Open Cell Ceiling Machine

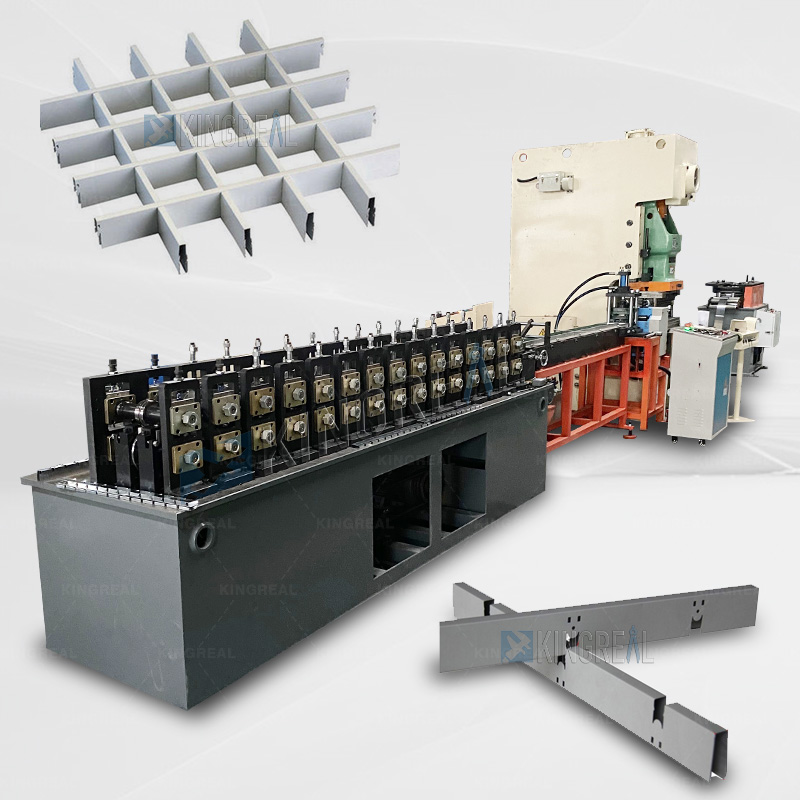

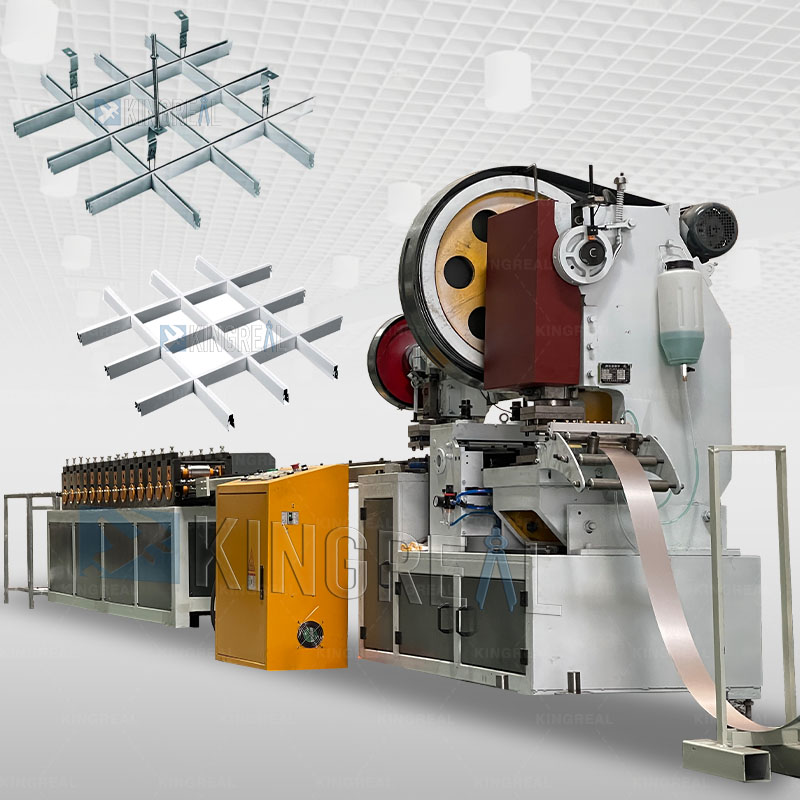

KINGREAL CEILING MACHINERY open cell ceiling machine is also called grilyato ceiling machine, mainly used to produce open cell ceilings of different sizes and types.

