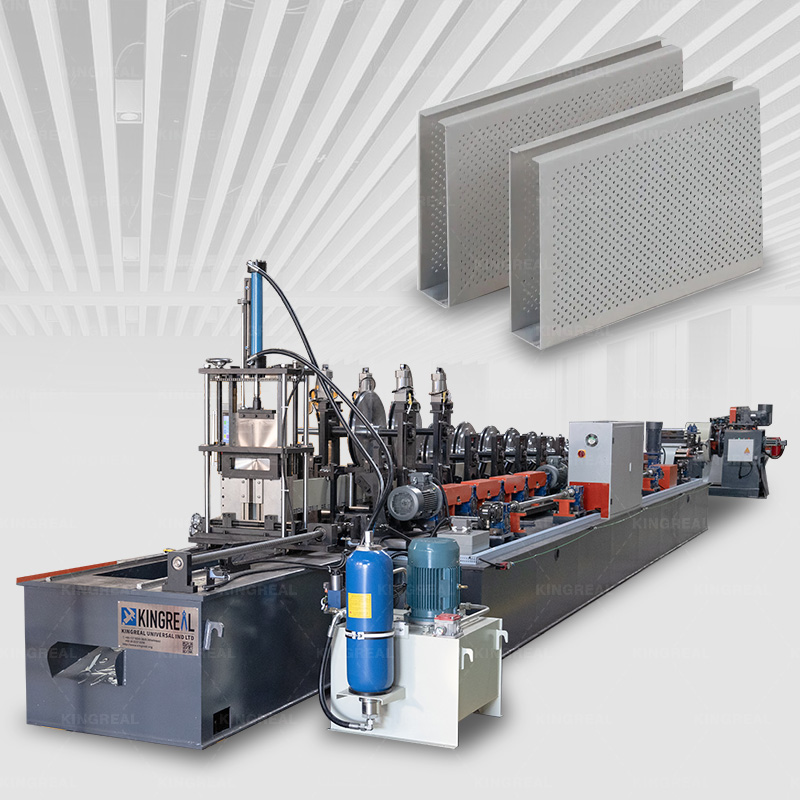

Acoustic Metal Baffle Ceiling Machine

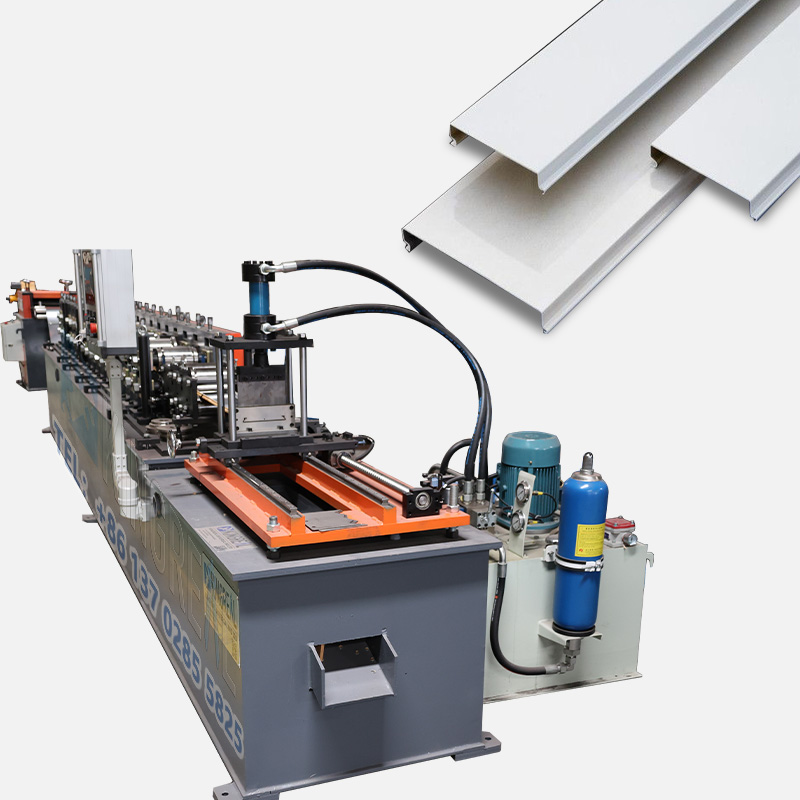

Baffle Ceiling Machine produces different sizes of sound baffle by setting the program to automatically adjust the width. It is a high economic benefits baffle ceiling machine for u baffle ceiling manufacturing industry.

