Progressive Die Mechanical Press

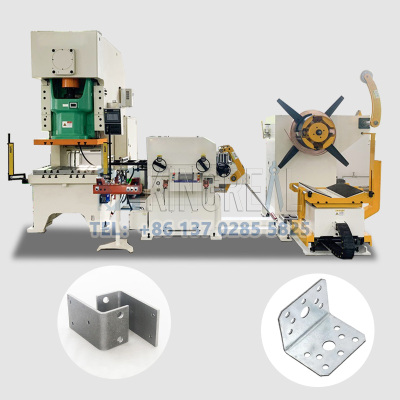

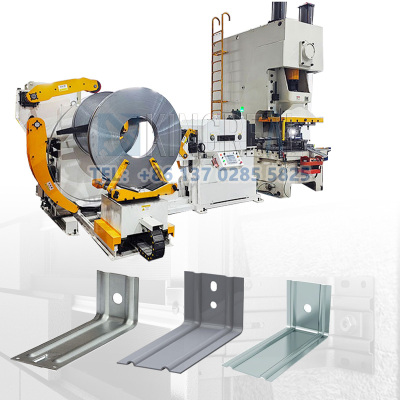

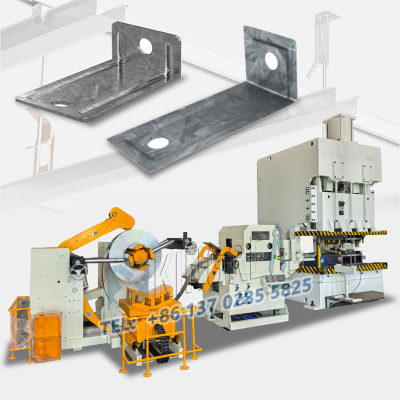

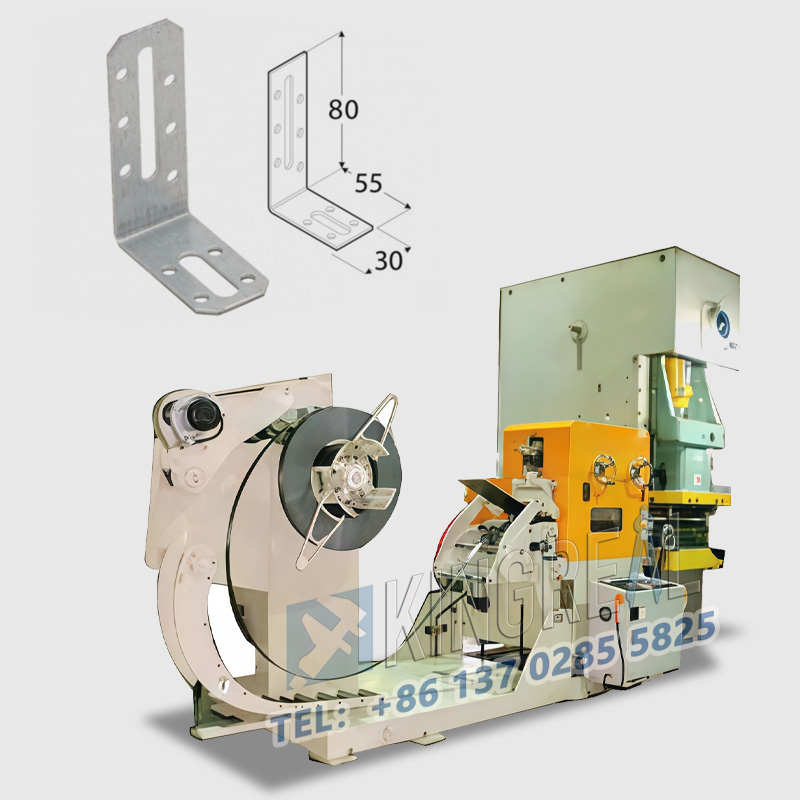

KINGREAL CEILING MACHINERY progressive die mechanical press can handle almost all metal materials, including aluminum, steel, and brass. This progressive die stamping press features high production speed and simple operation, enabling the rapid and precise production of uniform stamped parts.

- KINGREAL CEILING MACHINERY

Details

Video About Progressive Die Mechanical Press

Definition of Progressive Die Mechanical Press

KINGREAL CEILING MACHINERY progressive die mechanical press can handle almost all metal materials, including aluminum, steel, and brass. This progressive die stamping press features high production speed and simple operation, enabling the rapid and precise production of uniform stamped parts. Whether for large or small batch production, KINGREAL CEILING MACHINERY progressive die mechanical press can flexibly adapt and is often combined with other metal processing techniques (such as machining, assembly, and finishing) to achieve higher processing efficiency and better finished products.

