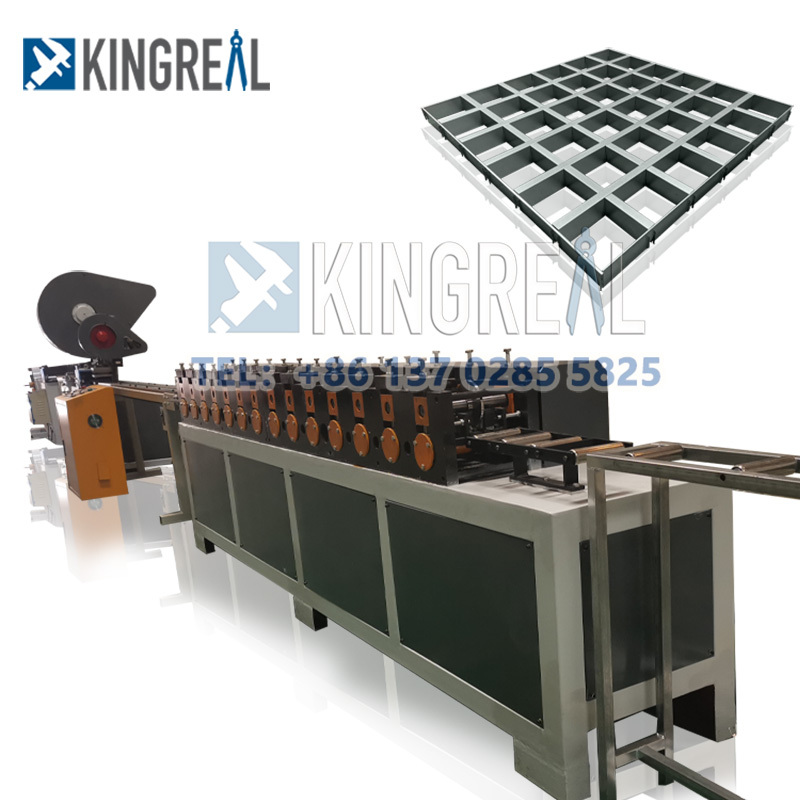

Full Automatic Open Cell Ceiling Production Line

KINGREAL CEILING MACHINERY is a professional open cell ceiling machine supplier in China. The grilyato ceiling machine can produce multiple sizes of metal grid ceiling, is selling well around the world. Welcome to contact us and visit our factory!

- KINGREAL CEILING MACHINERY

Details

Video About Open Cell Ceiling Production Line

Description of Open Cell Ceiling Making Machine

| KINGREAL CEILING MACHINERY Grilyato Ceiling Making Machine is design for product different sizes and shape open cell ceiling produce. Now successfully exported to Italy, UAE, Russia, Argentina and other countries. This metal open cell ceiling making machine width can be adjusted by NC system, it can be change automatically only need the operator to input the product width, height, length. And the open cell ceiling machine use the AC motor (speed adjustable) to do the continously automatically cold roll forming process. The open cell ceiling making machine can work with both iron and aluminum, so you don't need to buy multiple production lines. It is able to efficiently produce two different materials of grille ceiling in a single production line, greatly improving the production convenience. |  |

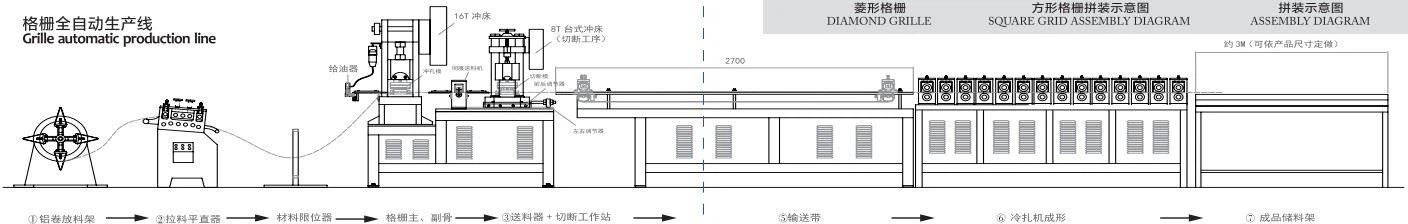

Main Components of Open Cell Ceiling Machine

● Decoiler for Grilyato Ceiling Machine-- It is an efficient automated equipment specially designed for unwinding heavy metal coils. Through advanced mechanical structure and control system, it can easily unwind metal coils without human intervention.