- KINGREAL CEILING MACHINERY

Details

Video About Baffle Ceiling Machine

Description Of Baffle Ceiling Machine

KINGREAL CEILING MACHINERY Baffle Ceiling Machine can produce sound baffle ceilings with perforation which allows u baffle ceiling more beautiful and perform better in soundproofing. This baffle ceiling making machine is compatible with pre-painted and pre-perforated raw material coils. And this baffle ceiling machine has the characteristics of fast production, stable operation, and adjustable production parameters. |  |

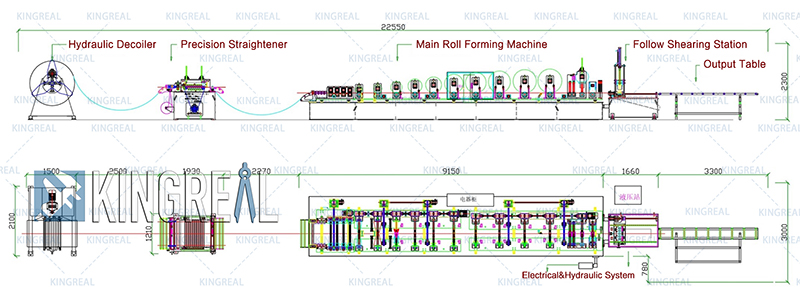

Working Process of Baffle Ceiling Machine

Decoiler -- Precision Leveling Machine --Roll Forming Machine --Cutting Station

Parameter of Baffle Ceiling Machine

| Baffle Ceiling Making Machine | |

| Material | GI Steel or Aluminum Coils |

| Material Thickness | 0.4-0.7mm for GI Steel Coil, 0.4-1.1mm for Aluminum Coi |

| Length | 1-8m |

Length Tolerance | ±1mm, when length is more than 3m |

Production Speed | 0-30m/min, adjustable by servo motor |

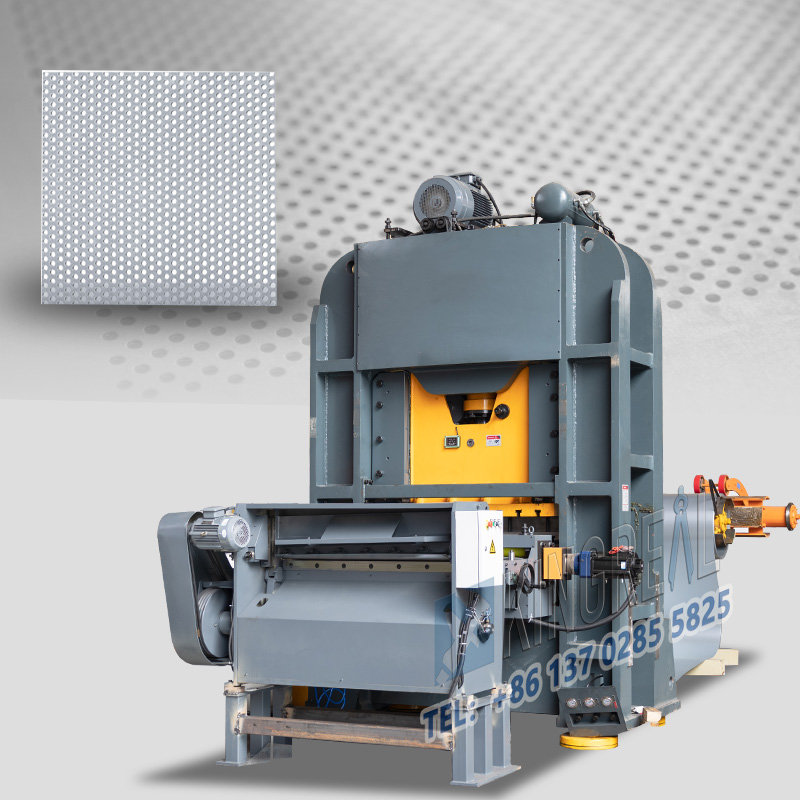

Combination With Metal Perforation Machine

How to produce an acoustic baffle? The production process is very simple. You only need to equip a metal punching press on the basis of the baffle ceiling machine to fully automatically complete the operation from raw materials to the forming of acoustic baffles. KINGREAL CEILING MACHINERY Full Automatic Metal Perforated Machine is used for producing different kinds of perforation coil or panel, raw material can be stainless steel, alloy aluminum and galvanize steel etc. The punched coils can be wound up and used as punched raw material for the acoustic baffle forming process. |  |

Main Features of Baffle Ceiling Machine

(1) Automatic Width Adjustment

KINGREAL CEILING MACHINERY baffle ceiling machines can produce different lengths and widths of sound baffle ceilings in one machine. The sizes are controlled by the rotate encoder and it can be set on the touch screen. Acoustic baffle ceilings are available from the smallest sizes (30-150mm) to a maximum of 300mm height. Clients can flexibly choose their product sizes.

(2) Following Shearing Station for Baffle Ceiling Machine

KINGREAL CEILING MACHINERY equipped a hydraulic following shearing station in a baffle ceiling machine, this baffle ceiling making machine can reach up to 30m/min production speed, highly increasing the production efficiency.

(3) High Precision Forming for Baffle Ceiling Machine

This baffle ceiling making machine is featured high-precision Cr12MoV-mold-steel-made rollers, with more than 14 roller stations, raw material coil is cold roll formed into sound baffle ceilings. And PLC system to precisely control each rolling station to accurately form.

