Sheet Metal Flattening Machine for Different Materials

2025-11-26 17:00

A sheet metal flattening machine is a specialized device for straightening various materials such as metal profiles, metal bars, metal pipes, and metal wires. It transforms warped and deformed metal materials into perfectly flat surfaces, preparing them for subsequent production. From automotive panels to aerospace components, the pursuit of absolute flatness has driven the rapid development of metal sheet leveling machines. This article will delve into the working principle of sheet metal flattening machines, the types of metal sheet leveling machines suitable for different materials, and their applications and significance in modern industry.

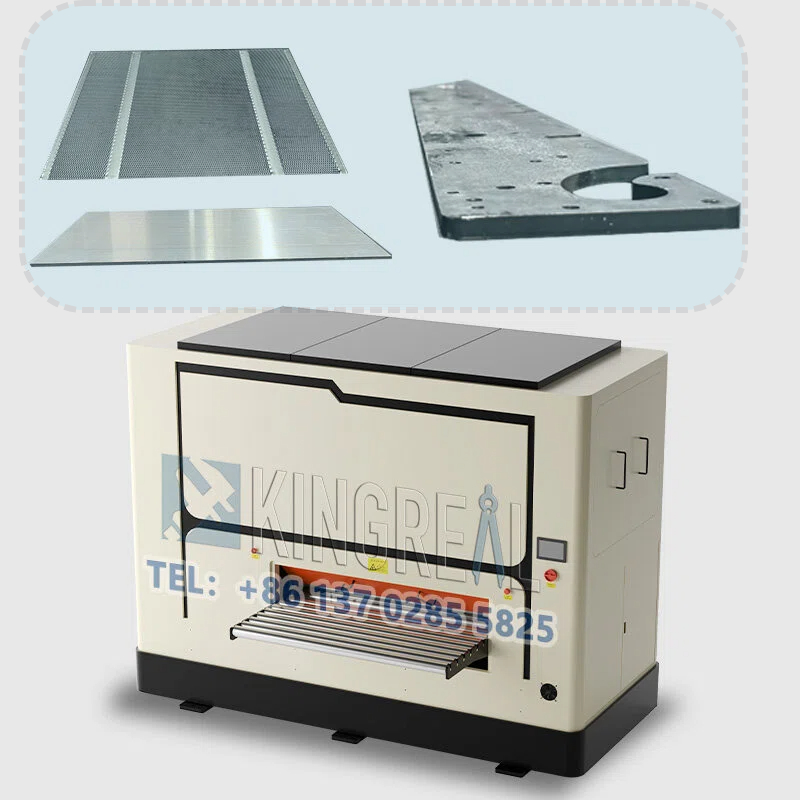

Introduction to Sheet Metal Flattening Machine

The working principle of a metal sheet leveling machine is relatively simple yet extremely efficient. When the material to be leveled is fed into the sheet metal flattening machine, the equipment applies a certain pressure to the material through rollers. During this process, the metal material undergoes repeated bending and stretching. The surface of the material is subjected to tensile stress, while the core is subjected to compressive stress. When the applied stress exceeds the yield strength of the material, the material will undergo plastic deformation, achieving the desired flatness. A screed typically consists of multiple sets of rollers. As the material passes through each set of rollers, the applied pressure gradually decreases, resulting in smaller and more precise bending amplitudes with each pass. Ultimately, this method effectively eliminates internal stress, ensuring a smooth material surface.

The key components of a metal sheet leveling machine include the work rollers that come into direct contact with the metal, support rollers that support the work rollers, a rigid frame that maintains precise alignment, a drive system that drives the rollers, and a control system that manages operating parameters. These components work together to ensure the screed maintains high efficiency and stability even under high loads and continuous operation.

Metal Sheet Leveling Machine Solutions for Different Materials

The wide range of applications of sheet metal flattening machines allows them to handle various types of metal materials. When selecting a metal sheet leveling machine, the material to be screed must be clearly defined, as this directly affects design parameters such as roller diameter, spacing, number of roller sets, and processing speed. The following introduces several common screed solutions, which handle materials widely used in modern industry.

1) Metal sheet leveling machine for sheet metal

Sheet metal is one of the most widely used metal materials. KINGREAL CEILING MACHINERY sheet metal flattening machines can efficiently screed steel, aluminum, copper, and other metal materials. Whether in construction projects, electronic components, or aerospace, various industries have extremely high requirements for the flatness of sheet metal. With the help of a metal sheet leveling machine, uneven metal sheets can be quickly transformed into high-quality, flat materials suitable for subsequent processing. The application of sheet metal flattening machines allows for the widespread use of leveled metal sheets in fields such as construction and automotive, significantly improving the appearance and performance of products.

