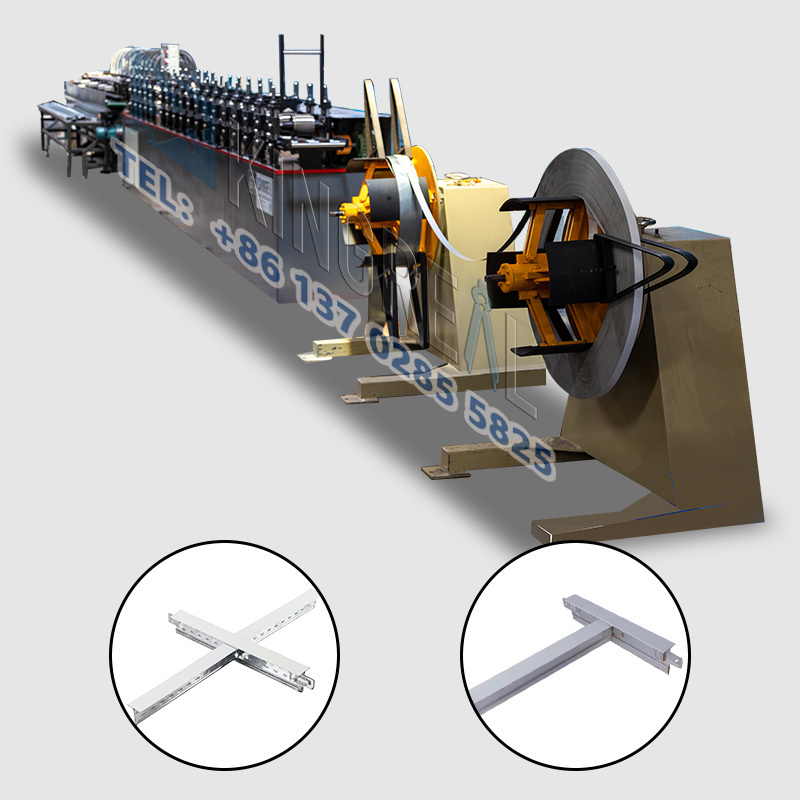

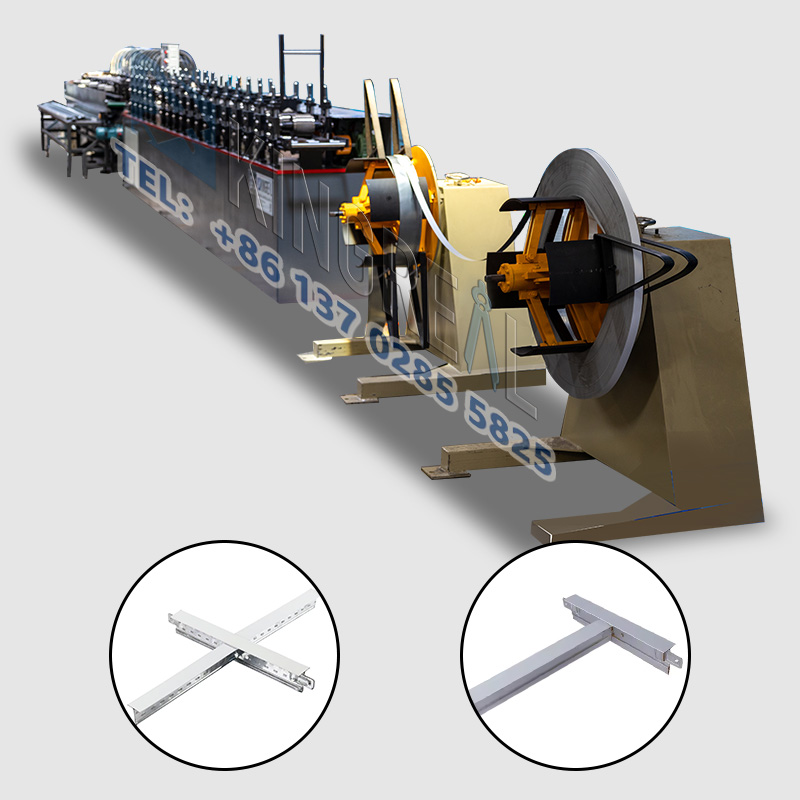

Ceiling T Grid Production Line

KINGREAL CEILING MACHINERY offers a wide range of ceiling t grid production lines. KINGREAL CEILING MACHINERY specialize in designing and manufacturing various ceiling t bar production lines: ▷flat t grid machine | Silhouette Groove Ceiling T Grid Machine, Black Line Ceiling T Bar Machine, FUT ceiling t bar Machine |L Angle Profile Roll Forming Machine.◁

KINGREAL CEILING MACHINERY ceiling t grid production lines are specifically designed to produce high-quality main t or cross t, ensuring that every finished product meets our customers' high standards.

