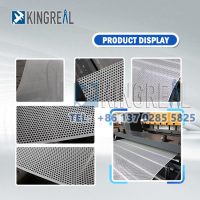

Metal Sheet Perforation Production Line

KINGREAL CEILING MACHINERY Metal Sheet Perforation Production Line can punching different hole in sheet metal by changing molds, including round hole, long round hole, square hole, triangle hole, diamond hole, hexagonal hole, crossed hole and so on. On KINGREAL CEILING MACHINERY metal sheet perforated machine, different raw materials such as iron plate, stainless steel plate, copper plate, aluminum plate, galvanized plate, etc, can be used for having perforated plate. It is the best choice for your perforated sheet metal production.

- KINGREAL CEILING MACHINERY

Details

Video About Metal Sheet Perforated Machine

Metal Sheet Perforated Machine Description

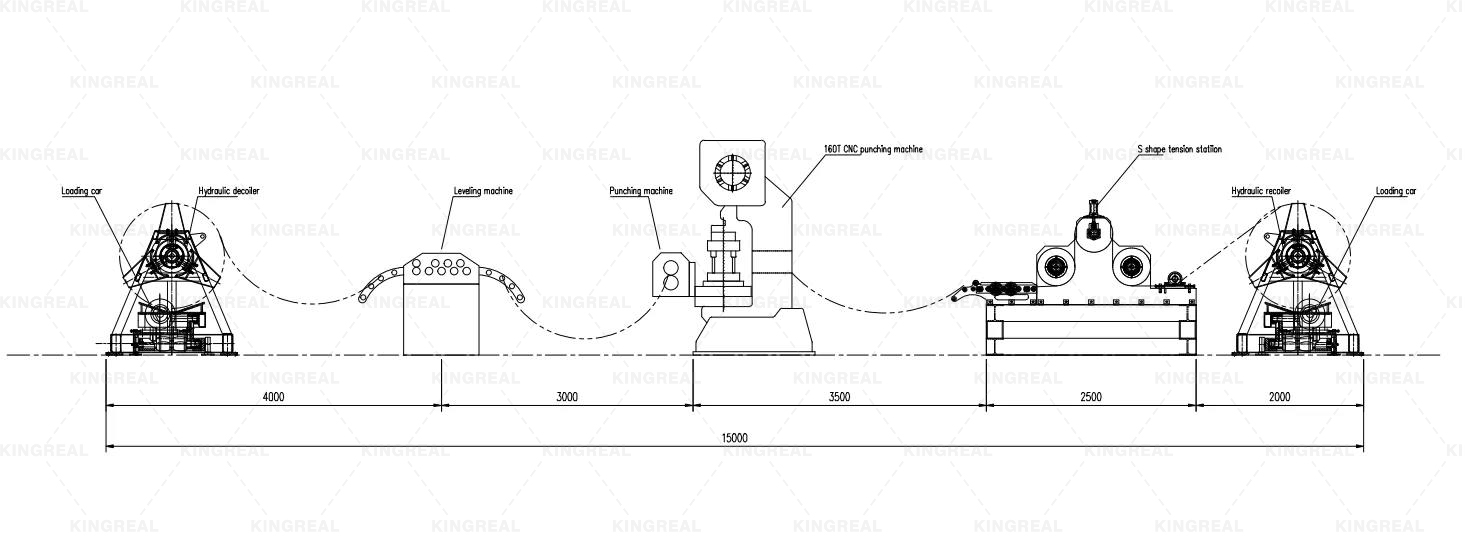

Aluminum Sheet Perforated coils are manufactured by Metal Sheet Perforated Machine. Usually aluminum, iron, and stainless steel are used as metal raw materials. Throughout the rolling and feeding operation, their ends are free to distort. After stamping, they are then twisted back into regular coils. The metal sheet perforated machine is run by a decoiler that coils the sheet metal before it is fed to the punching machine, which punches it with a precision die. Once the punching is complete, the sheet metal is then recoiled by the rewind machine to complete the line.

Working Process of Metal Sheet Perforeated Machine

Decoiler -- Precision Leveling Machine -- Metal Punching Machine -- Recoiler

Main Component Details Of Metal Sheet Perforated Machine

(1) Decoiler with trolley for metal sheet perforated machine

Loading capacity: 5T

The combination decoiler and trolley saves time and labor in loading metal coils, enhancing automation in the metal sheet perforated machine.

(2) Precision leveler for metal sheet perforated machine

Upper rollers:4, Lower rollers:5

KINGREAL design a precision straightener for metal sheet perforated machine. This professional 9-roller flattening device flattens coil material for a smooth surface, improving punching accuracy.

(3) Perforated punching machine for metal sheet perforated machine

100-180SPM

This metal sheet perforated machine has a pneumatic brake system for high-speed, precise punching, and a durable DC53 die that ensures accuracy during continuous operation.

