Products Lists

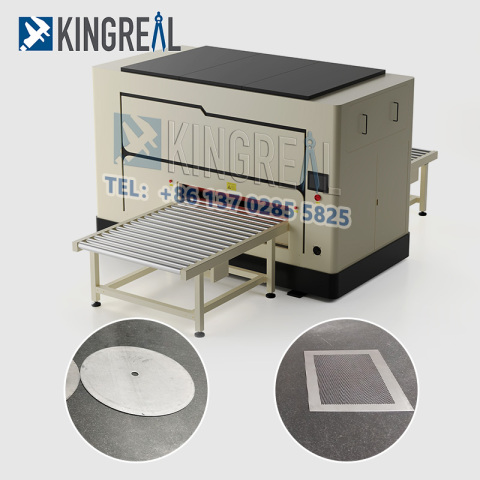

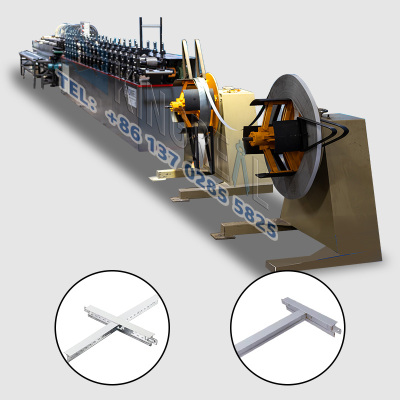

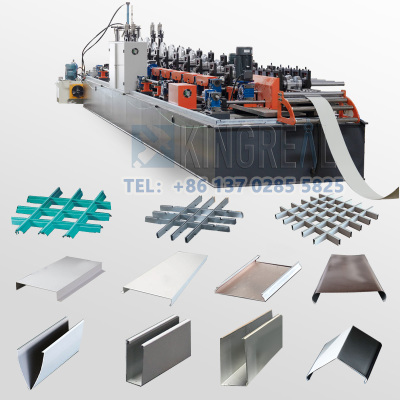

1/What is a Metal Sheet Leveling Machine?

A metal sheet leveling machine is a device specifically designed to flatten metal materials with curved surfaces. This sheet metal straightener can process various types of metal materials, including copper plates, aluminum plates, carbon steel plates, galvanized plates, and stainless steel plates. Metal sheet leveling machines can process not only metal parts, metal sheets, and metal rods, but also complex products such as perforated metal mesh. Applications span multiple industries, including automotive parts, aerospace, high-speed rail, chain plates, saw blades, precision stamping, and sheet metal and furniture appliance manufacturing. With the ever-changing market demands, the design and classification of sheet metal straighteners have become increasingly diverse. To meet the needs of different customers, KINGREAL CEILING MACHINERY has developed various models of metal sheet leveling machines, such as thin plate leveling machines, heavy duty sheet leveling machines, high-speed metal sheet leveling machines, and precision sheet metal straighteners. These metal sheet leveling machines ensure that metal materials of different thicknesses and materials can be properly leveled, guaranteeing the quality and precision of the final product.

2/Why is Leveling Important in Metal Fabrication?

In metal processing, leveling is a crucial step. Metal materials processed through the leveling process achieve a flat and smooth surface without warping or bending. This is especially important because many high-precision manufacturing processes require very strict geometric shapes of components, and any deviation can affect the final product quality. Proper leveling not only reduces material waste but also significantly improves assembly accuracy. Materials that are not adequately leveled often develop defects during subsequent forming, welding, or coating processes, leading to increased costs and wasted time. Therefore, leveling should be a mandatory step before metal processing. Whether in automotive manufacturing, aerospace, or home appliance production, leveling plays a vital role in ensuring product quality and performance. In practical applications, sheet metal straighteners are frequently used in batch processing. For example, the aerospace industry has extremely strict requirements for aluminum alloy sheets, requiring them to meet international standards after leveling; in automotive manufacturing, metal sheet leveling machines ensure the high degree of fit of body parts. These requirements have made the application of sheet metal straighteners increasingly widespread and continuously driven the advancement of leveling technology.

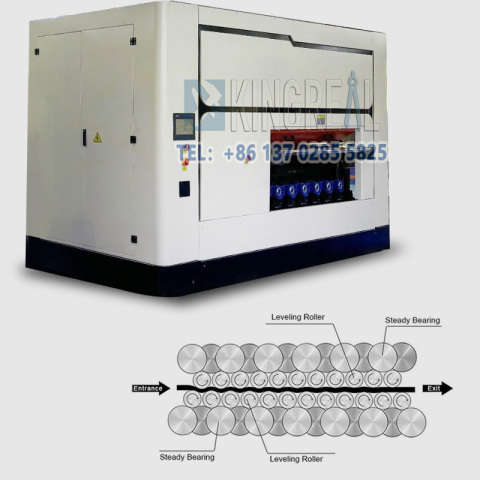

3/How Does a Metal Sheet Leveling Machine Work?

