Metal Stamping Making Machine

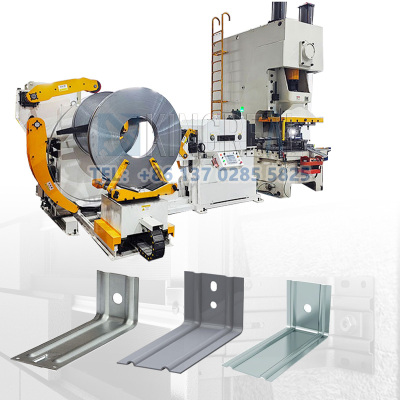

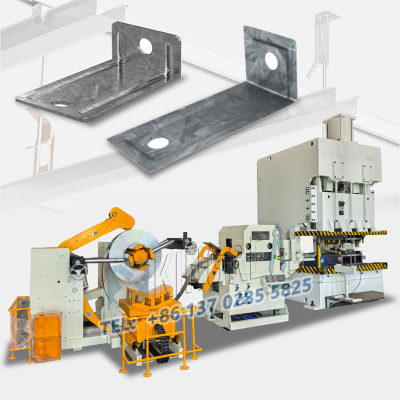

Metal stamping making machines, also known as sheet metal stamping presses, use matching molds to bend, plastically deform, and punch metal coils such as stainless steel, aluminum, iron, and copper to produce metal brackets of various shapes.

- KINGREAL CEILING MACHINERY

Details

Video About Sheet Metal Stamping Press

Definition of Metal Stamping Making Machine

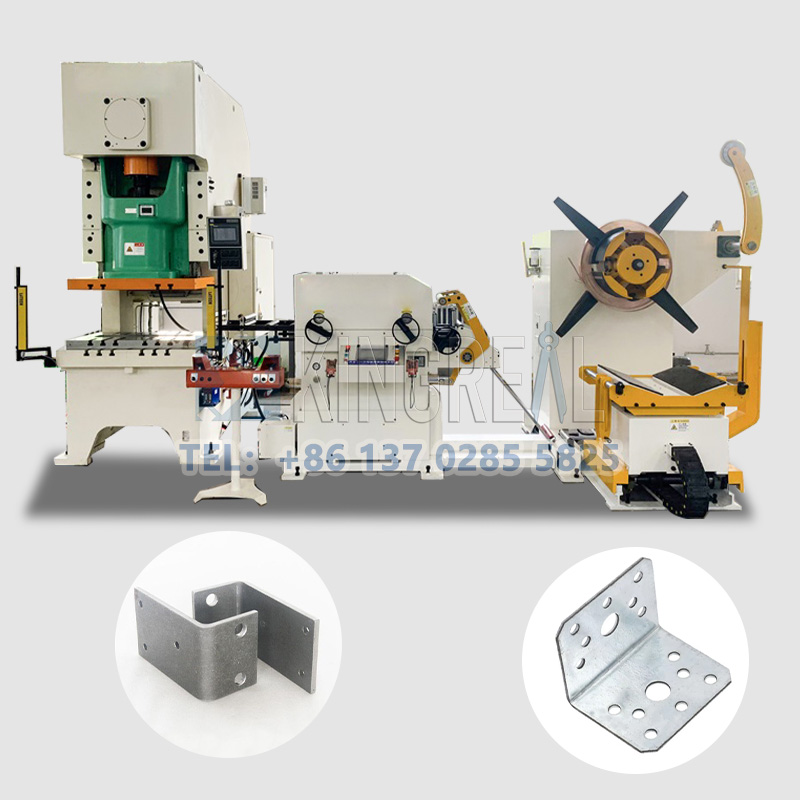

In modern manufacturing, metal stamping making machines are specialized in producing metal brackets. Consisting of an decoiler, straightener, and punching machine, these sheet metal stamping presses can bend, plastically deform, punch holes, and reinforce metal coils, ultimately producing a variety of metal connectors. These metal brackets are widely used in applications such as suspended ceiling systems, photovoltaic mounting systems, and pallet racking systems.

This sheet metal stamping press features fast production, stable operation, and high precision. Leveraging our extensive industry experience and advanced technology, KINGREAL CEILING MACHINERY can provide customized metal stamping making machine manufacturing solutions tailored to our customers' specific production needs.