2) Metal sheet leveling machine for perforated sheets

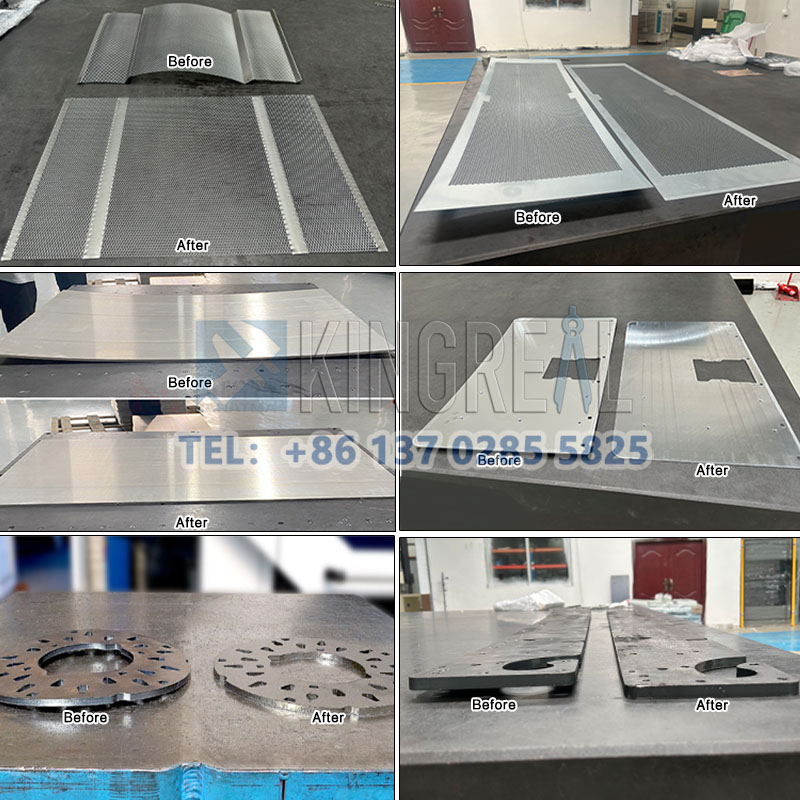

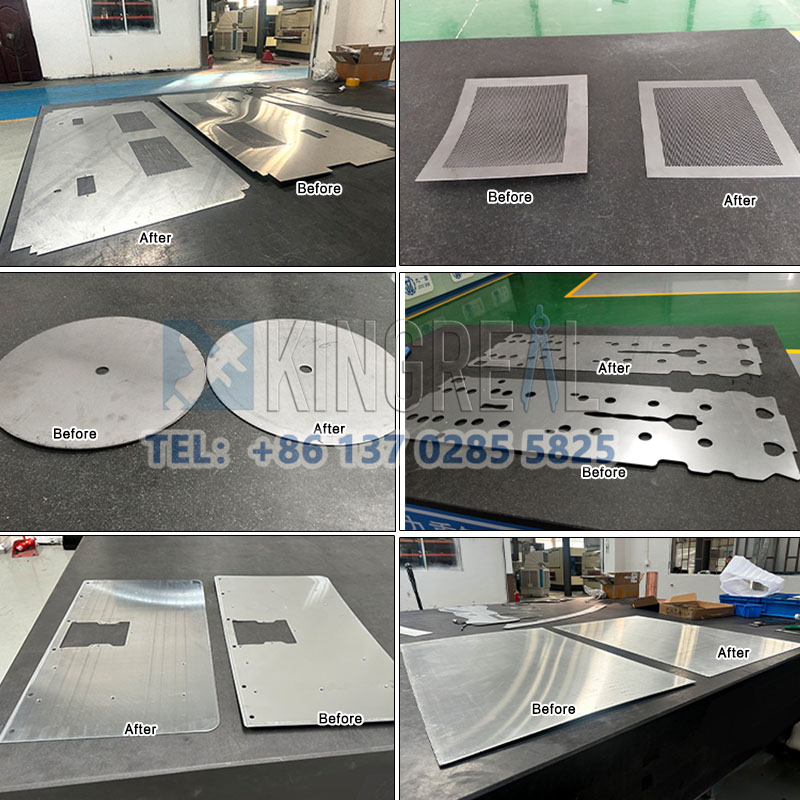

Perforated sheets are widely used in architectural design, offering both aesthetic appeal and high functionality. However, this precision-manufactured material requires extremely high flatness. The use of a sheet metal flattening machine ensures a perfectly flat surface on perforated metal sheets, avoiding the time and financial losses associated with manual rework.

Metal perforated sheets processed by a sheet metal flattening machine also have prominent applications in the electronics industry. For example, leveling ultra-thin mesh ensures uniform air permeability in filters; processing nickel mesh in batteries ensures precise electrode bonding. For micro-perforated components in medical devices, the use of a screed ensures their precision assembly and has become a cost-effective option for processing small, precision parts in small and medium-sized factories.

3) Metal sheet leveling machine for thick steel plates

For thick steel plates, the sheet metal flattening machine also demonstrates its superior capabilities. Metal sheet leveling machines can even handle steel plates thicker than 20mm, and their advanced functions bring numerous advantages. Firstly, these sheet metal flattening machines achieve exceptional flatness accuracy, typically within 0.5mm per meter, which is crucial for downstream processing and final product quality.

The application of automated control systems eliminates human error, ensuring consistency in results during mass production, thereby reducing material waste and improving cost-effectiveness. The metal sheet leveling machine's rapid adjustment function allows the production line to quickly switch between different sheet metal sizes, minimizing downtime. Furthermore, the sheet metal flattening machine's robust structure and high-quality components ensure long-term reliability, reduce maintenance requirements, and deliver excellent return on investment.

4) Metal sheet leveling machine for thin metal sheets

KINGREAL CEILING MACHINERY sheet metal flattening machines can efficiently process ultra-thin metal sheets as thin as 0.1mm, and are widely used in mobile phone accessory shielding, frames, antennas, hinges, and computer accessory optical drive brackets, etc. The leveling of ultra-thin metal materials is crucial to the functionality and appearance quality of the finished product. The application of metal sheet leveling machines in this field ensures the quality of precision hardware components for various digital products, meeting the market's demand for high-quality, high-precision products.

5) Metal sheet leveling machine for metal parts

Sheet metal flattening machines are not limited to specific types of metal materials; they can also process metal parts of various materials and shapes. Through metal sheet leveling machines, manufacturers can perform fine processing on metal parts, improving their flatness and appearance quality, which is crucial for the proper functioning of many machines and equipment.

Contact KINGREAL CEILING MACHINERY now for your customized sheet metal flattening machine manufacturing solutions!

Get the latest price? We'll respond as soon as possible(within 12 hours)