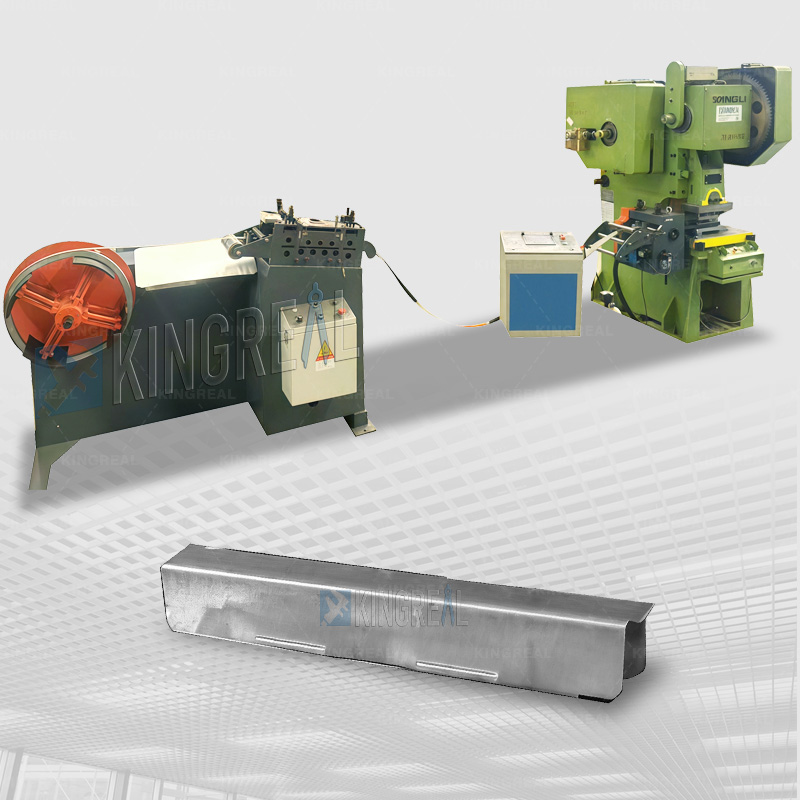

Profile Connectors Roll Forming Machine

The profile connectors roll forming machine is specifically designed to produce profile connectors of various specifications. These connectors connect to open cell ceilings to form a complete grilyato ceiling system, improving ventilation and significantly enhancing maintenance convenience.

- KINGREAL CEILING MACHINERY

Details

Video About Profile Connectors Roll Forming Machine

Definition of Profile Connectors Roll Forming Machine

| The profile connectors roll forming machine is specifically designed to produce profile connectors of various specifications. These connectors connect to open cell ceilings to form a complete grilyato ceiling system, improving ventilation and significantly enhancing maintenance convenience. This profile connectors making machine works seamlessly with the open cell ceiling machine, ensuring precise dimensional matching and a smoother installation process. Whether producing standard products or custom-made items, this profile connectors roll forming machine efficiently meets customer needs, and it has become a popular choice for various projects, especially in the Russian market. |

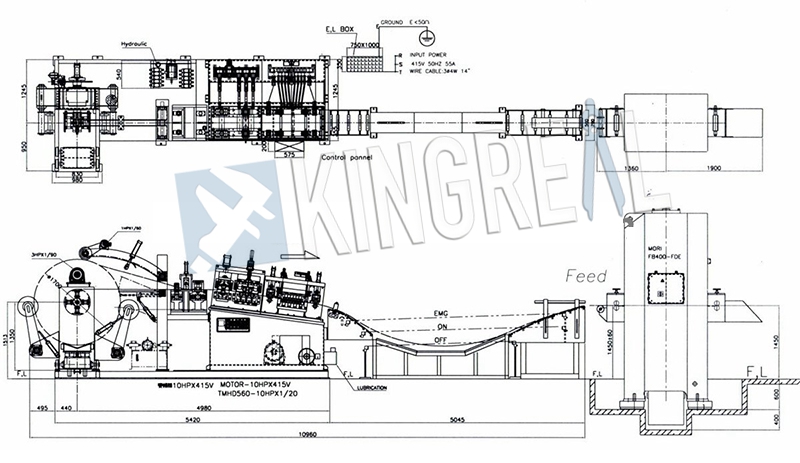

Workflow of Profile Connectors Roll Forming Machine

2-in-1 Decoiler & Metal Leveling Machine → Servo Feeder → 25 Ton Punch Press → Products Output

