Metal Perforated Making Machine for Baguette Pan

2026-01-30 17:00

Metal perforated making machines are typically used for multiple process steps on metal materials such as galvanized steel sheets with a thickness of 0.4-2.0 mm, including uncoiling, leveling, punching, cutting, and recoiling. Through these processes, the metal perforated machine can punch various holes on the material surface, thus producing high-quality perforated materials. Today, metal perforated making machines are widely used in many industries, one of which is the manufacturing of baguette pans. This article will explore the importance of metal perforated machines in baguette pan production and their working principles.

What are Baguette Pans?

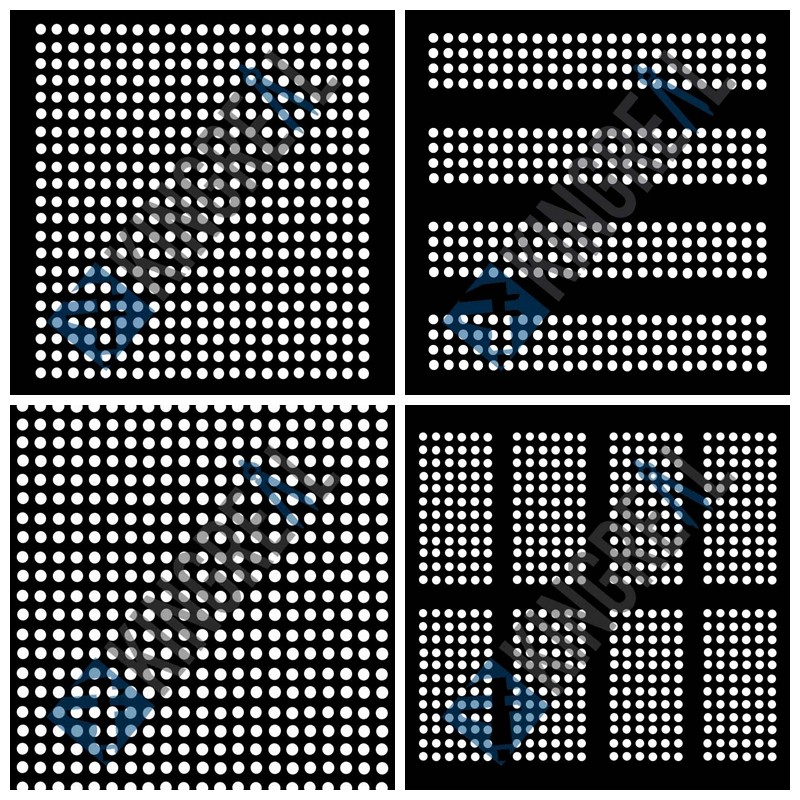

Baguette pans are specialized baking tools, usually made of perforated metal, characterized by long, narrow grooves (molds) used to support and shape baguettes during baking. The perforated design of the baguette pan not only allows for even air circulation but also effectively promotes heat circulation between the flame and the dough, helping the bread develop the ideal crispy crust and soft interior, allowing home bakers to easily bake baguettes of professional bakery quality. Baguette pans are not only suitable for baguettes but can also be used to bake other types of bread, such as French bread, Italian bread, and submarine sandwiches, making them a popular choice for family breakfasts or afternoon tea.

Why are Metal Perforated Machines Crucial for Manufacturing of Baguette Pans?

Even airflow is crucial in the baking process of baguettes. Metal perforated making machines, by creating uniform holes on the metal surface, promote the circulation of hot air, thus shortening baking time and improving baking efficiency. The perforated design helps in moisture release and allows for even heat circulation, which is essential for making baguettes with a crispy crust. Therefore, metal perforated machines are particularly important; only through precise punching can high-quality baguette pans that meet baking requirements be produced.

|  |  |

●Customized Manufacturing KINGREAL CEILING MACHINERY metal perforated making machines not only have standardized functions but also support customer customization. Based on each customer's project requirements, the metal perforated machine can be designed with different hole patterns and diameters. Baguette pans typically require round holes, but the specific hole diameter and arrangement will vary depending on different product requirements. KINGREAL CEILING MACHINERY professional team will meticulously analyze each customer's drawings to design and manufacture customized punching dies, ensuring that each metal perforated making machine meets diverse production needs. | ●Flexibility and Efficiency In terms of material handling capabilities, KINGREAL CEILING MACHINERY metal perforated machines can process materials with widths ranging from 100 to 1300mm and thicknesses from 0.4 to 2.0mm. This flexibility and wide applicability allow KINGREAL CEILING MACHINERY metal perforated making machine to meet the diverse needs of different customers. Meanwhile, KINGREAL CEILING MACHINERY metal perforated machines can operate at speeds up to 220SPM, greatly satisfying customers' demands for high production capacity. Furthermore, by changing the dies, the metal perforated making machine can flexibly produce different hole shapes or diameters, further improving production efficiency. | ●High Precision and Stability KINGREAL CEILING MACHINERY metal perforated machines are equipped with high-quality punching dies, ensuring that the punched materials produced have high precision and consistency. Every hole shape and diameter meets strict quality standards, and the surface is smooth and burr-free. This high-precision production standard not only enhances the market competitiveness of baguette pans but also improves the user experience. |

Baguette Pan Market and Future of Metal Perforated Machine

The baguette pan market is fundamental to the kitchenware industry, primarily meeting the diverse product needs of both household and commercial markets. With the rise of more cooking enthusiasts and home bakers, the demand for baguette pans is gradually increasing, which in turn drives the demand for high-quality metal perforated making machines. The application of metal perforated machines in baguette pan production allows bakers to efficiently produce products that meet mass market demands.

With continuous technological advancements and market changes, the future development trends of metal perforated machines will mainly focus on the following aspects:

●Intelligentization: Future metal perforated making machines will integrate more intelligent technologies to improve the automation level of the production process and achieve more efficient production.

●Energy Saving and Environmental Protection: In terms of production processes, metal perforated making machines will also move towards energy saving and environmental protection, using more environmentally friendly materials and processes to reduce energy consumption.

●Product Customization: With market diversification, customers' personalized needs for products will become increasingly prominent, which requires metal perforated making machines to provide flexible adjustment solutions in their design. KINGREAL CEILING MACHINERY is a professional manufacturer and supplier of metal perforated machines, and has successfully manufactured highly efficient metal perforated making machines for baguette pan projects. These metal perforated making machines have resulted in baguette pans that have received widespread acclaim in the market, while also significantly improving production efficiency and product quality. Customer feedback indicates that they are very satisfied with the efficiency and stability of KINGREAL CEILING MACHINERY metal perforated making machines.

For more information about metal perforated machines, or to learn about their applications in other fields, please contact KINGREAL CEILING MACHINERY directly – a professional company specializing in the manufacturing and service of high-quality metal perforated making machines.

Get the latest price? We'll respond as soon as possible(within 12 hours)