Whether your requirements are simple or highly efficient, our engineers will provide expert assistance to help you select and implement the solution that best suits your application. If you have sheet metal stamping press needs, please feel free to contact KINGREAL CEILING MACHINERY. Our professional sheet metal stamping press manufacturing solutions await you! |  |

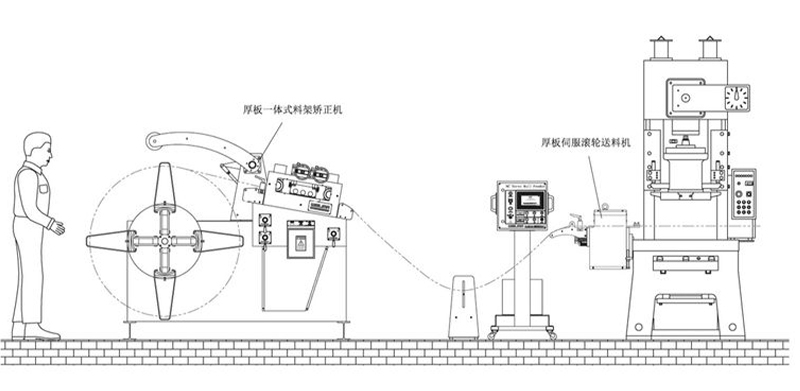

Workflow of Metal Stamping Making Machine

Decoiler ↓ Straightener ↓ Metal Punching Machine |  |

Parameters of Metal Stamping Making Machine

| Model | Model 1 | Model 2 | |

| Tonnage | ton | 220 | 300 |

| Stroke | mm | 30 | 30 |

| Strokes per minute | SPM | 50 | 60 |

| Lower table dimensions | mm | 1900x1000 | 2200x1000 |

| Feed hole | mm | 1400x300 | 2000x300 |

| Slide Area | mm | 1900x750 | 2100x900 |

| Die Height Adjustment Stroke | mm | 370-420 | 400-450 |

| Die Height Adjustment Motor | kW | 1.5 | 2.2 |

| Feed Line Height | mm | 200±50 | 210±50 |

| Main Motor | kW | 45 | 55 |

These parameters provide customers with a variety of options to meet different production scales and product requirements.

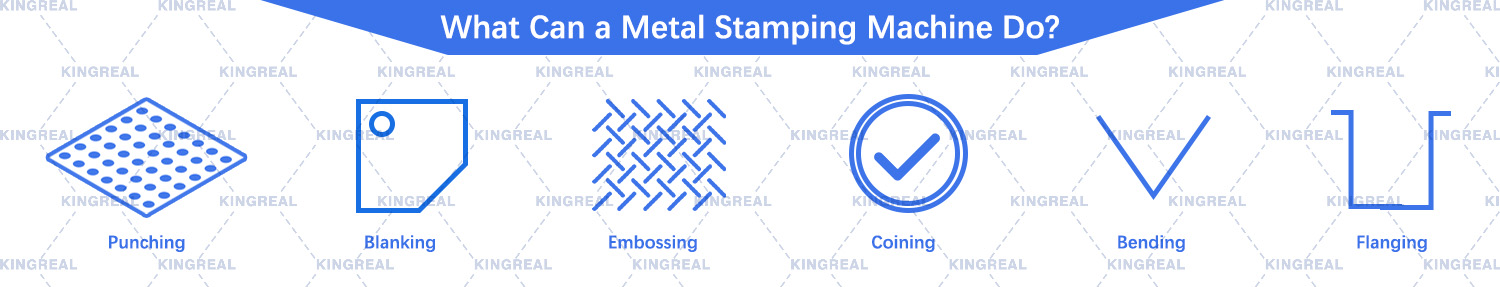

What Does a Metal Stamping Making Machine Do?

KINGREAL CEILING MACHINERY metal stamping making machines are capable of producing uniform products at scale and with high precision, meeting customers' specific finished product requirements. These include:

●Punching: Using dies and presses to create holes in a workpiece.

●Blanking: Punching the desired workpiece from sheet metal.

●Embossing: Creating raised or recessed text, patterns, and designs on sheet metal.

●Coining: Similar to embossing, but stamping is performed on both sides of the workpiece to create raised or recessed designs and text.