- KINGREAL CEILING MACHINERY

Details

Video About Ceiling T Grid Production Line

Description of Ceiling T Grid Production Line

KINGREAL CEILING MACHINERY offers a wide range of ceiling t grid production lines. KINGREAL CEILING MACHINERY specialize in designing and manufacturing various ceiling t bar production lines: ▷Flat T Grid Machine | Silhouette Groove Ceiling T Grid Machine, Black Line Ceiling T Bar Machine, FUT ceiling t bar Machine | L Angle Profile Roll Forming Machine.◁

KINGREAL CEILING MACHINERY ceiling t grid production lines are specifically designed to produce high-quality main t or cross t, ensuring that every finished product meets our customers' high standards. KINGREAL CEILING MACHINERY ceiling t bar production lines can fully automatically produce high-precision ceiling t bar of varying sizes at a speed of 30 m/min, significantly improving production efficiency and market competitiveness. To date, KINGREAL CEILING MACHINERY customized ceiling t grid production lines have been successfully exported to countries including India, Brazil, Saudi Arabia, Vietnam, and Russia.

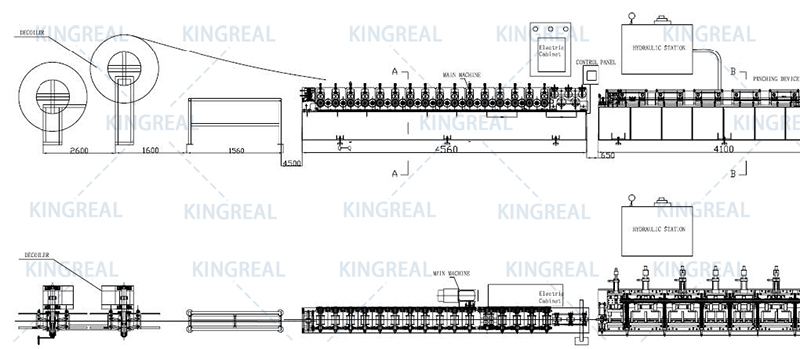

Workflow of Ceiling T Grid Production Line

Hydraulic Decoiler--Main Roll Forming Machine--Punching and shearing station--Product table

