- Home

- >

- News

- >

- Metal Stamping Press 101

- >

Metal Stamping Press 101

2025-10-23 17:00

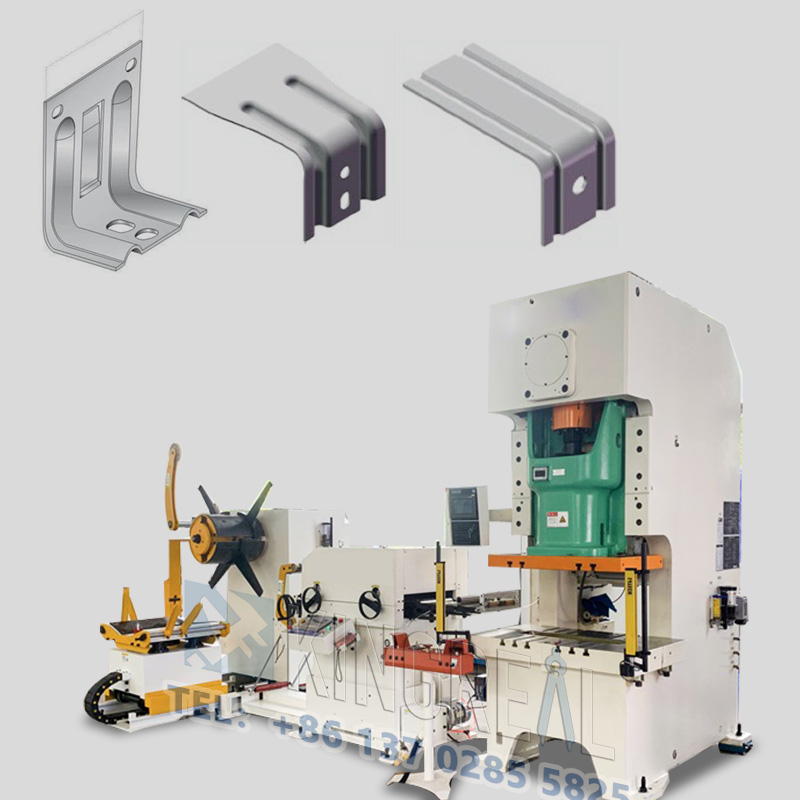

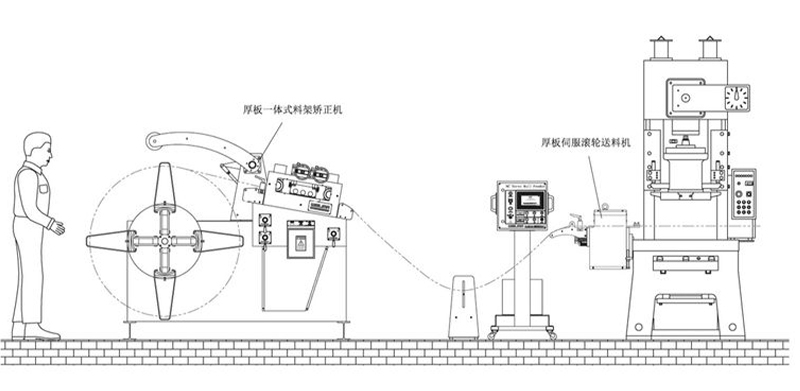

Metal stamping presses are an advanced manufacturing technology widely used in modern industry. Stamping is the mechanical conversion of flat metal coils or sheets into exactly formed parts. This method guarantees accuracy and consistency in addition to being very effective. Mechanical power presses can handle several metal materials, including stainless steel, aluminum, iron, and copper, using tailored progressive stamping dies. The metal stamping press can accomplish several tasks, including bending, plastic deformation, punching, and reinforcement, by positioning the metallic material inside the die. Shape the metal as desired.

Mechanical power presses abound in applications including construction, photovoltaic systems, shelving systems, automotive, electronics, aviation, and domestic appliances. Metal stamping presses cut production expenses in these sectors in addition to increasing production efficiency.