- KINGREAL CEILING MACHINERY

Details

Video About Open Cell Ceiling Machine

Introduction to Open Cell Ceiling Machine

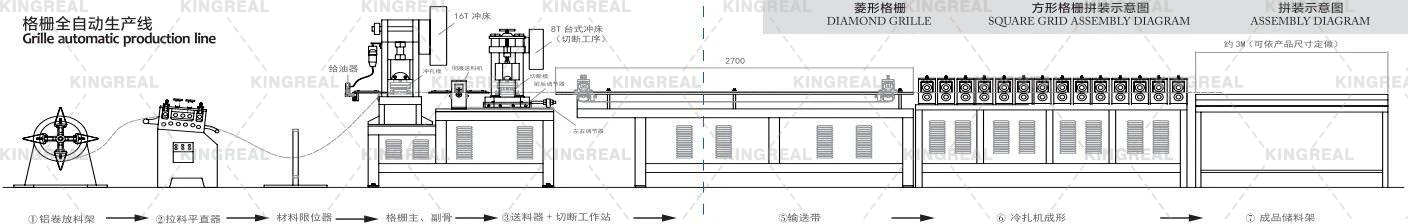

KINGREAL CEILING MACHINERY open cell ceiling machine is mainly used to produce open cell ceilings of different sizes and types. The entire open cell ceiling production line includes decoiler, straightener, servo feeder, power press, cutting unit, conveyor, roll forming machine, output table and electrical control system. The production speed of this open cell ceiling machine can reach up to 30m/min, which can meet the production needs of customers. |  |

Workflow of Open Cell Ceiling Machine

Hydraulic Decoiler -- Precision Leveling Machine-- Punching Machine-- Cutting Station -- Main Roll Forming Machine -- Discharging Table

Main Components of Open Cell Ceiling Production Line

| NO. | Equipment | Specification | Qty. |

1 | Manual Decoiler | (1) Material Width: ≤200MM (2) Coil Inner Diameter: Φ 508 MM (3) Max Coil External Diameter: Φ 1200 MM (4)Max Bear Weight: 1000KG (5)Expansion Diameter: Φ450-Φ530 (6)Expansion Method:Manual Expansion | 1 Unit |

2 | Precision Leveler | (1) Leveling Rolls: 10 Up Rollers, 9 Down Rollers (2) Material Thickness: 0.2-2.0MM (3) Drive Roller Feeding, Output: 1 Pair for Feeding and Output (4)Feeding Speed: 15M/MIN | 1 Unit |

3 | Servo Feeder | (1) Servo Motor: 0.85 KW (2) Feeding Material Thickness: 0.30 - 0.40 MM (3) Feeding Length: Adjustable | 1 Unit |

4 | Power Press | (1) Punching Tool: 2 PCS (For Main Grid & Cross Grid) (2) Punching Distance: 50 / 60 / 75 / 86 / 100 / 120 / 150 / 200 MM (8 Sizes) (3) Press Power: 16 Tons (4) Motor Power: 2.2 KW, 380 V (5) Capacity: 120 Strokes / Minute | 1 Unit |

5 | Cutting Unit | (1) Cutting Tool: 1 PCS (2) Press Power: 2 Tons (3) Motor Power: 0.55 KW, 380 V (4) Capacity: 180 Strokes / Minute (5) Cut to Length: 592.2 MM | 1 Unit |

| 6 | Conveyor | (1) Auto Conveying: Speed Adjustable (2) Motor Power: 90 W, 220 V | 1 Unit |