● Leveler for Open Cell Ceiling Machine -- Due to the long-term winding process of metal coils, creases and deformations often appear on the surface, affecting the subsequent processing quality. The leveler equipped by KINGREAL CEILING MACHINERY can efficiently level the sheet material to ensure that its surface is smooth and flat.

● Perforation and Cut-to-Length Machine for Open Cell Ceiling Machine-- It can customize the punching die according to the specific needs of customers to meet the requirements of different shapes and apertures. Customers only need to set the required finished product length, and the shearing station will automatically perform precise shearing.

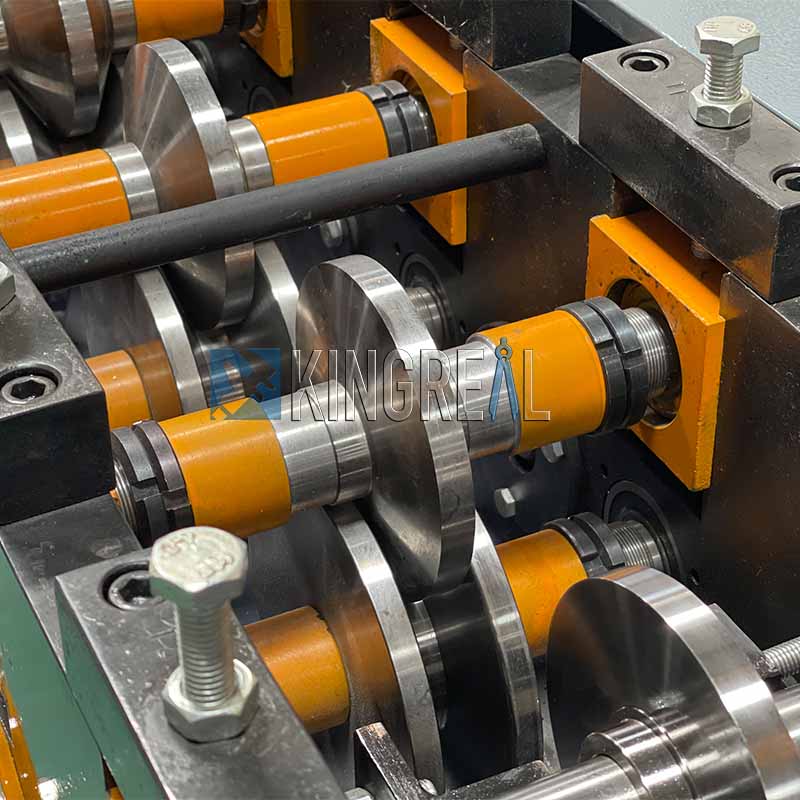

● Main Roll Forming Machine for Grilyato Ceiling Machine-- It presses the metal sheet through a high-precision roller set to accurately form the grid shape required by the customer. The flexibility and adaptability of the equipment enables it to handle metal materials of various sizes and thicknesses, ensuring that the final product meets the design requirements.

|  |

Decoiler | Leveler Machine |

|  |

| Perforation and Cut-to-Length Machine | Main Roll Forming Machine |

Specification of Open Cell Ceiling Machine

1.Roll forming speed: 0-20m/min

2. Open cell ceiling material thickness: 0.3-0.5mm

3. Working process: Material decoiler - High precision leveling machine - Perforation Press - Shearing Machine - Main Roll Forming Machine - Hydraulic Station - Control Cabinet and the output station.

Parameter of Grilyato Ceiling Production Line

| Raw materials | Pre-painted Aluminum or Pre-painted Galvanized steel |

| Ceiling sizes | Width: 10mm / 15mm / 25mm Height: 40mm / 50mm/ 30mm |

| Length control | Automatic servo control |

| Maximum forming speed | 20 m / min |

| Roll Forming stands | 14 roll forming stations |

| Machine Power | ~ 12KW |

Features of Grilyato Production Line

The width of the open cell ceiling machine can be adjusted by the numerical control system, and the width, height and length of the product can be automatically changed by the operator.

Fully automated grilyato ceiling machine to ensure the stable operation of production, improve production efficiency, reduce safety risks.

