Furring Channel Machine

KINGREAL CEILING MACHINERY furring channel machine can produce furring channels to meet customers' mass production needs, with a production speed of up to 120m/min. It is mainly used to provide a stable frame for fixing ceiling tiles and wall panels.

Furring Channel Machine | Hat Channel Machine | Omega Channel Machine

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About Furring Channel Machine

Introduction of Furring Channel Machine

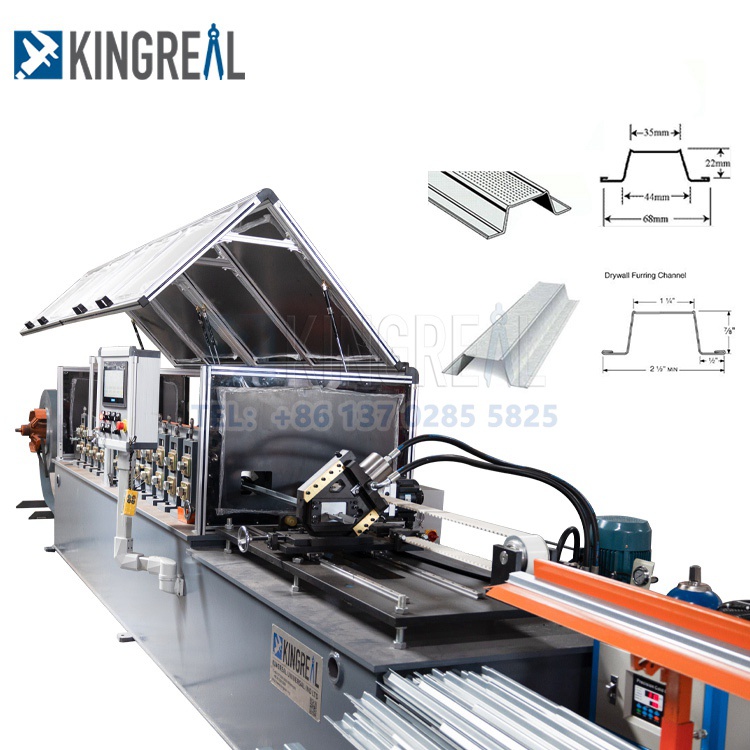

A furring channel machine or hat channel machine is a false ceiling channel machine used to make furring channels. They are commonly used in the construction industry. And they are used as structural supports or frame components in a variety of applications, including walls, ceilings, and roofs. Among them, the furring channel machine feeds large rolls of metal coils into the machine, and gradually forms the metal into the hat channel shape required by the customer through a series of rollers and dies. KINGREAL CEILING MACHINERY can provide customers with hat channel machines with stable performance, high precision and high efficiency, and KINGREAL CEILING MACHINERY can provide personalized furring channel machine manufacturing solutions according to customer needs.

In the false ceiling channel system, KINGREAL CEILING MACHINERY can provide the following types of metal ceiling channel machines: |  |

Parameters of Hat Channel Machine

| Raw material | GI Strip, Strip Thickness: 0.4-1.3mm |

Machine Layout |  |

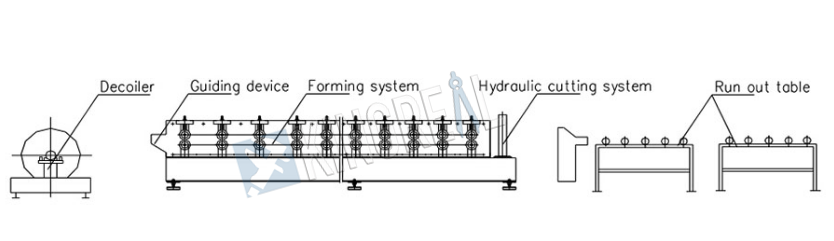

| Process | Decoiler -- Main Roll Forming Machine -- Cutting Station -- Product Table |

Features | 1. Fully automatic production process 2. Production speed: up to 120m/min 3. Automatic hydraulic cutting device 4. Product length: can be adjusted according to demand |