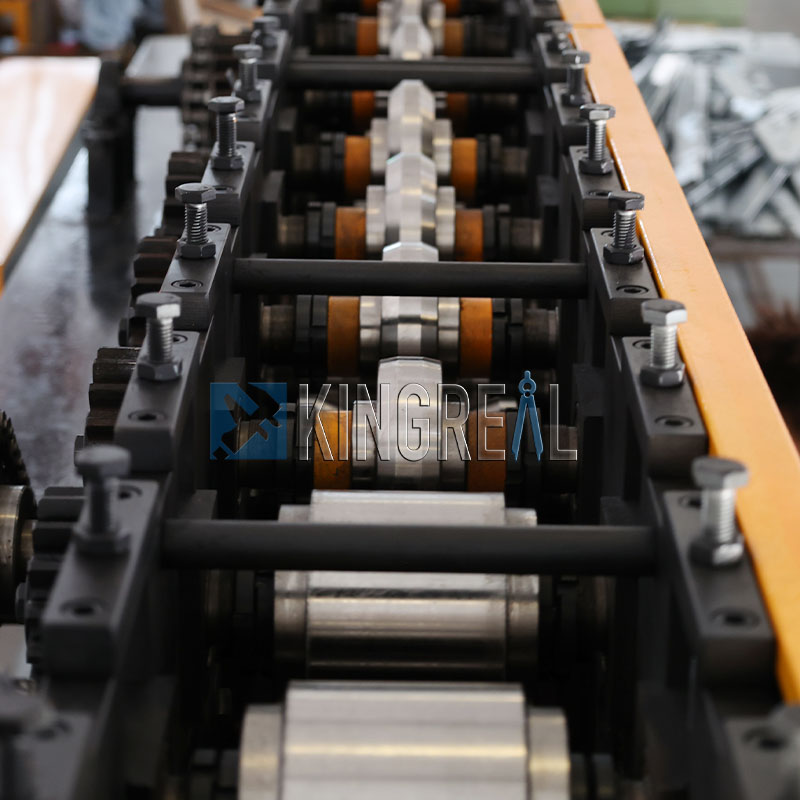

7 | Roll Forming Machine | (1) Forming Roller: 14 Stations; Including Straightening; 45# (2) Treatment For Rollers: Quenched And Hard Chrome Plating (3) Side-Wall Thickness: 25 MM (4) Main Shaft: Φ38 MM; 45# (5) Bearing: HRB 6206 (6) Motor Power: 4.0 KW (7) Transmission System: By Gears & Chains | 1 Unit |

| 8 | Run-Out Table | (1) Table Length: 3 Meters; No Power | 1 Set |

9 | Electric Control System | (1) PLC (2) Touch Screen (3) Servo Motor (4) Power Supplier: 380 V, 50 HZ, 3 PHS | 1 Unit |

