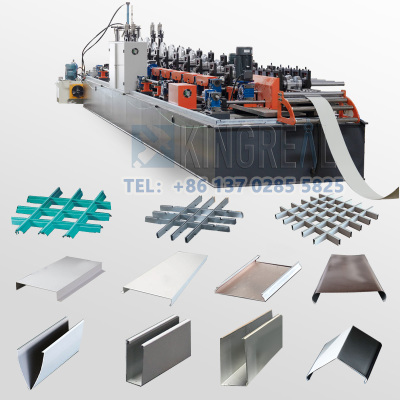

Products Lists

1/ What is a Sheet Metal Stamping Press?

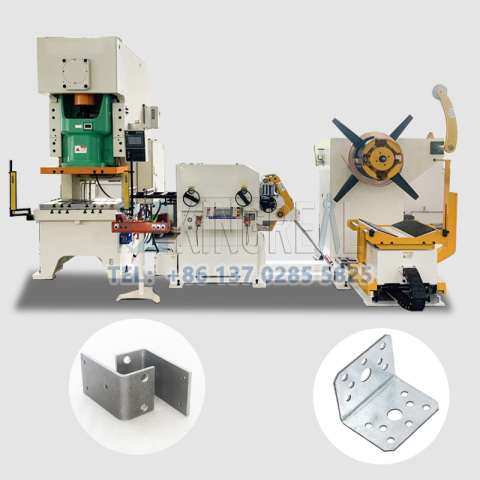

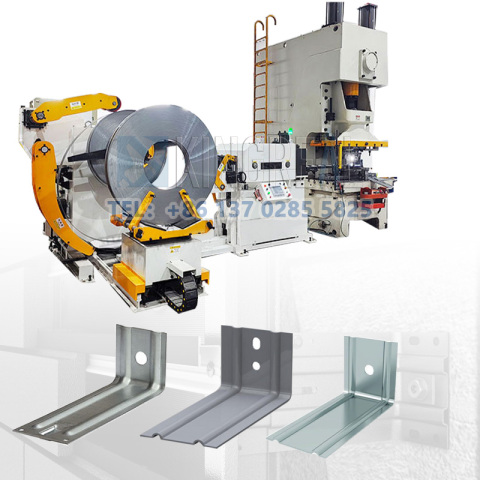

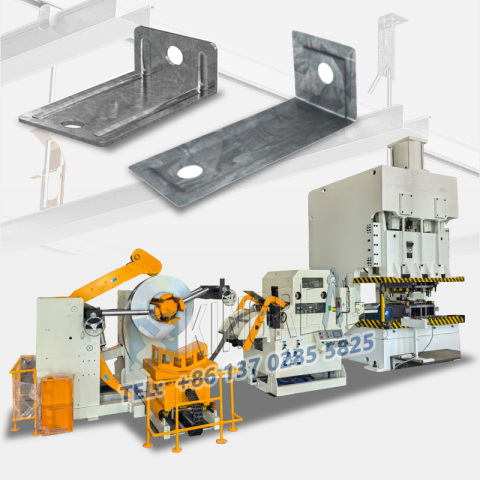

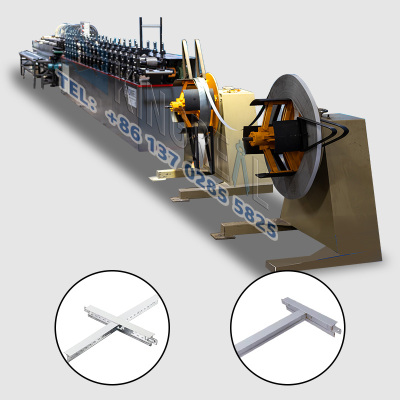

A metal stamping making machine is an essential piece of equipment in modern manufacturing, primarily used for efficient metal processing. It typically processes metals ranging in thickness from 0.1 to 3 mm for iron and stainless steel, and from 0.1 to 4 mm for copper and aluminum. Using progressive dies, a mechanical press punch can perform a variety of processes on metal coils, including bending, drawing, and partial forming.

