Application of Wall Siding Panel Making Machine

2026-01-24 17:00

Wall siding panel making machines are specifically designed for the continuous production of various wall panels. With the continuous development of the construction industry, wall siding panel forming machines are increasingly widely used in residential, commercial, industrial, and public infrastructure projects. These wall siding panel making machines can process flat rolls (such as steel and aluminum) into decorative and functional wall panels, possessing multiple properties such as heat insulation, waterproofing, and aesthetics, thereby significantly improving construction efficiency and meeting the diverse needs of modern architecture.

▴Working Principle of Wall Siding Panel Making Machines

Wall siding panel forming machines process raw materials through high-precision rolling. This process not only ensures the consistency of wall panel thickness and length but also guarantees structural strength and surface quality. The wall siding panel making machines are typically equipped with advanced control systems, making the entire production process efficient and automated. Furthermore, wall siding panel forming machines can flexibly switch molds to produce wall panels of different specifications according to different design requirements.

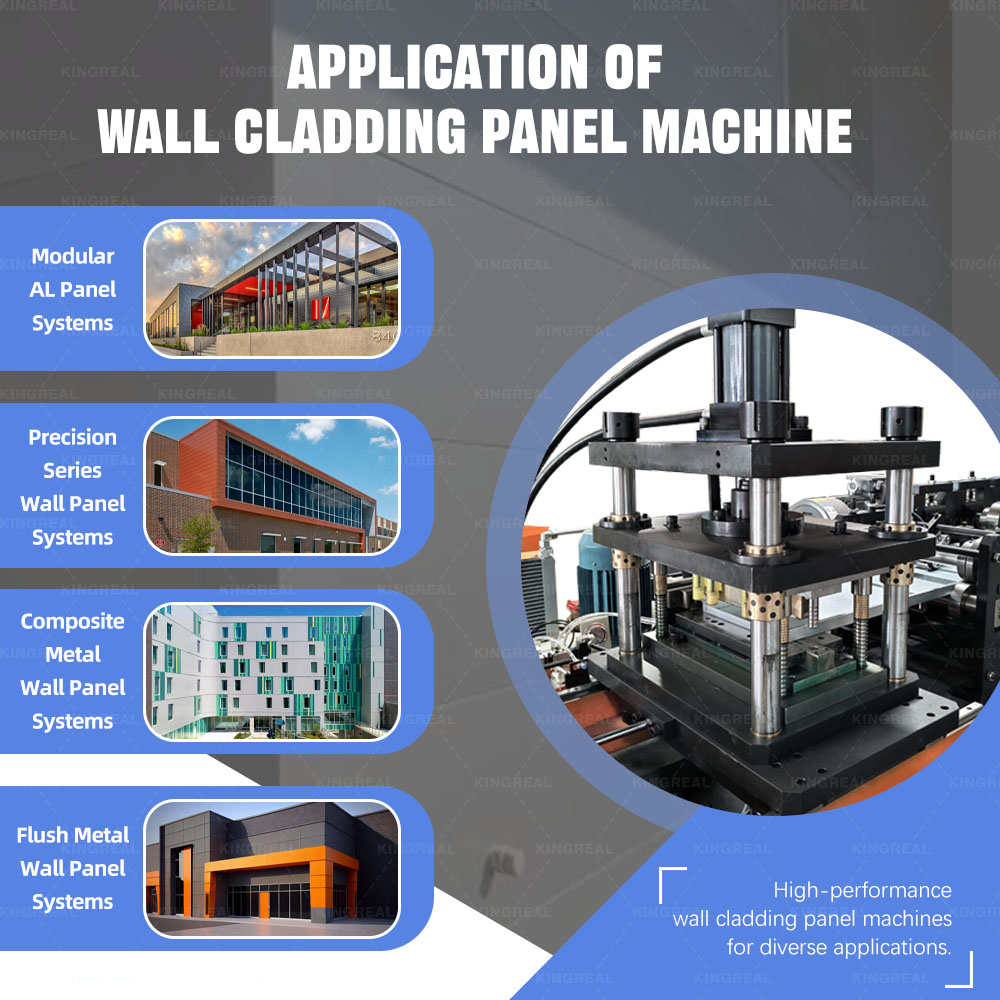

▴Applications of Various Wall Panel Systems

Wall siding panel making machines can produce various types of wall panel systems. Below, we will introduce several major wall panel systems and their application areas.