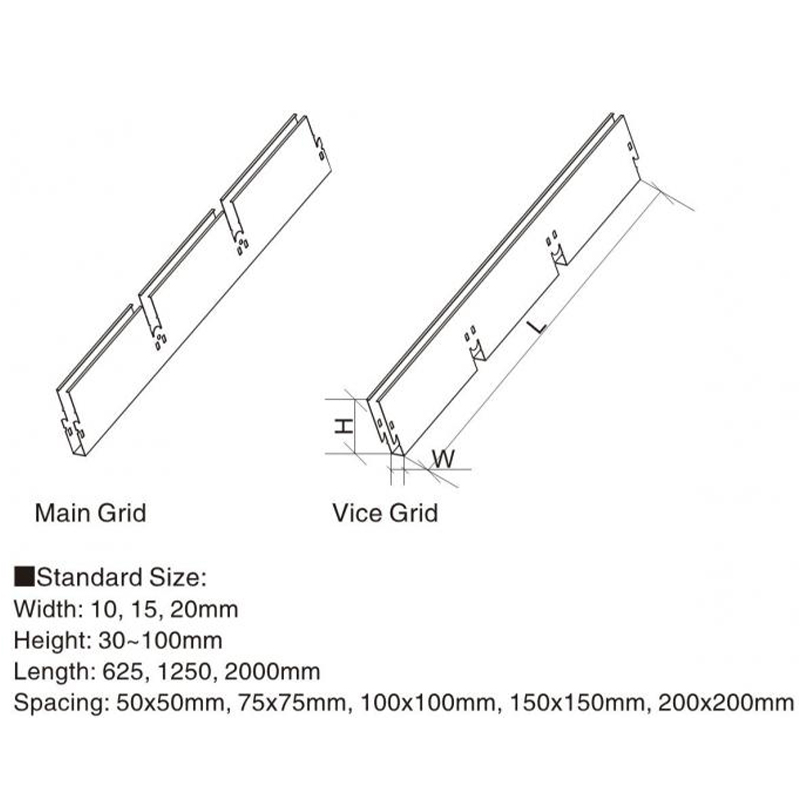

Drawing About Open Cell Ceiling

Advantages of Open Cell Ceiling Machine

(1) Customized open cell ceiling machine manufacturing solution. KINGREAL CEILING MACHINERY insists on providing customized open cell ceiling production line manufacturing solutions for each customer. We are well aware that each customer has different requirements for machine speed, finished product size, type (including C-type open cell ceiling, U-type open cell ceiling and pyramid open cell ceiling), and precision. Therefore, KINGREAL CEILING MACHINERY will design a customized solution for open cell ceiling machine manufacturing based on the customer's drawings and after full communication between engineers and customers. KINGREAL CEILING MACHINERY customized open cell ceiling production line include the weight of the coil that the decoiler can bear, the leveling accuracy of the leveling machine, the tonnage of the punching machine, the blade material of the shearing station, the number of rollers of the roll forming machine, the running speed of the open cell ceiling machine, etc., which can be personalized. |  |

