How to Produce Main and Cross T Using a Ceiling T Grid Machine?

2025-12-17 17:00

| With the rapid development of the modern construction and decoration industry, the importance of suspended ceiling systems in interior design is becoming increasingly prominent. In this context, the main t and cross t produced by ceiling t grid machines, as core components of suspended ceiling systems, are gradually receiving widespread attention and demand. To meet the dual demand for both main t and cross t, using a single ceiling t grid roll forming machine to flexibly produce both types of finished products is becoming increasingly feasible. This article will explore this process in detail. |  |

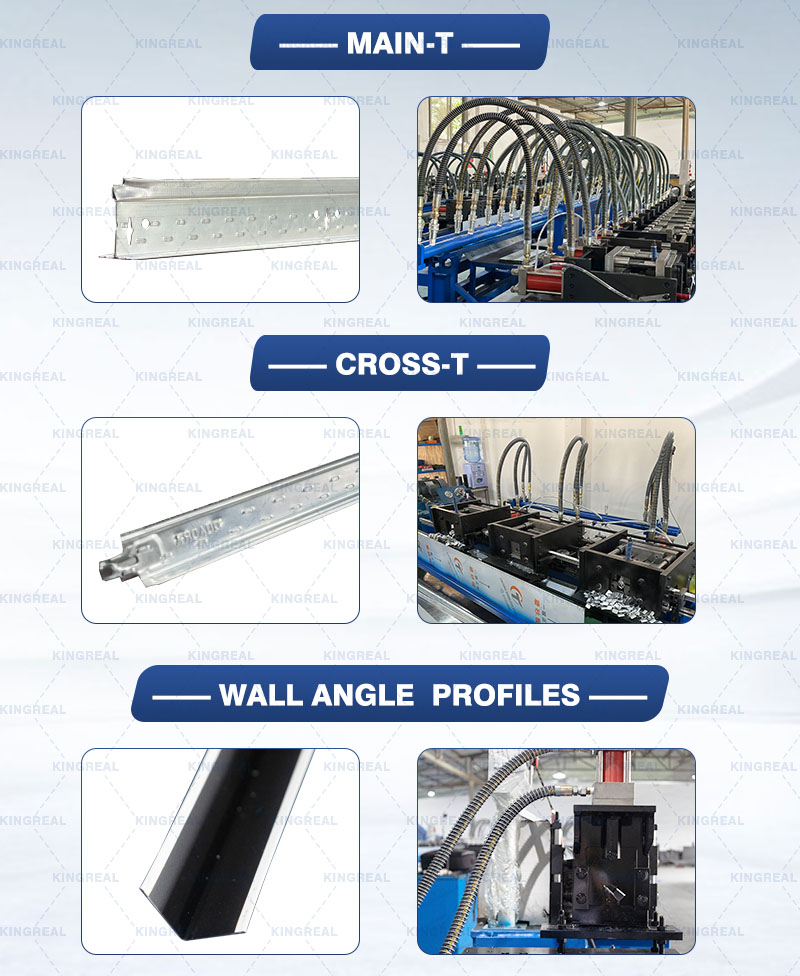

1. Introduction to Main T and Cross T

Before understanding the production capabilities of a ceiling t grid machine, we need to clarify the functions and characteristics of main t and cross t.

1.1Main T The main T-bar is the primary load-bearing component in the ceiling grid structure, usually running the length of the entire room and supporting the weight of the entire ceiling system. The standard length of the main T-bar is 3.6 meters. Because it bears the main weight and load, it requires strong load-bearing capacity and stability.

1.2 Cross T The cross t is located between the main t and is mainly used to connect the main t, forming a fine ceiling grid structure. It usually comes in two specifications: 0.6 meters and 1.2 meters. The cross T not only helps to enhance the stability of the entire suspended ceiling but also helps to improve the room's acoustics. |  |

After understanding the basic characteristics of the main t and cross t, we can delve into how to achieve efficient production using a single ceiling t grid roll forming machine.

2. What are the Features of a Ceiling T Grid Machine?

2.1 Multi-functional ceiling t grid roll forming machine

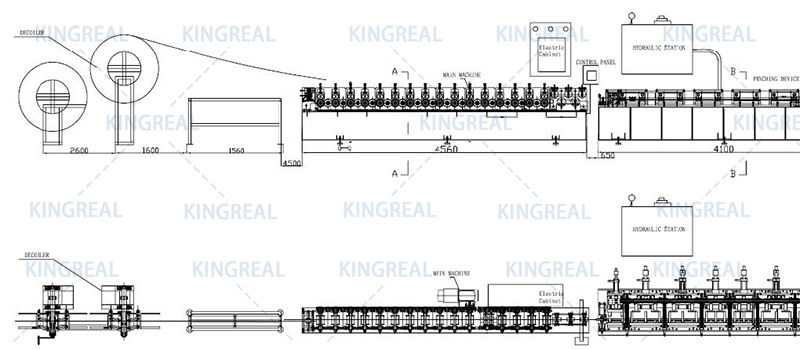

Modern ceiling t grid machines have the great advantage of being "multi-functional." Through simple adjustments, the ceiling t grid roll forming machine can easily switch between producing main t and cross t. When producing main t, the 18th and 19th rolling mill stands of the ceiling t grid machine form the core groove. By simply adjusting the gap between the upper and lower rollers, so that the metal strip passes through the rolling mill stands without a groove, the production of flat ceiling t grid can be achieved.