Installation Drawing About Baffle Ceiling

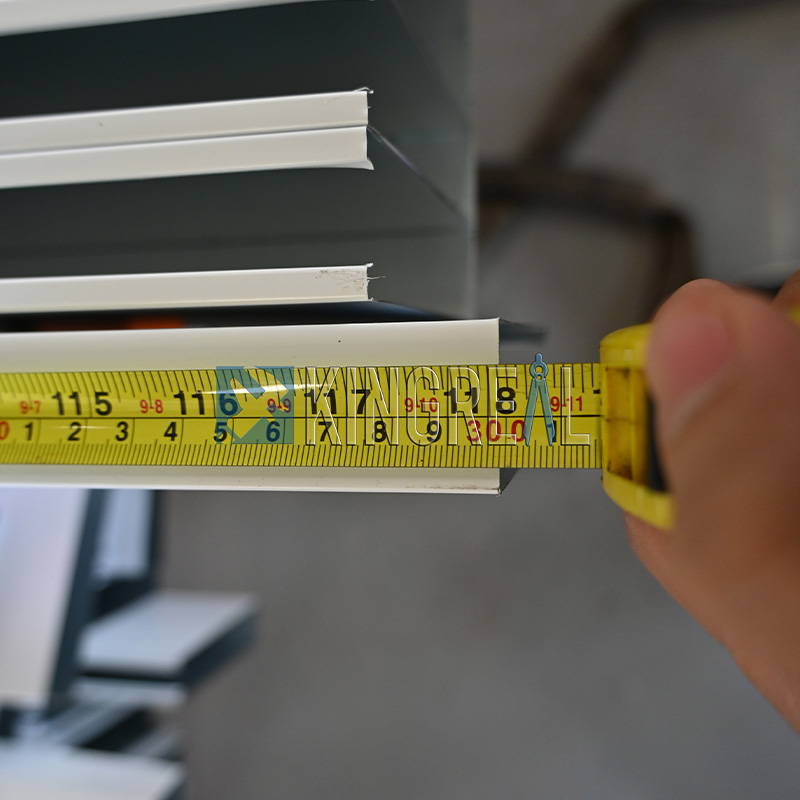

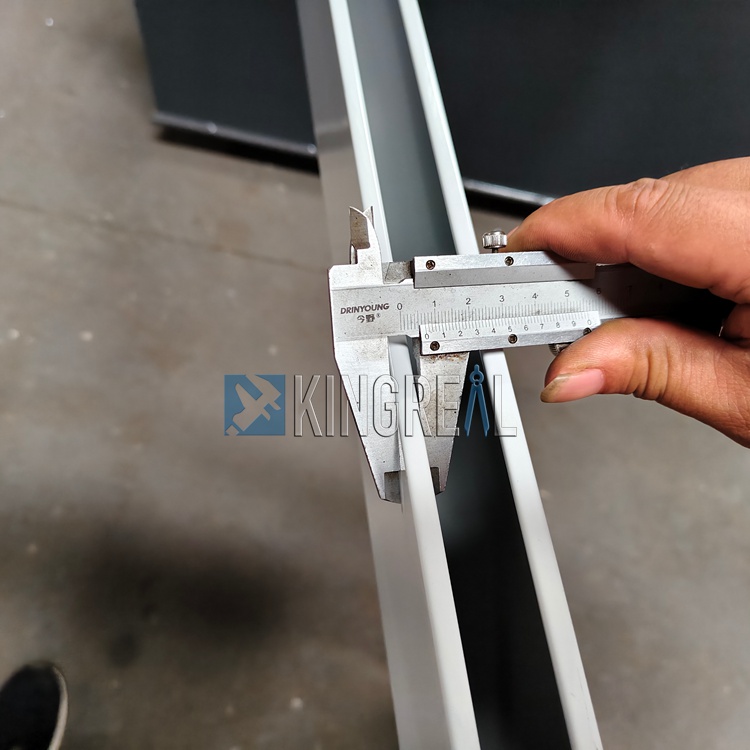

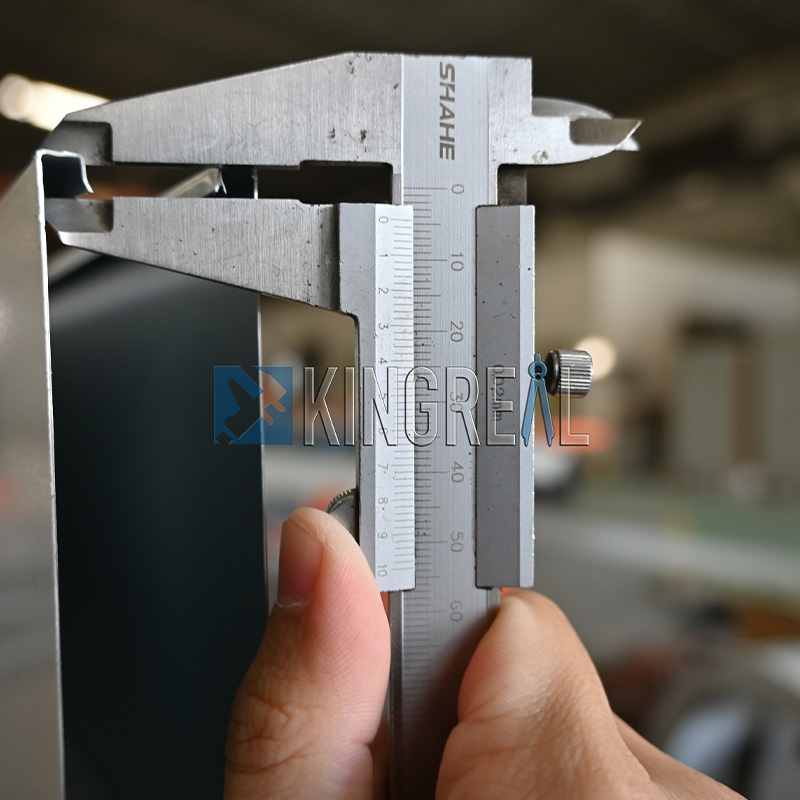

Product Measurement

KINGREAL CEILING MACHINERY baffle ceiling machine can produce baffle ceilings of different heights and specifications, and the finished products produced by KINGREAL CEILING MACHINERY baffle ceiling machine have high consistency under the same parameters. KINGREAL CEILING MACHINERY baffle ceiling making machine is often reported by customers as "it can produce baffle ceilings with good precision and quality."

