Products Lists

01 What is the Purpose of a Baffle Ceiling System?

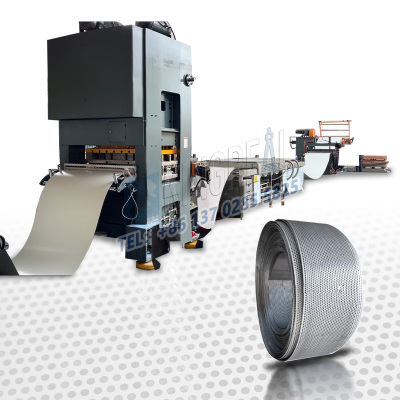

Baffle ceiling systems are a new type of ceiling material that has emerged in recent years. They are characterized by their open view and excellent ventilation. Baffle ceilings not only provide a sense of spaciousness visually but also offer superior ventilation performance structurally, greatly enhancing indoor comfort. Compared to traditional ceiling materials, the simple and smooth lines of baffle ceilings showcase a unique, minimalist, and modern style, making the space appear more spacious and elegant, meeting the aesthetic needs of modern people. The The baffle ceiling machine is a crucial tool for producing these baffle ceilings. Through processes such as uncoiling, leveling, forming, and cutting, the baffle ceiling machine can efficiently produce baffle ceilings of different types and specifications. The design and manufacturing process of these baffle ceiling machines involve multiple technical stages, ensuring the quality and stability of the final product. Baffle ceiling machines can produce common baffle sizes on the market, including widths of 25-100 mm and heights of 75-300 mm. To adapt to different market demands, the baffle ceiling machine can be automated with simple parameter adjustments, minimizing labor costs and ensuring that the mass-produced baffle ceilings have high precision and excellent basic characteristics.

02 Successful Project About Baffle Ceiling Machine

Baffle ceiling machines are one of KINGREAL CEILING MACHINERY signature products, and we collaborate frequently with clients every year. The KINGREAL CEILING MACHINERY team, with its professional technical background and rich industry experience, excels at customizing the most suitable baffle ceiling machines based on clients' actual project needs. KINGREAL CEILING MACHINERY not only focuses on client needs but also fully considers the economic environment and policy impacts of various countries to ensure the efficiency and compatibility of the baffle ceiling machine. To date, KINGREAL CEILING MACHINERY baffle ceiling machines have brought great convenience and profits to clients in Italy, Turkey, India, Vietnam, Uzbekistan, and other countries. In the implementation of each project, KINGREAL CEILING MACHINERY consistently provides comprehensive services, including on-site baffle ceiling machine installation and detailed operational training for clients. After the successful installation of the baffle ceiling machine, the KINGREAL CEILING MACHINERY team does not stop there, but continues to track the latest status of the baffle ceiling machine, ready to provide spare parts and troubleshooting services at any time. Every baffle ceiling machine KINGREAL CEILING MACHINERY manufactures for its clients is based on the principle of deeply understanding client needs. The team fully considered factors such as national and regional policies affecting the baffle ceiling machine, the climate conditions in the customer's region, and the limitations of the customer's site during the design process. This personalized service ensures that each baffle ceiling machine has customized features, guaranteeing optimal results for the customer in actual production.

- Enhanced work safety: KINGREAL CEILING MACHINERY can equip the baffle ceiling machines with protective shield, preventing workers from being injured by accidental contact during machine operation. This design significantly improves work safety and reduces potential personal injury.

- Increased automation: To maximize the automation of the entire work process and accelerate work efficiency, KINGREAL CEILING MACHINERY has equipped the baffle ceiling machines with feeding trolleys. The baffle ceiling machine can automatically feed the coil material into the decoiler, eliminating the need for excessive manual intervention. This not only improves production efficiency but also effectively reduces labor intensity.

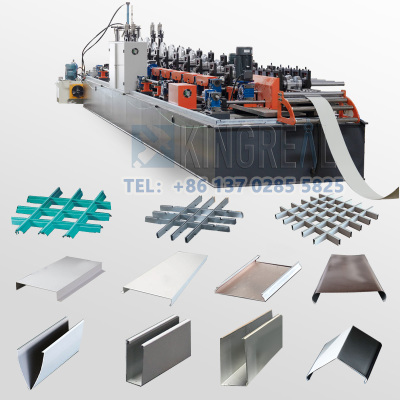

- Meeting diverse production needs: The market demand for baffle ceiling sizes varies. Therefore, KINGREAL CEILING MACHINERY, based on market and customer needs, has designed baffle ceiling machines of different specifications, including 150mm height, 200mm height, and 300mm height baffle ceiling machines. This design flexibility allows the baffle ceiling machines to produce baffle ceilings of various heights, avoiding resource waste due to mismatched sizes, truly achieving on-demand production and making full use of every resource.

03 FAQ About Baffle Ceiling Machine

Q1: How to change different sizes in the baffle ceiling machine?

A1:The customer simply needs to input the corresponding dimensions into the PLC controller system, and the baffle ceiling machine will automatically adjust the size.

Q2:What materials can this baffle ceiling machine process?

A2:This baffle ceiling machine is designed for processing iron sheets with a thickness of 0.4-0.7mm and aluminum sheets with a thickness of 0.3-1.0mm.

