| Who Are We?

"KINGREAL CEILING MACHINERY develops and manufactures machines for a variety of industries, including metalworking, construction, automotive, and marine. KINGREAL CEILING MACHINERY offers the best solutions for semi-automatic to fully automated production lines.

Located in Foshan, Guangdong, KINGREAL CEILING MACHINERY employs a team of experienced engineers and skilled production and testing personnel. Using the latest design software, KINGREAL CEILING MACHINERY precision and durable equipment are capable of producing a wide range of high-precision finished products. All engineering processes are performed in a fully equipped machine shop, staffed by experienced machine operators and technicians operating the most advanced CNC technology. KINGREAL CEILING MACHINERY also has a sales center in Guangzhou, Guangdong, with a responsive and professional service team. KINGREAL CEILING MACHINERY has successfully completed over 500 projects in over 50 countries over the past 28 years, including the United States, Canada, Mexico, Brazil, Russia, and the Middle East.

KINGREAL CEILING MACHINERY provides personalized support and advice based on customer drawings and actual production requirements, and is committed to finding customized machine solutions that meet their needs.”

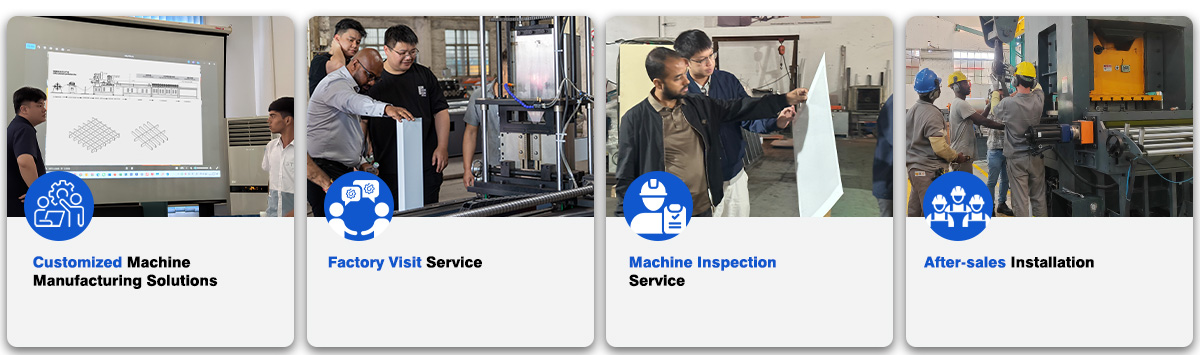

| KINGREAL CEILING MACHINERY Service

"In addition to providing high-quality machines, KINGREAL CEILING MACHINERY one-stop service has also received widespread acclaim from customers. KINGREAL CEILING MACHINERY understands that high-quality products andattentive service are crucial components of customer satisfaction. Therefore, KINGREAL CEILING MACHINERY offers comprehensive and personalized services, including customized machine manufacturing solutions, factory visits, machine inspection services, after-sales installation, spare parts supply, machine overhaul, machine maintenance, and machine upgrades."

●Customized Machine Manufacturing Solutions

KINGREAL CEILING MACHINERY engineers will comprehensively consider various factors, including the climate and policies of the customer's region. Based on the customer's drawings and actual production needs, they will tailor a unique machine manufacturing solution for the customer. Each machine's parameters, performance, and component configuration can be adjusted to meet the customer's specific requirements, ensuring the equipment they receive fully meets their production requirements, achieving true customization.

●Factory Visit Service

KINGREAL CEILING MACHINERY welcomes customers from around the world to visit our factory for an in-person tour and evaluate whether our machines meet their production needs. At KINGREAL CEILING MACHINERY, customers can not only operate the machines themselves and experience their performance, but also conduct on-site inspections of the finished products. Furthermore, customers can visit the materials workshop to learn about KINGREAL CEILING MACHINERY rigorous raw material selection process before manufacturing the machines, and observe the rigorous manufacturing process in the manufacturing workshop. To ensure a smooth customer experience, KINGREAL CEILING MACHINERY will dispatch professional staff to accompany customers throughout the entire visit and answer any questions.

●Machine Inspection Service

After the machine is manufactured, KINGREAL CEILING MACHINERY will conduct multiple inspection procedures to ensure its quality. First, KINGREAL CEILING MACHINERY engineers will conduct a comprehensive inspection and commissioning of the machine. Afterward, KINGREAL CEILING MACHINERY will invite customers to visit the factory for a personal test run to ensure the equipment meets their requirements. If the customer is unable to visit for any reason, KINGREAL CEILING MACHINERY engineers will conduct an inspection and provide detailed feedback via text, images, and videos to ensure customer satisfaction with all machine specifications and a perfect match.

