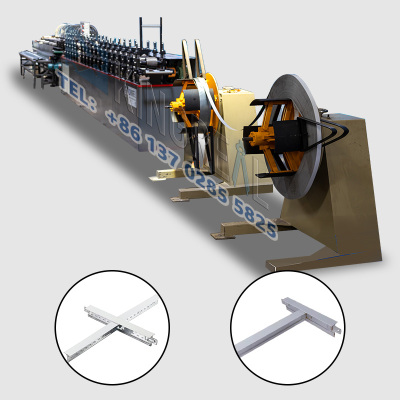

Ceiling T Grid Machine

KINGREAL CEILING MACHINERY can provide customers with ceiling t grid machines to produce various types of ceiling t grids to meet customers' different production needs for ceiling t bar sizes and types.

- KINGREAL CEILING MACHINERY

Details

Video About Ceiling T Grid Machine

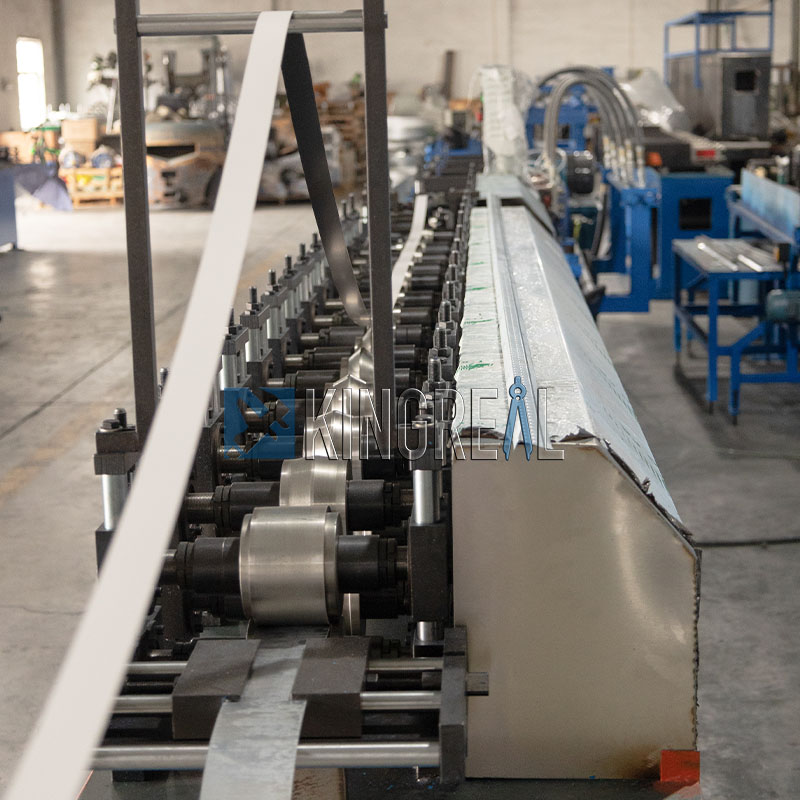

Introduction of Ceiling T Grid Machine

KINGREAL CEILING MACHINERY ceiling t grid machine is customized according to each customer's special specifications. It can produce main t, cross t and wall angle of different sizes, so it can perfectly meet the customer's project needs. And the ceiling t bar machine is equipped with complete safety protection to allow operators to work with peace of mind; the maximum working speed of the ceiling t bar machine can reach 30m/min.