KINGREAL CEILING MACHINERY progressive die stamping press uses an advanced automatic feeding system to progressively push metal material to each stamping station. Each station performs one or more operations during part production, with the final cutting station separating the finished part from the support strip. The support strip and the metal stamped off in previous processes become scrap. Each stroke cuts off and removes one or more finished parts from the die, ensuring production efficiency and product quality. |  |

Working Principle of Progressive Die Mechanical Press

At the start of production, the operator places the progressive die into the progressive die stamping press. As the progressive die stamping press cycles, the upper die moves upward, allowing the material to pass through the die. As the upper die moves downward, the die closes and performs the stamping operation. As the part moves to other stations within the progressive die mechanical press, KINGREAL CEILING MACHINERY progressive die stamping press quality assurance procedures ensure the alignment accuracy of the metal strip with the die is within a few thousandths of an inch. This high-precision alignment guarantees dimensional consistency for each part, improving product quality. Through this efficient working principle, KINGREAL CEILING MACHINERY progressive die mechanical press enables continuous, rapid production, adapting to diverse production needs. Whether the part is complex or simple, the progressive die stamping press handles it efficiently, ensuring that each part meets stringent quality standards. |  |

Parameter of Progressive Die Stamping Press

| Model | Unit | Model 1 | Model 2 | Model 3 | Model 4 | ||||

| Stroke Length | mm | 200 | 200 | 200 | 200 | ||||

| Stroke Per Minute | S.P.M | 20-50 | 20-50 | 20-50 | 20-50 | ||||

| Tonnage Rated Point | mm | 6 | 6 | 7 | 7 | ||||

| Max. Die Height | mm | 460 | 460 | 500 | 500 | ||||

| Slide Adjustment | mm | 100 | 110 | 120 | 120 | ||||

| Slide Area | mm | 1000*1000 | 1000*1000 | 1050*1000 | 1200*1000 | 1050*1000 | 1200*1000 | 1050*1000 | 1200*1000 |

| Bolster Area | mm | 1200*1200 | 1200*1200 | 1300*1300 | 1400*1300 | 1300*1300 | 1400*1300 | 1300*1300 | 1400*1300 |

| Side Opening Size | mm | 700*500 | 700*500 | 900*600 | 900*600 | ||||

| Dia Of Shank Hole | mm | 65 | 65 | 65 | 65 | ||||

| Main Motor | KW*P | 18.5*4 | 22*4 | 30*4 | 37*4 | ||||

| Max. Upper Die Weight | kg | 600 | 700 | 1000 | 1200 | ||||

| Left And Right Column Spacing | mm | 2400 | 2400 | 2700 | 2900 | ||||

| Required Air Pressure | kgf/cm² | 5~6 | |||||||

| Press Accuracy | CNS(JIS)1cIass | ||||||||

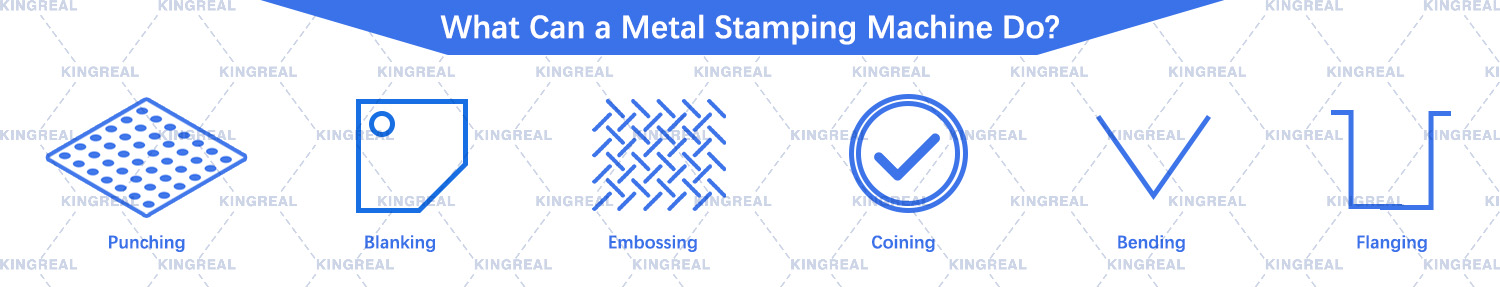

Functions of KINGREAL CEILING MACHINERY Progressive Die Mechanical Press

KINGREAL CEILING MACHINERY progressive die stamping press has multiple functions, capable of performing various processing steps on metal materials to produce a variety of specific finished effects. The main functions are as follows:

Punching: Punching is a commonly used technique in metal stamping, using a punch and die to cut, pierce, or shape metal work-pieces. The punch applies force, while the die forms the desired shape or opening. This process creates holes, slots, or other geometric features in metal materials and is widely used in various industries.