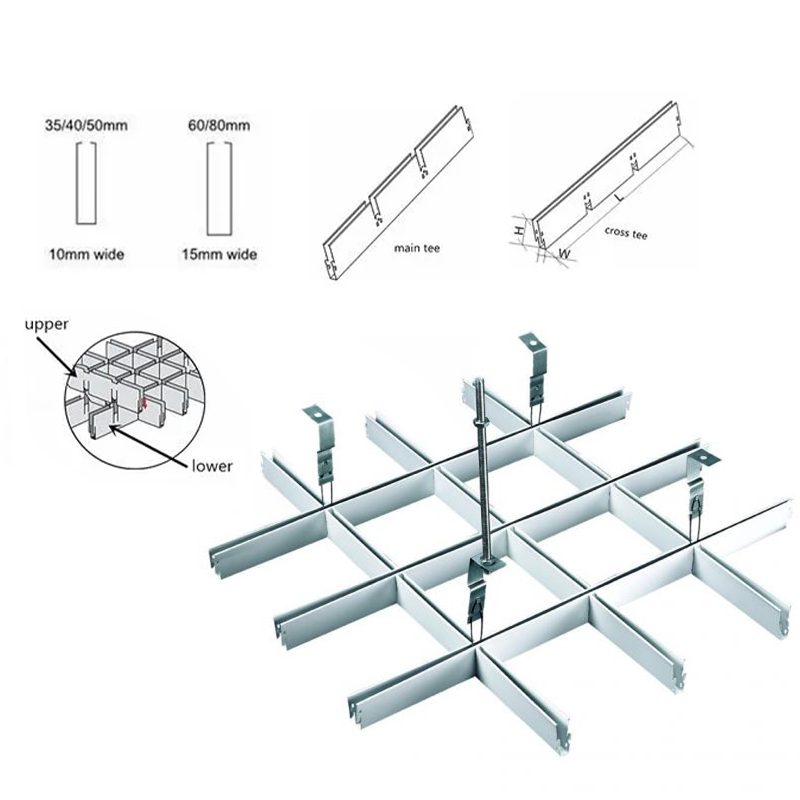

(2) Highly flexible open cell ceiling production line. Whether it is different metal materials, different punching apertures, or different open cell ceiling sizes, KINGREAL CEILING MACHINERY open cell ceiling machines can adapt perfectly. Customers do not need to purchase multiple open cell ceiling production lines to meet the production needs of different open cell ceilings. A KINGREAL CEILING MACHINERY open cell ceiling machine can produce both aluminum and iron open cell ceilings. By replacing the punching die, different hole diameters or hole shapes can be punched out on the metal surface. What is more worth mentioning is that when you need to produce open cell ceilings of different sizes, you only need to adjust the parameters on the control panel, and the roller of the roll forming machine will automatically adjust the width to produce open cell ceilings of different sizes. |  |

(3) Durable open cell ceiling production line. The KINGREAL CEILING MACHINERY open cell ceiling machine is composed of precision components. The roll forming machine roller of the KINGREAL CEILING MACHINERY open cell ceiling production line is made of CR12MOV material, the motor is a well-known domestic and foreign brand, and the blade of the shearing station is selected from a high-hardness material. Therefore, it can provide customers with an open cell ceiling machine that runs smoothly, has a long service life, and has low maintenance costs. |  |

Application of Open Cell Ceiling Production Line

The open cell ceilings produced by the KINGREAL CEILING MACHINERY open cell ceiling production line are of high precision, strong consistency, and burr-free appearance. They are widely used in open spaces such as subway station passages, airports, high-speed rail stations, offices, shopping malls, clubs, and restaurants. They are popular for their easy installation and strong sense of fashion. In addition, KINGREAL CEILING MACHINERY can provide customers with a variety of open cell ceiling solutions. KINGREAL CEILING MACHINERY open cell ceiling machine can also be used in conjunction with a ceiling t bar machine, with the ceiling t bar produced by the ceiling t bar machine as the open cell ceiling edge to form an open cell ceiling with an edge. |  |