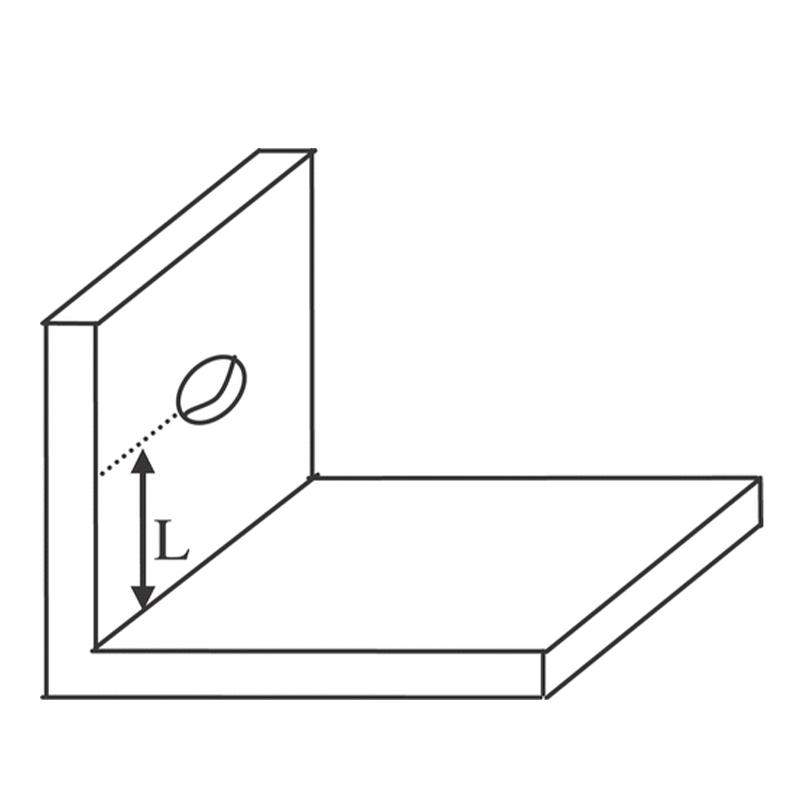

●Bending: Using a press brake to bend a metal workpiece at a specific angle, creating a V- or U-shaped structure.

●Flanging: Bend the edge of the workpiece around the punched hole to 90°, creating a lip around each hole.

Features of Metal Stamping Making Machine

1.High precision and high efficiency sheet metal stamping press

This metal stamping making machine accurately punches a variety of metal connectors, making it an ideal choice for sheet metal processing in the automotive, hardware, and electronics industries. Its stable output and low vibration ensure reliable daily operation.

2. Rugged and Durable Construction for sheet metal stamping press

The metal stamping making machine utilizes a high-strength frame and advanced drive system to ensure long service life and minimal load deformation, delivering stable performance for punching a wide range of materials and thicknesses.

3.User-Friendly Operation for sheet metal stamping press

The metal stamping making machine's intuitive control system allows operators to easily adjust stroke, speed, and positioning, reducing setup time and improving shop floor efficiency.

4.Low Maintenance Costs for sheet metal stamping press

Designed to reduce energy consumption and maintenance requirements, this metal stamping making machine helps factories lower operating costs while maintaining high-quality output.

Technology Explanation of Sheet Metal Stamping Press

1. Progressive die for metal stamping making machine

The progressive die technology used in metal stamping making machines is a highly efficient metal forming process consisting of multiple stations. In a single stroke, the part is advanced through the die, undergoing processes such as punching, blanking, bending, and trimming. This process is ideal for high-volume production and can operate at higher speeds, thereby improving production efficiency.

KINGREAL CEILING MACHINERY customizes die sets based on customer part drawings. By changing the die, we can meet the production requirements of various metal brackets.

2. Different types of punching machines

KINGREAL CEILING MACHINERY offers a variety of punching machine types to meet different application needs:

-Mechanical punching machines for sheet metal stamping press: These machines utilize a large flywheel to store and release energy, making them suitable for high-speed part production. They offer stable production capacity and are ideal for high-volume production environments.

-Hydraulic punching machines for sheet metal stamping press: These machines utilize hydraulic cylinders to generate force, enabling precise pressure control. They are suitable for deep drawing, complex forming, and processing high-strength materials. Its high tonnage makes it ideal for large workpieces.

