5 Factors for Choosing a Metal Sheet Leveling Machine

2025-11-21 17:00

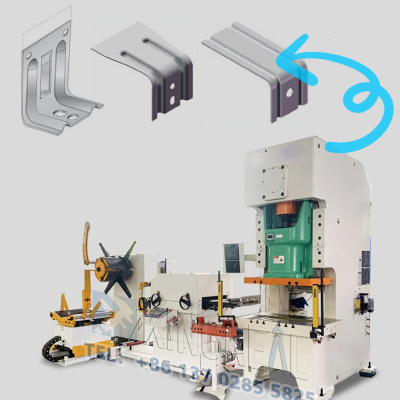

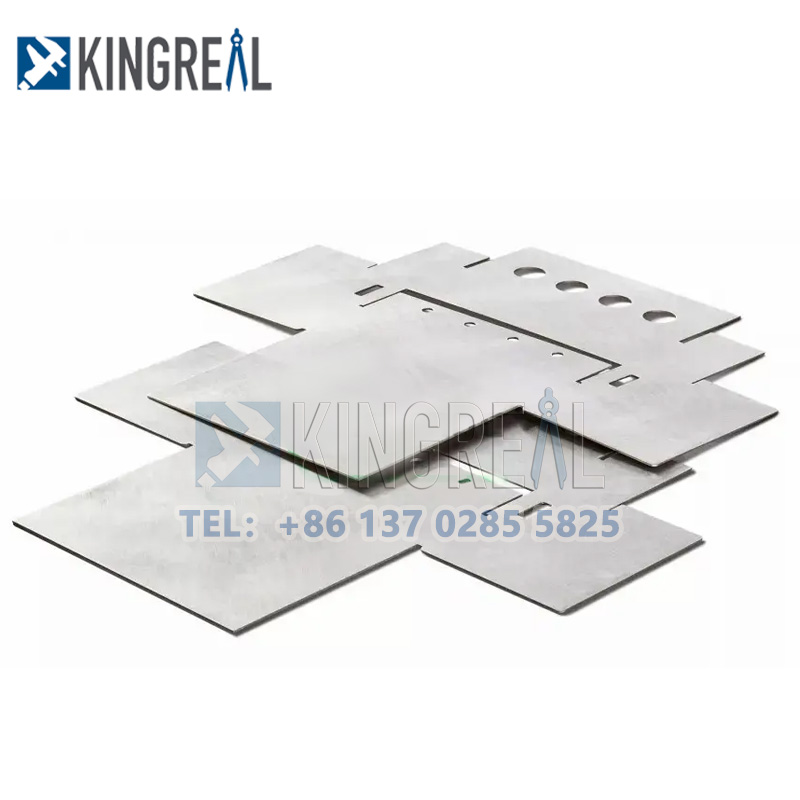

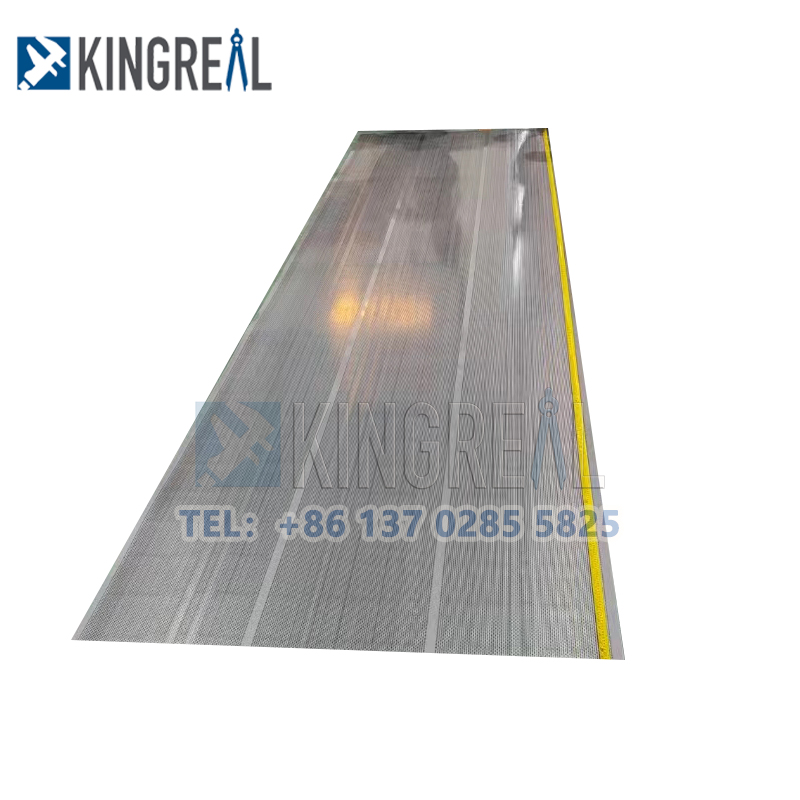

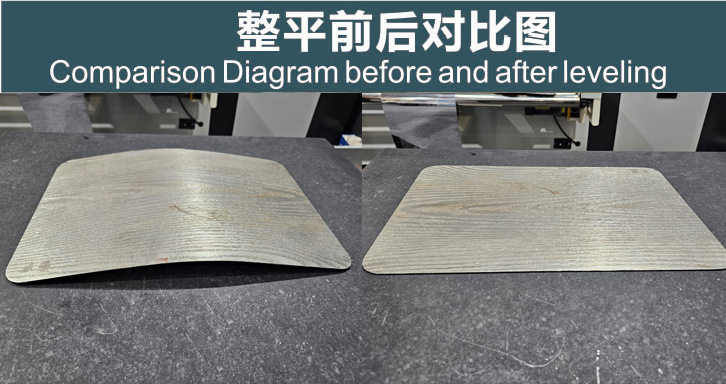

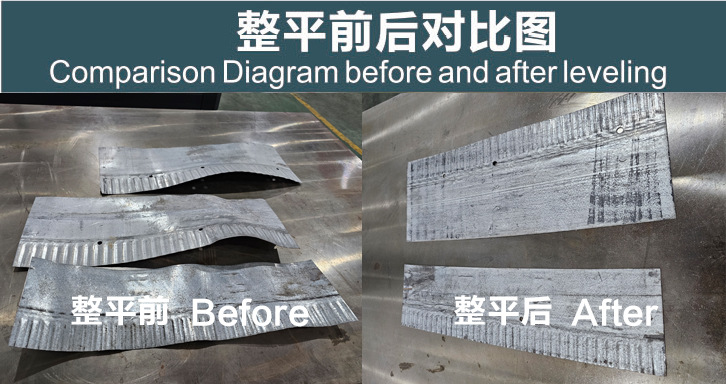

Metal sheet leveling machines are used in various fields of industrial production and are one of the basic pieces of equipment in metal processing. Flatness of the material comes first, whether it's metal coils, sheets, components, strips, or perforated metal sheets, before further treatment. Choosing an appropriate sheet metal leveling machine is hence vital. The standards for metal sheet leveling machine therefore vary depending on the properties of the metal materials to be processed in the market.

1. Material Type for Metal Sheet Leveling Machine

First, you need to clearly define the material of the metal you need to process. Though the properties of various materials directly influence the core design of the metal sheet leveling machine, KINGREAL CEILING MACHINERY sheet metal leveling machines can handle several metals like as aluminum, stainless steel, iron, and copper. For metals like stainless steel and aluminum sheets, for instance, you need to be particularly careful about the hardness of the rollers of the sheet metal leveling machine and the accuracy of pressure regulation. This is so that various metals have distinct elasticity and toughness; failure to correctly level might harm the material or even impact the leveling effect.

A six-roll metal sheet leveling machine would be the best choice if you are dealing with delicate items like high-strength aluminum alloys or thin stainless steel. The six-roll sheet metal leveling machine's intermediate rollers provide a transition, effectively preventing indentations and scratches on the material surface. When selecting a metal sheet leveling machine, you should also inform KINGREAL CEILING MACHINERY engineers of the type and characteristics of the materials you are handling. If your production requires handling multiple materials, KINGREAL CEILING MACHINERY engineers will design a sheet metal leveling machine compatible with various materials, providing a flexible solution for your production.