KINGREAL CEILING MACHINERY can provide two different punching stations, giving you two choices. The standard grilyato ceiling making machine is equipped with a 16-ton punching machine for middle punching stations.Compared with the standard open cell ceiling production line, the high-end open cell ceiling machine upgrades the punching station to 63 tons of punching station, and upgrades the tooling, which can punch the entire line at one time.

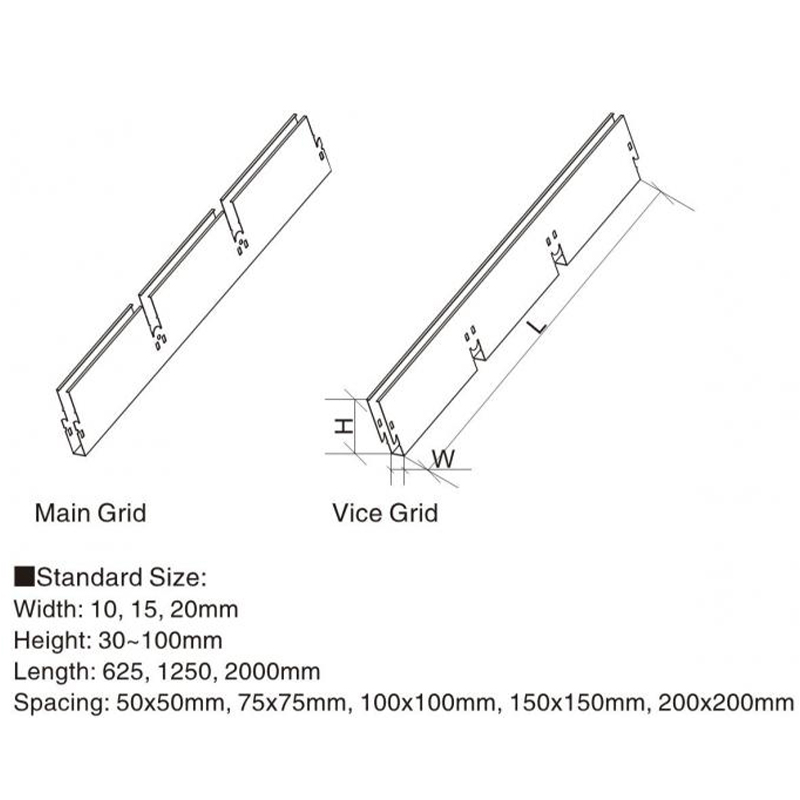

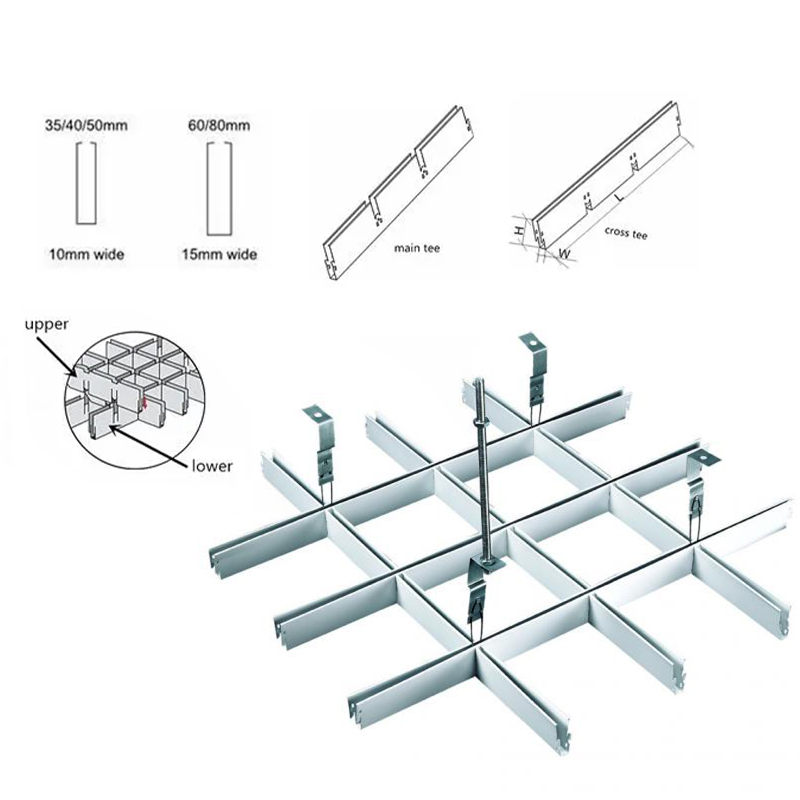

Drawing About Open Cell Ceiling Product

Complete Suspended Ceiling Machine Manufacturing Solution

KINGREAL CEILING MACHINERY is a professional manufacturer the complete machine for metal linear strip ceiling making machine, baffle ceiling roll forming machine, open cell ceiling production line, and other type suspended metal ceiling making machine. KINGREAL CEILING MACHINERY can make machine according with your different design and. KINGREAL CEILING MACHINERY machines have exported to many oversea countries,and have the good reputations. KINGREAL CEILING MACHINERY can provide the suitable solution of machine for you according to your detail request and product size.

(1) Linear Strip Ceiling Machine Linear strip ceiling machineis made of material decoiler, precision straightener, notching station of the strip ceiling, roll forming machine part, shearing and bending forming part. Precision Straightener is very important for the quality control of the metal linear strip ceiling, due to different width of the strip ceiling from 100-600mm. After precision straightening process of the material, the roll forming and shearing would be more accurate. |  |

Video About Linear Strip Ceiling Machine:

(2) Open Cell Ceiling Machine The open cell ceiling machine is one of KINGREAL CEILING MACHINERY most popular suspended ceiling machines. It can make open cell ceilings of different sizes and can also make pyramid open cell ceilings to meet your different production needs. |  |

Video About Open Cell Ceiling Machine:

(3) Baffle Ceiling Machine KINGREAL CEILING MACHINERY is engaged in manufacturing excellent quality Baffle Ceiling Machine. |  |

Video About Baffle Ceiling Machine:

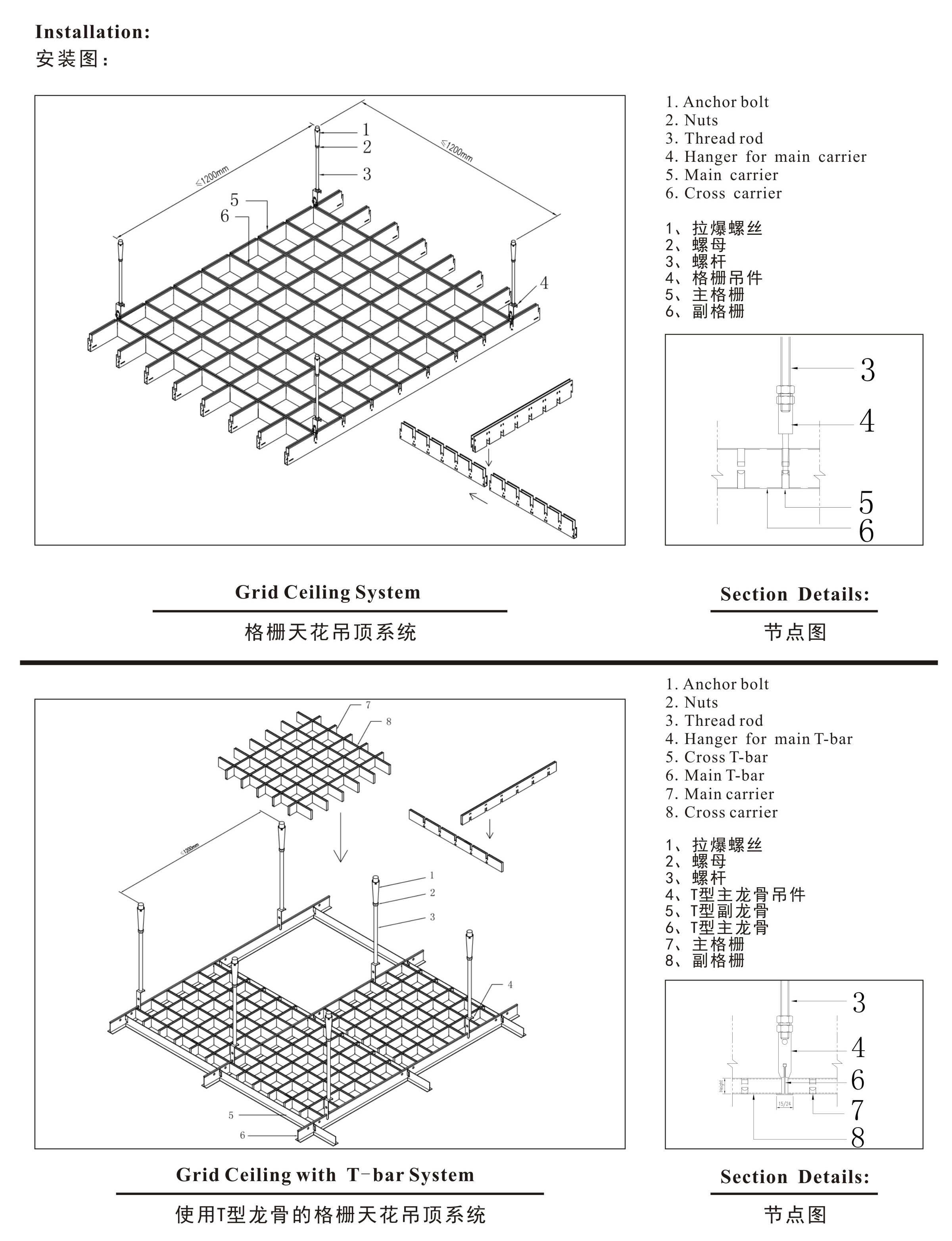

Installation drawing Of Open Cell Ceiling

By splicing open cell ceilings, a complete open cell ceiling system can be easily constructed. This system not only has a beautiful appearance, but also effectively enhances the sense of transparency and layering of the space. Each grilyato unit can be flexibly combined according to actual needs, making the design more personalized and adapting to different architectural styles and interior decoration requirements.

When constructing a open cell ceiling, ceiling t bar can also be used as keel support structures. Ceiling t bar is made by ceiling t bar machines and are generally used as keel supports for ceiling systems. This design not only enhances the stability of the ceiling, but also forms a open cell ceiling system with a surround. The use of ceiling t bar makes the open cell ceiling more three-dimensional, and the design of the surround adds a layer of exquisite decorative effect to the overall space. Whether it is a commercial space or a residential environment, this system can provide good acoustic performance and visual effects, meeting the modern people's dual pursuit of aesthetics and functionality.