Parameters of Profile Connectors Roll Forming Machine

Decoiler | Power | 2KW |

| Decoiler speed | < 25m/min | |

| Material Inner diameter | φ460mm-φ520mm | |

Metal Leveling Machine | Straightening speed | <25m/min |

| Material thickness | 0.5-3.2mm | |

| Leveling roller material | Gcr15, processed with quenched-tempered heat treatment, fine grinding, chrome surface plated and polish surface | |

25Tons Punching Press | Nominal force | 250kN |

| Nominal Stroke | 2.5mm | |

| Slide Stroke | 60mm | |

| Strokes per minute | 80-100 |

The above parameters are for reference only. KINGREAL CEILING MACHINERY will customize the profile connectors making machine design according to each customer's actual project needs.

Advantages of Profile Connectors Roll Forming Machine

1)Fully automated profile connectors making machine

The profile connectors roll forming machine automatically completes the unwinding, leveling, feeding, and punching of the coil material, requiring almost no manual intervention throughout the process. Operators only need to tidy up the produced profiles at the end of the profile connectors making machine to ensure a highly efficient and smooth production process. Furthermore, the profile connectors making machine is equipped with multiple fault indication functions, such as insufficient air pressure, lubrication failure, and double valve malfunction, ensuring timely detection and resolution of problems during operation, further reducing maintenance costs and manpower input.

2)Customized tonnage and stroke for profile connectors making machine

KINGREAL CEILING MACHINERY customizes punching machines to meet the specific project needs of customers. Both the punching machine's tonnage and stroke can be designed according to customer requirements, ensuring full and rational use of resources. For example, for projects with smaller requirements, customers do not need to purchase excessively high-tonnage punching machines, and vice versa. This flexibility effectively reduces investment risk and improves customer economic benefits.

3)Superior progressive die design for profile connectors roll forming machine

The progressive die is a key component of the profile connectors making machine, responsible for the initial stamping and cutting of the metal material. KINGREAL CEILING MACHINERY maintains extremely high standards in progressive die manufacturing, using ultra-hard materials for working parts to ensure mold durability. By using multi-station progressive dies, the complex forming process is simplified into step-by-step stamping at multiple stations, each with relatively low complexity. This not only improves production efficiency but also reduces the probability of failure.

Russian Customer Acceptance: Profile Connectors Making Machine

After the profile connectors making machine was manufactured, KINGREAL CEILING MACHINERY specifically invited Russian customer to the KINGREAL CEILING MACHINERY factory for on-site inspection. During the inspection, KINGREAL CEILING MACHINERY engineers started the profile connectors roll forming machine and adjusted the parameters on the PLC control panel to meet the Russian customer's production needs. Test results showed that the profile connectors roll forming machine could efficiently and stably produce high-quality grid connectors under different production parameters. The Russian customer expressed satisfaction and confirmed the profile connectors making machine's shipment.

Why Does Russia Need a Profile Connectors Making Machine?

With the rapid development of the construction industry, grilyato ceilings are becoming increasingly popular in Russia. These grilyato ceilings can be integrated with modern lighting and ventilation systems and feature an open-plan design, making interior spaces appear more spacious. In this context, the profile connectors roll forming machine is of great significance. Customers can freely choose connectors of different sizes, widths, heights, and lengths according to specific project needs, flexibly combining design solutions.

