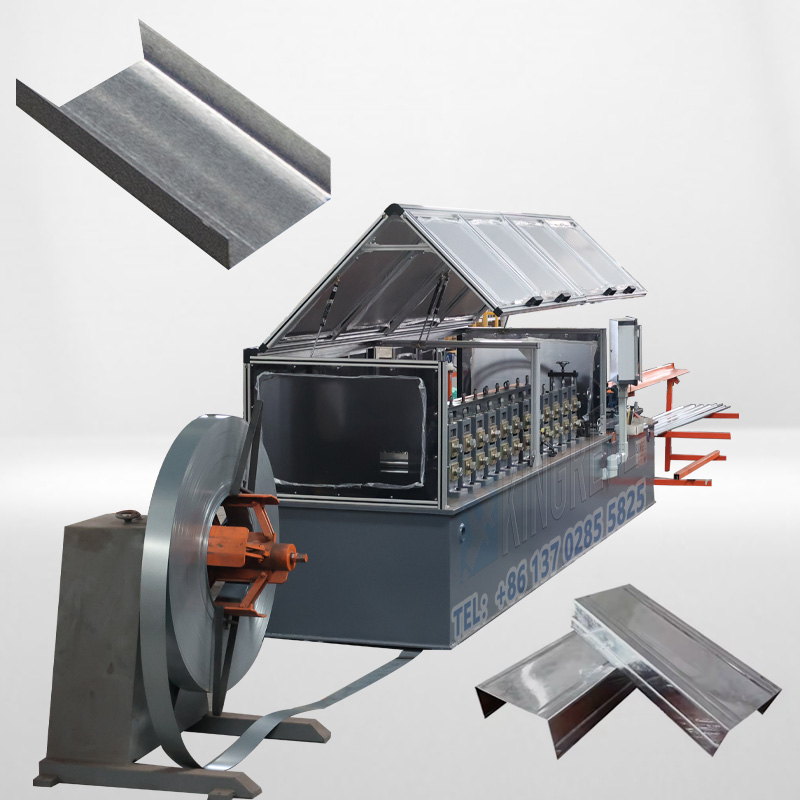

U Channel Roll Forming Machine

KINGREAL CEILING MACHINERY can provide multiple false ceiling channel roll forming machine, including U Channel Roll Forming Machine, Furring Channel Machine and Wall Angle Machine, now is successfully shipped to Russia, India, Turkey and other countries.