●After-sales Installation

Once the machine arrives safely at the customer's facility, KINGREAL CEILING MACHINERY engineers will conduct on-site professional installation services. To date, KINGREAL CEILING MACHINERY has provided on-site installation services for customers in the United States, Canada, Mexico, Brazil, Morocco, Russia, Saudi Arabia, and other countries, ensuring rapid production and improved efficiency.

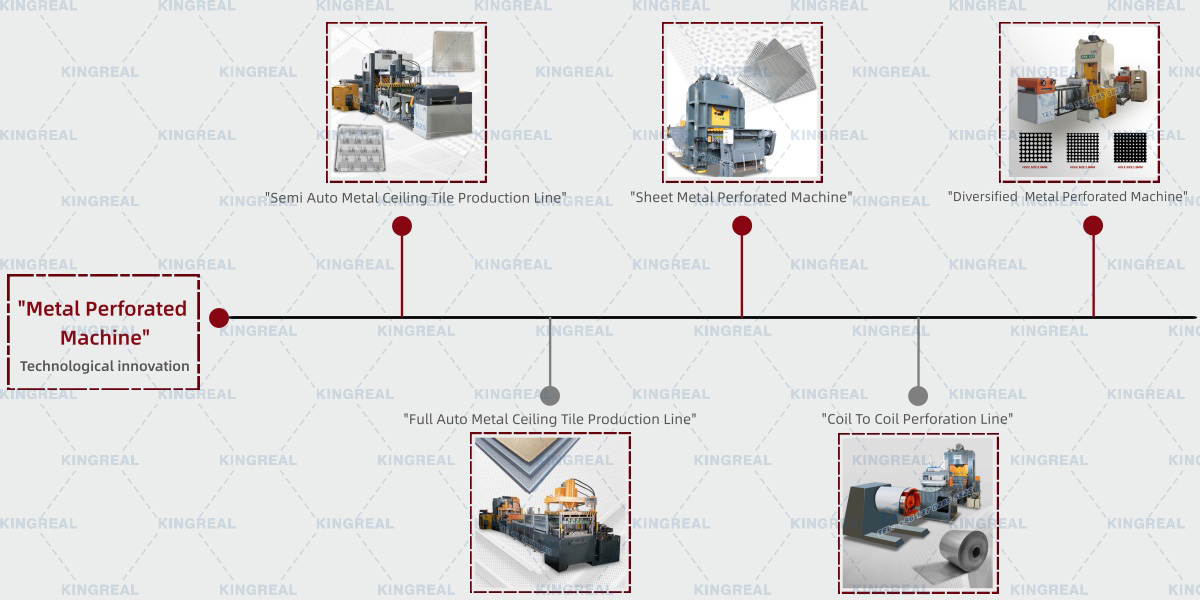

| KINGREAL CEILING MACHINERY Technological Innovations

1. Metal Perforated Making Machine

Metal punching technology uses perforated metal machines to efficiently process metal coils, producing uniformly perforated metal sheets or coils. This precise punching process is widely used in a variety of industries, including construction, chemicals, food processing, automotive, etc.KINGREAL CEILING MACHINERY is committed to continuously improving the design and functionality of perforated metal machines based on customer production needs and market trends.

Initially, KINGREAL CEILING MACHINERY provided semi-automatic perforated metal machines for small-scale production. As customer demand increased and production scale expanded, KINGREAL CEILING MACHINERY gradually introduced fully automatic perforated metal machines to meet efficient production requirements. Currently, KINGREAL CEILING MACHINERY perforated metal machines can process both sheet metal and coiled metal. This flexibility allows customers to select the appropriate material based on their specific production needs. Furthermore, KINGREAL CEILING MACHINERY designs punching dies with various hole shapes and diameters based on customer drawings, greatly enhancing the applicability and flexibility of the perforated metal machines.

To date, KINGREAL CEILING MACHINERY has successfully designed a perforated metal machine capable of punching micro-holes as small as 1.0mm. Going forward, KINGREAL CEILING MACHINERY will continue to prioritize customer needs and continuously upgrade and innovate its perforated metal machine technology, striving to provide customers with more efficient and precise perforated metal machine manufacturing solutions.