2/ Basic Types of Stamping Processes

●Bending: Bending is the process of shaping sheet metal into desired angles and shapes along specific bend lines. This process is particularly important for manufacturing parts with complex geometries, meeting diverse design requirements.

●Drawing: Drawing transforms flat sheet material into various hollow parts, or further modifies the shape and dimensions of these parts. This process enables the production of complex structures such as automobile bodies and containers.

●Partial Forming: Partial forming processes alter the shape of a blank or stamped part by locally deforming it to achieve different properties. Common partial forming operations include flanging, bulging, flattening, and forming, which are often used to enhance the functionality and aesthetics of a part.

●Furthermore, to enhance the load-bearing capacity of metal brackets, KINGREAL CEILING MACHINERY mechanical press punches can add reinforcing ribs to key locations. This design effectively distributes loads, increases rigidity, and reduces stress concentration, significantly extending the service life of the metal brackets.

3/ What can a Metal Stamping Making Machine Produce?

The flexibility of a sheet metal stamping press enables it to produce a variety of metal connector shapes and hole patterns using different dies. Common products include: U-shaped Carbon Steel Small Bracket, Small Stamping and Bending Bracket, Carbon Steel Angle Bracket, Steel Brackets, Aluminum Machining Connecting Bracket, Heavy Duty Metal Bracket, Bracket Machining,etc. These products are widely used in a variety of industries, including the automotive and parts industries, construction-related industries, home appliance industries, and the electrical and electronic components industries.

4/ FAQ about Metal Stamping Making Machines

(1) What types of punching machines do you offer?

KINGREAL CEILING MACHINERY offers a variety of punching machine types, including:

●Hydraulic punching machine for sheet metal stamping press: Suitable for high-strength and high-precision stamping, they are widely used in industries such as automotive and aerospace. Hydraulic punching machines can provide greater pressure and are suitable for processing thicker metal materials.

●Mechanical punching machines for sheet metal stamping press: Popular for their speed and efficiency, they are suitable for high-volume production. Mechanical punching machines are primarily used for thinner metal sheets and can perform rapid, repetitive stamping operations.

●Pneumatic punching machines for sheet metal stamping press: Suitable for lightweight materials that require rapid stamping. Due to their ease of operation and low maintenance, they are commonly used in the electronics and appliance industries.

These sheet metal stamping presses are designed for diverse applications and production needs, meeting customers' diverse production requirements and ensuring product quality and efficiency.

(2) What materials can your metal stamping making machines process?

KINGREAL CEILING MACHINERY mechanical press punches can effectively process a variety of materials, including: 1) Mild carbon steel: Suitable for manufacturing parts requiring high strength, widely used in the structural and automotive industries. 2) Stainless steel: Due to its excellent corrosion resistance, it is often used in household appliances, kitchen appliances, and medical devices. 3) Aluminum: Lightweight and with good processability, it is suitable for aerospace and electronic equipment. 4) Copper: Due to its excellent conductivity, it is often used in the manufacture of electrical and electronic components.

Specific processing capabilities depend on the machine model and tooling used by the customer. If a customer requires processing a special metal material, KINGREAL CEILING MACHINERY engineers will tailor the sheet metal stamping press construction plan to meet the customer's specific needs.

(3) Can your metal stamping making machines be customized for specific applications?

Of course! KINGREAL CEILING MACHINERY offers customization options to meet specific production requirements. This includes:

●Adjusting the punching capacity: Adjusting the force and speed of the mechanical press punch to accommodate processing of different materials and thicknesses based on the customer's production needs.

●Tool Selection: Depending on the metal stamping making machine design, we offer a variety of mold and tool options for greater production flexibility.

●Additional Function Modifications: KINGREAL CEILING MACHINERY can add or modify additional features, such as automatic feeding systems and cooling systems, to meet specific customer needs, enhancing production efficiency and safety.

