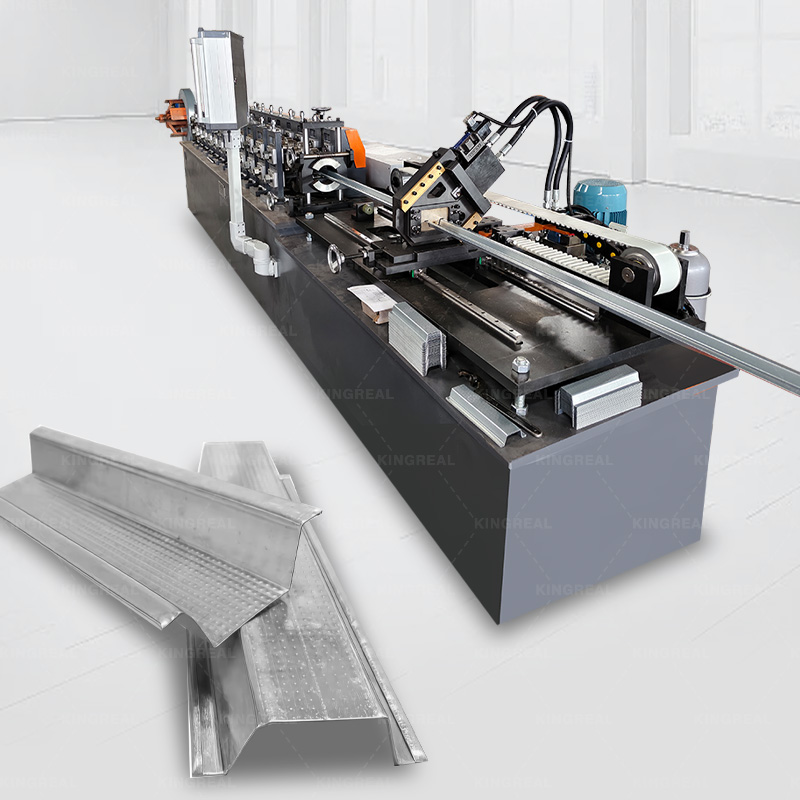

Omega Profile Roll Forming Machine

KINGREAL CEILING MACHINERY Omega Channel Machine is a kind of False Ceiling Channel Roll Forming Machine, the main features are high production speed and accuracy.

- KINGREAL CEILING MACHINERY

Details

Video Display About Omega Channel Machine

Description of Omega Channel Machine

KINGREAL CEILING MACHINERY Omega Channel Machine can shape metal coils into omega shape by putting them through a series of bending, cutting and forming processes. KINGREAL CEILING MACHINERY can provide different types of False Ceiling Channel Machine for producing differtent shapes of steel profiles, including hat shape, U shape and L shape. KINGREAL CEILING MACHINERY also provides protective shield for you to choose. |  |

Parameter of Furring Channel Machine

| Raw material | Gi steel, pre-painted gi steel |

| Product shape | hat channel |

| Production capacity | 120m/min |

| Electricity requirment | 380v 50 Hz 3 Phases |

| Power consumption | 30KW |

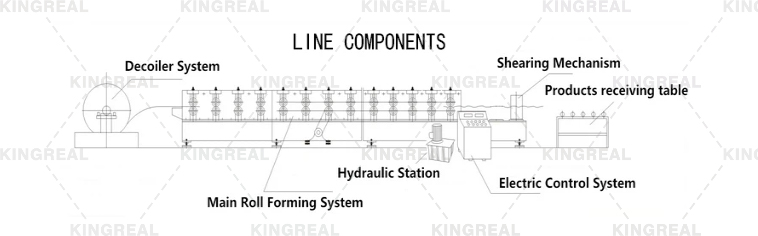

Main Components of Omega Channel Machine

- Hydraulic decoiler - Main roll forming machine - Shearing station - Output table - Electrical & Hydraulic system - Protective shield (optional) |  |

Features of Omega Channel Machine

(1)High speed hat channel machine The production speed of this omega channel machine can reach up to 120 m/min, which greatly improves the production efficiency of customers. KINGREAL CEILING MACHINERY engineers specially designed an independent arch for the roll forming machine part of this hat channel machine, giving this omega channel machine higher flexibility and easy removal of the roller set. The independent arch not only improves the stability of the hat channel machine, but also ensures smooth operation at high speeds. In addition, the rollers are made of high-hardness materials, with excellent wear resistance and excellent forming accuracy, ensuring excellent performance in long-term use. |  |