- KINGREAL CEILING MACHINERY

Details

Video Display About U Channel Machine

Description of U Channel Machine

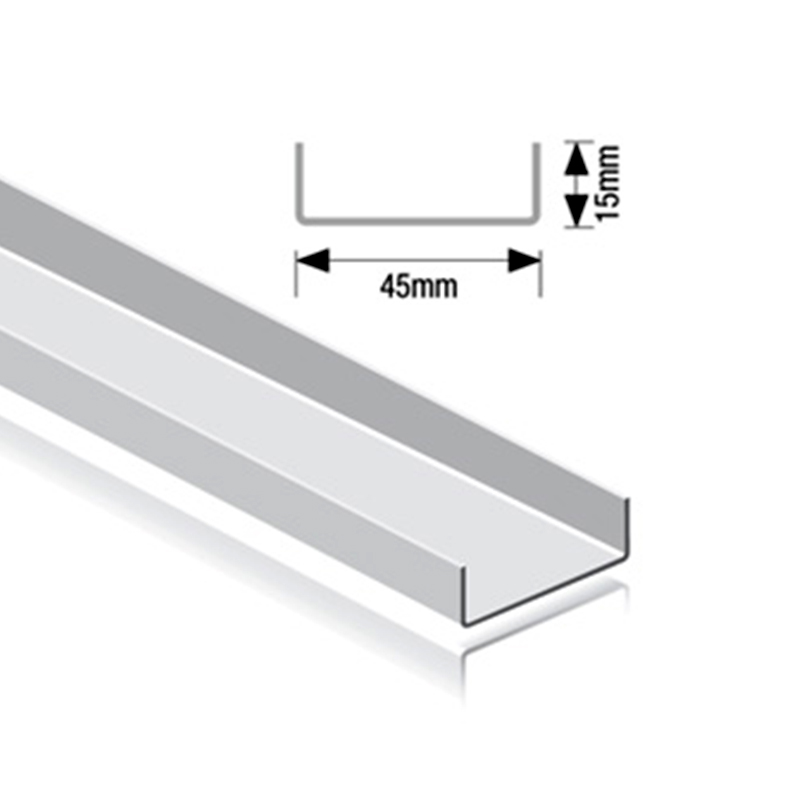

U channel machine is a commonly used false ceiling channel machine. It uses strip steel as raw material and forms a u-shaped channel through continuous cold rolling. This u channel machine has a fast production speed, up to 120m/min. And different sizes of u channels can be flexibly produced by one main channel making machine.

KINGREAL CEILING MACHINERY can provide false ceiling channel machine for the production of steel profiles of different shapes, including main channel making machines, furring channel machines and wall angle machines. The u channel machine has a fast production speed and can be equipped with optional components such as protective shields, embossing rollers, auto packaging machine and inkjet devices. |  |

KINGREAL CEILING MACHINERY Successful Projects

KINGREAL CEILING MACHINERY is a professional main channel making machine manufacturer, committed to providing high-quality equipment and customized solutions to customers around the world. KINGREAL CEILING MACHINERY has established long-term friendly cooperative relations with customers in Saudi Arabia, Qatar, Turkey and other countries, fully understanding and meeting their specific needs. During the cooperation process, KINGREAL CEILING MACHINERY designs and manufactures customized main channel making machine solutions based on the drawings provided by customers and combined with actual production needs. This personalized service not only improves the production efficiency of customers, but also greatly enhances the market competitiveness of products. KINGREAL CEILING MACHINERY engineering team has traveled to customers' countries many times to personally install and trial the u channel machines for them, and provide professional operation training to ensure that customers can quickly get started with the main channel making machine. Customers highly praised the high-quality main channel making machines and detailed and thoughtful services provided by KINGREAL CEILING MACHINERY, and praised the excellent performance and stability of KINGREAL CEILING MACHINERY u channel machine. |  |

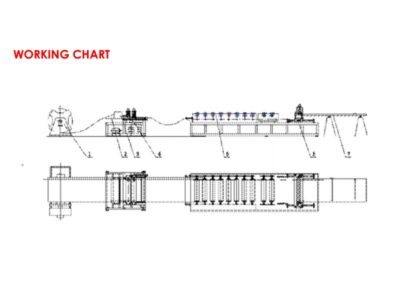

Working Process of U Channel Machine

Decoiler--Main Roll Forming Machine--Cutting Station--Product Table |  |

Main Components of U Channel Machine

Decoiler for u channel machine This decoiler is designed for carrying heavy metal coils. It has excellent load-bearing capacity and stability to ensure that there will be no deformation or damage during the uncoiling process. It can uncoil quickly, reduce waiting time, and make the entire production process smoother. |  |

