Automated Precision Progressive Die Mechanical Press Solutions

2025-11-25 17:00

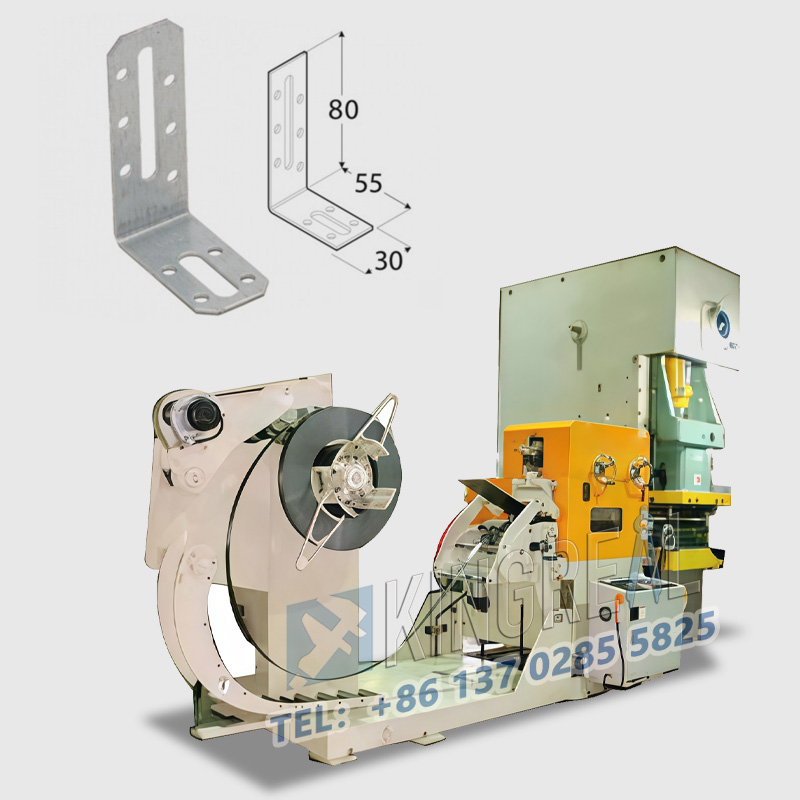

Progressive die mechanical presses are specifically designed for punching, blanking, embossing, stamping, bending, and flanging of metal materials. With constantly changing market demands and technological advancements, various automated precision progressive die stamping mechanical press solutions have emerged to meet the diverse project needs of customers. These solutions aim to optimize production processes, improve efficiency, and reduce costs, thereby better meeting the actual needs of the market and customers.

1.Basic Working Principle of Progressive Die Mechanical Press

Progressive die mechanical presses use an automatic feeding system to continuously push metal strips to various stamping stations, each performing a specific processing operation. In continuous die stamping, the last station acts as a cutting station, effectively separating the finished part from the supporting strip. Scrap and unused material are automatically handled during this process, ensuring smooth production.

1.1 Automatic feeding system for progressive die mechanical press

The automatic feeding system is a core component of progressive die stamping mechanical presses. This system can operate at high speeds, effectively reducing downtime and significantly shortening the production cycle.

By precisely controlling the feeding speed and position of the metal material, each station can complete processing operation within the optimal time-frame, thus optimizing the entire production process.

1.2 Die operation

In each stamping cycle of the progressive die mechanical press, the upper die moves up and down periodically, stamping the material as it passes through. After each stamping, the metal material moves to the next station for further processing. During this process, a quality assurance program ensures the alignment accuracy between the metal strip and the die, down to one-thousandth of an inch. The guide design further enhances alignment reliability, ensuring the precision and consistency of the parts.

2. High-Efficiency Solutions for Progressive Die Mechanical Press

2.1 Increased production speed

The automatic feeding system enables progressive die mechanical presses to operate quickly and efficiently. The precise feeding system significantly increases production speed, greatly shortening the production cycle and meeting the growing market demand for faster production.

2.2 Reduced labor costs

Because progressive die stamping mechanical presses are generally equipped with advanced sensing systems, they can operate unattended, reducing reliance on manual labor. This feature not only reduces labor costs but also minimizes errors and potential safety hazards caused by manual operation.

2.3 Extended equipment uptime

Automatic feeding systems not only improve production efficiency but also support continuous operation of progressive die mechanical press for extended periods. This allows manufacturers to complete more production tasks in a shorter time, increasing output and profits.

2.4 Reduced scrap generation

Scrap generation is unavoidable in any manufacturing process. However, progressive die stamping mechanical presses minimize scrap generation through optimized die design. During the design phase, reasonable layout and stamping strategies reduce material waste and improve resource utilization.

2.5 Reduced part costs

All the advantages mentioned above ultimately lead to a significant reduction in the manufacturing cost of each part. Less scrap and higher production efficiency each contribute to lower overall costs.

2.6 Quick setup and changeover

Another significant advantage of progressive die mechanical presses is their relatively simple setup process. Compared to other stamping methods, progressive die stamping mechanical presses require only one setup, which greatly saves production preparation time and improves production flexibility.

2.7 Capability to manufacture complex geometries

Through precise die design, progressive die mechanical presses can manufacture parts with complex geometries with high precision. This allows manufacturers to meet more complex design requirements and enhance product competitiveness.

2.8 High repeatability and consistency

The dies of progressive die stamping mechanical presses are treated with a hard coating, providing wear resistance and stability, enabling mass production without performance degradation. High repeatability ensures consistent product quality throughout the production process, reducing defect rates.

3. Applications of Progressive Die Mechanical Press

3.1 Progressive die mechanical press for automotive manufacturing

In the automotive manufacturing industry, progressive die stamping mechanical presses are widely used in the manufacture of body parts. Due to the complexity and extremely high dimensional accuracy requirements of automotive parts, progressive die mechanical presses provide an ideal solution, efficiently producing high-quality automotive parts, reducing production costs, and increasing production speed.

3.2 Progressive die stamping mechanical press for electronics industry

Progressive die mechanical presses also play a crucial role in the production of electronic components. For producing small, precision components such as switches, connectors, and circuit board supports, advanced die technology effectively meets the demands of high repeatability.

3.3 Progressive die mechanical press for home appliance industry

The home appliance industry is also a significant application area for progressive die mechanical presses. In the assembly of large appliances such as washing machines and refrigerators, progressive die stamping mechanical presses are responsible for manufacturing the metal casing and internal frame. These components require good strength and precision, which progressive die mechanical presses can easily meet.

3.4 Progressive die mechanical press for metalworking industry

The metalworking industry is a traditional application area for progressive die mechanical presses. By stamping different materials (metals, plastics, etc.), various specifications of parts, such as supports, accessories, and frames, are produced to meet the diverse needs of the industry.

For more information about these progressive die stamping mechanical presses, please feel free to contact KINGREAL CEILING MACHINERY!

Get the latest price? We'll respond as soon as possible(within 12 hours)