Blanking: The blanking process uses a die to cut sheet metal into the desired shape. A punch cuts along the contour of the desired shape, while the die provides support to prevent tearing. Blanking is a crucial step in achieving efficient production, ensuring accurate shape and dimensions of the product.

Embossing: The embossing process presses raised or recessed text, patterns, and designs onto a metal sheet, adding a unique appearance to the product. This process is widely used in the production of decorative parts to enhance the visual appeal of the product.

Coining: Coining is similar to embossing, but pressure is applied to both sides of the work-piece to create more intricate text, patterns, and designs. The material is subjected to significant pressure between the die and the punch, resulting in tight tolerances on the part's surface, ensuring high product quality.

Bending: The bending process applies force to a metal work-piece, causing it to bend at an angle relative to its original axis, forming a V-shape or U-shape. This process is essential for part design and forming, enabling it to meet specific application requirements.

Flanging: The flanging process bends the edge of the work-piece around a punch at a 90° angle to the sheet metal, creating an edge around each hole, enhancing the strength and rigidity of the part. This process is applied in many fields, ensuring the quality and durability of parts.

Features of Progressive Die Mechanical Press

High-strength welded body for progressive die stamping press

The KINGREAL CEILING MACHINERY progressive die stamping press features a high-strength welded body design, ensuring machine stability under high-load operating conditions. This layout not only enhances the progressive die mechanical press's general impact resistance and durability but also greatly lengthens its operational life.

Easy and safe operation for progressive die mechanical press

The progressive die stamping press is designed with ease of operation and safety in mind. The intuitive control panel allows operators to easily learn and quickly master the progressive die mechanical press's operation. Multiple safety protection mechanisms ensure that the risk of accidents is minimized during operation.

PLC control system for progressive die stamping press

The KINGREAL CEILING MACHINERY progressive die stamping press uses an improved PLC control system to provide automatic control of the manufacturing process. This system guarantees accurate control of several parameters by continuously monitoring the progressive die mechanical press's operating condition in real time, hence boosting product consistency and manufacturing efficiency.

High production speed for progressive die stamping press

The KINGREAL CEILING MACHINERY progressive die mechanical press is designed with production efficiency in mind, featuring a high production speed. The combination of an advanced automatic feeding system and efficient stamping technology allows the progressive die stamping press to complete a large number of stamping tasks in a short time, significantly shortening the production cycle.

High stamping precision for progressive die stamping press

KINGREAL CEILING MACHINERY progressive die mechanical press is renowned for high stamping precision, achieved through advanced die design and rigorous production process control. This ensures that the dimensions and shape of each part meet design requirements.