2.2 Efficient production for ceiling t grid machine

Using a ceiling t grid roll forming machine, the production length of the main t is 3.6 meters, with one piece produced at a time; while the production length of the cross t can be 0.6 meters or 1.2 meters. For the 0.6-meter specification, two pieces can be produced at a time, while for the 1.2-meter specification, one piece can be produced at a time. This production efficiency not only improves the production turnover rate but also greatly reduces the defect rate.

2.3 High speed operation for ceiling t grid machine

This ceiling t grid roll forming machine boasts a main t forming speed of up to 35 meters per minute, while the cross t speed reaches 25 meters per minute. This high-speed operation significantly improves production efficiency, enabling manufacturers to complete the production of a large number of suspended ceiling components in a short time.

2.4 Integrated process for ceiling t grid machine

The ceiling t grid roll forming machine integrates punching and cutting functions. Both punching and cutting can be completed in a single operation, ensuring accuracy and consistency in dimensions during the production process, while reducing manual intervention and improving the level of automation.

2.5 Flexibility and stability for ceiling t grid machine

The ceiling t grid roll forming machine adopts a modular design. By adjusting the number and pressure of the rolling mill stands, it can easily produce products of different specifications, ensuring flexibility and stability in the production process to meet diverse market demands.

3. What are Innovative Aspects of Ceiling T Grid Machine Design?

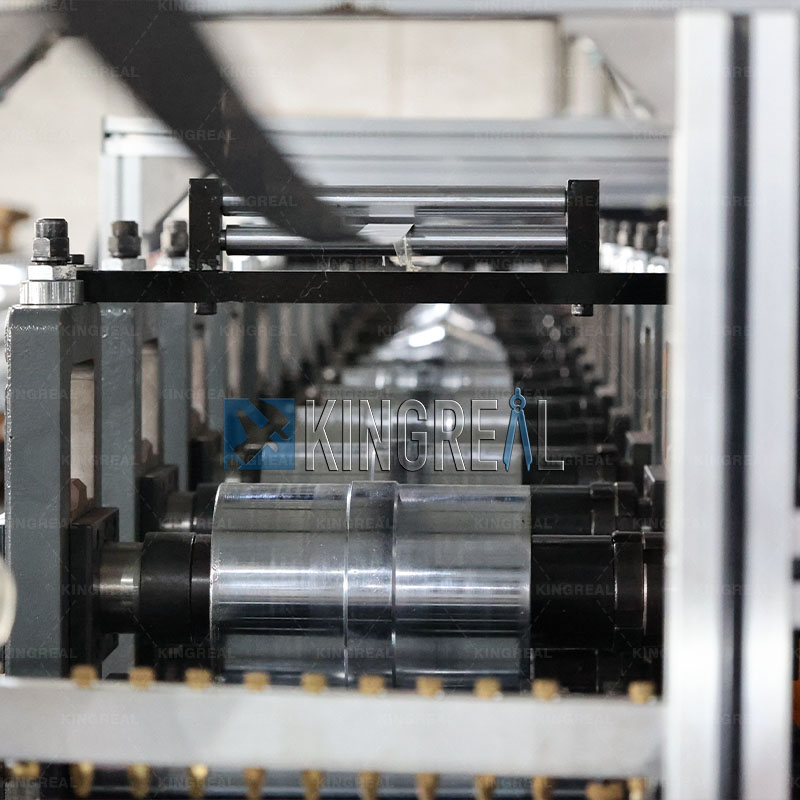

3.1 Rolling mill stand design for ceiling t grid machine

This ceiling t grid roll forming machine is equipped with 21 rolling mill stands, especially stands 18 and 19. These specially designed rolling mill stands allow for flexible adjustment of the gap to accommodate different specifications of ceiling t bar. This design makes the ceiling t grid roll forming machine's process more flexible and able to quickly respond to market changes.

3.2 Precision control for ceiling t grid machine

The ceiling t grid roll forming machine uses a precise control system, ensuring that every production step, such as punching, cutting, and forming, operates with high precision to guarantee the quality of the final product. In addition, the user-friendly control interface reduces operator training costs.

3.3 Environmentally friendly and efficient for ceiling t grid machine

Nowadays, environmental protection has become an important consideration in the production process. The ceiling t grid roll forming machine is designed with full consideration of resource utilization, minimizing material waste during the production process to achieve green manufacturing.

4. How Does Ceiling T Grid Machine Work?

First, the necessary metal materials for production need to be prepared. Commonly used materials include galvanized steel sheets, etc. After cutting and adjustment, these materials can enter the next production stage. The operator needs to set the relevant parameters of the ceiling t grid roll forming machine according to the target product type, including the gap between the rolling mill stands and the production speed. These parameters will directly affect product quality and production efficiency. After setting the parameters, the ceiling t grid machine can be started for production. The ceiling t grid machine will automatically complete punching, cutting, and forming processes, with minimal manual intervention required throughout the entire process. After production is complete, the finished products must undergo quality inspection to ensure that the dimensions and other specifications of the main t and cross t meet the standards. This step is crucial for controlling production quality.

With the increasing demand for suspended ceiling systems, the market prospects for producing main t and cross t using a ceiling t grid roll forming machine are vast. The efficiency and versatility of the ceiling t grid machine make it an indispensable piece of equipment in the construction industry.

Through this ceiling t grid roll forming machine, manufacturers can not only flexibly respond to market demands but also achieve efficient production and lower operating costs. Therefore, for any company that wants to gain a foothold in the suspended ceiling system market, investing in an efficient ceiling t grid machine is a very wise choice.

Ready to Own a Brand New Ceiling T Grid Machine?

Contact KINGREAL CEILING MACHINERY to get your customized ceiling t grid roll forming machine manufacturing solution.

Get the latest price? We'll respond as soon as possible(within 12 hours)