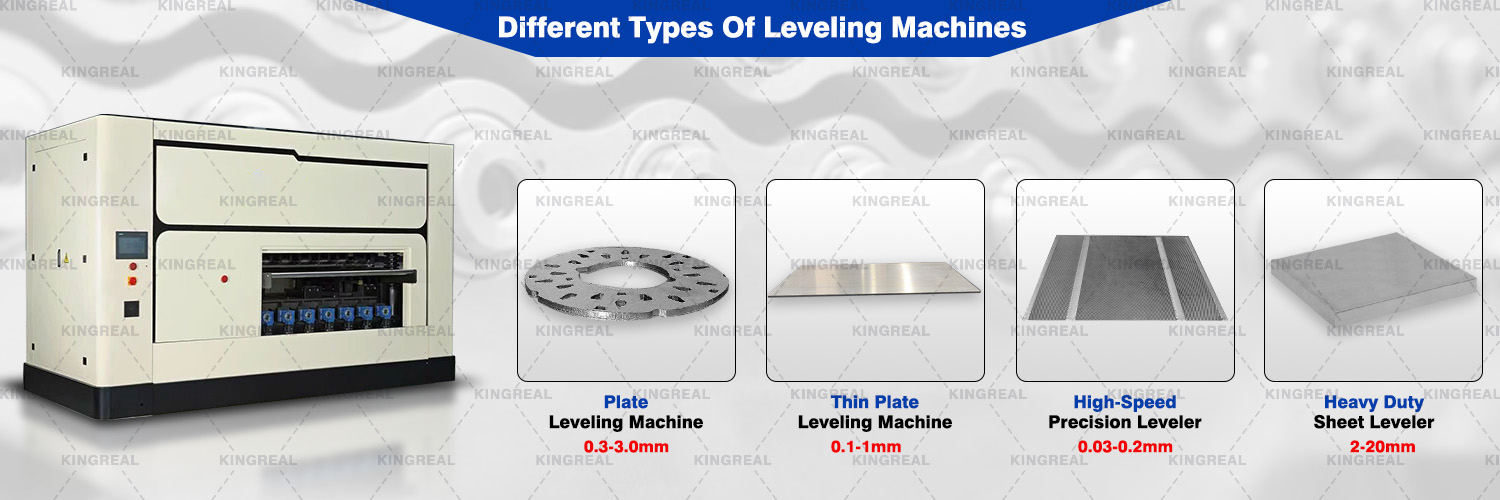

2. Material Thickness for Metal Sheet Leveling Machine

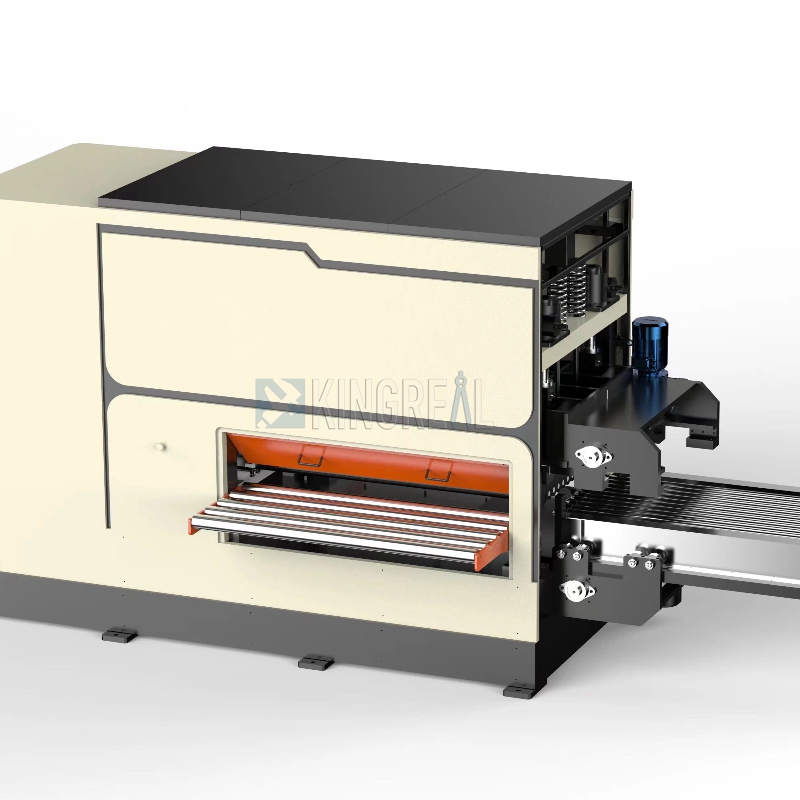

Another key factor is material thickness. KINGREAL CEILING MACHINERY has designed various models of metal sheet leveling machines to meet different customers' leveling needs for metal material thickness. For example, for ultra-thin materials (0.03-0.2mm), KINGREAL CEILING MACHINERY offers ultra-thin sheet metal leveling machines; for thin materials (0.1-1mm), there are dedicated thin metal sheet leveling machines; and for standard thickness materials (0.3-3mm), standard sheet metal leveling machines can be selected. Meanwhile, for thicker metal materials (2-20mm), KINGREAL CEILING MACHINERY can also design highly efficient heavy duty metal sheet leveling machines.

When selecting a sheet metal leveling machine, it is crucial to determine the thickness range of the target material and inform KINGREAL CEILING MACHINERY engineers. This information directly affects the metal sheet leveling machine's roller design, required power, and straightening effect during the leveling process. If you are continuously processing materials of varying thicknesses, KINGREAL CEILING MACHINERY can also customize a sheet metal leveling machine to meet your needs, ensuring optimal leveling results for each material.

3. Leveling Accuracy Requirements for Metal Sheet Leveling Machine

Leveling accuracy is another important factor influencing the selection of a metal sheet leveling machine. Customers' requirements for leveling accuracy are usually directly related to their application field. For example, in the precision electronics industry, the leveling accuracy requirements for sheet metal leveling machines are extremely high, directly affecting the performance and quality of the final product. KINGREAL CEILING MACHINERY metal sheet leveling machines typically feature four or six layers of rollers. Usually, the leveling impact improves with the quantity of rollers. Six-layer roller sheet metal leveling machines ensure high throughput while providing consistent and standard-compliant flatness by offering greater precision and stability during correction. For users requiring high-precision leveling, KINGREAL CEILING MACHINERY provides data analysis and ongoing technical support to ensure each metal sheet leveling machine operates at its optimal condition. Furthermore, KINGREAL CEILING MACHINERY engineers will help you select the most suitable leveling precision configuration based on your production needs.