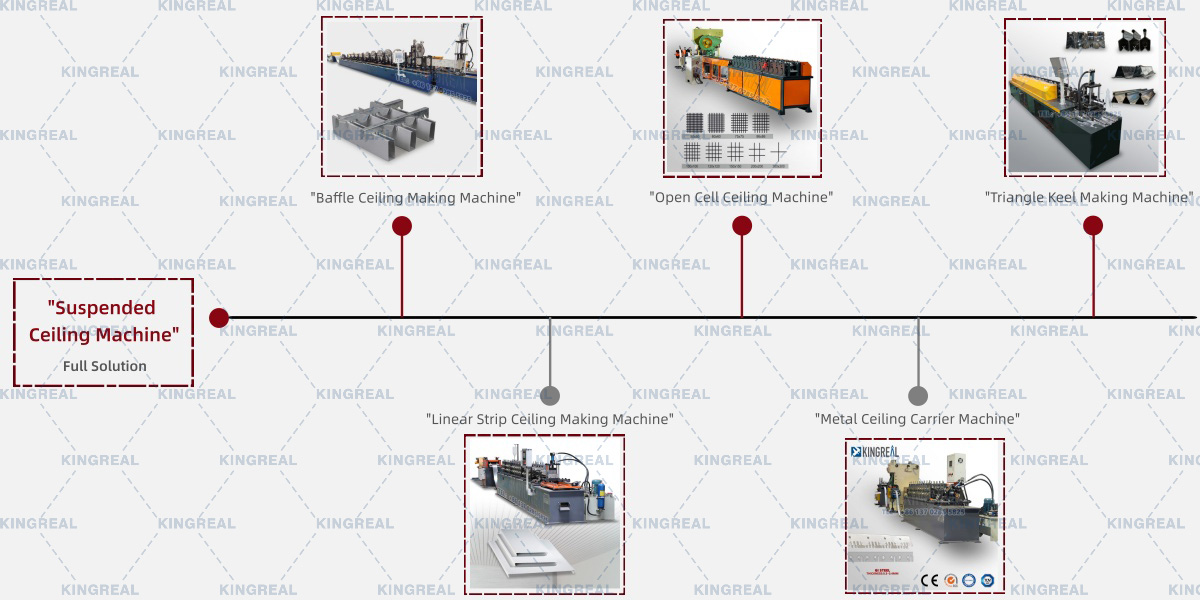

2. Suspended Ceiling Making Machine

Roll forming machine technology primarily involves the use of rollers to roll-form metal coils into various profiles to produce the desired profiles. KINGREAL CEILING MACHINERY has successfully applied this technology to suspended ceiling making machines, launching a variety of equipment, including open cell ceiling machine, linear strip ceiling machine, baffle ceiling making machine and metal ceiling carrier making machine.These suspended ceiling making machines offer flexible production capabilities, allowing them to quickly adapt to varying finished product specifications by adjusting parameters such as production speed and roller width. Whether for large-scale production or small-batch customization, KINGREAL CEILING MACHINERY suspended ceiling making machine operates efficiently to meet the diverse needs of KINGREAL CEILING MACHINERY customers.

In addition to providing a variety of suspended ceiling making machines, KINGREAL CEILING MACHINERY also specializes in providing complete suspended ceiling system solutions. This includes supporting equipment for supporting suspended ceilings, which are essential for suspended ceiling system installation. This integration not only simplifies the purchasing process for customers but also ensures efficient compatibility between equipment, enhancing installation convenience. KINGREAL CEILING MACHINERY continues to conduct technological research and development in the field of suspended ceiling making machines, striving to develop new equipment and solutions. Through in-depth analysis of market demand, KINGREAL CEILING MACHINERY continuously expands suspended ceiling tile making machine range to ensure a more comprehensive service offering for customers.

