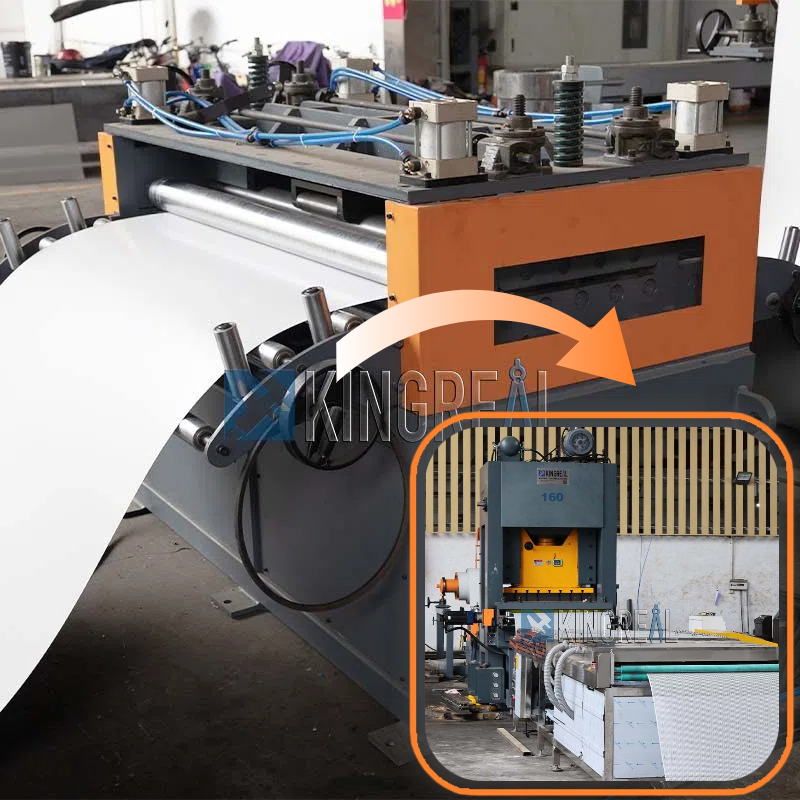

Sheet Metal Straightener for Metal Sheet Perforated Machine

2025-11-28 17:00

A sheet metal straightener is a mechanical device specifically designed for leveling the surface of metal materials. It applies uniform pressure to the metal material using leveling rollers, achieving a smooth surface. In metal sheet perforated machines, the metal plate straightening machine plays a crucial role, ensuring the metal coil is in a perfect state before punching. Utilizing stepper motors and advanced control systems, the sheet metal straightener not only precisely controls the leveling amount but also adjusts the leveling speed, adapting to metal materials with thicknesses ranging from 0.1 to 10mm. This allows the metal plate straightening machine to efficiently meet the demands of the modern metal processing industry.

This article by KINGREAL CEILING MACHINERY will delve into the importance of the sheet metal straightener in metal sheet perforated machines, working principle of sheet metal straightener, main components of metal plate straightening machine, and maintenance methods of sheet metal straightener.

Importance of Sheet Metal Straightener in Metal Sheet Perforated Machine

Metal plate straightening machine in metal sheet perforated machines are typically located after the decoiler and before the metal punching machine. Their core function is to level the surface of the metal coil to be processed. The efficient operation of the sheet metal straightener significantly improves the accuracy of punching, thereby affecting the quality of the final product. A metal plate straightening machine eliminates bending and deformation of metal coils during transportation and storage. Without leveling, irregular shapes in the coil can lead to reduced punching accuracy and even rework during high-speed punching. Especially in fine punching processes, good coil guidance is crucial for ensuring high stroke rates.

KINGREAL CEILING MACHINERY sheet metal straighteners for metal sheet perforated machine typically consist of four upper rollers and five lower rollers. This precision leveling design results in a more significant leveling effect. The more rollers, the better the surface leveling, meeting high production standards. KINGREAL CEILING MACHINERY can also customize metal plate straightening machines to meet higher customer requirements.

Working Principle of Sheet Metal Straightener

During the feeding process, the metal coil first passes through a guiding device, guiding it into the metal plate straightening machine. Then, through the alternating action of the leveling rollers, the material is evenly stressed, ultimately achieving the desired leveling effect. This process is extremely important because good leveling significantly improves the quality and efficiency of subsequent punching.

A metal plate straightening machine relies primarily on the pressure applied to the metal coil by the leveling rollers. As the metal material passes through the sheet metal straightener, the rollers gradually level the material through the applied pressure. The coordinated operation of the stepper motor and control system allows for precise adjustment of both the leveling amount and speed.

Main Components of Sheet Metal Straightener

The metal plate straightening machine has a relatively complex structure, mainly composed of the following key components:

- Transmission System: Responsible for transmitting power to all components of the sheet metal straightener, ensuring the smooth operation of the leveling rollers. A good transmission system improves leveling efficiency and reduces the failure rate.

- Leveling Rollers: This is the core component of the metal plate straightening machine, typically composed of multiple rollers to ensure even stress on the material. The multi-roller design provides better leveling results and reduces material bending.

- Control System: Modern sheet metal straighteners are equipped with advanced control systems that can monitor and adjust various parameters during the leveling process in real time, such as leveling speed and leveling amount, thereby ensuring high punching precision.

- Feeding and Discharging Device: This device is responsible for evenly feeding the metal coils to be leveled into the metal plate straightening machine and smoothly outputting the leveled material. A well-designed feeding and discharging system improves production efficiency and reduces material waste.

Maintenance of Sheet Metal Straightener

Regular maintenance and care of the metal plate straightening machine are crucial for extending its lifespan and improving production efficiency. Here are some maintenance tips:

- Lubrication System Maintenance: After prolonged operation, the lubrication system may require attention. Regularly check and add lubricating oil or rust-preventive oil to all components to ensure smooth operation. Parts such as gears and sprockets are prone to failure and require regular maintenance.

- Leveling Roller Cleaning: The sheet metal straightener accumulates dust during production, making it essential to keep the leveling rollers clean. Using a long cloth sprayed with rust-preventive oil for manual cleaning effectively removes dirt from the rollers, ensuring optimal leveling results.

- Safe Operation: Special attention must be paid to safety during the cleaning and maintenance of the metal plate straightening machine. Ensure operation by qualified personnel to avoid accidents.

KINGREAL CEILING MACHINERY supports the purchase of sheet metal straighteners independently, suitable for various fields or used in conjunction with other machines. They also provide complete metal sheet perforated machine solutions. KINGREAL CEILING MACHINERY designs the parameters and performance of metal plate straightening machines according to the specific needs of customers, ensuring that every customer receives the most suitable leveling solution. If you have special requirements for leveling accuracy, please contact KINGREAL CEILING MACHINERY!

Get the latest price? We'll respond as soon as possible(within 12 hours)