Key Steps in Mechanical Power Press

1. Bending

Bending is a key process in metal stamping. During this process, the metal stamping press applies force to the metal material, bending it at a specific angle to form a V, U, or other predetermined shape.

2. Plastic Deformation

Plastic deformation refers to the process of permanently changing a metal material through the application of external forces. This process enables manufacturers to create a wide variety of geometric shapes and contours in stamped metal parts.

3. Punching

Punching is the process of creating holes, slots, or other geometric features in metal materials. The high-precision dies used in mechanical power presses enable the completion of large numbers of punching operations in a short period of time, ensuring production efficiency and product quality. In many applications, punching is a necessary step for subsequent processing and assembly.

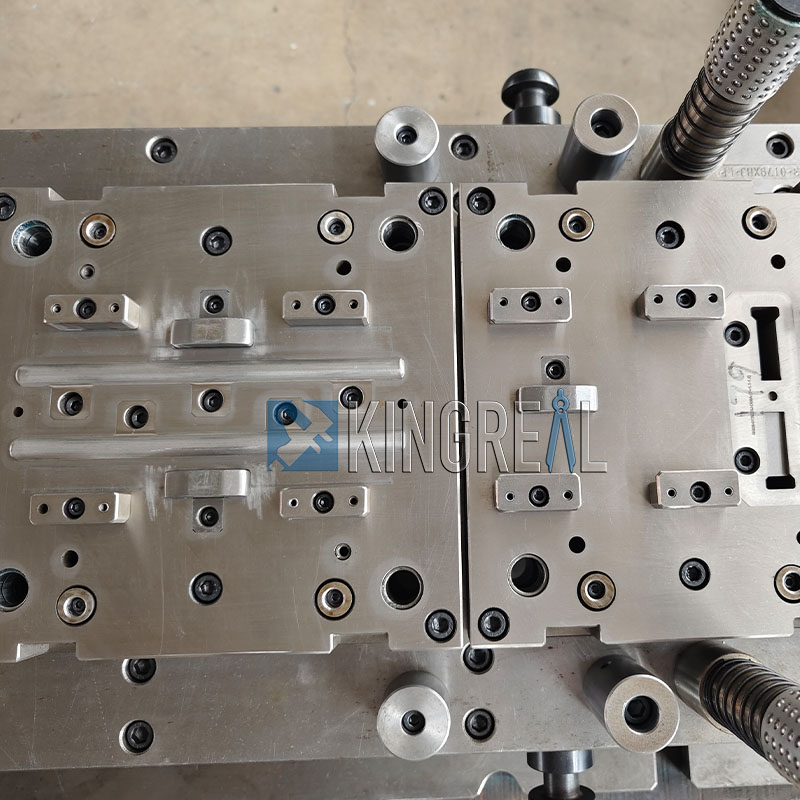

Introduction to Progressive Stamping Die

Progressive stamping dies are key tools in metal stamping presses, characterized by their complex design and diverse functions. They consist of multiple stations, each connected in sequence to complete different processing steps. During a single press stroke, the die can perform various stamping procedures including punching, blanking, bending, trimming, and drawing.

Usually speaking, one progressive stamping die can be used to finish several processes and intricate stamping parts. Customizing progressive stamping dies depending on consumer drawings, KINGREAL CEILING MACHINERY engineers guarantee their accuracy and manufacturing quality much above that of normal dies. Once production is finished, the mold is reworked, honed, and test punch to guarantee its performance satisfies production specifications.

Besides raising the pace of production, this effective progressive stamping die design lowers expenses, making mechanical power presses especially useful for the high-volume manufacturing of intricate components.