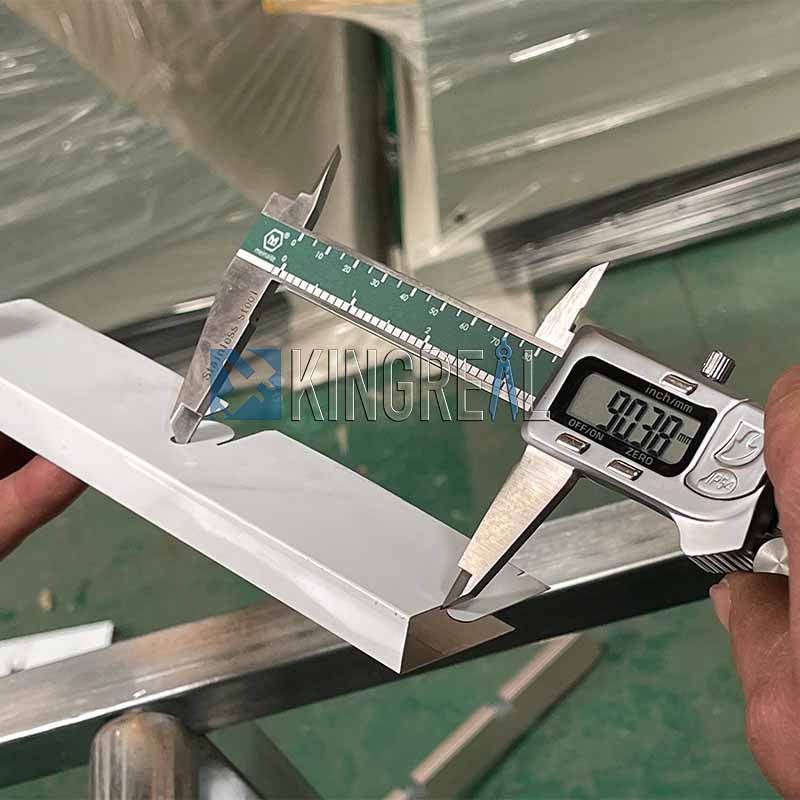

Quality Assurance

After the open cell ceiling machine is manufactured, KINGREAL CEILING MACHINERY engineers will put in a large roll of metal coils for testing. And measure the height and width of the finished product including the aperture to confirm whether the finished product produced by the open cell ceiling production line meets the customer's needs. Only open cell ceiling machines that pass a series of strict tests will be sent to the customer's factory.

Various Types of Open Cell Ceiling Machines

KINGREAL CEILING MACHINERY open cell ceiling production lines have had friendly cooperation with customers from Russia, Turkey, Vietnam, India, Saudi Arabia and other countries. The following are three special open cell ceiling machines of KINGREAL CEILING MACHINERY:

(1) High-end open cell ceiling production line KINGREAL CEILING MACHINERY designed a high-end open cell ceiling machine for Russian customers. The tonnage of the punching station of this high-end open cell ceiling production line has been upgraded to 63 tons. The most significant advantage of this high-end open cell ceiling machine is that it can punch a row of holes at one time, which greatly improves production efficiency and improves punching accuracy. |  |

(2) Standard open cell ceiling production line The standard open cell ceiling machine is a machine that KINGREAL CEILING MACHINERY has sold many units. Compared with the high-end open cell ceiling production line, this standard open cell ceiling production line is equipped with a punching station with a tonnage of 16 tons and can only punch one hole at a time. Therefore, it is more suitable for customers with small production scale or no high requirements for production speed. This standard open cell ceiling machine also performs well, and its performance parameters meet the general needs of customers on the market. |  |

(3) Customized open cell ceiling production line This customized open cell ceiling machine was designed by KINGREAL CEILING MACHINERY for a Vietnamese customer. Because the customer's site area is limited, he has special requirements for open cell ceiling specifications, and because he has just entered this field, he does not have a high budget for purchasing machines. Therefore, KINGREAL CEILING MACHINERY manufactured a small open cell ceiling production line suitable for limited site area according to the customer's situation, and customized the punching mold and cutting mold according to the drawings to meet the customer's requirements for special specifications of the finished product. |  |

Customer Visit -- Open Cell Ceiling Machine

KINGREAL CEILING MACHINERY warmly welcomes customers from all over the world to visit our factory to visit our open cell ceiling machines. During the visit, KINGREAL CEILING MACHINERY staff will accompany customers throughout the whole process to ensure that customers can have a deep understanding of the production process of the open cell ceiling production line. Whether customers want to visit the raw material workshop, machine manufacturing workshop, machine installation workshop or open cell ceiling machine inspection workshop, KINGREAL CEILING MACHINERY will lead customers to visit one by one.

At present, KINGREAL CEILING MACHINERY has successfully received customers from more than 20 countries, including Vietnam, Algeria, Canada, the Philippines, Russia and Kyrgyzstan. During the visit, KINGREAL CEILING MACHINERY encourages customers to operate the open cell ceiling production line and inspect the finished product in person. This personal experience helps customers have a deeper understanding of KINGREAL CEILING MACHINERY open cell ceiling machine. If you are confused about choosing an open cell ceiling machine, KINGREAL CEILING MACHINERY welcomes you to visit in person. KINGREAL CEILING MACHINERY provides a variety of types of open cell ceiling production lines for you to experience, and looks forward to helping you find the most suitable open cell ceiling machine through offline communication.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)