-Pneumatic punching press for metal stamping making machine: With its high safety and ability to stop at any point, it's ideal for producing high-precision parts.

With its diverse punching machine options, KINGREAL CEILING MACHINERY ensures customers receive optimal production results when using metal stamping making machines.

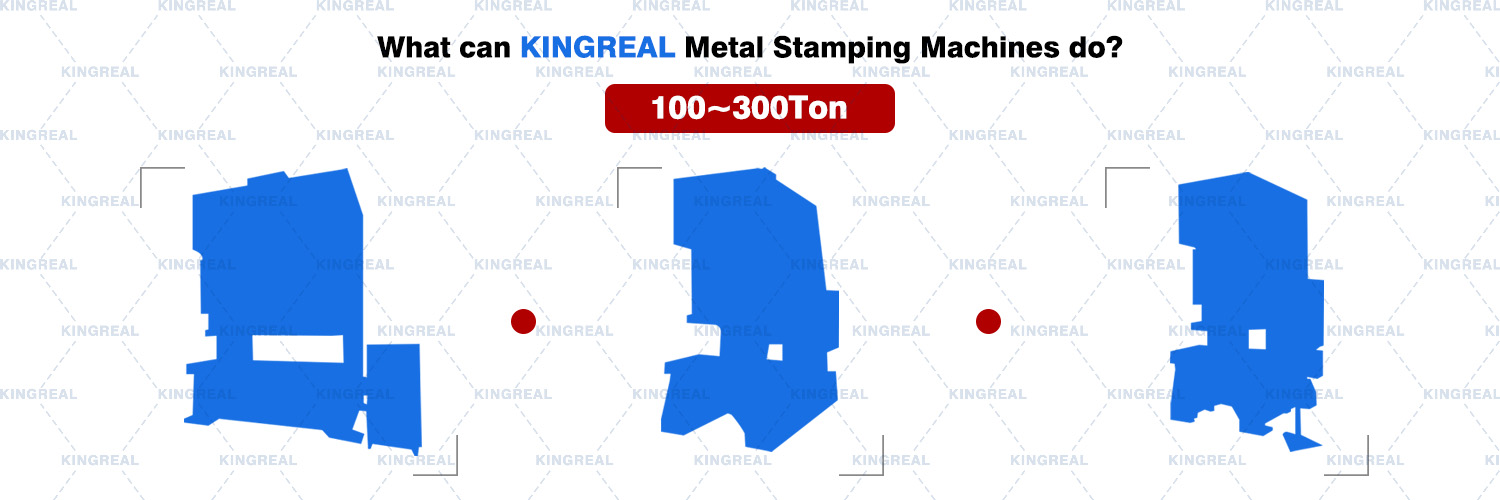

Multiple Metal Stamping Making Machine Solutions Available

KINGREAL CEILING MACHINERY engineers can customize personalized metal stamping making machine solutions for clients based on their actual production needs and projects. KINGREAL CEILING MACHINERY can provide metal punching machines ranging from 100 to 300 tons, depending on the materials to be processed, the required production efficiency, and other relevant factors. KINGREAL CEILING MACHINERY engineers will provide customers with reasonable suggestions based on their extensive experience.

