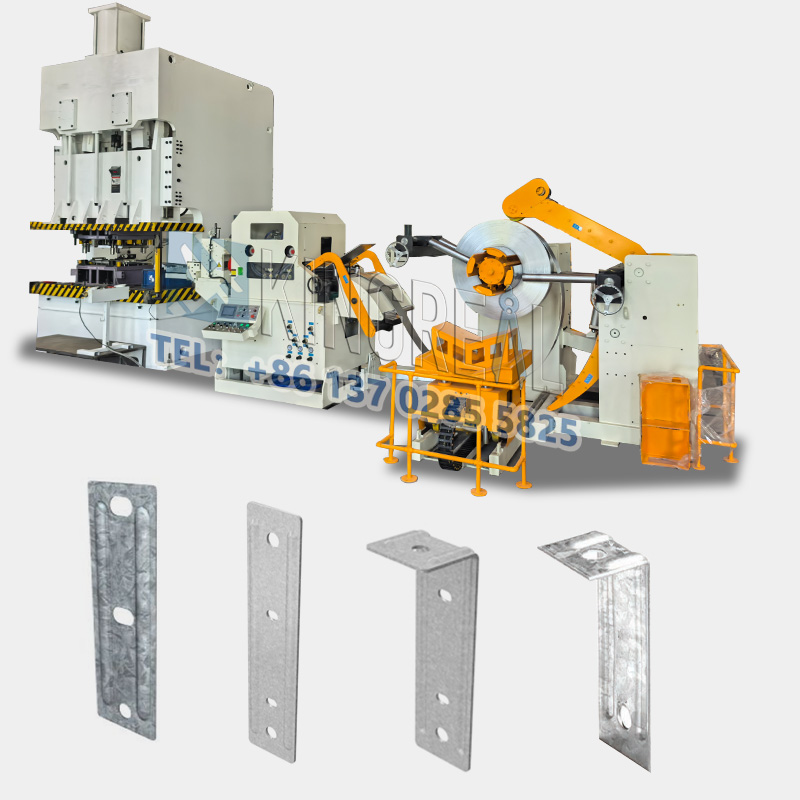

Automatic Punch Press machine

KINGREAL CEILING MACHINERY provides customers with complete suspended ceiling system solutions, including suspension rod brackets produced using sheet metal punch press machine, and baffle ceiling, open cell ceiling, and linear strip ceiling manufactured using suspended ceiling machine. Furthermore, KINGREAL CEILING MACHINERY false ceiling channel machines are capable of producing furring channels, u channels, and angle beads.

- KINGREAL CEILING MACHINERY

Details

Video About Automatic Punch Press Machine

Description of Automatic Punch Press Machine

Automatic punch press machines are in high demand because they can process a variety of metal materials. The metal mounting brackets they produce are widely used in a variety of applications, including automotive equipment, electronics, medical devices, construction tools, and building materials. Demand for these sheet metal punch press machines is particularly high in suspended ceiling systems. KINGREAL CEILING MACHINERY provides customers with complete suspended ceiling system solutions, including suspension rod brackets produced using sheet metal punch press machine, and baffle ceiling, open cell ceiling, and linear strip ceiling manufactured using suspended ceiling machine. Furthermore, KINGREAL CEILING MACHINERY false ceiling channel machines are capable of producing furring channels, u channels, and angle beads. The effective combination of these components ensures smooth installation of the entire suspended ceiling. KINGREAL CEILING MACHINERY also offers automatic punch press machines with varying performance and specifications tailored to customer needs. |  |

Parameter of Sheet Metal Punch Press Machine

| Item | Item 1 | Item 2 | Item 3 | Item 4 | Item 5 | ||||||

| Model | V | H | V | H | V | H | V | H | V | H | |

| Capacity | 110 | 160 | 200 | 250 | 315 | ||||||

Rated Tonnage Point | mm | 5 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

Stroke | mm | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 | 280 | 170 |

Stable speed | s.p.m | 35-65 | 50-100 | 30-55 | 40-85 | 25-45 | 35-70 | 20-35 | 30-60 | 20-35 | 30-50 |