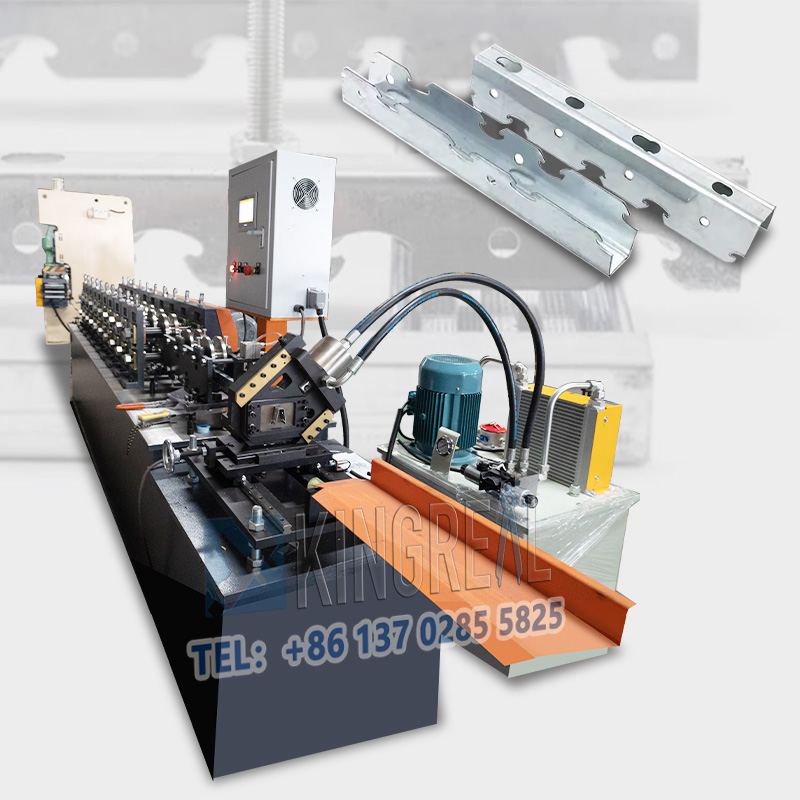

Complete Suspended Ceiling Machine Solution

With more than 20 years of experience in the suspended ceiling machine manufacturing market, KINGREAL CEILING MACHINERY has not only accumulated rich experience in the field of baffle ceiling making machines, but the successful sales of the other suspended ceiling machines have also earned KINGREAL CEILING MACHINERY a good reputation around the world:

1. Open Cell Ceiling Machine

2. Linear Strip Ceiling Machine

3. Metal Ceiling Carrier Machine

How KINGREAL CEILING MACHINERY Ensures The Quality of Beffle Ceiling Machine?

※ Establish a strict quality system

In order to better control the quality of the machine, KINGREAL CEILING MACHINERY has established its own factory and technical team. KINGREAL CEILING MACHINERY has established standardized work process standards to ensure that the machine maintains a high standard from manufacturing to debugging. From the selection of parts to the debugging of the machine, KINGREAL CEILING MACHINERY team works strictly in accordance with the standards. To provide customers with professional and high-quality machines, in order to fulfill this promise, KINGREAL CEILING MACHINERY has subdivided the work into every step.

※ Quality certified

KINGREAL CEILING MACHINERY has passed ISO9000 certification and has the ability of ISO9000 quality system management. It has also passed the international CE certificate certification.

Customer Visit -- Baffle Ceiling Machine

It is such a delight to have friends coming from afar. KINGREAL CEILING MACHINERY warmly welcomes customers to visit KINGREAL CEILING MACHINERY factory and communicate with us!

FAQ About Baffle Ceiling Machine

1/What is baffle ceiling machine?

2/How does baffle ceiling machine work?

3/What's the advantages of baffle ceiling machine?

4/How to improve the quality of baffle ceiling machine?

5/How to choose a baffle ceiling machine?

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)