Specification | A. Decoiler x one unit. 2. Max. Loading Capacity: 5Ton 4. Max Material External Diameter:<Ф1200mm 2. Archway Panel:independent structure & surface blackening process 3. Driving system:Gear driving roller’s structure,the main axle material is 40CR,the AXLE diameter is Ф40mm 4. Roller Materials:CR12Mov mold steel,heat treatment hardness up to HRC 58°-60° 2. Shearing Method:servo follow cut without stop the machine 3. Blade Material:D2withquenching treatment hardness up to HRC60℃ |

Main Components of Furring Channel Machine

1. Decoiler for hat channel machine The decoiler is the first component of the furring channel machine. KINGREAL CEILING MACHINERY can equip the hat channel machine with a heavy-duty decoiler. This decoiler can bear heavy and large coils, ensuring stability and efficiency during large-scale production. The design of the decoiler not only focuses on the load-bearing capacity, but also takes into account the uncoiling speed. The fast uncoiling speed can greatly improve production efficiency and ensure the smooth progress of the subsequent forming process. |  |

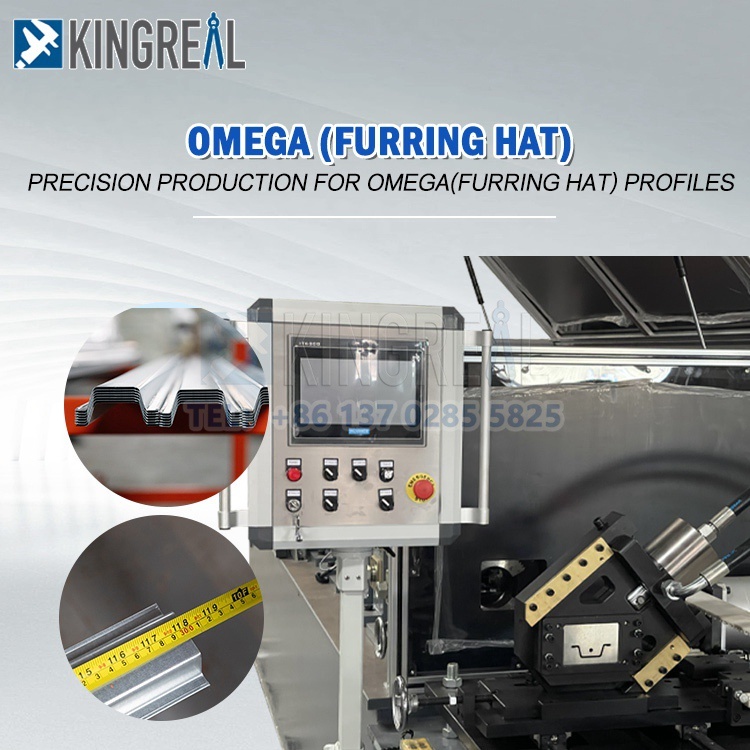

2. Roll forming machine for furring channel machine KINGREAL CEILING MACHINERY has equipped the roll forming machine with an independent arch design, which makes the roll forming machine more stable during operation, thereby improving the durability of the overall hat channel machine. In addition, according to customer needs, KINGREAL CEILING MACHINERY can also equip the roll forming machine with embossed rollers. When the metal coil is rolled through the rollers of the roll forming machine, the surface will be printed with patterns to achieve an anti-slip effect. |  |

3. Shearing station for furring channel machine KINGREAL CEILING MACHINERY has equipped the shearing station with a following shear system. The system has the ability to quickly cut and process without stopping the hat channel machine, which greatly improves the efficiency of the production line. The shear blades are made of high-hardness materials to ensure high shearing accuracy, thereby improving the consistency and quality of the finished product. Whether in mass production or small batch customization, the high efficiency of the shearing station saves customers time and cost. |  |

Advantages of Furring Channel Machine

①Equip the hat channel machine with a protective shield. In order to improve the production safety of customers and provide customers with furring channel machines with high safety performance, KINGREAL CEILING MACHINERY has designed a solution to equip the hat channel machine with a protective shield. When the furring channel machine is running, the protective shield covers the roll forming machine to prevent workers from being injured by accidentally touching the running machine parts. |  |