Applications of Metal Stamping Press

Mechanical power presses have a wide range of applications. The following is a detailed introduction to several key areas:

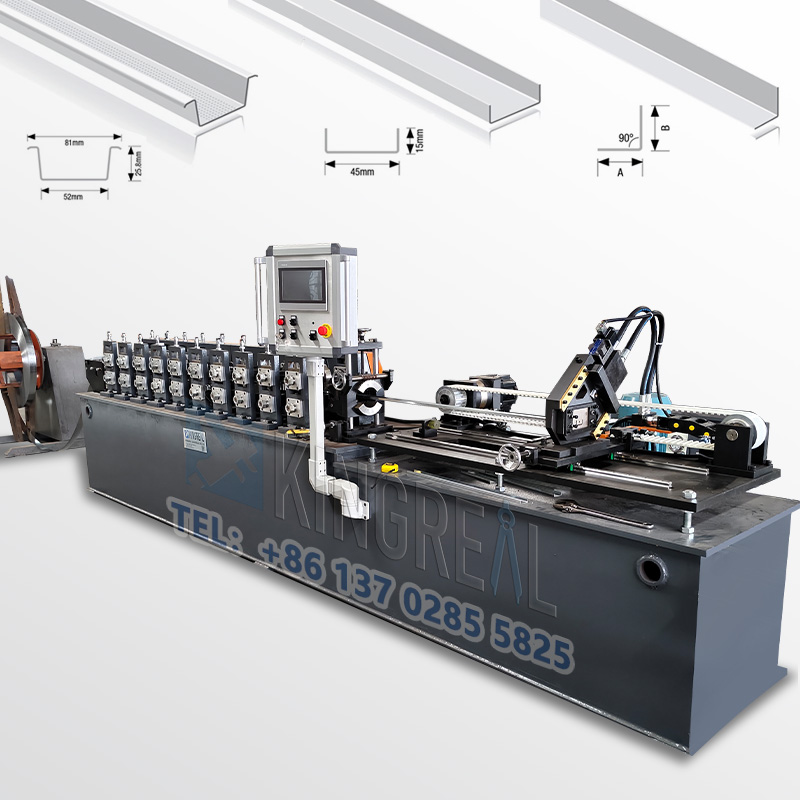

1. Metal stamping press in suspended ceiling systems

In suspended ceiling systems, metal brackets produced by mechanical power presses are often used for connection and fixing. Stamping parts, such as connectors and brackets, ensure the stability and security of suspended ceilings. KINGREAL CEILING MACHINERY not only provides high-quality metal stamping presses, but also offers corresponding roll forming machine such as furring channel machine, u channel machine, and gypsum board wall angle machine, as well as suspended ceiling making machines such as baffle ceiling machine, open cell ceiling machine, and linear strip ceiling machine. These machines simplify the installation process by allowing the effective manufacture of sophisticated suspended ceiling components.

Load-bearing capability and corrosion resistance are among the criteria to be considered in suspended ceiling systems' metal bracket design. By using high-quality metal materials and advanced stamping processes, metal brackets produced meet stringent building standards.