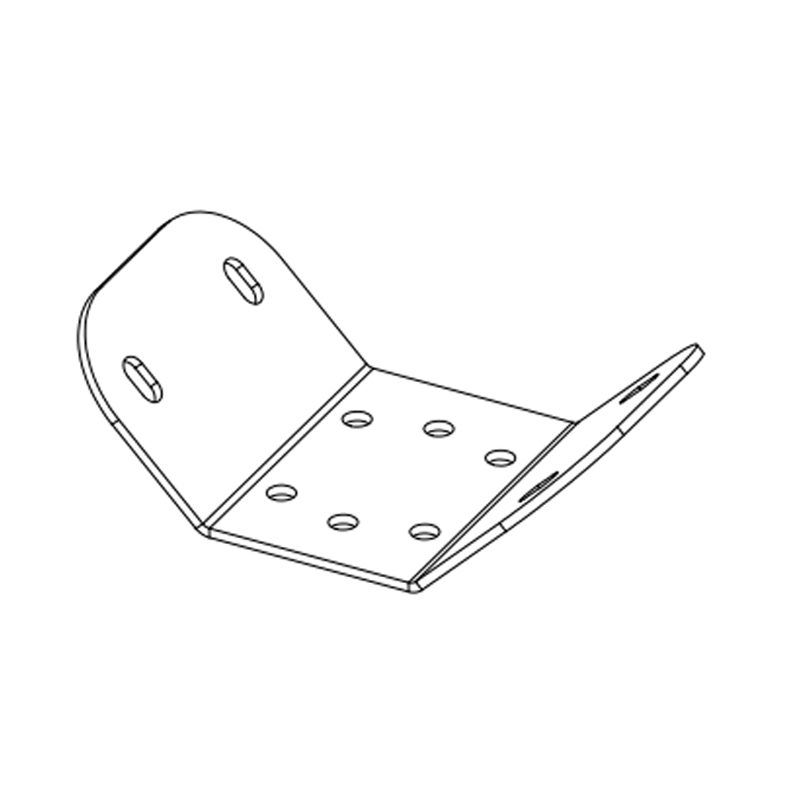

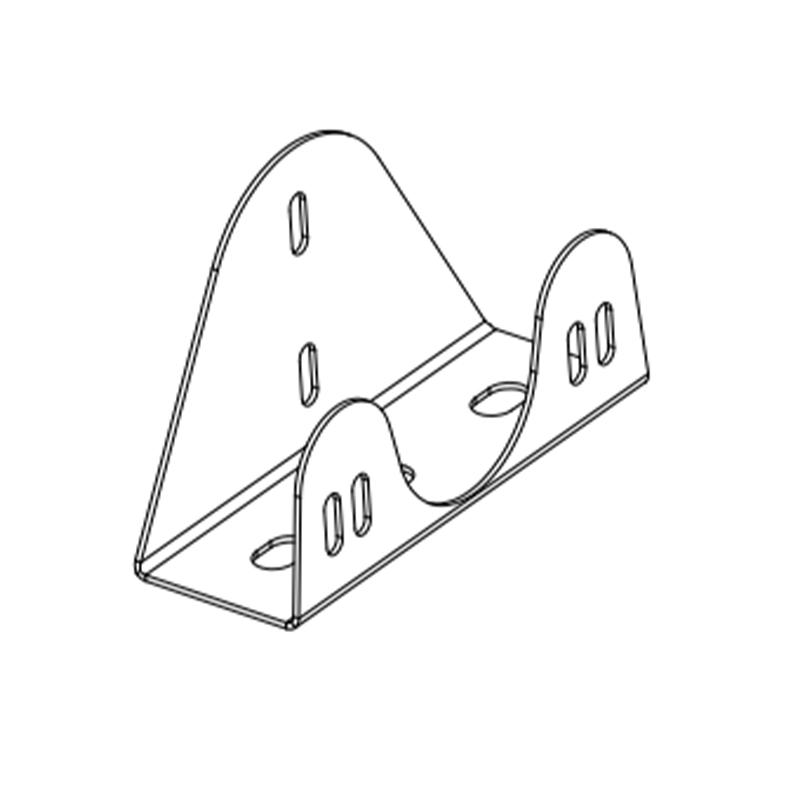

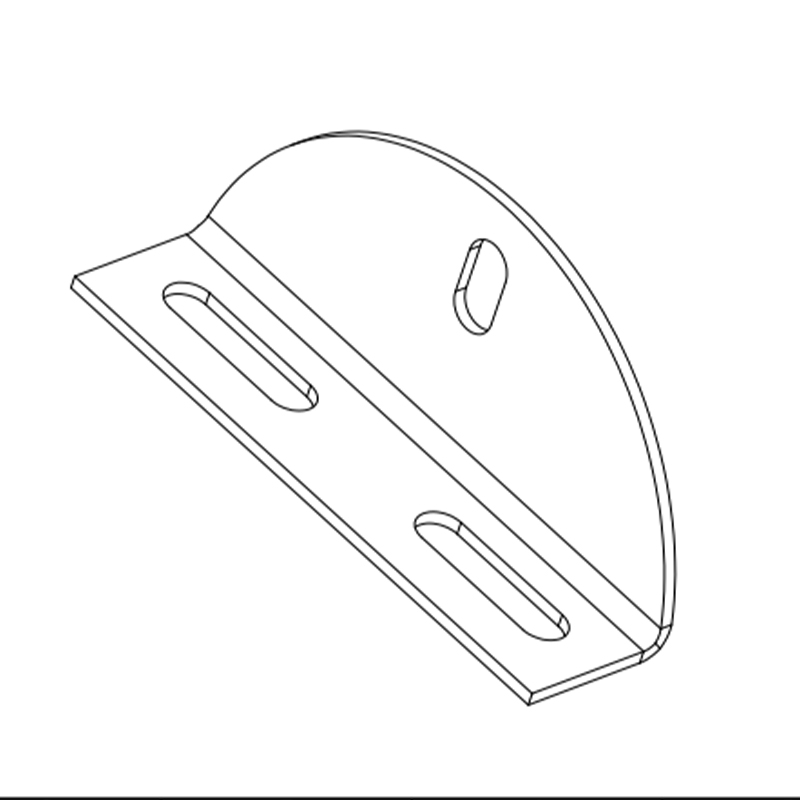

What Kind of Metal Brackets can Sheet Metal Stamping Press Produce?

Applications of Metal Stamping Making Machine

Metal stamping making machines can produce a variety of metal parts in various shapes, such as V, U, and Z-shaped metal connectors. These are widely used in suspended ceiling systems, photovoltaic mounting systems, and pallet racking systems. KINGREAL CEILING MACHINERY also provides metal ceiling tile production lines, pv support bracket machines, and pallet upright rack roll forming machines, ensuring customers receive one-stop service.

Metal Stamping Process Tips

How to Reduce Springback During Metal Stamping and Bending?

During metal stamping and bending, bending stress is generated within the material, which can cause springback. Here are some tips to reduce springback:

Material Selection: Select the appropriate metal material to reduce its elastic recovery.

Mold Design: Optimize mold design to ensure a reasonable bend angle and radius.

Bending Process: Use appropriate bending speed and pressure to reduce stress concentration in the material.

Post-Processing: Perform appropriate heat treatment after forming to relieve stress and reduce springback.

Metal stamping parts also require corrosion protection during production to prevent corrosion during use. Effective corrosion protection methods include:

1) Use aluminate cement coating or sulfate cement coating.

2) Use epoxy ceramic lining, spray-coated asphalt paint, or epoxy coal tar paint.

3) Use new environmentally friendly coatings such as polyurethane paint.

4) These methods not only improve the durability of metal stampings but also ensure their reliability in various environments.

FAQ About Metal Stamping Making Machine

1/What training is required to operate a metal stamping making machine?