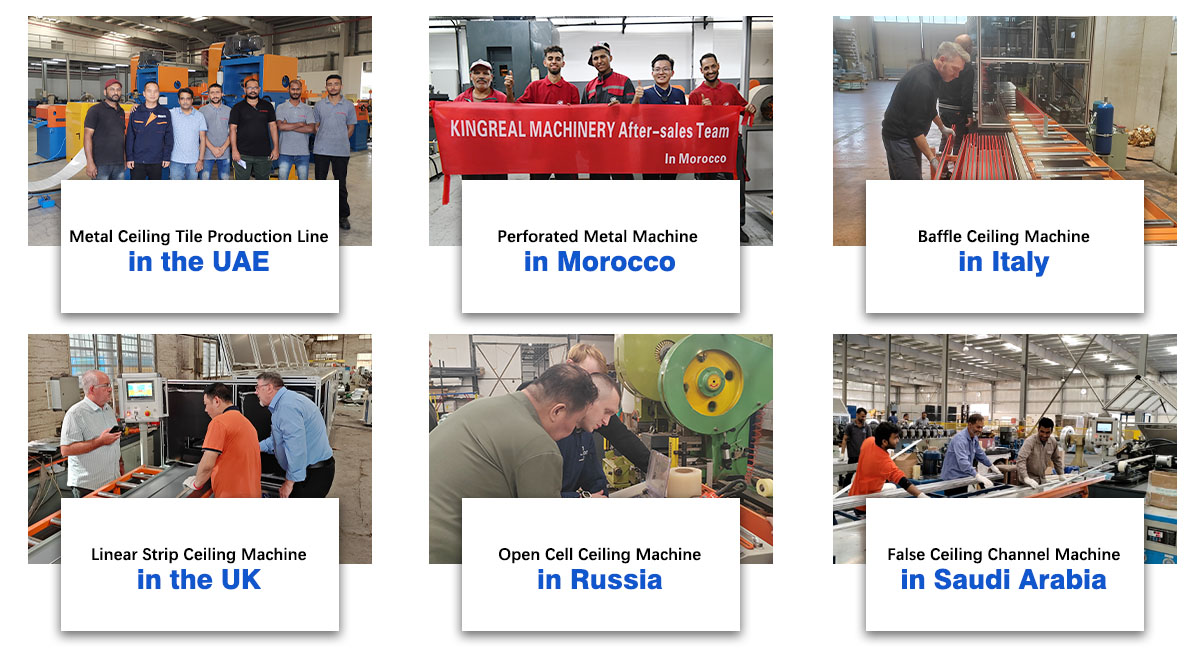

| Highlights of KINGREAL CEILING MACHINERY Projects

"KINGREAL CEILING MACHINERY machines are now available in over 50 countries around the world, with many customers drawn to KINGREAL CEILING MACHINERY products and services through recommendations from peers or word of mouth in the local market."

1

Metal Ceiling Tile Production Line in the UAE

A fully automated metal ceiling tile production line is operating smoothly at a customer's factory in the UAE. To meet the customer's demand for fully automated production, KINGREAL CEILING MACHINERY engineers equipped the metal ceiling tile production line with advanced components, including a flipping machine, an automatic tiles feeding machine, an auto bending forming machine, and a metal sheet cleaning machine, ensuring efficient production.

2

Perforated Metal Machine in Morocco

This Moroccan customer recorded a video expressing their gratitude for KINGREAL CEILING MACHINERY excellent service and the outstanding performance of the perforated metal machine. This perforated metal machine allows for the flexible production of various hole shapes and diameters of perforated metal sheets by replacing different punching dies, perfectly meeting the customer's production needs in Morocco.

3

Baffle Ceiling Machine in Italy

To meet the Italian customer's specific requirements for finished products, KINGREAL CEILING MACHINERY engineers designed a 300mm height baffle ceiling machine for the Italian client. By adjusting various production parameters, this baffle ceiling machine can accurately produce finished products with heights ranging from 35-300mm and widths ranging from 50-100mm, fully meeting the customer's individual needs.

4

Linear Strip Ceiling Machine in UK

After the linear strip ceiling machinewas manufactured, KINGREAL CEILING MACHINERY invited the British customer to visit the factory for a personal inspection. After obtaining the customer's permission, the two parties discussed the delivery schedule in detail. Upon arrival in the UK, KINGREAL CEILING MACHINERY engineers immediately visited the site to install the linear strip ceiling machine and provided professional operator training to the British workers to ensure smooth operation.

5

Open Cell Ceiling Machine in Russia

In early 2025, KINGREAL CEILING MACHINERY engineers visited the Russian customer's factory to install the open cell ceiling machine. Based on the specific needs of the Russian customer, KINGREAL CEILING MACHINERY engineers meticulously tuned the open cell ceiling machine to ensure it perfectly matched their daily usage requirements. After the installation was complete, the Russian customer warmly invited the KINGREAL CEILING MACHINERY engineers to lunch and danced with them to express their satisfaction and gratitude.

6

False Ceiling Channel Machine in Saudi Arabia

To meet the Saudi Arabian customer's demand for fully automated production processes, KINGREAL CEILING MACHINERY engineers equipped the false ceiling channel machine with a packaging unit, enabling automatic bundling and stacking of profiles. This false ceiling channel machine has been in use at the Saudi Arabian factory for nearly a year and has generated significant economic benefits for the customer.

Get the latest price? We'll respond as soon as possible(within 12 hours)

What customers says