Die Height | mm | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 | 550 | 605 |

Slide Adjustment | mm | 100 | 100 | 120 | 120 | 120 | |||||

Slide Area | mm | 1400x500x70 | 1600x550x70 | 1850x650x95 | 2100x700x95 | 2100x700x95 | |||||

Bolster Area | mm | 1800x650x130 | 2000x760x150 | 2400x840x170 | 2700x900x170 | 2800x950x170 | |||||

Main Motor | kw.p | 7.5x4 | 11x4 | 15x4 | 18.5x4 | 22x4 | |||||

Air Pressure | kg/cm² | 5-6 | 5-6 | 5-6 | 5-6 | 5-6 | |||||

Presses Precision | Ton | JAPAN JIS CLASS 1 | |||||||||

Die Cushion | Two plate & two cylinders | ||||||||||

Capacity | Ton | 3.6×2 | 6.3x2 | 10x2 | 14x2 | 14x2 | |||||

Stroke | mm | 70 | 70 | 80 | 100 | 120 | |||||

Die Cushion work part dimension | mm | 350×235×2 | 410x260x2 | 540x350x2 | 640x470x2 | 640x470x2 | |||||

KINGREAL CEILING MACHINERY Offers a Complete Suspended Ceiling Solution

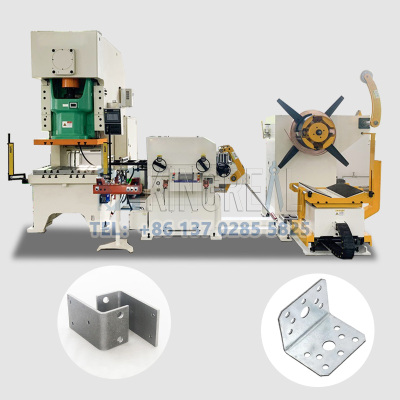

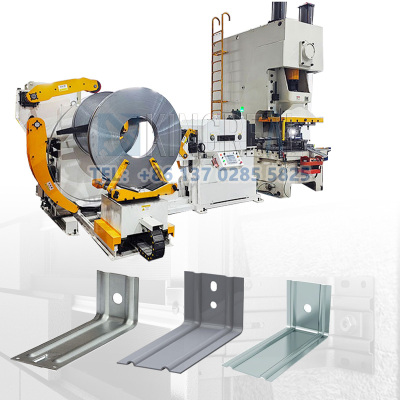

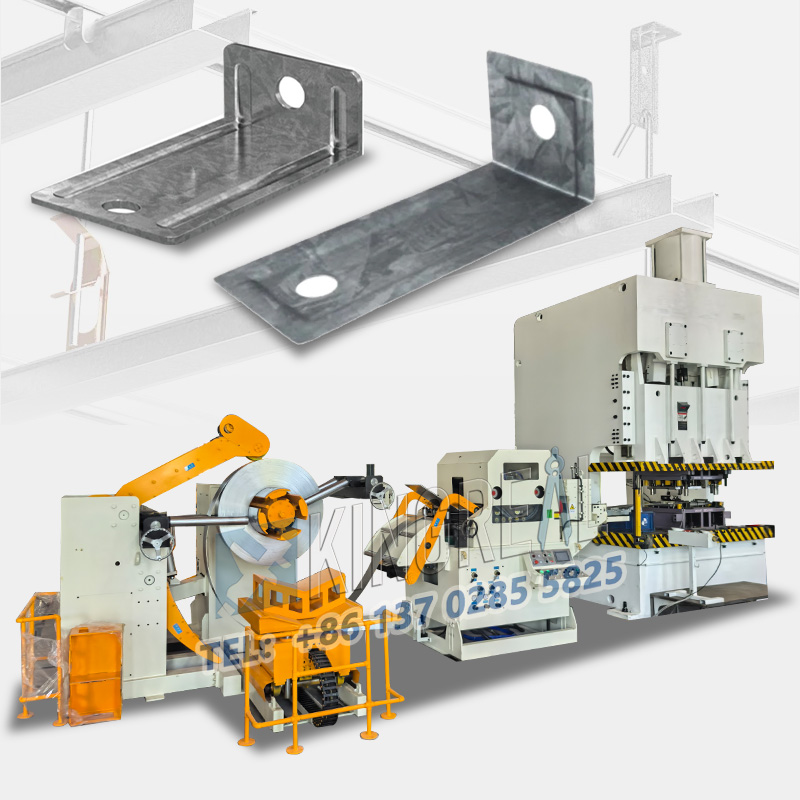

(1)Automatic Punch Press Machine

A sheet metal punch press machine is used to bend, plastically deform, and punch metal coils of varying thicknesses and materials into metal connectors of various shapes and sizes as required by the customer. The automatic punch press machine can also add reinforcing ribs to these metal mounting brackets to enhance their strength and load-bearing capacity. In suspended ceiling systems, KINGREAL CEILING MACHINERY sheet metal punch press machines are capable of producing a variety of suspension rod brackets, such as straight rod hangers and angle rod brackets. Suspension rod brackets of different shapes and types play their respective roles in suspended ceiling installations.