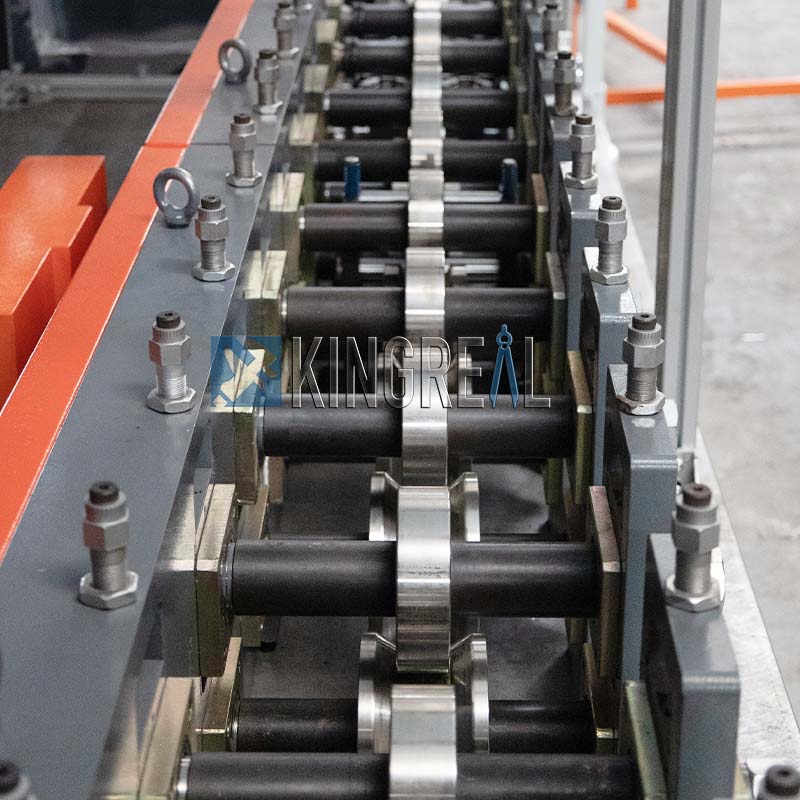

Roll forming machine for main channel making machine KINGREAL CEILING MACHINERY has equipped this roll forming machine with carefully designed high-hardness rollers to ensure the wear resistance and stability of the main channel making machine during long-term operation. These rollers are made of high-quality materials and have excellent pressure resistance and wear resistance, allowing the u channel machine to maintain excellent working conditions under high-load working conditions. Whether it is production speed or finished product quality, the strong hardness of the rollers can effectively guarantee it, reducing the frequency of equipment wear and thus extending the service life of the main channel making machine. |  |

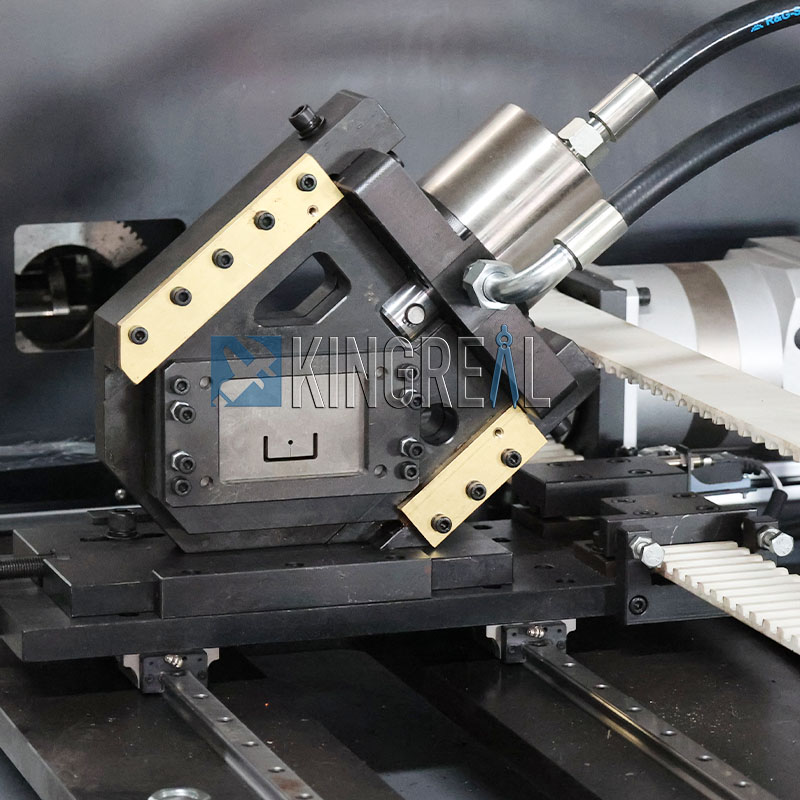

Cutting station for u channel machine This cutting station uses an advanced flying shear system to achieve fast and accurate shearing operations. Users only need to set the required finished product length in advance on the control panel, and the main channel making machine will automatically cut without manual intervention, greatly improving production efficiency and finished product consistency. In addition, the design of the flying shear system ensures the smoothness and accuracy of the shearing process and reduces material waste. |  |

