Understanding the Sheet Metal Stamping Press Process

2025-09-17 17:00

A sheet metal stamping press is a highly efficient metalworking machine capable of performing various operations on metal coils, including bending, plastic deformation, and punching. It is widely used in a variety of industries, including automotive, electronics, medical equipment, construction tools, and building materials.

Metal stamping making machines are primarily used to process a variety of metal materials, such as stainless steel, aluminum, iron, and copper. Sheet metal stamping presses can not only create conventional parts but also customize them—adding reinforcing ribs to increase product strength and stability—depending on customer demand. Metal stamping making machines satisfy market demand for a range of goods by processing a range of materials.

Because of their speed and accuracy, sheet metal stamping presses may quickly turn out large quantities of excellent goods, hence lowering manufacturing expenses and raising productivity.

How a Metal Stamping Making Machine Works?

The metal stamping making machine, which imparts the required force and pressure to shape metal sheets or coils into the desired form, forms the center of metal stamping. Specialized dies on the press machine carry out a variety of stamping activities including cutting, bending, and forming. The movement of the press and the interplay between the die and the metal are essential throughout the stamping process. Through exact management of pressure and motion path, the stamping technique can dramatically alter the material's form and structure, therefore producing the needed visual appearance and function.

Structure of Sheet Metal Stamping Press

A sheet metal stamping press typically consists of the following main components:

-Main body: Carries all components and provides a stable working platform.

-Power system: Drives the press, typically using an electric motor.

-Die: Tool used to form and process metal materials.

-Control system: Monitors and adjusts the parameters of the stamping process.

Workflow of Metal Stamping Making Machine

-Material preparation: Prepares the metal coil to ensure it meets processing requirements.

-Feeding: The material is fed into the press via a feeder.

-Stamping and forming: The press applies pressure, and the die forms the metal.

-Finished product output: The stamped parts are removed via an output device and prepared for further processing.

Through this series of steps, a metal stamping making machine can efficiently and accurately produce products.

Metal Stamping Making Machine Design

KINGREAL CEILING MACHINERY engineers take several things into account when developing a sheet metal stamping press for metal stamping to guarantee equipment performance and dependability. During the design phase, major considerations are:

1. Material properties for sheet metal stamping press

The stamping method is influenced by the physical and mechanical properties of several materials. The strength, ductility, and elasticity of the material must be taken into account during design to avoid cracking or deformation during the stamping procedure.

2. Die design for metal stamping making machine

The die is a crucial component of a metal stamping making machine. Based on the customer's drawings, KINGREAL CEILING MACHINERY engineers customize a suitable progressive die. This die supports high-volume production and can create complex parts with multiple features in a single stamping pass.

3. Other considerations for sheet metal stamping press

During the metal stamping making machine design process, one must also take into account things like electrical conductivity, cost, and corrosion resistance. To guarantee the quality and performance of the ultimate product, the chosen material should match the stamping process and the intended part function.

Applications of Sheet Metal Stamping Press in Construction Industry

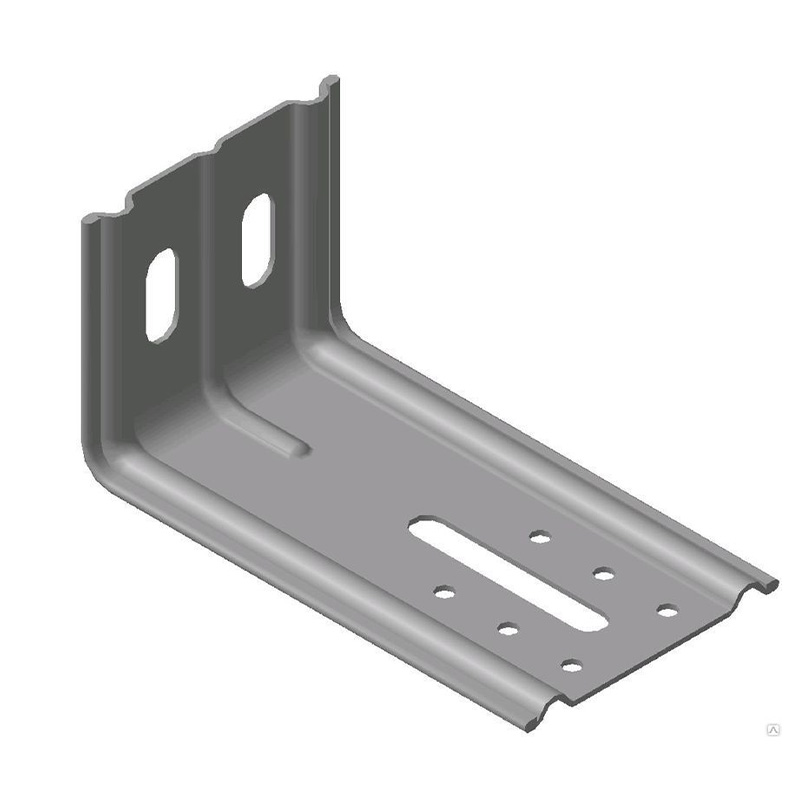

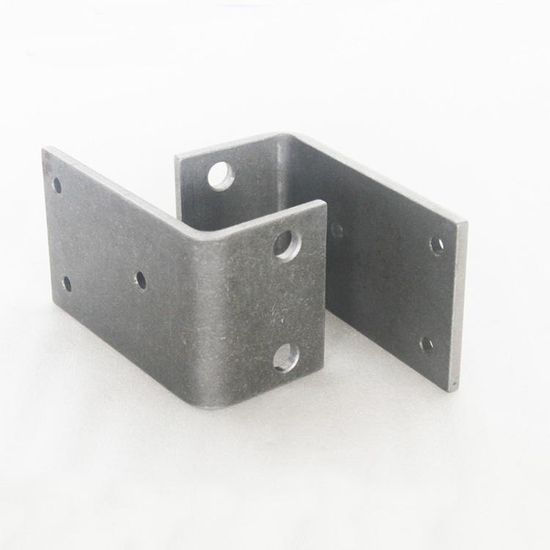

Metal stamping making machines are widely used in construction industry, producing a variety of connectors and support structures, enhancing the overall performance and aesthetics of buildings. The following are several typical application scenarios:

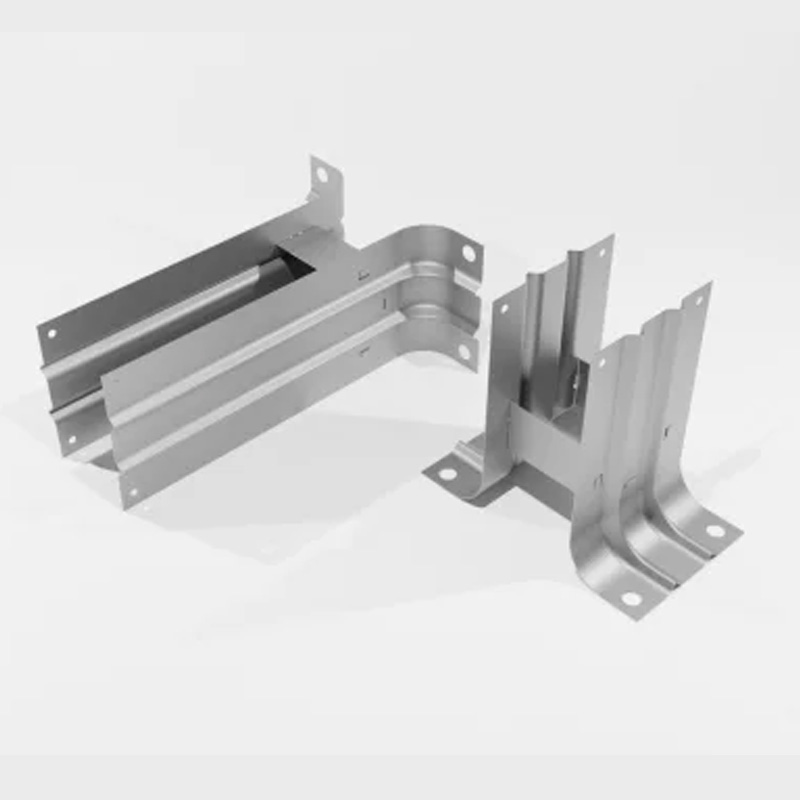

1. Sheet metal stamping press in open cell ceiling system

Metal stamping making machines can produce connectors for open cell ceilings. These connectors allow the open cell ceiling to be joined together to form a complete grilyato ceiling system. KINGREAL CEILING MACHINERY not only offers a variety of open cell ceiling machines, but also produces connectors for grilyato ceiling systems, ensuring the stability and aesthetics of the overall structure.

2. Sheet metal stamping press in pallet racking system

In modern warehousing and logistics systems, the support structure of racks is crucial. Connectors produced by metal stamping making machines can be assembled with finished products produced by pallet upright rack roll forming machine, storage shelf panel machine, and other equipment to form a complete pallet racking system. These connectors not only provide necessary support but also optimize space utilization.

3. Sheet metal stamping press in suspended ceiling systems

Metal stamping making machines can also produce connectors for suspended ceiling systems. To create a full suspended ceiling system, these connectors are put together with profiles generated by false ceiling channel machine including omega profile, u shaped profile, and wall angle. This technique also helps to better regulate indoor acoustics and temperature in addition to being beautiful.

Main Types of Sheet Metal Stamping Presses

To meet different manufacturing needs, sheet metal stamping presses employ several drive methods and press configurations in metal stamping making machines. The main types of sheet metal stamping presses include single-action, double-action, mechanically driven, and hydraulically driven presses.

Single-action vs. Double-action Presses

In sheet metal stamping presses, single-action presses have a single slide, while double-action presses have separate slides. Single-action presses perform one task per cycle, while double-action presses use two slides to perform two tasks simultaneously: one to hold the blank and the other to punch or coin. In both single-action and double-action presses, the slides are mounted on the press top and generate the motion that presses the sheet metal against the die. Before entering the press in the metal stamping line, the workpiece's sheet metal is straightened to create a more streamlined flow.

Mechanically Driven Presses

In metal stamping making machines, mechanically driven presses are driven by an electric motor and flywheel mechanism. A flywheel transfers kinetic energy to the press, moving the ram toward the sheet in a smooth, regular motion. Mechanical presses are fast and efficient in metal stamping lines, reliably producing consistent results over repeated cycles. Their speed and precision make them particularly well-suited for assembly lines and industrial manufacturing within metal stamping making machines.

Hydraulically Driven Presses

Hydraulically driven presses utilize fluid or gas pressure to transmit force within the press. They press the ram down onto the workpiece with constant pressure, unlike mechanical presses, which apply pressure incrementally. Hydraulic presses operate slower than mechanical presses but offer a high degree of flexibility and control over tonnage, workpiece size, and part complexity. Therefore, hydraulic presses are ideal for producing delicate, complex, and unusually shaped parts in sheet metal stamping presses.

By choosing between different types of presses, a metal stamping making machine can meet diverse production needs and improve overall production efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)