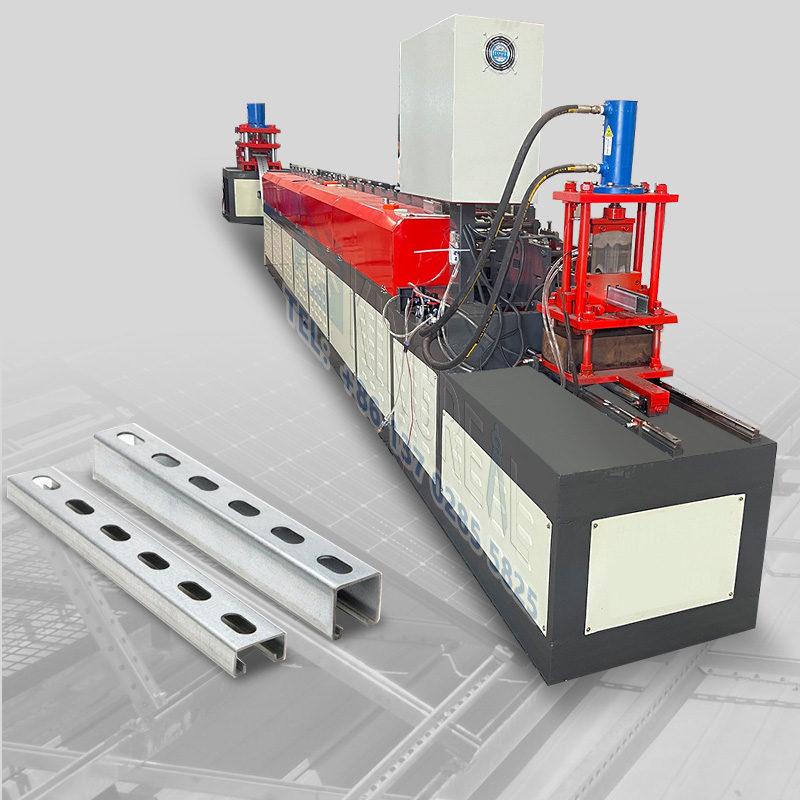

2. Mechanical power press in photovoltaic system

In photovoltaic systems, metal mounting brackets produced by mechanical power presses are used in conjunction with solar channel making machines to form key components. These components, in sizes such as 41×21, 41×41, 41×62, and 41×82 mm, are precisely manufactured on the mechanical power press. The efficient operation of photovoltaic systems depends on these precision metal mounting brackets, ensuring the stability and security of photovoltaic panels.

Efficient forming and processing of photovoltaic brackets is made possible by metal stamping presses, which lowers manufacturing expenses and increases market competitiveness.

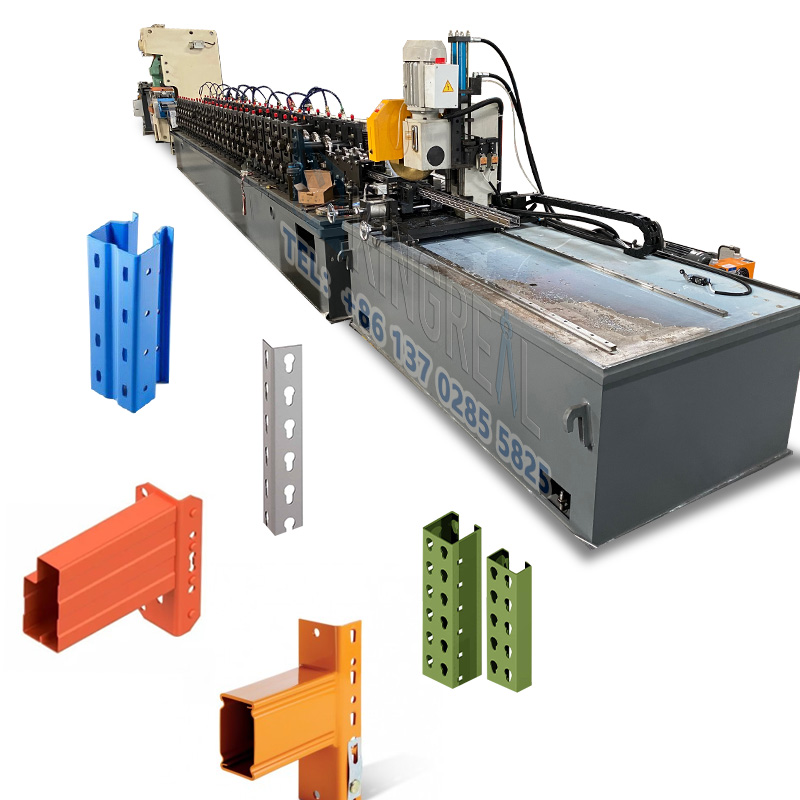

3. Mechanical power press in racking system

In racking systems, metal brackets produced by metal stamping presses are used in conjunction with upright rack making machine and shelf panel making machine to create a complete racking system. These metal brackets include shelf panels, upright racks, box beams, step beams, and slotted angles, meeting various storage needs. Using a mechanical power press, companies can efficiently produce these components, ensuring the stability and durability of the racking system.

The design and manufacture of a racking system must consider load-bearing capacity, space utilization, and ease of assembly. Metal stamping presses play a crucial role in this process. The modular design allows the racking system to be quickly assembled and disassembled to accommodate diverse storage needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)