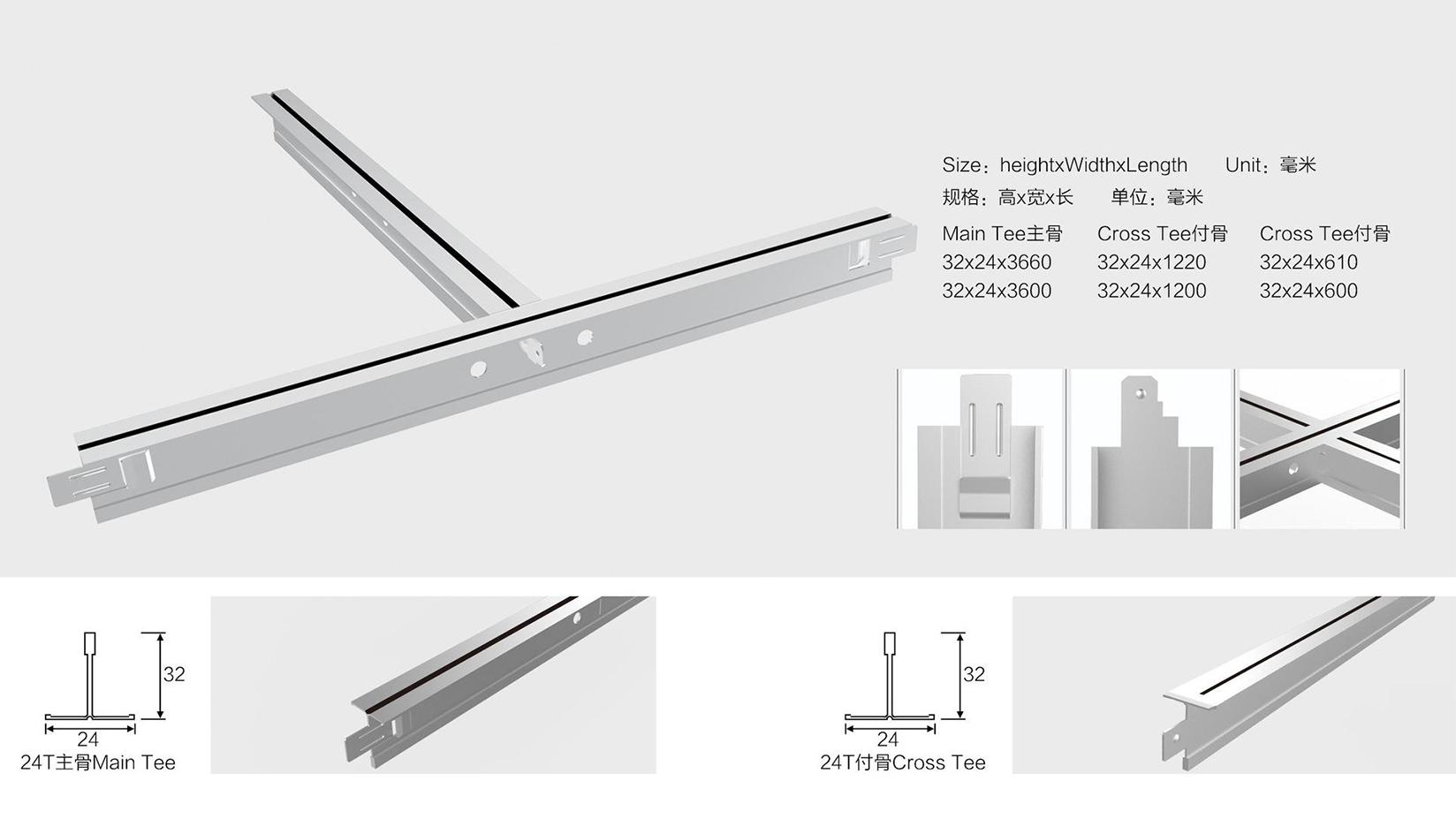

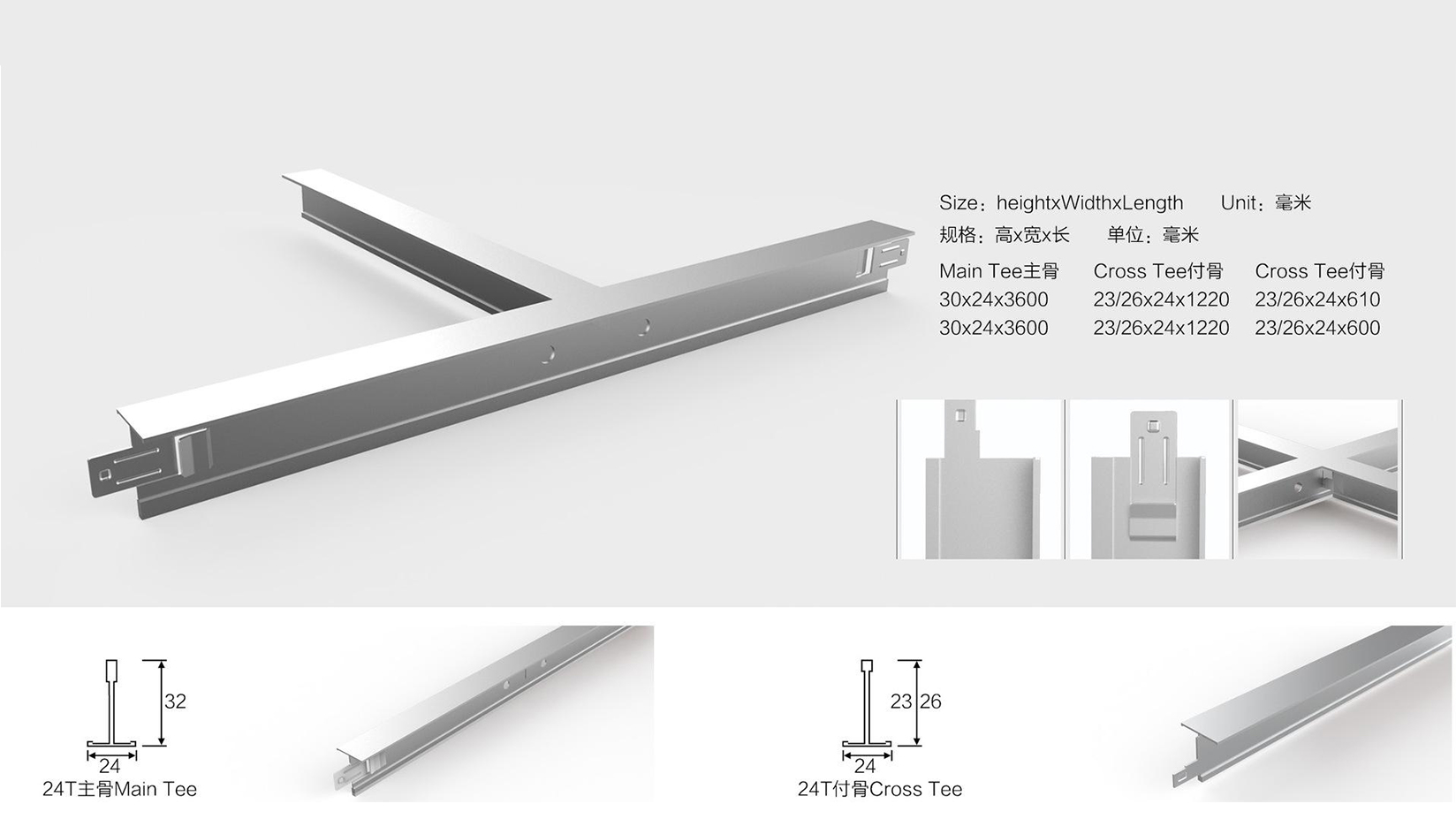

Main T size: 24mm*30mm, thickness range 0.2mm–0.3mm Cross T size: 24mm*23mm, thickness range 0.2mm–0.3mm Wall Angel size: 22mm*22mm, thickness range 0.25mm–0.5mm |  |