(2)Fly shearing system for omega channel machine KINGREAL CEILING MACHINERY engineers equipped the omega channel machine with a fly shearing system, which can accurately cut the omega channel to ensure the quality of the finished product. During the shearing process, the system can achieve non-stop processing, which brings customers significant production efficiency improvement and finished product accuracy guarantee. The blades used in the fly shearing system are carefully designed, and the surface of the finished product after cutting is smooth, burr-free, and highly consistent, meeting high-standard production requirements, providing customers with a more reliable solution. |  |

(3)PLC control panel for hat channel machine KINGREAL CEILING MACHINERY has equipped the omega channel machine with an intelligent PLC control panel, and users can flexibly set the language according to the needs of the region, including English, Russian, Spanish, etc. This control panel has multiple functions such as monitoring and data transmission to ensure convenient and efficient operation. When in use, the operator only needs to set the production parameters on the panel, and the machine can achieve a highly automated production process, reducing the need for human intervention. |  |

Options for Hat Channel Machine

(1)Protective shield for hat channel machine The omega channel machine can be equipped with an optional protective shield, which is designed to effectively protect the machine itself and significantly extend its service life. The main function of the protective shield is to reduce potential safety hazards in the production process and ensure the safety of the operator. In addition, the protective shield can also keep the factory clean and prevent metal sheets from flying around during production. When the omega channel machine is paused, the protective shield can be easily opened to facilitate daily maintenance and cleaning of the roll forming machine. This design not only improves the safety of the hat channel machine, but also provides a more convenient maintenance experience for the operator, ensuring that the omega channel machine is always in the best working condition. |  |

(2)Auto packaging machine for hat channel machine In order to further improve production efficiency, the omega channel machine can also be equipped with a fully automatic packaging unit. This equipment can quickly and efficiently package the omega channel, greatly shortening the time from production to sales. The fully automatic packaging machine has an intelligent operating system that can automatically complete a series of tasks such as packaging, bundling and stacking of hat channels. Through this automated packaging solution, customers can not only ensure the work quality of the finished product, but also greatly improve work efficiency and reduce labor costs. |  |

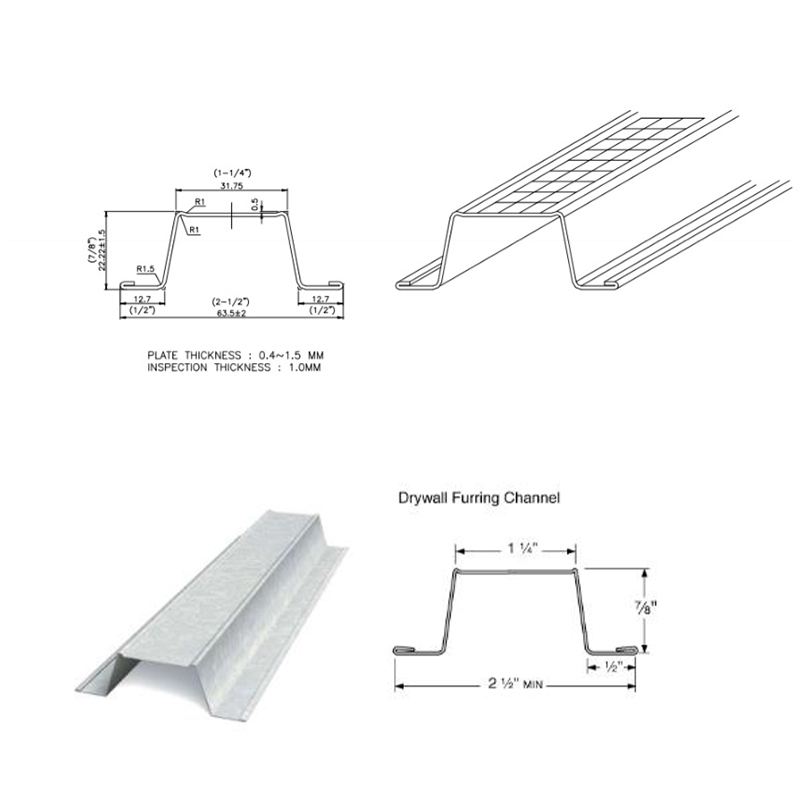

False Ceiling Channel Making Machine Solution

Maybe you have the production needs of U shape and L shape profiles at the same time, don’t worry, KINGREAL CEILING MACHINERY can provide 3 in 1 false ceiling channel roll forming machine solution. Just need to change the roller and cutting mold, you can easily produce 3 kinds of false ceiling channels: hat channel, U channel and wall angle shape. |  |