Since metal brackets with varying thicknesses, hardnesses, and other requirements vary across applications, KINGREAL CEILING MACHINERY customizes these features to ensure an efficient and smooth production process.

(4)What safety features are included in your sheet metal stamping presses?

Safety is a top priority at KINGREAL CEILING MACHINERY. Our metal stamping making machines are equipped with several safety features, including:

●Emergency Stop Button for mechanical press punch: In the event of an emergency, the operator can quickly stop the sheet metal stamping press to ensure personal safety.

●Safety Guards for mechanical press punch: A safety guard is installed around the sheet metal stamping press to prevent accidental contact with moving parts during operation.

●Overload Protection System for mechanical press punch: This system automatically shuts down the metal stamping making machine if the load exceeds a set value, preventing damage.

●Photoelectric Sensor: This detects objects within the work area, ensuring the metal stamping making machine is not activated until they are clear.

These safety features ensure safe operation, reduce potential operational risks, and enhance the overall safety of the work environment.

(5) How do we ensure the correct installation and operation of the sheet metal stamping press?

To ensure the correct setup and efficient operation of your metal stamping making machine, KINGREAL CEILING MACHINERY provides the following services:

●Complete Installation Service: After the mechanical press punch arrives at your facility, KINGREAL CEILING MACHINERY professional engineers will visit you to install it on-site, ensuring it is optimally configured.

●Operation Training: During the installation process, KINGREAL CEILING MACHINERY will provide comprehensive training to your operators to ensure they master proper operation and maintenance techniques.

●Post-installation Support: After installation, KINGREAL CEILING MACHINERY will continue to provide technical support to answer any questions you may have during operation and ensure the sheet metal stamping press remains in optimal working condition.

Through these measures, KINGREAL CEILING MACHINERY ensures that customers can fully utilize the metal stamping making machine’s capabilities and maximize production efficiency.

A metal stamping making machine is an essential piece of equipment in modern manufacturing, primarily used for efficient metal processing. It typically processes metals ranging in thickness from 0.1 to 3 mm for iron and stainless steel, and from 0.1 to 4 mm for copper and aluminum. Using progressive dies, a mechanical press punch can perform a variety of processes on metal coils, including bending, drawing, and partial forming.

2/ Basic Types of Stamping Processes

●Bending: Bending is the process of shaping sheet metal into desired angles and shapes along specific bend lines. This process is particularly important for manufacturing parts with complex geometries, meeting diverse design requirements.

●Drawing: Drawing transforms flat sheet material into various hollow parts, or further modifies the shape and dimensions of these parts. This process enables the production of complex structures such as automobile bodies and containers.

●Partial Forming: Partial forming processes alter the shape of a blank or stamped part by locally deforming it to achieve different properties. Common partial forming operations include flanging, bulging, flattening, and forming, which are often used to enhance the functionality and aesthetics of a part.

●Furthermore, to enhance the load-bearing capacity of metal brackets, KINGREAL CEILING MACHINERY mechanical press punches can add reinforcing ribs to key locations. This design effectively distributes loads, increases rigidity, and reduces stress concentration, significantly extending the service life of the metal brackets.

3/ What can a Metal Stamping Making Machine Produce?

The flexibility of a sheet metal stamping press enables it to produce a variety of metal connector shapes and hole patterns using different dies. Common products include: U-shaped Carbon Steel Small Bracket, Small Stamping and Bending Bracket, Carbon Steel Angle Bracket, Steel Brackets, Aluminum Machining Connecting Bracket, Heavy Duty Metal Bracket, Bracket Machining,etc. These products are widely used in a variety of industries, including the automotive and parts industries, construction-related industries, home appliance industries, and the electrical and electronic components industries.

4/ FAQ about Metal Stamping Making Machines

(1) What types of punching machines do you offer?

KINGREAL CEILING MACHINERY offers a variety of punching machine types, including:

●Hydraulic punching machine for sheet metal stamping press: Suitable for high-strength and high-precision stamping, they are widely used in industries such as automotive and aerospace. Hydraulic punching machines can provide greater pressure and are suitable for processing thicker metal materials.