(4) Recoiler with trolley for metal sheet perforated machine

Motor: 5.5KW

The recoiler is equipped with a unloading trolley that can quickly rewind and transport to the designated location, eliminating the need for manual handling.

Features of Metal Sheet Perforated Machine

Raw material width

When designing the metal sheet perforated machine solution, KINGREAL CEILING MACHINERY fully considers the customer's raw material width to ensure that the machine's parameters and performance can perfectly match it.

Through in-depth analysis of customer needs, KINGREAL CEILING MACHINERY is able to tailor the metal sheet perforated machine to ensure that it always maintains high efficiency and precision when processing metal coils of different widths.

This not only improves production efficiency, but also effectively reduces material waste, allowing customers to obtain higher economic benefits in the production process.

Raw material thickness

KINGREAL CEILING MACHINERY metal sheet perforated machines are designed to process metal coils with a thickness range of 0.4 to 1.0 mm.

This thickness range allows our equipment to adapt to a variety of metal materials to meet the needs of different customers.

Whether it is thin plates or thicker metal materials, KINGREAL CEILING MACHINERY can ensure a smooth and high-quality punching process to help customers achieve ideal production results.

Raw material weight

Typically, KINGREAL CEILING MACHINERY is equipped with a metal sheet perforated machine that can carry up to 5 tons of metal coils for punching. For customers who need to process heavier coils, we encourage you to communicate with the KINGREAL CEILING MACHINERY team.

Our engineers will customize the design based on the drawings and other relevant information you provide to meet specific production needs.

This flexibility and customization ensures that our equipment can adapt to various production environments and help customers achieve the best production results.

PLC Control Panel

KINGREAL CEILING MACHINERY metal sheet perforated machines are equipped with an intelligent PLC control panel, which users can set to the language used in the customer's country according to their own needs, such as Russian, Spanish, Arabic, Portuguese and other languages.

This user-friendly design makes operation more convenient, and users can easily adjust production parameters and monitor the equipment operating status in real time, thereby improving production efficiency and operating experience.

Through the intuitive interface, customers can quickly get started, reduce training time, and improve the overall operating efficiency of the production line.Foreign trade cattle is based on the premise of big data analysis.

Advantage About Metal Sheet Perforated Machine

1. Fully automatic metal sheet perforated machine

This metal sheet perforated machine only needs to enter the production parameters on the PLC control panel, and the machine can run automatically to complete the punching of the coil, with almost no human intervention. In order to maximize the production efficiency of customers, KINGREAL CEILING MACHINERY can also equip this metal sheet perforated machine with a feeding trolley, a metal sheet cleaning machine and a unloading trolley. With these additional components, the KINGREAL CEILING MACHINERY metal sheet perforated machine can provide customers with fast and neat punching coil production.

2. Metal sheet perforated machine with multiple punching options

Customers can freely choose the hole type, feed material and hole diameter according to the punching requirements of the metal plate. KINGREAL CEILING MACHINERY can provide support for any special hole type and hole diameter. We will customize the punching die according to customer needs to ensure that the punching effect meets the customer's punching effect and produce high-precision and consistent holes.

The punching machine is driven by a pneumatic brake system, which can withstand continuous and rapid punching operations to ensure accurate and stable punching process. The punching machine equipped has a punching speed of up to 180SPM and is safe. If an emergency occurs, it can be stopped in time.

3. Metal sheet perforated machines that reduce production costs

Metal sheet perforated machines enable large-scale processing and production. In addition to rewinding, KINGREAL CEILING MACHINERY CEILING MACHINERY also provides a variety of metal perforated machines such as metal sheet perforated machine and metal ceiling tile perforation lines to meet the needs of customers in different industries and significantly reduce the processing and handling costs of raw materials in factories.

It is worth mentioning that when customers need both punching & rewinding and punching & shearing processes, KINGREAL CEILING MACHINERY can provide a perforated metal machine equipped with a recoiler and a cutting station. Customers only need to click on the start to switch functions, avoiding the cost and energy of buying two metal perforated machines.

Combination With Metal Sheet Cleaning Machine

Equipping the metal sheet perforated machine with a metal sheet cleaning machine is the choice of many perforated metal sheet manufacturers. KINGREAL CEILING MACHINERY is a professional metal processing manufacturing machine supplier.

The metal sheet cleaning machine produced by KINGREAL CEILING MACHINERY can automatically clean perforated metal plates or metal coils, effectively clean the dirt or oil stains on the surface of the metal plate, make the surface more beautiful, and will not cause damage to the surface. The cleaned punched metal sheet can be directly sent to the next process or packaged and sent to the market for sale after rewinding through the rewinder.

FAQ About Metal Sheet Perforated Machine

Customized Metal Perforated Machine

After years of experience accumulation,KINGREAL CEILING MACHINERY has successfully customized diverse solutions in different perforation production area, such as Coil to coil Perforation Line , Metal Sheet Perforated Machine, Metal Ceiling Tile Perforation Line. If you have special perforated production needs, welcome to contact us!