Parameter of Ceiling T Grid Production Line

| 1 | Name of commodity & specificatio | Ceiling T Grid Production Line |

| 2 | Main motor power | 7.5kw, 3 phas |

| 3 | Hydraulic motor power | 4kw |

| 4 | Hydraulic Pressure | 10-12MPa |

| 5 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

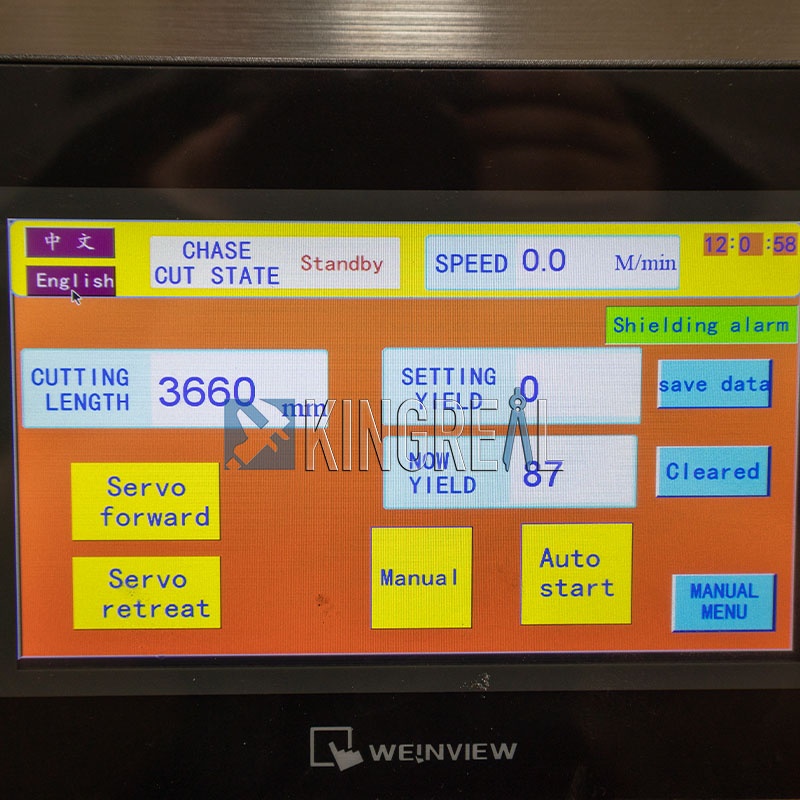

| 6 | Control Syste | PLC Delta Inverter |

| 7 | Main Frame | 300mm H-Beam or 350mm |

| 8 | Backboard Thicknes | 10mm |

| 9 | Chain Size | 20m |

| 10 | Feeding Material | color steel coils |

| 11 | Feeding Thickness | 0.22mm-0.3mm |

| 12 | Feeding Width | 30mm 90mm |

| 13 | Effective width | 25*24mm |

| 14 | Productivity | 30m/min |

| 15 | Roll Station | 16 roll steps(according to different design) |

| 16 | Roller Diameter | 50mm(depend on different design) |

| 17 | Roller material | 45# steel |

| 18 | Cutter material | Cr12 , quenched |

| 19 | Cr-Plating Size | 0.05mm |

| 20 | Overall Size | 6500×1400×1500mm |

| 21 | Total Weight | 4.0T |

22 | Components | Manual Uncoiler-------------------1 set |

| Guiding Platform------------------1 set | ||

| Coil Strip Leveler------------------1 set | ||

| Main Machine of Roll Forming------1 set | ||

| Electric-Motor---------------------1 set | ||

| Cutting Device--------------------1 set | ||

| Hydraulic Station------------------1 set | ||

| PLC Control-----------------------1 set | ||

| OutputTable-------------------1 set |

Features of Ceiling T Bar Production Line

1) Decoiler for ceiling t grid production line KINGREAL CEILING MACHINERY ceiling t bar production line is equipped with two decoilers, specifically designed to handle both color-coated and galvanized coils. These decoilers can feed both coils simultaneously, significantly improving production efficiency for customers. |  |

2) Roll forming machine for ceiling t bar production line KINGREAL CEILING MACHINERY offers multiple options for producing ceiling t bar shapes of varying sizes using a single ceiling t bar production line. The first option involves replacing the roller groups and cutting die, while the second simply requires replacing the roller and cutting die. This flexibility allows KINGREAL CEILING MACHINERY ceiling t grid production line to meet diverse customer needs. KINGREAL CEILING MACHINERY will provide the most appropriate recommendations and customized ceiling t bar production line solutions based on the customer's specific production requirements. |  |

3) Punching and Shearing System for ceiling t bar production line KINGREAL CEILING MACHINERY ceiling t grid production line features an integrated punching and shearing system, with a main panel thickness of 20 mm and a side panel thickness of 6 mm. This system allows for single-shot punching without machine downtime, significantly improving production efficiency. It also allows for precise cutting to the customer's pre-set length. The punching die can be designed based on customer drawings, and the hole pattern and diameter can be adjusted to meet customer requirements. |  |

4) PLC System for ceiling t bar production line KINGREAL CEILING MACHINERY ceiling t bar production lines are equipped with an advanced PLC system that can be set to the language of the customer's country. Operators simply enter the desired parameters, such as the finished product length and production speed, on the control panel, and the ceiling t grid production line automatically operates, requiring virtually no human intervention. The system also features a fault location function, ensuring that any production issues can be quickly resolved. |  |

Diverse Solutions for Ceiling T Bar Production Line

KINGREAL CEILING MACHINERY specializes in providing customized ceiling t grid production line solutions tailored to each customer's specific needs. KINGREAL CEILING MACHINERY can adjust the ceiling t bar production line's performance parameters and add additional features as needed, such as:

Protective shield for ceiling t grid production line: To protect operator safety, KINGREAL CEILING MACHINERY equips its ceiling t bar production lines with a high-quality protective shield. This not only effectively prevents workers from accidentally touching the ceiling t bar production line's moving parts during operation, but also reduces the risk of accidents during production. Made of durable material, the protective shield is designed to withstand mechanical shock and is user-friendly. During operation, the shield effectively isolates workers from the ceiling t bar production line, allowing them to maintain a safe distance while operating other equipment or inspecting the surrounding environment. Even in high-intensity production environments, the protective shield maintains its stable performance, reducing potential risks to workers. When production is complete or the ceiling t grid production line is stopped, the protective shield can be easily opened for routine cleaning and maintenance.