Q3:Is the baffle ceiling machine easy to operate?

A3:Yes, this baffle ceiling machine is equipped with a PLC control panel with a touchscreen, which facilitates settings, length adjustments, and production monitoring.

Q4:What is your baffle ceiling machine speed?

A4:30 m/min, adjustable according to project requirements.

Q5:Can the baffle ceiling machine be customized for special profiles?

A5:Absolutely! Please share your drawings with KINGREAL CEILING MACHINERY. We can design and manufacture custom molds based on your specifications to produce unique baffle ceilings.

Baffle ceiling systems are a new type of ceiling material that has emerged in recent years. They are characterized by their open view and excellent ventilation. Baffle ceilings not only provide a sense of spaciousness visually but also offer superior ventilation performance structurally, greatly enhancing indoor comfort. Compared to traditional ceiling materials, the simple and smooth lines of baffle ceilings showcase a unique, minimalist, and modern style, making the space appear more spacious and elegant, meeting the aesthetic needs of modern people. The The baffle ceiling machine is a crucial tool for producing these baffle ceilings. Through processes such as uncoiling, leveling, forming, and cutting, the baffle ceiling machine can efficiently produce baffle ceilings of different types and specifications. The design and manufacturing process of these baffle ceiling machines involve multiple technical stages, ensuring the quality and stability of the final product. Baffle ceiling machines can produce common baffle sizes on the market, including widths of 25-100 mm and heights of 75-300 mm. To adapt to different market demands, the baffle ceiling machine can be automated with simple parameter adjustments, minimizing labor costs and ensuring that the mass-produced baffle ceilings have high precision and excellent basic characteristics.

02 Successful Project About Baffle Ceiling Machine

Baffle ceiling machines are one of KINGREAL CEILING MACHINERY signature products, and we collaborate frequently with clients every year. The KINGREAL CEILING MACHINERY team, with its professional technical background and rich industry experience, excels at customizing the most suitable baffle ceiling machines based on clients' actual project needs. KINGREAL CEILING MACHINERY not only focuses on client needs but also fully considers the economic environment and policy impacts of various countries to ensure the efficiency and compatibility of the baffle ceiling machine. To date, KINGREAL CEILING MACHINERY baffle ceiling machines have brought great convenience and profits to clients in Italy, Turkey, India, Vietnam, Uzbekistan, and other countries. In the implementation of each project, KINGREAL CEILING MACHINERY consistently provides comprehensive services, including on-site baffle ceiling machine installation and detailed operational training for clients. After the successful installation of the baffle ceiling machine, the KINGREAL CEILING MACHINERY team does not stop there, but continues to track the latest status of the baffle ceiling machine, ready to provide spare parts and troubleshooting services at any time. Every baffle ceiling machine KINGREAL CEILING MACHINERY manufactures for its clients is based on the principle of deeply understanding client needs. The team fully considered factors such as national and regional policies affecting the baffle ceiling machine, the climate conditions in the customer's region, and the limitations of the customer's site during the design process. This personalized service ensures that each baffle ceiling machine has customized features, guaranteeing optimal results for the customer in actual production.

- Enhanced work safety: KINGREAL CEILING MACHINERY can equip the baffle ceiling machines with protective shield, preventing workers from being injured by accidental contact during machine operation. This design significantly improves work safety and reduces potential personal injury.

- Increased automation: To maximize the automation of the entire work process and accelerate work efficiency, KINGREAL CEILING MACHINERY has equipped the baffle ceiling machines with feeding trolleys. The baffle ceiling machine can automatically feed the coil material into the decoiler, eliminating the need for excessive manual intervention. This not only improves production efficiency but also effectively reduces labor intensity.

- Meeting diverse production needs: The market demand for baffle ceiling sizes varies. Therefore, KINGREAL CEILING MACHINERY, based on market and customer needs, has designed baffle ceiling machines of different specifications, including 150mm height, 200mm height, and 300mm height baffle ceiling machines. This design flexibility allows the baffle ceiling machines to produce baffle ceilings of various heights, avoiding resource waste due to mismatched sizes, truly achieving on-demand production and making full use of every resource.

03 FAQ About Baffle Ceiling Machine

Q1: How to change different sizes in the baffle ceiling machine?

A1:The customer simply needs to input the corresponding dimensions into the PLC controller system, and the baffle ceiling machine will automatically adjust the size.

Q2:What materials can this baffle ceiling machine process?

A2:This baffle ceiling machine is designed for processing iron sheets with a thickness of 0.4-0.7mm and aluminum sheets with a thickness of 0.3-1.0mm.

Q3:Is the baffle ceiling machine easy to operate?

A3:Yes, this baffle ceiling machine is equipped with a PLC control panel with a touchscreen, which facilitates settings, length adjustments, and production monitoring.

Q4:What is your baffle ceiling machine speed?

A4:30 m/min, adjustable according to project requirements.

Q5:Can the baffle ceiling machine be customized for special profiles?

A5:Absolutely! Please share your drawings with KINGREAL CEILING MACHINERY. We can design and manufacture custom molds based on your specifications to produce unique baffle ceilings.

Get the latest price? We'll respond as soon as possible(within 12 hours)