The configuration and performance parameters of a automatic punch press machine are determined by the customer's specific requirements for product thickness, strength, and flexibility. KINGREAL CEILING MACHINERY engineers will provide customized sheet metal punch press machine manufacturing solutions based on the customer's specific needs. |  |

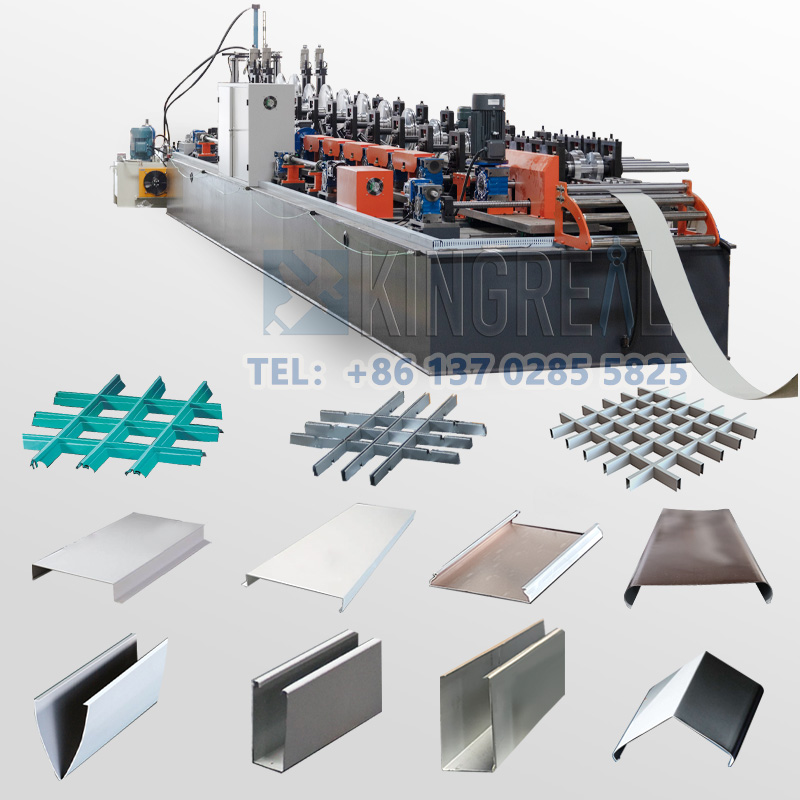

(2) False Ceiling Channel Machine

KINGREAL CEILING MACHINERY offers a variety of false ceiling channel machines, including omega channel machine, u channel machine, and corner bead making machine, to meet customer production needs for omega channels, u channels, and angle beads. KINGREAL CEILING MACHINERY false ceiling channel machines feature high production speeds, reaching a maximum speed of 120m/min(adjustable). To meet customer safety requirements, KINGREAL CEILING MACHINERY can equip the false ceiling channel machines with protective shields. Furthermore, KINGREAL CEILING MACHINERY 3-in-1 false ceiling channel machine allows for the production of three different types of profiles using a single machine by replacing molds. Accessories such as a packaging machine and inkjet device can be integrated with the false ceiling channel machine to create a fully automated, efficient production line. False ceiling channels of varying specifications can also be customized according to customer drawings.