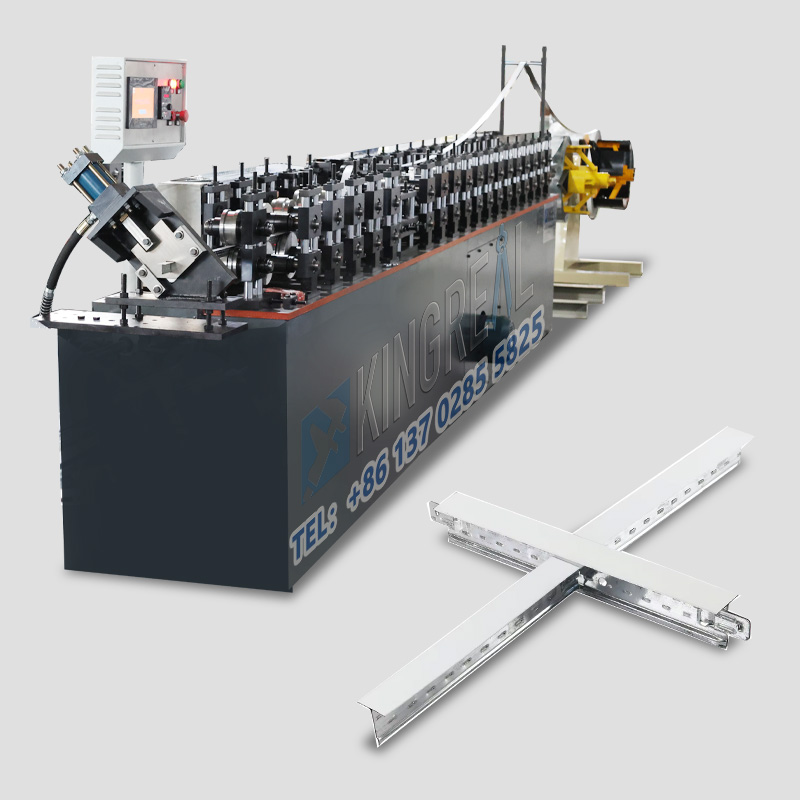

Parameters of Ceiling T Bar Machine

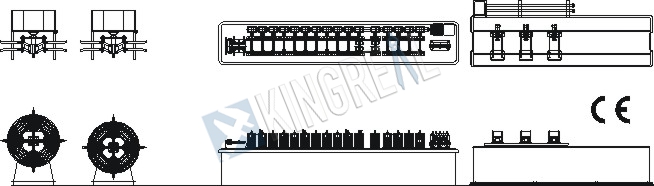

Machine Layout |  |

| Working process | Decoiler -- Roll Forming Machine -- Punching and shearing station -- Product table |

Specification | Decoiler: Inner Diameter 450-530mm Outer Diameter1200mm Loading weight 1000kg |

Roll Forming Machine: ROLLER STANDS:18 SETS,2 SETS OF ROLLERS FOR ALIGNMENT(MAIN-T)18 SETS,1 SETS OF ROLLERS FOR ALIGNMENT(MAIN-T) ROLLER MATERIAL:CR12 MOLD STEEL,AVERAGE HARDNESS HRC55 PRODUCTION SPEED Working speed:30M/Min MACHINE FRAME: 20MM THICKNESS BASE PANEL.6MM SIDE PANEL,45# STEEL | |

Punching and shearing station : Punching System: integrated type,20mm main panel, 6mm side panel, fine milled Punching Type: all-punching-at-once type, no stopping |