The working principle of a metal sheet leveling machine is relatively simple but effective. A sheet metal straightener typically consists of components such as an infeed roller, an outfeed roller, and leveling rollers. First, the workpiece to be leveled is manually placed into the infeed roller. After the machine starts, the workpiece is transported into the sheet metal straightener. During operation, the leveling rollers are supported from above and below to ensure their incompressibility, effectively reducing the gap between the upper and lower leveling rollers. The leveling process of the metal sheet leveling machine relies on the "Bauschinger effect" of the material. This effect utilizes the plastic deformation characteristics of the material, gradually eliminating the curvature of the metal through repeated bending of the workpiece. As the number of leveling rollers increases, the number of alternating bends the workpiece undergoes also increases, allowing metal sheets with different initial curvatures to ultimately achieve a uniform flatness. After this series of leveling processes, the workpiece reaches the desired flatness precision, meeting the requirements of subsequent processes. Once the leveling process is complete, the leveled workpiece is automatically released through the outfeed port and then manually sorted and stacked. Through this design, the sheet metal straightener can efficiently process large quantities of metal materials, meeting the needs of industrial production.

A metal sheet leveling machine is a device specifically designed to flatten metal materials with curved surfaces. This sheet metal straightener can process various types of metal materials, including copper plates, aluminum plates, carbon steel plates, galvanized plates, and stainless steel plates. Metal sheet leveling machines can process not only metal parts, metal sheets, and metal rods, but also complex products such as perforated metal mesh. Applications span multiple industries, including automotive parts, aerospace, high-speed rail, chain plates, saw blades, precision stamping, and sheet metal and furniture appliance manufacturing. With the ever-changing market demands, the design and classification of sheet metal straighteners have become increasingly diverse. To meet the needs of different customers, KINGREAL CEILING MACHINERY has developed various models of metal sheet leveling machines, such as thin plate leveling machines, heavy duty sheet leveling machines, high-speed metal sheet leveling machines, and precision sheet metal straighteners. These metal sheet leveling machines ensure that metal materials of different thicknesses and materials can be properly leveled, guaranteeing the quality and precision of the final product.

2/Why is Leveling Important in Metal Fabrication?

In metal processing, leveling is a crucial step. Metal materials processed through the leveling process achieve a flat and smooth surface without warping or bending. This is especially important because many high-precision manufacturing processes require very strict geometric shapes of components, and any deviation can affect the final product quality. Proper leveling not only reduces material waste but also significantly improves assembly accuracy. Materials that are not adequately leveled often develop defects during subsequent forming, welding, or coating processes, leading to increased costs and wasted time. Therefore, leveling should be a mandatory step before metal processing. Whether in automotive manufacturing, aerospace, or home appliance production, leveling plays a vital role in ensuring product quality and performance. In practical applications, sheet metal straighteners are frequently used in batch processing. For example, the aerospace industry has extremely strict requirements for aluminum alloy sheets, requiring them to meet international standards after leveling; in automotive manufacturing, metal sheet leveling machines ensure the high degree of fit of body parts. These requirements have made the application of sheet metal straighteners increasingly widespread and continuously driven the advancement of leveling technology.

3/How Does a Metal Sheet Leveling Machine Work?

The working principle of a metal sheet leveling machine is relatively simple but effective. A sheet metal straightener typically consists of components such as an infeed roller, an outfeed roller, and leveling rollers. First, the workpiece to be leveled is manually placed into the infeed roller. After the machine starts, the workpiece is transported into the sheet metal straightener. During operation, the leveling rollers are supported from above and below to ensure their incompressibility, effectively reducing the gap between the upper and lower leveling rollers. The leveling process of the metal sheet leveling machine relies on the "Bauschinger effect" of the material. This effect utilizes the plastic deformation characteristics of the material, gradually eliminating the curvature of the metal through repeated bending of the workpiece. As the number of leveling rollers increases, the number of alternating bends the workpiece undergoes also increases, allowing metal sheets with different initial curvatures to ultimately achieve a uniform flatness. After this series of leveling processes, the workpiece reaches the desired flatness precision, meeting the requirements of subsequent processes. Once the leveling process is complete, the leveled workpiece is automatically released through the outfeed port and then manually sorted and stacked. Through this design, the sheet metal straightener can efficiently process large quantities of metal materials, meeting the needs of industrial production.

Get the latest price? We'll respond as soon as possible(within 12 hours)