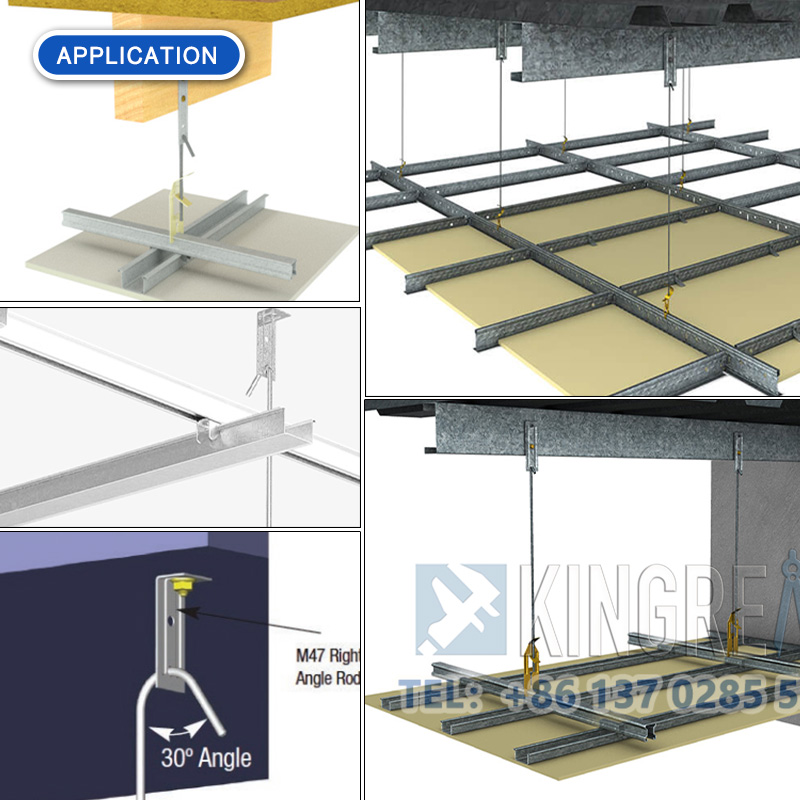

In suspended ceiling systems, omega channels produced by omega channel machines are attached to suspension brackets, typically secured with screws or clamps. U channels produced by u channel machines provide additional support and are also typically secured with suspension brackets. The corner bead making machines produce corner beads for installation at the top of walls, typically secured with screws to support the edges of ceiling panels. |  |

KINGREAL CEILING MACHINERY offers high-demand suspended ceiling machines, including baffle ceiling machines, open cell ceiling machines, and linear strip ceiling machines. The baffle ceiling machines can produce u baffle and v baffle with widths of 25-100mm and heights of 75-300mm, with a production speed of 30m/min and can be equipped with baffle ceiling carrier machines. The linear strip ceiling machine can produce not only R84 shapes but also custom shapes such as C, G, F, B, and S. The open cell ceiling machine can produce open cell ceilings of various specifications, including u typed open cell ceiling, c typed open cell ceiling and pyramid open cell ceiling. Product sizes range from 10/15mm wide and 30/40/50mm high, with opening sizes of 75x75/100x100/150x150/200x200mm, with a production capacity of 10-30 m/min. These suspended ceiling machines can meet the production needs of various ceiling sizes and offer a variety of parameters and configurations.The choice of suspended ceiling machine depends on the customer's application and personal preference. The suspended ceiling, combined with straight rod hanger, angle rod bracket, u channel, omega channel and corner bead, forms a complete suspended ceiling system. |  |

Features of Automatic Punch Press Machine

-Automatic feeding system for automatic punch press machine: The automatic feeding system enables the sheet metal punch press machine to operate at high speeds, minimizing downtime, significantly shortening production cycles, and improving cycle efficiency. This system also supports extended production runs, enabling more parts to be produced in a shorter time-frame.