Product Display

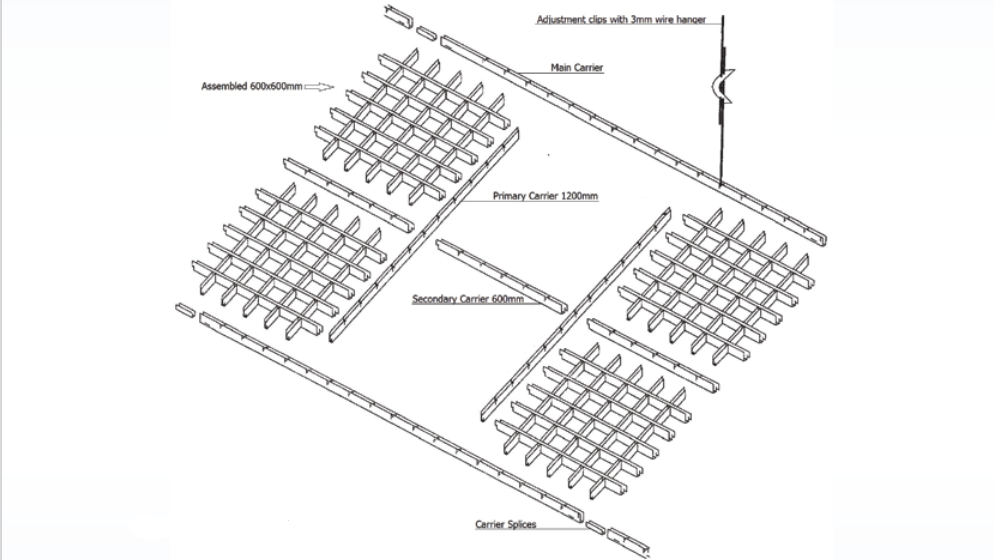

Grilyato Ceiling System Installation Process

When installing a grilyato ceiling system, first, anchor bolts must be fixed to the ceiling base plate, above the main joists. Next, install 3mm steel wire hangers or threaded rods with adjusting clips. The main joists must be securely fixed to the steel wire hangers or threaded rods, and then spring brackets are connected to the main joists using steel wire supports, ensuring proper spacing. The entire installation process is crucial; it is essential to ensure all levels are correct for subsequent beam and tile installation.

FAQ About Profile Connectors Making Machine

1. What aspects are included in profile connectors making machine customization?

The profile connectors roll forming machine offers extensive customization. Customers can select the brand and parameters of the machine's motor, punch press, and PLC control panel as needed. Furthermore, other equipment components can be customized according to actual requirements, ensuring each machine perfectly fits the user's specific needs.

2. What is the stroke of the punching machine equipped with the profile connectors making machine?

KINGREAL CEILING MACHINERY profile connectors roll forming machine is equipped with a punching frequency between 80-100 strokes/minute, flexibly designed according to customer needs. For higher stroke requirements, please contact KINGREAL CEILING MACHINERY.

3. What materials should I provide to KINGREAL CEILING MACHINERY?

To better meet customer needs, it is recommended to provide finished product samples or design drawings. This will help the KINGREAL CEILING MACHINERY team more accurately understand your requirements, thus enabling us to tailor a suitable profile connectors making machine for you.

4. Can the profile connectors making machine be adjusted according to actual conditions?

Yes, the profile connectors roll forming machine's PLC control panel has various adjustable settings, including production speed and output, which customers can adjust according to actual conditions to ensure efficient and stable production.

5. Besides the profile connectors roll forming machine, what other equipment does KINGREAL CEILING MACHINERY offer to create a complete grilyato ceiling system?

To help customers build a complete grilyato ceiling system, KINGREAL CEILING MACHINERY also offers a ceiling t grid machine. This ceiling t grid machine efficiently produces ceiling t bar that serve as the edging for the grilyato ceiling. By equipping their systems with both the ceiling t grid machine and the grilyato ceiling machine, customers can easily achieve a high-quality grilyato ceiling system.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)