The coil to coil perforation line is equipped with an efficient recoiler, and the punched metal sheets are directly sent to the recoiler for sorting and rewinding. It is convenient for subsequent transportation, storage and secondary processing. This system is widely used in many fields such as baffle ceilings, ventilation and heat dissipation panels, filters, screens, washing baskets, grills, wind power equipment protective covers and solar panel brackets.

The metal sheet perforated machine is equipped with a precise cutting station that can cut the perforated metal sheets according to the length set by the customer. The cutting station uses blades made of high-hardness and high-quality materials to ensure that the cut punched sheets have extremely high flatness. This technology is widely used in the manufacture of products such as wall panels, balcony guardrails, screens, stairs, separators and filter devices.

The metal ceiling perforation line can be combined with the metal ceiling tile making machine to flexibly produce a variety of types and sizes of perforated ceilings to meet the needs of different projects.

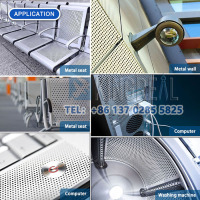

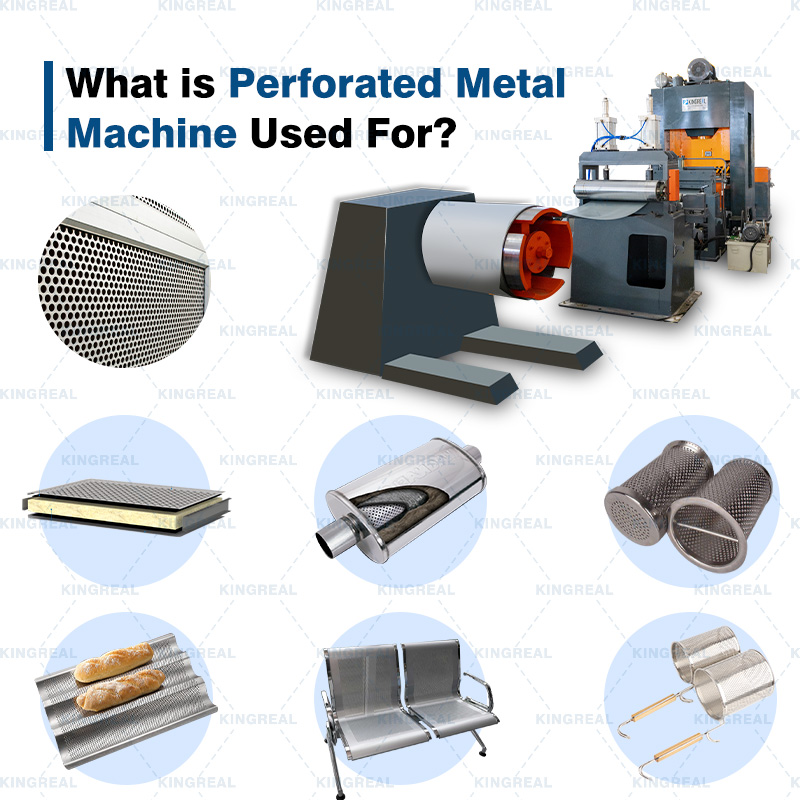

Application Of Metal Sheet Perforated Machine

In addition to being frequently employed in architectural constructions, where it can be utilized for supporting structures and decoration, the perforate sheet is also used to produce home appliances, furniture, building decoration, industry, chemical pharmaceuticals, environmental protection and energy, and parts for automobiles.

It can also be utilized as a heat exchanger material and in the production of several mechanical devices, including reels and propellers.

KINGREAL CEILING MACHINERY Factory

To integrate R&D, KINGREAL CEILING MACHINERY has established our own factory, located in Foshan, Guangdong. In addition to maintaining close contact online, many of KINGREAL CEILING MACHINERY customers also choose to visit KINGREAL CEILING MACHINERY factory to observe the production of machines and communicate with us face to face. KINGREAL CEILING MACHINERY is looking forward to reaching long-term and stable relationships with customers around the world with KINGREAL CEILING MACHINERY professional capability and consistent level of service!

Package&Shipping

After KINGREAL CEILING MACHINERY metal sheet perforated machines are manufactured in the factory, they will undergo a strict quality inspection process. First, KINGREAL CEILING MACHINERY will invite customers to come and inspect the machine in person to ensure that the equipment meets their specific needs. If the customer is unable to come, KINGREAL CEILING MACHINERY professional technical team will also conduct a detailed inspection of the metal sheet perforated machine. Only after confirming that the metal sheet perforated machine can operate normally and the punching accuracy reaches a high standard will it be shipped. This series of quality control measures is designed to ensure that each metal sheet perforated machine can achieve the highest performance and reliability before it is delivered to the customer, thereby enhancing customer trust and satisfaction.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)