Features of Metal U Profile Machine

Protective shield for u channel machine In order to meet customers who have extremely high requirements for production safety, KINGREAL CEILING MACHINERY engineers have carefully designed a main channel making machine with a protective shield. During the production process of this u channel machine, the protective shield fully covers the roll forming machine, effectively preventing workers from accidentally touching the running main channel making machine during operation and causing injuries. The design of the protective shield not only enhances operational safety, but also provides workers with a more secure working environment. In addition, when the u channel machine is suspended, the protective shield can be easily opened for daily cleaning and maintenance |  |

Packaging unit for main channel making machine In order to maximize the production efficiency of the whole process, KINGREAL CEILING MACHINERY provides customers with machine configuration with packaging unit. When the u channels are completed, these finished products will be automatically transported to the packaging unit for efficient automatic packing and stacking. Equipped with the innovative design of automatic packaging machine, it can significantly liberate manpower and reduce the need for manual operation, while ensuring the stability of work quality and efficiency. |  |

High-speed main channel making machine The production speed of this u channel machine can reach up to 120 m/min, which greatly improves the production capacity. At the same time, users can flexibly adjust the speed according to actual production needs to adapt to production tasks of different scales. For those customers with large production scales, this main channel making machine is undoubtedly an ideal choice, which can flexibly respond to market changes and demand fluctuations while ensuring production efficiency |  |

High-quality components for u channel machine KINGREAL CEILING MACHINERY main channel making machine uses high-precision and high-performance components such as FATEK PLC, Yaskawa servo motor, CR12 steel, etc., to ensure the stable operation and durability of the u channel machine. These high-quality components not only improve the overall performance of the u channel machine, but also reduce the failure rate and extend the service life. Whether in a high-load production environment or long-term continuous operation, customers can enjoy the excellent performance brought by this main channel making machine. |  |

Parameter of Main Channel Machine

| Raw material | Gi steel, pre-painted gi steel |

| Product shape | Wall angle, u shaped channel, hat channel |

| Production capacity | 120m/min |

| Electricity requirment | 380v 50 Hz 3 Phases |

| Power consumption | 30KW |

Multi-specification False Ceiling Channel Machine Manufacturing Solution

In order to meet the ever-changing production needs, KINGREAL CEILING MACHINERY has specially launched a multi-specification metal ceiling channel machine solution. This innovative machine design is designed to provide customers with greater flexibility and efficiency. By simply replacing the rollers and cutting molds, users can easily produce three different types of metal ceiling channels: u channels, wall channels and omega channels. This design not only simplifies the production process, but also greatly improves the diversity of production, allowing customers to meet multiple product needs on the same machine.

The launch of KINGREAL CEILING MACHINERY multi-specification false ceiling channel machine has greatly reduced customers' time and cost in equipment procurement. Traditionally, customers may need to purchase main channel making machines, wall angle machines and furring channel machines separately, which is time-consuming and labor-intensive. Now, with this integrated equipment, customers not only save valuable funds, but also effectively save production space.