②Improve the competitiveness of finished products. KINGREAL CEILING MACHINERY hat channel machine can produce finished products with customer brand logos on the surface, which is distinguished from ordinary hat channels on the market and improves competitiveness. KINGREAL CEILING MACHINERY can provide two solutions to achieve this. The first is to engrave the customer's brand logo on the roller of the roll forming machine during furring channel machine manufacturing, and engrave the logo on the roller on the surface of the hat channel profile through roll forming. The second way is that KINGREAL CEILING MACHINERY can equip the hat channel machine with an inkjet device. By setting it on the control panel, the required logo or words can be adjusted at any time, which improves flexibility and satisfies customers to produce hat channel profiles with different words on one machine. |  |

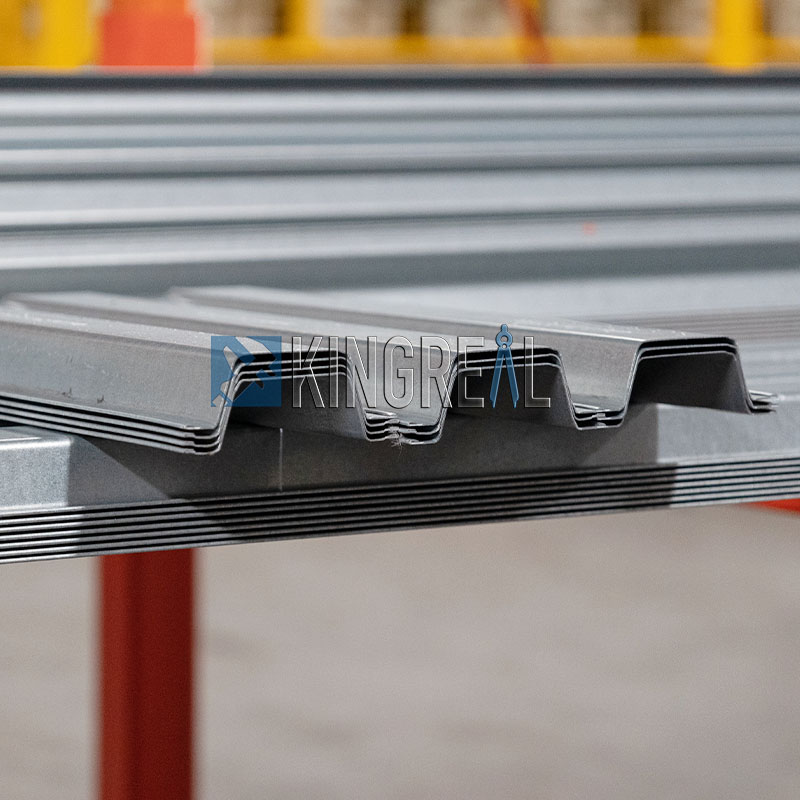

③Packaging unit for furring channel machine. In order to improve the production efficiency of customers, KINGREAL CEILING MACHINERY can equip the hat channel machine with an automatic packaging unit. The furring channels produced by the furring channel machine will be transported to the packaging unit for automatic stacking and bundling. The design of the hat channel machine with a packaging machine liberates manpower and ensures work quality and efficiency. |  |

④Multi-specification furring channel machine. KINGREAL CEILING MACHINERY hat channel machine can produce hat channel profiles of different heights, widths and lengths, with high flexibility. When it is necessary to produce furring channels of different lengths, only PLC control is needed to adjust the parameters on the touch screen. When it is necessary to produce hat channels of different heights and widths, KINGREAL CEILING MACHINERY can provide two solutions: roller replacement and hanger replacement. |  |

3-in-1 Metal Ceiling Channel Machine

For customers who have U channel, hat channel, and wall angle production needs at the same time, KINGREAL CEILING MACHINERY can also provide a 3-in-1 Metal Ceiling Channel Machine. It can realize the production of three different types of profiles by one machine, without changing multiple machines for production, improving efficiency and convenience. By choosing KINGREAL CEILING MACHINERY 3-in-1 False Ceiling Channel Machine, customers can save the cost of purchasing an u channel machine, a hat channel machine, and a wall angle machine at the same time. This integrated solution not only reduces equipment investment, but also simplifies the production process, allowing customers to be more efficient in equipment management and maintenance. In addition, the integrated design makes the production line more compact, saves factory space, and improves overall production efficiency. |