4. Sheet Metal Leveling Machine Quality

The quality of the metal sheet leveling machine directly determines leveling precision, equipment durability, and production efficiency. Low-quality sheet metal leveling machines may not only fail to achieve the required leveling precision but may also malfunction quickly, increasing maintenance and replacement costs. More importantly, inferior metal sheet leveling machine can lead to frequent downtime and delays in the production process, thereby reducing production efficiency.

When buying a sheet metal leveling machine, you should consider the quality of the materials employed as well as the manufacturer's reputation. KINGREAL CEILING MACHINERY uses high-quality raw materials in metal sheet leveling machine manufacturing, ensuring the stability and durability of the sheet metal leveling machines under various operating conditions. In addition, KINGREAL CEILING MACHINERY has multiple metal sheet leveling machine inspection stages to ensure that every metal sheet leveling machine delivered to customers meets international standards. Choosing a reliable sheet metal leveling machine not only improves production efficiency but also significantly reduces subsequent operational risks.

5. After-Sales Service for Sheet Metal Leveling Machine

Purchasing a metal sheet leveling machine is not the end; comprehensive after-sales service is equally crucial. Apart from supplying premium sheet metal leveling machine, KINGREAL CEILING MACHINERY provides a complete line of services. This covers maintenance techniques, quick reaction to any difficulties that could come up, and training on correct metal sheet leveling machine operation.

If the sheet metal leveling machine fail while in use, KINGREAL CEILING MACHINERY engineers would immediately examine the issue and offer solutions. If components need replacement because of extended use, KINGREAL CEILING MACHINERY guarantees quick spare part availability to prevent production line interruptions. Great after-sales support gives consumers confidence and peace of mind using metal sheet leveling machine.

If you want more information or have any needs for buying sheet metal leveling machines, please feel free to contact KINGREAL CEILING MACHINERY. We strive to serve you always!

Get the latest price? We'll respond as soon as possible(within 12 hours)