What is the cost of metal sheet perforated machine?

2025-07-27 17:00

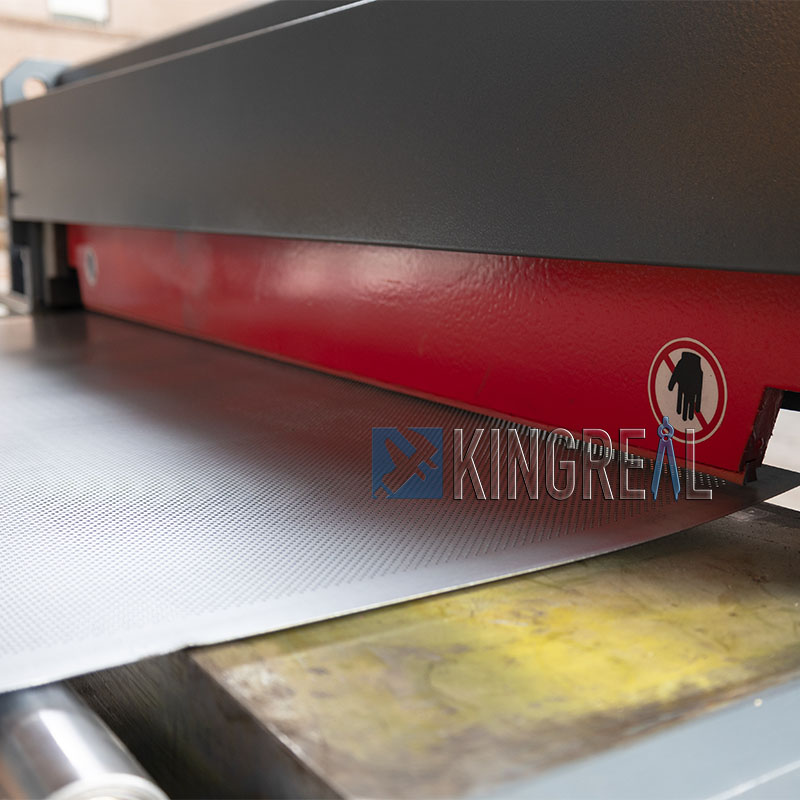

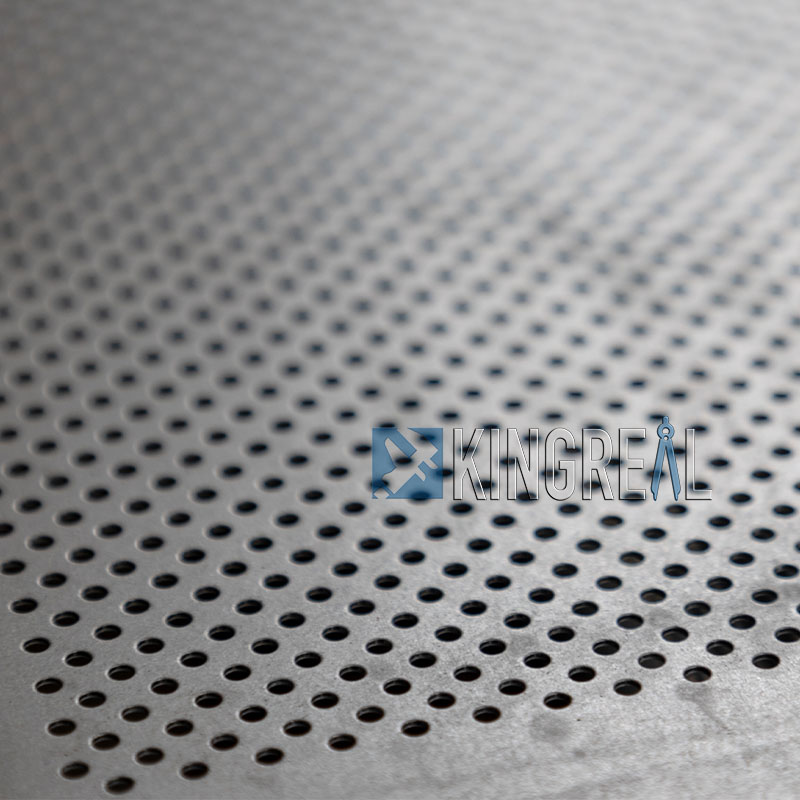

Metal sheet perforated machine is used to punch out various hole shapes and diameters on the surface of different metal materials (such as iron, stainless steel, copper, aluminum, galvanized, etc.) and accurately cut according to the length preset by the customer to produce high-quality perforated metal sheets.

The emergence of sheet metal perforation machines has not only improved the production efficiency of various industries, but also ensured product quality.

With the increase in market demand, more and more manufacturers are curious about the price of metal sheet perforated machines.

This article will deeply analyze the price components of sheet metal perforation machines to help potential customers make metal sheet perforated machine purchasing decisions.