1. Modular aluminum panel system

Modular aluminum panel wall panels have wide applicability. Metal cladding systems produced using wall siding panel forming machines offer a wealth of design inspiration. Customers can freely choose wall panels of different sizes, thicknesses, and colors to create unique facades. The wall panels can be designed with various techniques such as staggered joints, stacking, or mosaic patterns, providing exceptional flexibility.

Furthermore, the wall panels of modular aluminum panel systems can be perforated to create text or logos in specific patterns. This wall panel system requires no caulking or sealant, achieving a clean and aesthetically pleasing installation. Combined with an economical price, users can achieve the appearance of composite panels, while the modular aluminum panels are compatible with various substrates such as plywood, insulation materials, and purlins, offering greater design freedom.

2. Precision series wall panel systems

The Precision series wall panel systems combine striking visual appeal with convenient and economical installation. Metal sheets produced by wall siding panel making machines offer a variety of profiles and rib patterns for users to choose from. Each profile can be equipped with either clip-on or snap-on panels to accommodate thermal expansion and contraction. This series of wall panels offers a striking visual impact in architectural aesthetics, making it suitable for public buildings and commercial office buildings.

3. Composite metal wall panel systems

Composite metal wall panel systems provide superior performance and aesthetic appeal for a variety of commercial metal wall panels, industrial metal cladding panels, or retail applications. Wall siding panel forming machines produce precision panels, ensuring tight tolerances and dimensional accuracy, making composite metal wall panels ideal for exterior finishing and protection applications.

4. Flush metal wall panel systems

Flush metal wall panel systems are designed for applications requiring a smooth finish for walls, cornices, and basements. Flush metal wall panels produced by wall siding panel making machines feature rounded interlocking edges and a concealed fastening system, enhancing overall flatness and aesthetics. Simultaneously, the panel design enhances the strength of steel or aluminum wall panels, making them ideal for demanding construction projects.

▴Advantages of Using a Wall Siding Panel Forming Machine

1. Integrated manufacturing: The wall siding panel making machine can produce high-load-bearing, heat-insulating, and sound-insulating wall panels of superior quality, meeting the high standards of modern architecture. The design and material selection of the wall panels ensure stability and durability in various climatic environments.

2. Precision machining: The wall siding panel forming machine employs CNC roll forming technology, ensuring tight joints and improving wind and water resistance. Simultaneously, the wall panel surface undergoes a special coating treatment, providing scratch resistance and guaranteeing the lifespan and appearance of the wall panels.

3. High-efficiency production: This wall siding panel forming machine boasts a production speed of up to 20m/min. Combined with advanced automatic cutting technology, it significantly improves production efficiency, shortens project cycles, and meets the rapidly evolving needs of the construction industry.

4. Flexible conversion: The design of the wall siding panel making machine allows users to quickly convert between different types of wall panels by changing molds. It supports the processing of PPGI, steel, and other materials, showcasing the wall siding panel making machine's flexibility and adaptability.

▴Application of Wall Siding Panel

▴Market Prospects for Wall Siding Panel Making Machines

With the continuous development of the global construction industry, the demand for high-quality, low-cost, and high-efficiency wall panels is increasing dramatically. Wall panels produced by wall siding panel forming machines, with their combination of decorative and practical features, are capturing a larger market share. Especially with the growing trends of green building and sustainable development, the high-efficiency and energy-saving solutions provided by wall siding panel making machines will undoubtedly become a crucial tool in the construction industry.

Wall siding panel making machines not only excel in technology, but their innovative design concepts are also leading the industry's development direction. In the future, wall siding panel making machines are expected to make breakthroughs in intelligent manufacturing, digital control, and environmentally friendly materials, driving the transformation and upgrading of the entire construction industry.

For more information on wall siding panel making machines, please contact KINGREAL CEILING MACHINERY!

Get the latest price? We'll respond as soon as possible(within 12 hours)