, KINGREAL CEILING MACHINERY facade panel roll forming machine also offers perforated quad wall panel production, providing customers with a wider variety of quad wall panel options to meet the needs of different projects. The specific dimensions of the steel wall panels will vary depending on project requirements, typically with a width between 1200 mm and 1500 mm and a length up to 6000 mm. KINGREAL CEILING MACHINERY facade panel roll forming machine can be fully customized according to the customer's actual needs, ensuring the ideal cassette panels are provided to meet project requirements.

◀ Quality Assurance

Before shipment, the KINGREAL CEILING MACHINERY team conducts comprehensive testing of the facade panel making machine, including important inspections of the external condition, operating status, and finished product. This ensures the consistency and high precision of the finished product dimensions, matching the customer's project requirements and providing the necessary structural strength and rigidity for building facades. The tight, leak-proof joints during installation ensure the overall quality and safety of the building.

◀ Facade Panel Making Machine Success Project

Thanks to its efficient and precise performance, KINGREAL CEILING MACHINERY facade panel roll forming machine has been successfully applied in several countries, including Kazakhstan and Greece, providing numerous customers with efficient production solutions and significant profit returns. The facade panel making machine's design philosophy is specifically tailored for modular home builders, commercial contractors, and facade specialists, enabling the production of ready-to-install quad wall panels at industrial speeds, significantly reducing labor costs and accelerating project timelines.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)