|

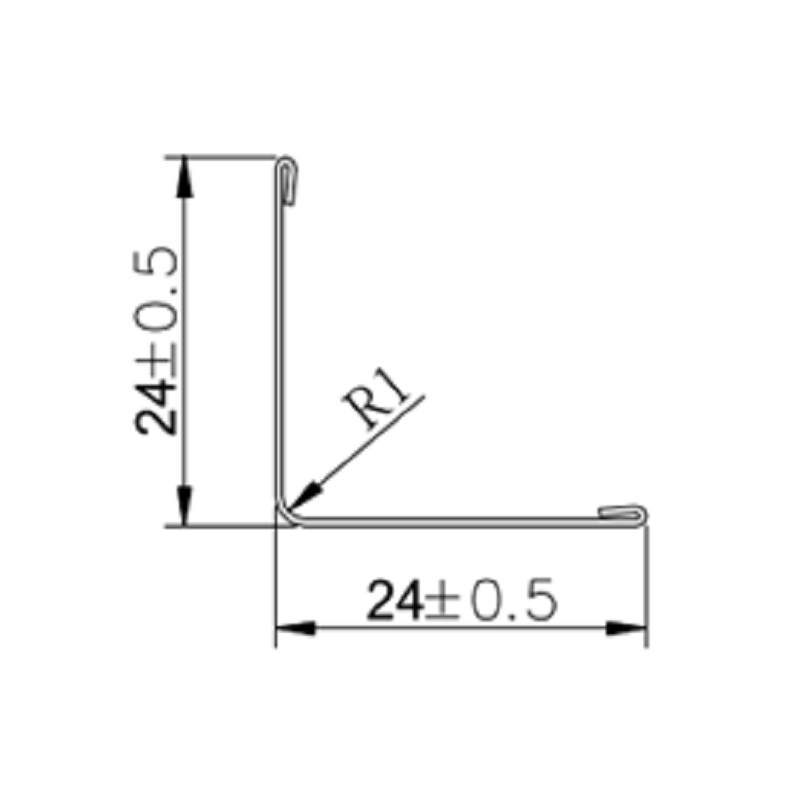

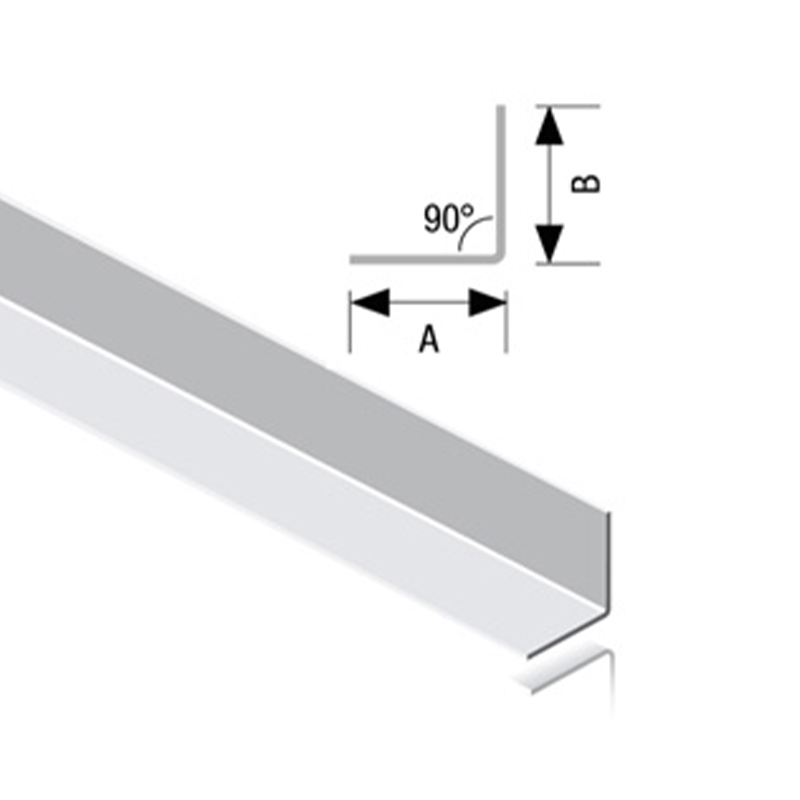

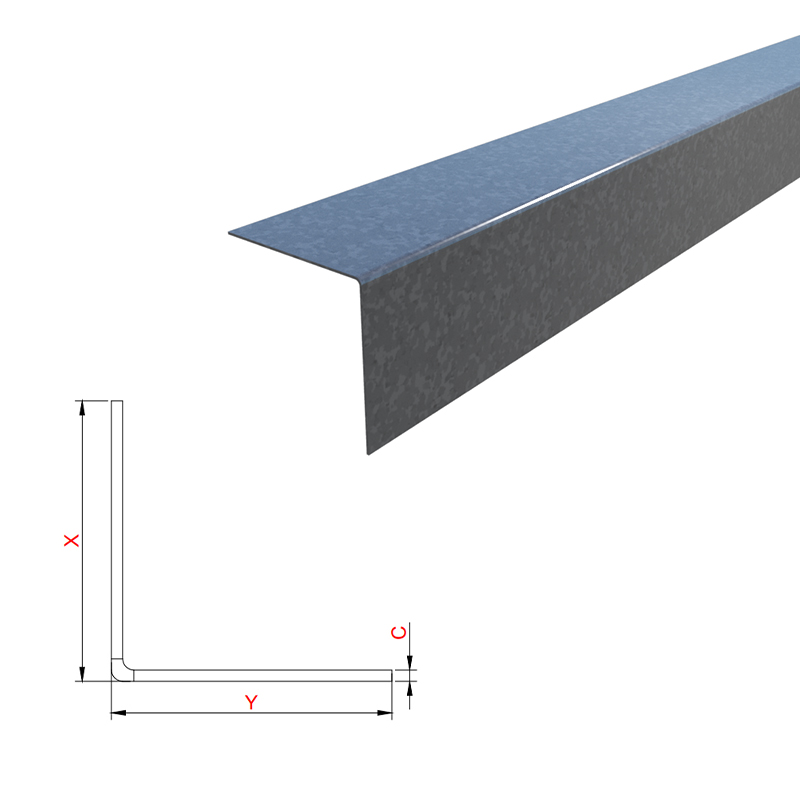

Drawing About Furring Channel

Application of Furring Channel Machine

The hat channel produced by the hat channel machine is a metal trough used in ceiling and wall frame systems. It is usually made of galvanized steel and provides a stable framework for the fixing of various building materials, such as gypsum board or other types of ceiling and wall panels. It helps to create a flat and firm surface for the installation of these materials. The main purpose of the furring channel produced by the furring channel machine is to form a cavity or space between the structural component and the final surface. This cavity can be used to install insulation materials, wires, pipes and other utilities, while also providing additional sound and thermal insulation. |  |

Packing & Delivery for Furring Channel Machine

KINGREAL CEILING MACHINERY has a complete set of packaging and shipping processes for hat channel machines to ensure that each furring channel machine is safe and intact during transportation.

First, KINGREAL CEILING MACHINERY will communicate with customers and arrange online meetings or invite customers to visit the factory for furring channel machine inspection. Online, KINGREAL CEILING MACHINERY staff will assist customers in hat channel machine acceptance to ensure that the equipment reaches the expected operating speed and production accuracy. If the customer chooses offline inspection, KINGREAL CEILING MACHINERY will send a special person to accompany to ensure that the customer conducts a comprehensive inspection of the hat channel machine on site.

Delivery will only be arranged if the customer is satisfied. If the customer has any doubts about the furring channel machine during the inspection, KINGREAL CEILING MACHINERY will immediately suspend delivery and readjust the hat channel machine for a second inspection until the customer is satisfied.

During the delivery process, KINGREAL CEILING MACHINERY has a dedicated staff member responsible for recording the entire process, taking photos and videos to provide real-time feedback to customers on the progress, so that customers can keep abreast of the delivery status of the hat channel machine. In order to ensure that the machine can remain in good condition after long-distance transportation, KINGREAL CEILING MACHINERY has formulated corresponding packaging standards for different parts.

For example, some parts will be wrapped in plastic film, while others will be placed in wooden boxes. In addition, common packaging methods include the use of bubble film for protection, foam filling to prevent vibration, and closed pallet transportation, etc. These diverse packaging methods ensure that the hat channel machine is fully protected during transportation and minimize the risk of damage.

|  |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)