●Mechanical punching machines for sheet metal stamping press: Popular for their speed and efficiency, they are suitable for high-volume production. Mechanical punching machines are primarily used for thinner metal sheets and can perform rapid, repetitive stamping operations.

●Pneumatic punching machines for sheet metal stamping press: Suitable for lightweight materials that require rapid stamping. Due to their ease of operation and low maintenance, they are commonly used in the electronics and appliance industries.

These sheet metal stamping presses are designed for diverse applications and production needs, meeting customers' diverse production requirements and ensuring product quality and efficiency.

(2) What materials can your metal stamping making machines process?

KINGREAL CEILING MACHINERY mechanical press punches can effectively process a variety of materials, including: 1) Mild carbon steel: Suitable for manufacturing parts requiring high strength, widely used in the structural and automotive industries. 2) Stainless steel: Due to its excellent corrosion resistance, it is often used in household appliances, kitchen appliances, and medical devices. 3) Aluminum: Lightweight and with good processability, it is suitable for aerospace and electronic equipment. 4) Copper: Due to its excellent conductivity, it is often used in the manufacture of electrical and electronic components.

Specific processing capabilities depend on the machine model and tooling used by the customer. If a customer requires processing a special metal material, KINGREAL CEILING MACHINERY engineers will tailor the sheet metal stamping press construction plan to meet the customer's specific needs.

(3) Can your metal stamping making machines be customized for specific applications?

Of course! KINGREAL CEILING MACHINERY offers customization options to meet specific production requirements. This includes:

●Adjusting the punching capacity: Adjusting the force and speed of the mechanical press punch to accommodate processing of different materials and thicknesses based on the customer's production needs.

●Tool Selection: Depending on the metal stamping making machine design, we offer a variety of mold and tool options for greater production flexibility.

●Additional Function Modifications: KINGREAL CEILING MACHINERY can add or modify additional features, such as automatic feeding systems and cooling systems, to meet specific customer needs, enhancing production efficiency and safety.

Since metal brackets with varying thicknesses, hardnesses, and other requirements vary across applications, KINGREAL CEILING MACHINERY customizes these features to ensure an efficient and smooth production process.

(4)What safety features are included in your sheet metal stamping presses?

Safety is a top priority at KINGREAL CEILING MACHINERY. Our metal stamping making machines are equipped with several safety features, including:

●Emergency Stop Button for mechanical press punch: In the event of an emergency, the operator can quickly stop the sheet metal stamping press to ensure personal safety.

●Safety Guards for mechanical press punch: A safety guard is installed around the sheet metal stamping press to prevent accidental contact with moving parts during operation.

●Overload Protection System for mechanical press punch: This system automatically shuts down the metal stamping making machine if the load exceeds a set value, preventing damage.

●Photoelectric Sensor: This detects objects within the work area, ensuring the metal stamping making machine is not activated until they are clear.

These safety features ensure safe operation, reduce potential operational risks, and enhance the overall safety of the work environment.

(5) How do we ensure the correct installation and operation of the sheet metal stamping press?

To ensure the correct setup and efficient operation of your metal stamping making machine, KINGREAL CEILING MACHINERY provides the following services:

●Complete Installation Service: After the mechanical press punch arrives at your facility, KINGREAL CEILING MACHINERY professional engineers will visit you to install it on-site, ensuring it is optimally configured.

●Operation Training: During the installation process, KINGREAL CEILING MACHINERY will provide comprehensive training to your operators to ensure they master proper operation and maintenance techniques.

●Post-installation Support: After installation, KINGREAL CEILING MACHINERY will continue to provide technical support to answer any questions you may have during operation and ensure the sheet metal stamping press remains in optimal working condition.

Through these measures, KINGREAL CEILING MACHINERY ensures that customers can fully utilize the metal stamping making machine’s capabilities and maximize production efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)