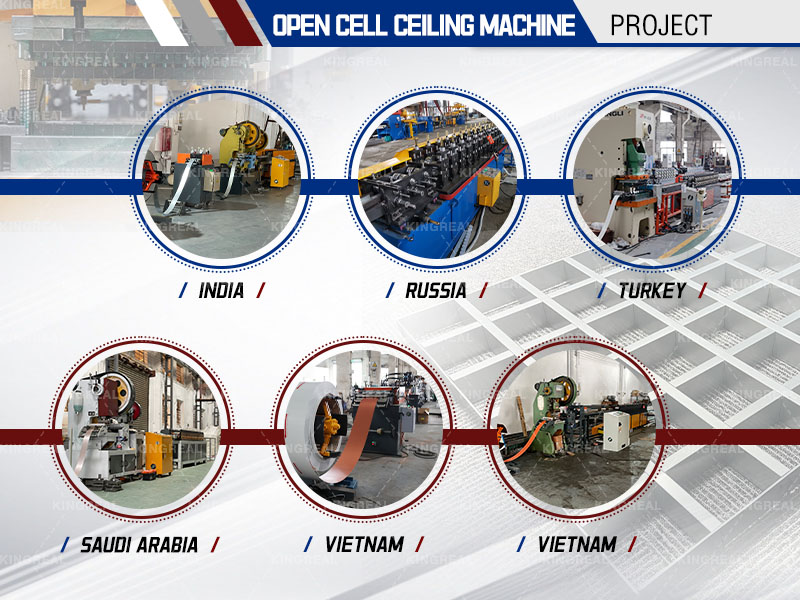

KINGREAL CEILING MACHINERY Grilyato Ceiling Making Machine Installation Projects

KINGREAL CEILING MACHINERY's open cell ceiling making machines have been sold to many places including India, Russia, Turkey, Saudi Arabia, Vietnam, etc. KINGREAL CEILING MACHINERY can provide customers with different grilyato ceiling machine models, which can be divided into C-shaped grilyato ceiling production line, U-shaped grilyato ceiling production line according to different finished product types, and grilyato ceiling production line with folding edge specially customized for Vietnamese customers. According to different parameter requirements, it can be divided into high-end open cell ceiling production line and standard open cell ceiling production line.

After-Sales Services

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL CEILING MACHINERY has been insisting on doing. The global localization service point is under construction.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)