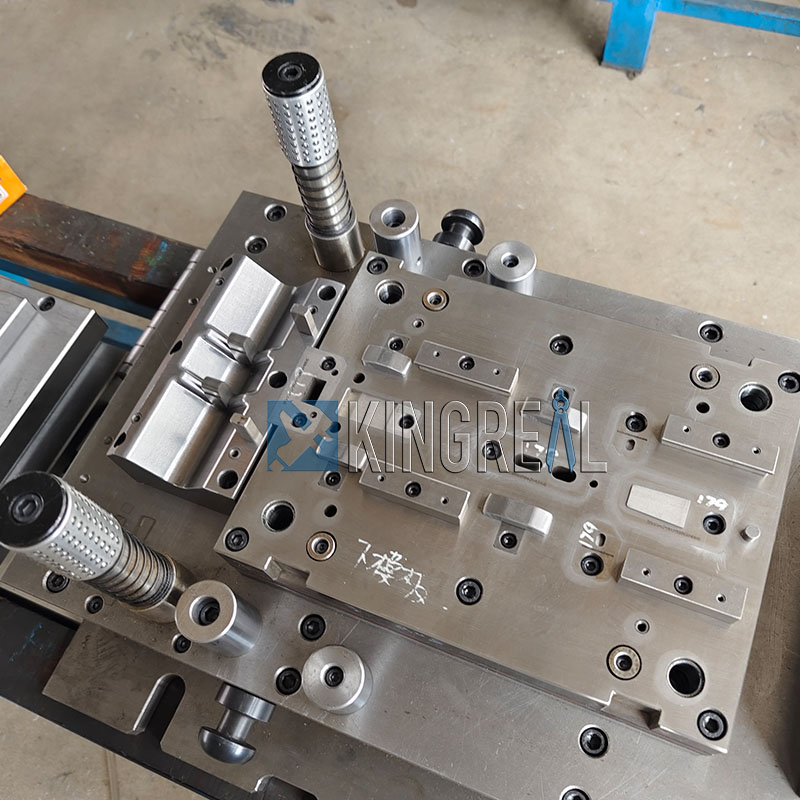

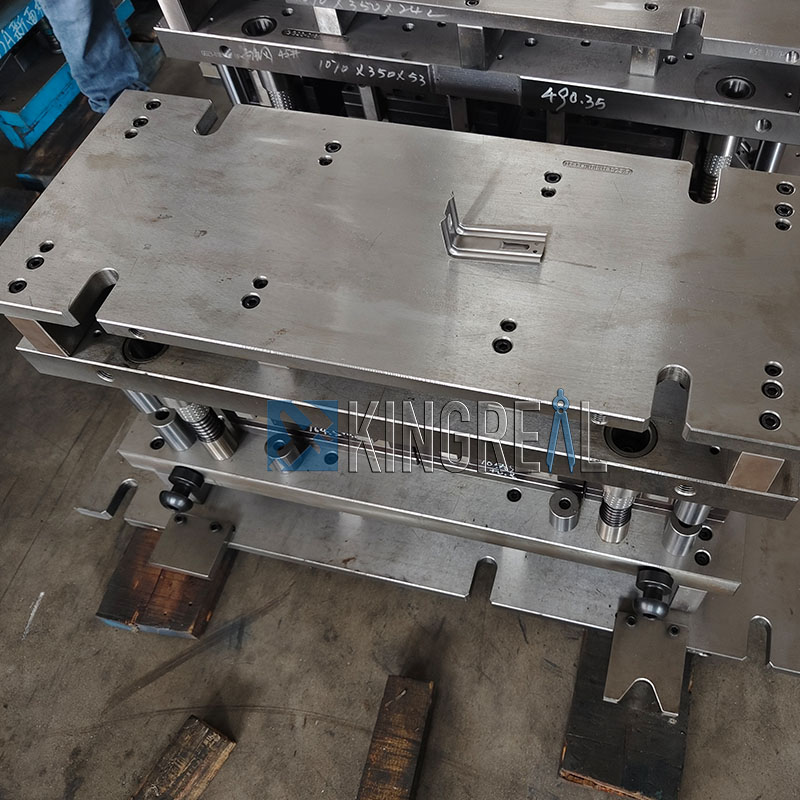

Introduction to Progressive Die

KINGREAL CEILING MACHINERY progressive die stamping presses are equipped with progressive dies designed for efficient and rapid production of multiple parts, particularly suitable for mass production of complex components. Sheet metal is cut and formed with unique dies in progressive die stamping. This process is made up of a number of separate stations each in charge of a particular job (such forming, punching, bending, or cutting metals). This simplified procedure lets enormous amounts of sophisticated components be made cost-effectively.

The progressive die design features multiple independently functional stations. Through an automatic feeding system, the material travels sequentially through each station in a single stamping stroke undergoing several operations like punching, bending, and cutting. This method guarantees stable quality and consistent product dimensions in addition to increasing manufacturing efficiency.

Precision Finished Product Display

Below are precision parts produced by KINGREAL CEILING MACHINERY progressive die mechanical press. This progressive die stamping press is specially designed for customers and is equipped with multiple functions such as embossing, punching, reinforcing rib pressing, and bending. Its efficient and stable operation provides customers with high-precision parts, perfectly suited for their actual projects.

FAQ About Progressive Die Mechanical Press

Can progressive die mechanical presses be customized?

Absolutely! KINGREAL CEILING MACHINERY progressive die mechanical presses can be customized according to customer requirements. KINGREAL CEILING MACHINERY engineers will tailor a progressive die mechanical press specifically for you, based on the needs of your particular production tasks.

What maintenance is required for progressive die mechanical presses?

Regular maintenance includes lubrication, replacement of worn parts, cleaning, and periodic inspections. The specific maintenance schedule and procedures will vary depending on the progressive die mechanical press model and usage.

What safety features are included in progressive die mechanical presses?

KINGREAL CEILING MACHINERY progressive die mechanical presses are equipped with various safety features, such as emergency stop buttons, light curtains, safety interlocks, and enclosed operating areas, to protect operators during machine operation. These systems automatically stop the machine when a dangerous situation is detected, thus reducing the likelihood of accidents.

What should I do if I don't know how to use certain functions after purchasing the progressive die mechanical press?

KINGREAL CEILING MACHINERY will send professional engineers to guide you on how to use the progressive die mechanical press perfectly. KINGREAL CEILING MACHINERY can provide offline technical support and operation videos.

What training is required to operate a progressive die mechanical press?

Operators typically require specialized training in the operation and maintenance of progressive die mechanical presses. If you purchase a machine from KINGREAL CEILING MACHINERY, KINGREAL CEILING MACHINERY will provide training for your operators before the equipment is delivered. We can provide on-site support, remote services, and training tailored to customer needs.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)