Roller Logo Engraving for ceiling t bar production line: To help customers enhance the market competitiveness of their finished products, KINGREAL CEILING MACHINERY offers roller logo engraving services for its ceiling t grid production lines. During the production process, the roller uses precision engraving technology to accurately imprint the customer's brand logo onto the surface of the ceiling t bar.

Hydraulic Oil Cooler for ceiling t grid production line: To address overheating issues caused by prolonged operation, KINGREAL CEILING MACHINERY has added a hydraulic oil cooling system to its ceiling t bar production lines. This system circulates and cools the hydraulic oil, ensuring a stable operating temperature even under high loads. The hydraulic oil cooler is designed to account for temperature fluctuations under varying operating conditions. It monitors oil temperature in real time and automatically adjusts cooling intensity based on demand. This intelligent cooling system not only prevents performance degradation of the hydraulic oil due to overheating, but also reduces ceiling t bar production line failures and extends the machine's service life.

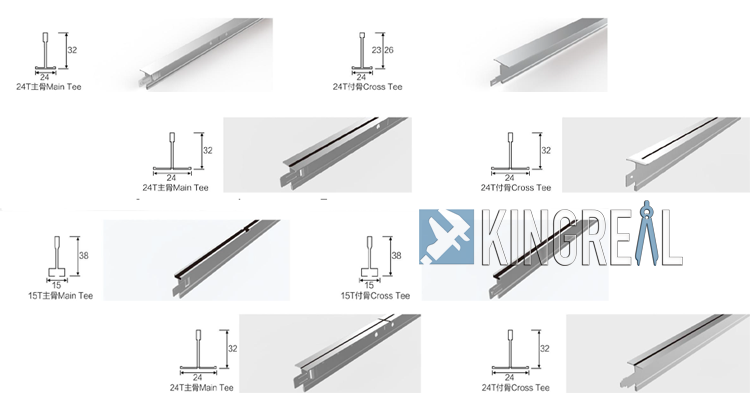

Specifications of Ceiling T Grid

KINGREAL CEILING MACHINERY ceiling t grid production lines produce ceiling t bar in a variety of sizes, with common main t heights of 32/38, cross t heights of 26/27, and wall angle heights of 19-24. Through flexible design and high-precision production processes, each finished product meets industry standards and customer needs.

Applications of Ceiling T Bar Production Line

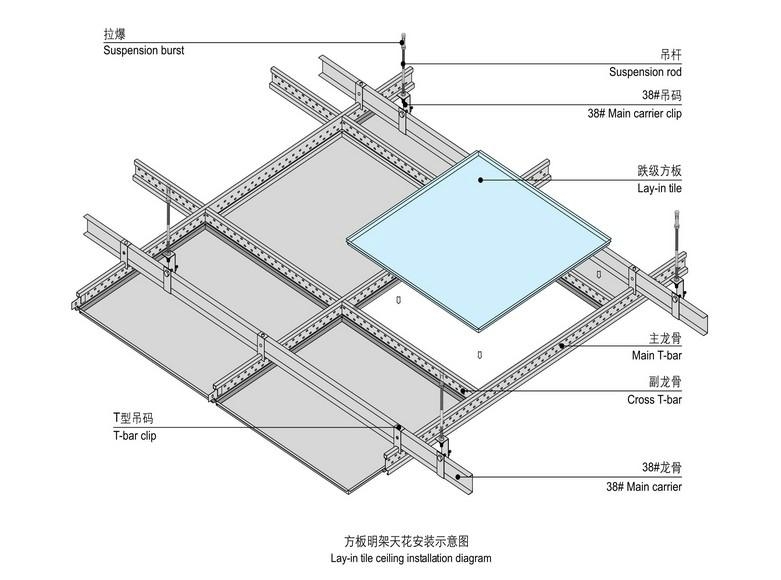

The ceiling t grid production line, combined with ceiling panels, creates the fastest-installing ceiling system in the industry. This system typically consists of a main t, cross t and wall angle. Quick-release cross-T-beam clamps make ceiling installation incredibly simple. These clips can be easily removed without tools, minimizing damage to the ceiling t grid. When the ceiling t bar are securely connected, a distinct click ensures a secure connection, giving installers confidence. This efficient and reliable installation method has made ceiling t grid production lines widely popular in the building and renovation industry.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)