Advantages of Ceiling T Bar Machine

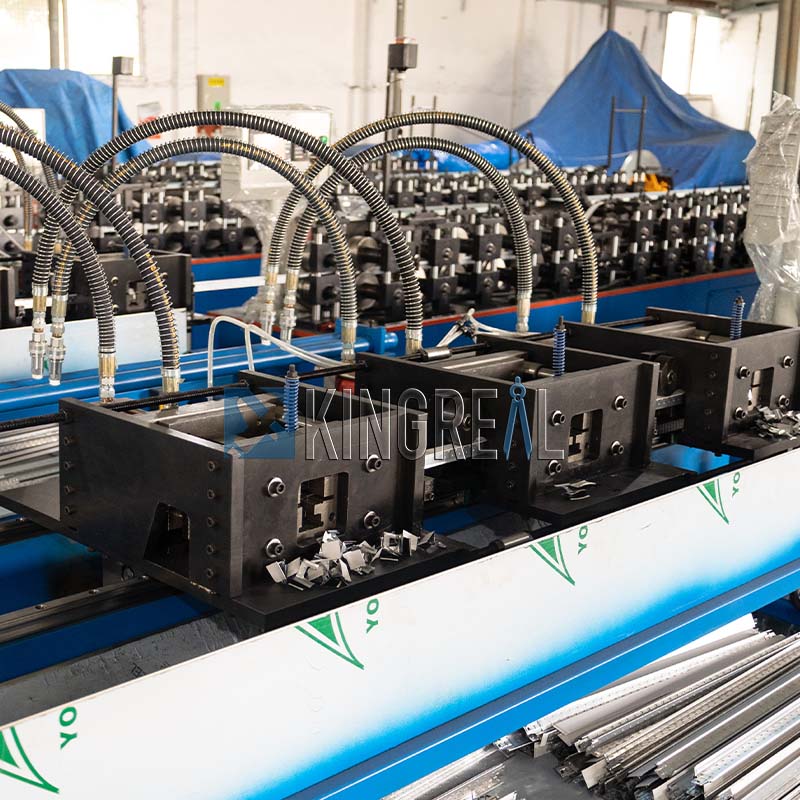

1. Punching and shearing station for ceiling t grid machine In the market, the punching function of many ceiling t bar machines is often processed hole by hole, which not only reduces production efficiency, but also may affect the accuracy of the product. KINGREAL CEILING MACHINERY ceiling t grid machine uses an advanced punching and shearing system, which can achieve simultaneous punching of all holes. This design allows the punching and shearing process to be carried out without stopping the ceiling t bar machine, significantly improving production efficiency and accuracy. For customers, using KINGREAL CEILING MACHINERY ceiling t grid machine can not only shorten the production cycle, but also ensure the consistency of each ceiling t bar in size and hole position. |  |

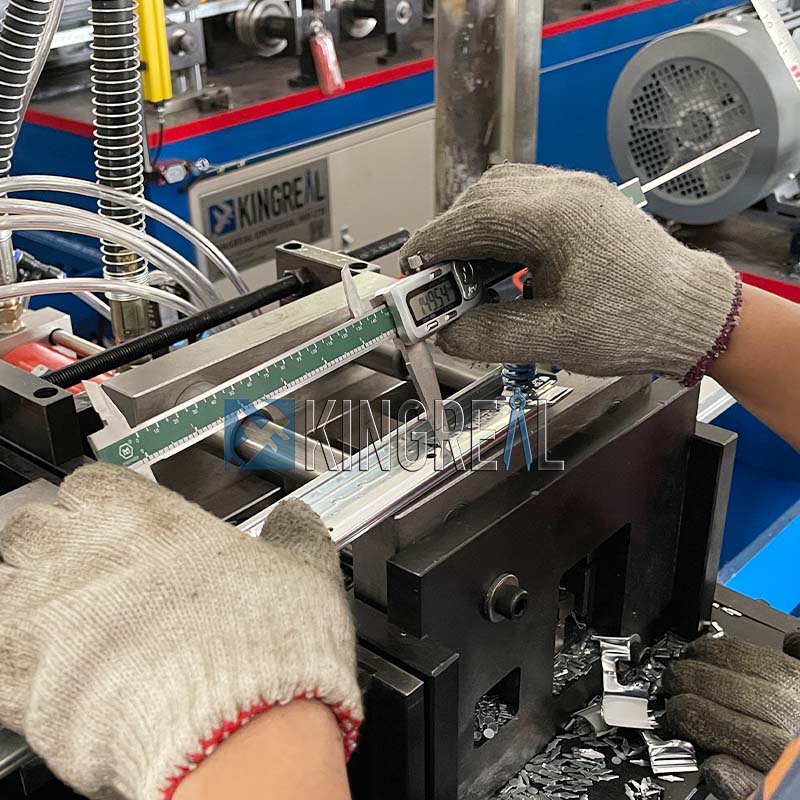

2. High-precision ceiling t grid machine KINGREAL CEILING MACHINERY ceiling t grid machine is equipped with high-quality rollers and high-precision servo systems to ensure that every detail in the production process is precisely controlled. Through precise design and manufacturing processes, KINGREAL CEILING MACHINERY ceiling t grid machine can provide extremely high product accuracy. Whether it is the size and thickness of the ceiling t grid, or the spacing and position of the punching holes, KINGREAL CEILING MACHINERY can provide reliable guarantees. This not only meets customers' high standards for products, but also reduces material waste caused by errors. |  |

3. Multi-specification ceiling t grid machines To meet the needs of different customers, KINGREAL CEILING MACHINERY provides multi-specification ceiling t bar machines, which can produce ceiling t grids of different sizes on the same ceiling t grid machine. Customers can choose to replace the hanger or replace the wheels of the roll forming machine separately to achieve the production of ceiling t grids of different specifications. This flexibility enables KINGREAL CEILING MACHINERY ceiling t bar machine to adapt to diverse market needs and help customers improve production capacity and market competitiveness. |  |

Different Types of Ceiling T Bar Machines

KINGREAL CEILING MACHINERY provides a variety of different types of ceiling t grid machines to meet customers' needs for the production of different types of ceiling t bar machines. Mainly including the following types:

Black Line Ceiling T Grid Machine The design feature of the Black Line Ceiling T Grid Machine is that it is equipped with an ink bottle. During the molding process, the production of black line ceiling t grids can be achieved. The ink used by KINGREAL CEILING MACHINERY is a quick-drying material, and no drying is required after production, which greatly saves time and cost. |  |

Silhouette Ceiling T Grid machine KINGREAL CEILING MACHINERY Silhouette Ceiling T Grid machine provides two options: fully automatic and semi-automatic, and customers can choose according to their own production needs. Fully automatic Silhouette Ceiling T Grid machines can punch and cut all holes in one step, while semi-automatic equipment requires the Silhouette Ceiling T Grid to be manually placed in the punch press for punching. This flexibility allows customers to choose the most suitable equipment according to their production capacity and budget. |  |

FUT T Grid Machines are known for their efficient production capacity and can produce smoothly at a speed of up to 30m/min. KINGREAL CEILING MACHINERY engineers have equipped the FUT T Grid Machine's roll forming machine with an independent archway to ensure the stability and durability of the production process. This highly efficient equipment is particularly suitable for customers with large-scale production, which can significantly improve production efficiency and reduce unit costs. |  |

KINGREAL CEILING MACHINERY Flat Ceiling T Bar Machine is equipped with a PLC monitoring system, which can quickly locate the problem when a fault occurs. This design not only improves the stability of the equipment, but also ensures the stability of production quality. Through real-time monitoring, customers can promptly discover and solve problems in production, thereby avoiding unnecessary downtime and losses. |  |

Drawing About Ceiling T Grid

Why Does KINGREAL CEILING MACHINERY Ceiling T Grid Machine Have Excellent Performance?

1. Quality control In the process of manufacturing ceiling t bar machine, KINGREAL CEILING MACHINERY completes blanking welding, wire cutting, drilling and other links in its own factory. This integrated production process ensures the reliability of ceiling t grid machine quality and can guarantee the stability of delivery time. The advantage of self-production enables KINGREAL CEILING MACHINERY to strictly control the quality of each equipment to ensure that every customer can get a high-performance ceiling t bar machine. |  |

2. Rich manufacturing experience KINGREAL CEILING MACHINERY has rich manufacturing experience and has sold ceiling t grid machines to Brazil, Saudi Arabia, Russia, Bangladesh, Vietnam and other countries. The expansion of these international markets has enabled KINGREAL CEILING MACHINERY to have an in-depth understanding of factors such as market demand, weather conditions and policy changes in different countries. This experience not only helps KINGREAL CEILING MACHINERY optimize product design, but also enables it to provide customized solutions for different markets to meet the special needs of customers. |  |

3. Customer feedback and continuous improvement KINGREAL CEILING MACHINERY attaches importance to customer feedback and continues to improve products and innovate technology. Through close communication with customers, KINGREAL CEILING MACHINERY can keep abreast of changes in market demand and quickly adjust product strategies. This flexibility enables KINGREAL CEILING MACHINERY to maintain its leading position in the fiercely competitive market. |  |

FAQ About Ceiling T Grid Machine

1/How long does it take to change between different ceiling t grids?

Roll changeover takes approximately 15-20 minutes for an experienced operator to complete.

2/What is the typical maintenance needed for the ceiling t grid machine?

Ceiling t bar machine maintenance includes tasks such as lubricating bearings, cleaning debris from the forming stations, and replacing worn parts. Regular training on machine operating procedures for operators is also required.

3/How many people do you need to run a ceiling t grid machine?

Once the ceiling t bar machine is turned on, only one worker is needed at the output station to organize the finished products.

4/Can you change the size of the ceiling t grids?

Of course, the ceiling t bar machine can change the size of the ceiling t grid by replacing the roller set and cutting die, or by replacing the wheels and cutting die.

5/How do you keep the ceiling t grid machine working well?

It is essential to focus on continuous and regular maintenance of the ceiling t bar machine, including regularly cleaning the rollers and molds, properly lubricating moving parts (gears, bearings), checking and adjusting tool alignment (rollers, cutters), monitoring the hydraulic/pneumatic systems, and following the manufacturer's operating guidelines for training and daily inspections.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)