|  |

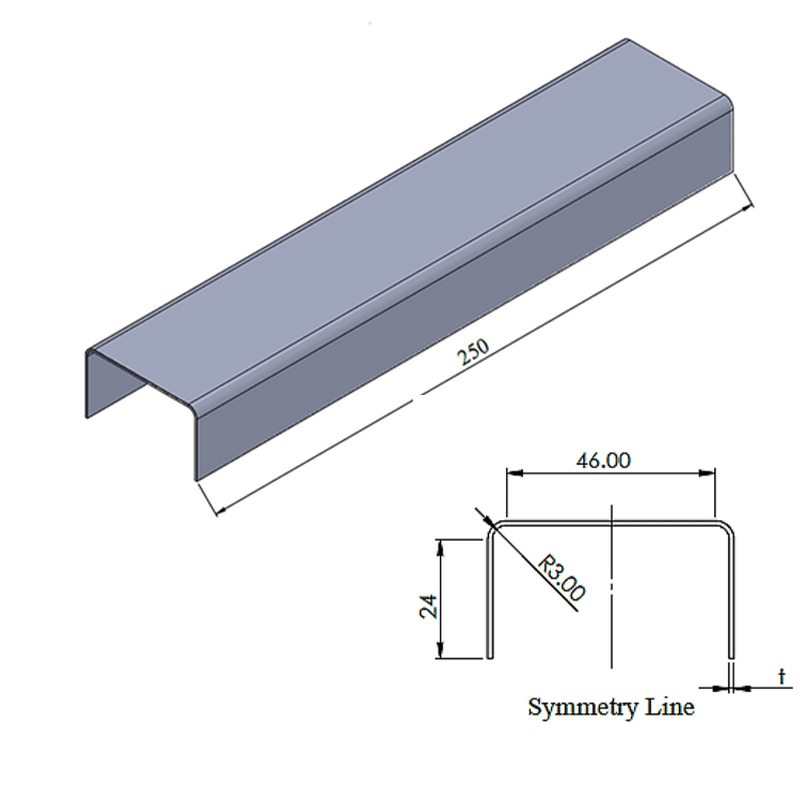

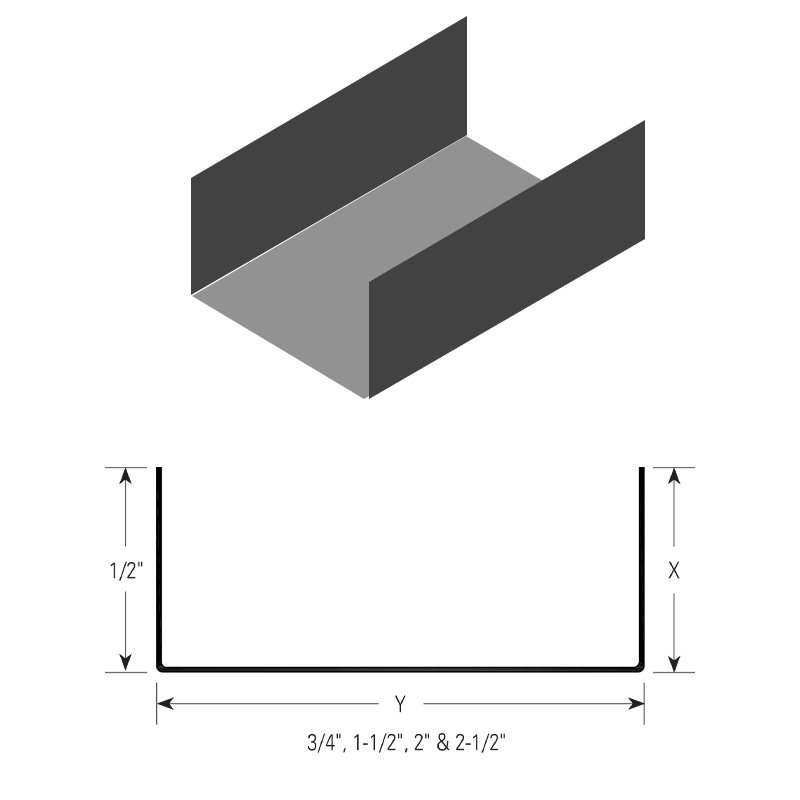

Drawing About U Channel

The Benefit If You Choose KINGREAL CEILING MACHINERY

● High Production Efficiency Proficiency in fully automatic technology and precise forming techniques. The metal u channel roll forming machines manufactured by KINGREAL CEILING MACHINERY can maintain consistent quality and accuracy while meeting rapid production needs. ● Cost-Effective Production After more than 20 years of experience accumulation, KINGREAL CEILING MACHINERY has established a systematic design-production team. KINGREAL CEILING MACHINERY designs machines to optimize efficiency, reduce material waste, and simplify manufacturing processes, working to reduce production costs for customers. |  |

KINGREAL CEILING MACHINERY Factory

To integrate R&D, KINGREAL CEILING MACHINERY has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of KINGREAL CEILING MACHINERY's customers also choose to visit KINGREAL CEILING MACHINERY factory to observe the production of machines and communicate with us face to face. KINGREAL CEILING MACHINERY is looking forward to reaching long-term and stable relationships with customers around the world with KINGREAL CEILING MACHINERY professional capability and consistent level of service! |  |

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)