Operators typically require specialized training in the operation and maintenance of metal stamping making machines. If you purchase a machine from KINGREAL CEILING MACHINERY, KINGREAL CEILING MACHINERY will provide training for your operators before the equipment is delivered. We can provide on-site support, remote services, and training tailored to customer needs.

2/What should I do if I don't know how to use certain functions after purchasing the metal stamping making machine?

KINGREAL CEILING MACHINERY will send professional engineers to guide you on how to use the metal stamping making machine perfectly. KINGREAL CEILING MACHINERY can provide offline technical support and operation videos.

3/What safety features are included in metal stamping making machines?

KINGREAL CEILING MACHINERY metal stamping making machines are equipped with various safety features, such as emergency stop buttons, light curtains, safety interlocks, and enclosed operating areas, to protect operators during machine operation. These systems automatically stop the machine when a dangerous situation is detected, thus reducing the likelihood of accidents.

4/Can metal stamping making machines be customized?

Absolutely! KINGREAL CEILING MACHINERY metal stamping making machines can be customized according to customer requirements. KINGREAL CEILING MACHINERY engineers will tailor a metal stamping making machine specifically for you, based on the needs of your particular production tasks.

5/What maintenance is required for metal stamping making machines?

Regular maintenance includes lubrication, replacement of worn parts, cleaning, and periodic inspections. The specific maintenance schedule and procedures will vary depending on the metal stamping making machine model and usage.

More Information About Metal Stamping Making Machine

1.Automated Precision Progressive Die Mechanical Press Solutions

3.Types of Metal Stamping Making Machine

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)