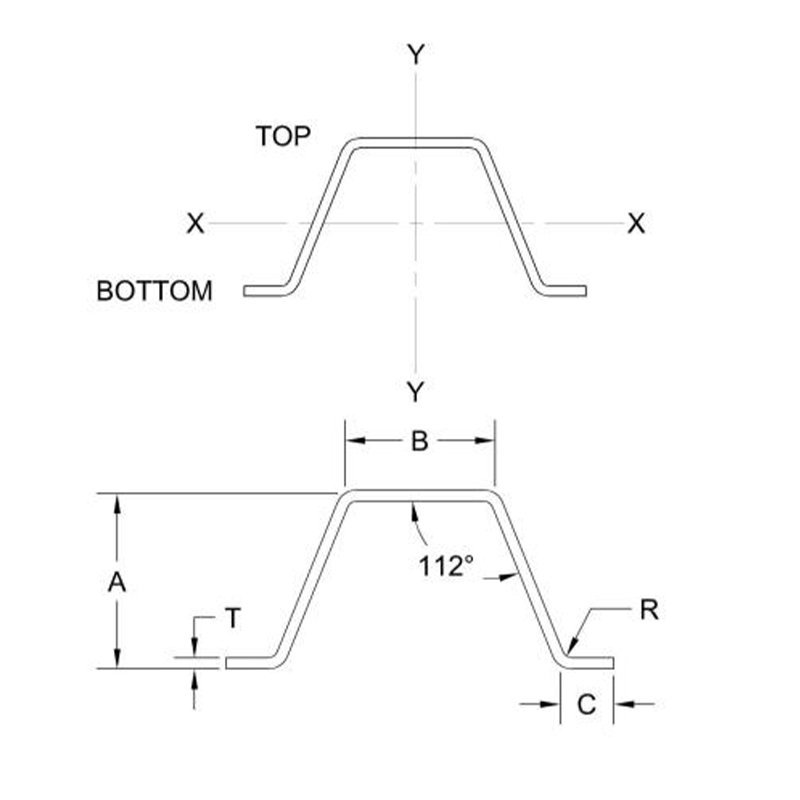

Quality Inspection

KINGREAL CEILING MACHINERY hat channel machines are widely praised by customers for their excellent production accuracy. This is all thanks to KINGREAL CEILING MACHINERY strict quality control and inspection procedures during the manufacturing process. At every stage of production, KINGREAL CEILING MACHINERY carefully inspects each component to ensure that it meets high standards of quality. After production is completed, the omega channel machine will also undergo multiple test runs to verify its performance and stability to ensure that it can continue to provide high-quality finished products.

Especially in the production process of hat channels, KINGREAL CEILING MACHINERY strictly inspects key parameters such as height and width to ensure that each finished product meets the customer's expected standards.

In addition, KINGREAL CEILING MACHINERY welcomes customers from all over the world to visit and experience the factory. Here, customers can operate the hat channel machine in person and conduct on-site inspection of the finished product.