1. Basic Concepts of Sheet Metal Perforation Machine

Definition of metal sheet perforated machine

Sheet metal perforation machine is a device specially used for processing metal sheets, usually suitable for metal materials with a thickness of 0.4-1.0mm. It can punch out a variety of hole shapes, including round holes, oblong holes, square holes, triangular holes, diamond holes, hexagonal holes and cross holes.

Application of metal sheet perforated machine

-Architectural decoration materials

Metal perforated sheets are often used for internal and external decoration of buildings. For example, in apartment balconies, fences, walls, and solar panel structures, perforated metal sheets not only provide beautiful visual effects, but also enable ventilation and lighting.

In interior decoration, perforated metal sheets are used as ceilings, wall panels, partitions, and lighting fixtures.

-Automotive parts

In the field of automobile manufacturing, perforated metal sheets are widely used in internal parts such as air filters, oil filters, exhaust mufflers, and speaker covers.

Through perforated metal sheets, cars can achieve functions such as heat dissipation, lightweight, dustproof and soundproof, and improve overall performance and comfort.

-Home appliance parts

Perforated metal sheets are also used in many home appliances. For example, filters for ventilation fans, stove grilles, and radiator grilles.

The design of perforated metal sheets can effectively prevent dust and garbage from adhering to the surface of the equipment, improving the efficiency and durability of the equipment.

2. Factors Affecting the Cost of Sheet Metal Perforation Machines

2.1 Customization of metal sheet perforated machines

The sheet metal perforation machines provided by KINGREAL CEILING MACHINERY are all customized and can be adjusted according to the specific needs of customers.

For example, customers can choose different hole types, material widths, material types, and material thicknesses. This customized feature makes the price of each metal sheet perforated machine different.

Customized sheet metal perforation machines can fully match the production needs of customers and help efficient and high-quality production.

2.2 Technical parameters of metal sheet perforated machine

Technical specifications such as punching speed and accuracy will significantly affect the price of the sheet metal perforation machine.

Metal sheet perforated machines are usually divided into three types on the market: manual, semi-automatic, and fully automatic. The different degrees of automation directly affect production efficiency and cost.

The most common influencing factor is the different tonnage of punching machines in the sheet metal perforation machine.

KINGREAL CEILING MACHINERY provides punching machines with various tonnages such as 120 tons, 125 tons, 160 tons, and 200 tons. These tonnage options are closely related to the hole type, material width, material type and thickness, and the production speed required by customers.

Generally, large width and large thickness holes require larger tonnage punching machines to ensure the accuracy and efficiency of processing.

2.3 Additional configurations of the metal sheet perforated machine

In order to improve the production efficiency of the sheet metal perforation machine, KINGREAL CEILING MACHINERY can equip the metal sheet perforated machine with a variety of intelligent configurations.

For instance, the feeding trolley can automatically move the coils, therefore lowering the necessity of manual handling; the metal sheet cleaning machine can clean the oil on the surface of the perforated plate, therefore improving the production process's efficiency.

These further settings will raise the initial expenditure, but in the long run they can greatly boost production efficiency and lower labor expenses.

3. Considerations When Purchasing a Sheet Metal Perforation Machine

Demand assessment: Define your own manufacturing requirements, including the necessary hole type, material type, and speed of production.

Supplier selection: Customers should weigh after-sales assistance and technical support as well as the quality of metal sheet perforated machine.

After-sales service: KINGREAL CEILING MACHINERY provides customers with after-sales services including machine installation, operation guidance, troubleshooting and machine maintenance, ensuring that customers have no worries during use.

4. Advantages of KINGREAL CEILING MACHINERY Sheet Metal Perforation Machine

4.1 Ability to provide customized solutions KINGREAL CEILING MACHINERY can provide personalized metal sheet perforated machine solutions based on the specific needs of customers, ensuring that each machine can meet the production requirements of customers.

4.2 Advanced Technology and Efficient Productivity With superior production capacity and cutting-edge technology, KINGREAL CEILING MACHINERY sheet metal perforation machines can greatly increase output efficiency while maintaining quality.

4.3 High-quality customer service and technical support Focused on customer experience, KINGREAL CEILING MACHINERY offers thorough technical assistance and after-sales care to guarantee that consumers may get prompt help and direction when using the metal sheet perforated machine. |  |

Many variables—including the machine's customization, technical specifications, and other configurations—affect the sheet metal perforation machine's cost structure.

Knowing these elements will enable consumers to choose sensibly when buying.

To satisfy various consumer needs, KINGREAL CEILING MACHINERY is dedicated to supplying premium metal sheet perforated machine.

Please call KINGREAL CEILING MACHINERY if you have any queries about the sheet metal perforation machine or need further information; we will provide you with custom solutions.

Get the latest price? We'll respond as soon as possible(within 12 hours)