-Stable performance automatic punch press machine: The sheet metal punch press machine can withstand large-scale production runs without compromising performance, ensuring consistent quality throughout the production process.

-Production of complex geometries: KINGREAL CEILING MACHINERY customizes progressive stamping dies based on customer drawings. The progressive stamping die construction enables the production of complex parts with greater precision. During the design phase, KINGREAL CEILING MACHINERY engineers optimize the progressive stamping dies to minimize scrap. |  |

Introduction to Suspension Rod Brackets

In suspended ceiling installation, two main types of suspension rod brackets are commonly used: straight rod hangers and angle rod brackets. Straight rod hangers provide primary suspension support, while angle rod brackets enhance structural stability and support. When using them, the appropriate connector and installation location should be selected based on the specific installation requirements and structural characteristics. Ensure that all connectors are securely installed to ensure the safety and durability of the ceiling. |  |

Function of Automatic Punch Press Machine

Drawing of Suspended Ceiling System Installation

FAQ About Automatic Punch Press Machine

What metals are used in automatic punch press machine?

Common alloys used in automatic punch press machine include steel, stainless steel, copper, brass, nickel, and aluminum. Choosing the appropriate press based on the type of metal you are using can help improve production efficiency and stamping accuracy.

Is metal stamping hard?

Using a KINGREAL CEILING MACHINERY automatic punch press machine is a convenient method for metal stamping. By choosing an automatic punch press machine with the appropriate pressure capacity, you can easily obtain high-quality finished products.

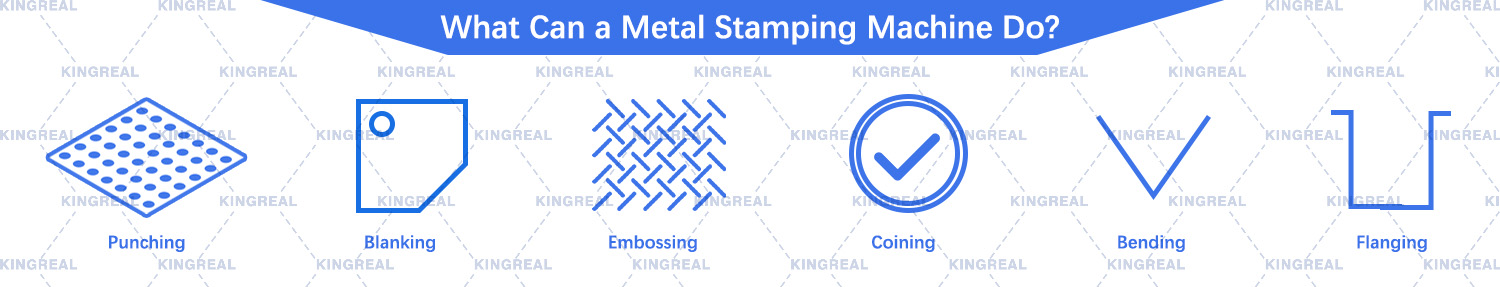

What does an automatic punch press machine do?

Automatic punch press machines use processes such as bending, punching, embossing, or coining to transform metal sheets into parts or products of specific shapes. By applying high pressure through dies, they can produce a wide range of products, from simple components to complex precision parts.

What functions can automatic punch press machines automate?

Based on your specific part requirements, KINGREAL CEILING MACHINERY automatic punch press machines can integrate multiple process steps such as punching, coining, blanking, bending, and flanging to produce high-precision plastic products.

What industries use automatic punch press machines?

KINGREAL CEILING MACHINERY automatic punch press machine is widely used in the automotive, electric mobility, electronics, and medical device manufacturing industries. For more information, please contact KINGREAL CEILING MACHINERY.

New Information About Automatic Punch Press Machine

1.Automated Precision Progressive Die Mechanical Press Solutions

3.Types of Metal Stamping Making Machine

4.Understanding the Sheet Metal Stamping Press Process

5.Metal Stamping Machine: Everything You Need to Know

If you want to know more information about automatic punch press machine, please contact KINGREAL CEILING MACHINERY!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)