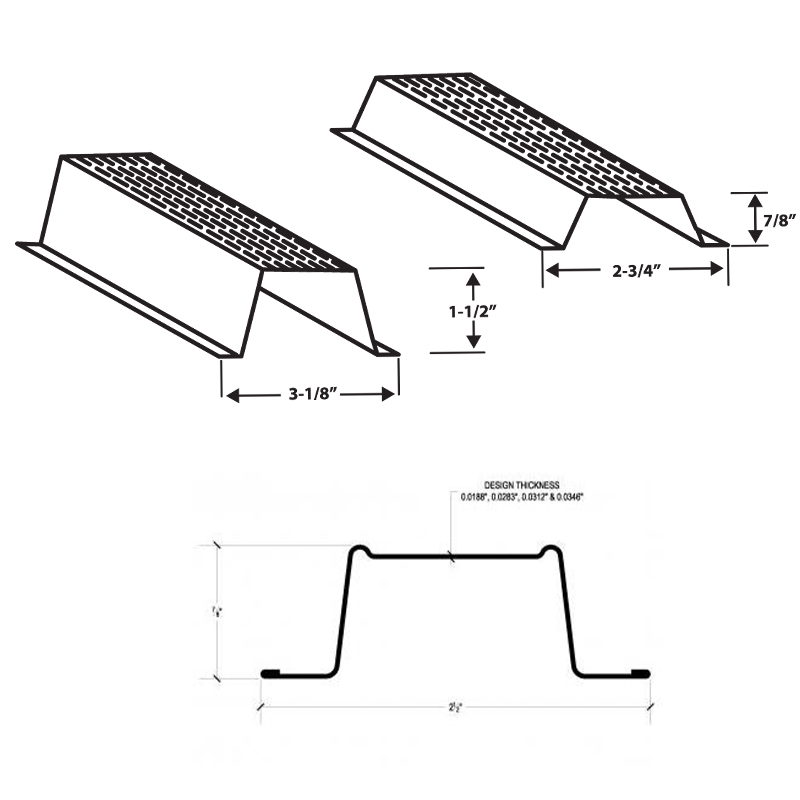

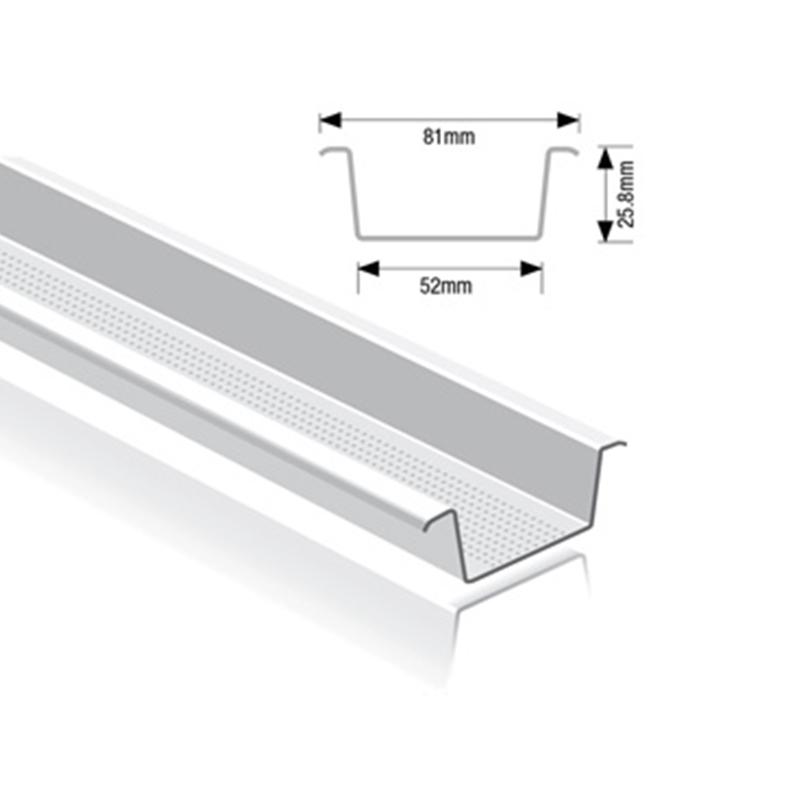

Drawing About Omega Channel

Customer Visit

It is such a delight to have friends coming from afar. KINGREAL CEILING MACHINERY is warmly welcome customers to visit our factory and communicate with us!

The Benefit If You Choose KINGREAL CEILING MACHINERY

⚙ High Production Efficiency Proficiency in fully automatic technology and precise forming techniques. The Omega Profile Roll Forming Machines manufactured by KINGREAL CEILING MACHINERY can maintain consistent quality and accuracy while meeting rapid production needs. ⚙ Cost-Effective Production After more than 20 years of experience accumulation, KINGREAL CEILING MACHINERY has established a systematic design-production team. KINGREAL CEILING MACHINERY designs machines to optimize efficiency, reduce material waste, and simplify manufacturing processes, working to reduce production costs for customers. |  |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)