Perforated metal machine in metal processing

2025-09-14 17:00

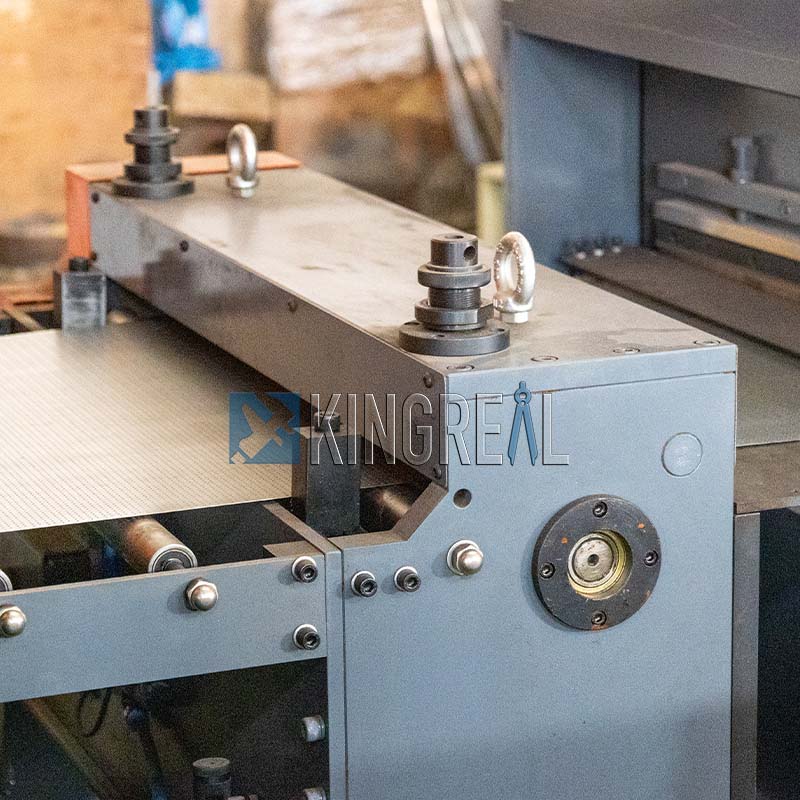

Perforated metal machines are widely used in the metalworking industry. KINGREAL CEILING MACHINERY offers advanced steel perforated machines, including three types: metal sheet perforated machines, coil to coil perforation lines, and metal ceiling tile perforation lines, ensuring that every perforated sheet meets the highest quality standards.

A steel perforated machine is a device specifically designed for precisely punching holes in metal materials. It uses a perforated metal machine and corresponding punching dies to quickly and efficiently create holes of various shapes and sizes in metal coils. Steel perforated machines not only improve production efficiency but also ensure product quality and consistency. For metalworking companies, selecting the right perforated metal machine is crucial for improving production capacity and product competitiveness.

Perforated Metal Machine Variety

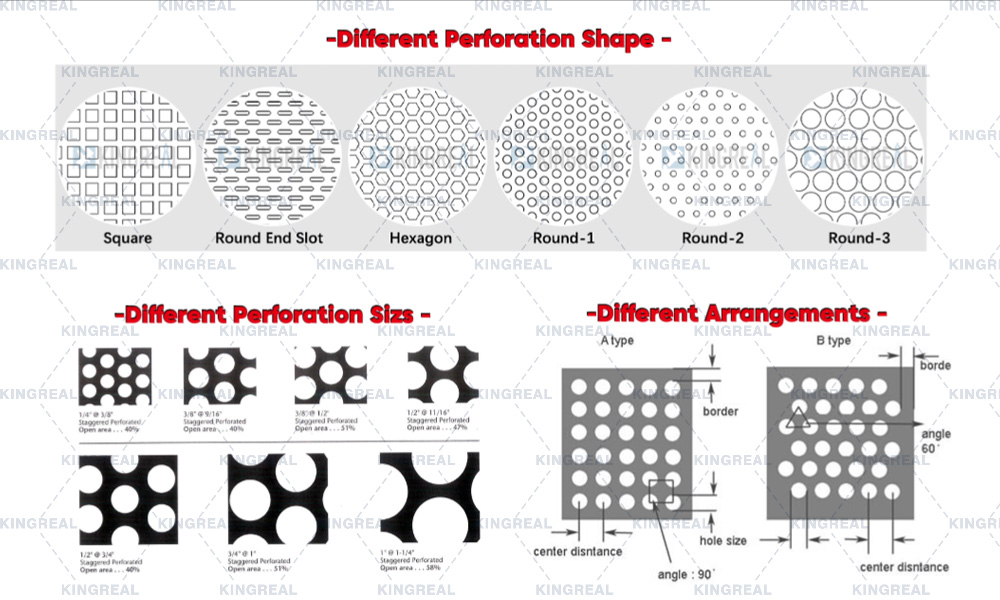

1)Different hole pattern designs for steel perforated machine

In metalworking, perforated metal machines can produce a variety of hole patterns to meet diverse customer needs. Common hole patterns include:

-Round holes: The most basic hole pattern, widely used in various applications.

-Oblong holes: Suitable for applications requiring ventilation or drainage.

-Square holes: Commonly used in the building materials and decoration industries. Triangular holes, diamond holes, and hexagonal holes: These special hole shapes are often used in precision machinery and specialty products.

-Cross holes: Suitable for applications requiring multiple connections.

KINGREAL CEILING MACHINERY steel perforated machines can design punching dies tailored to customer needs, enabling precise production of various hole shapes.

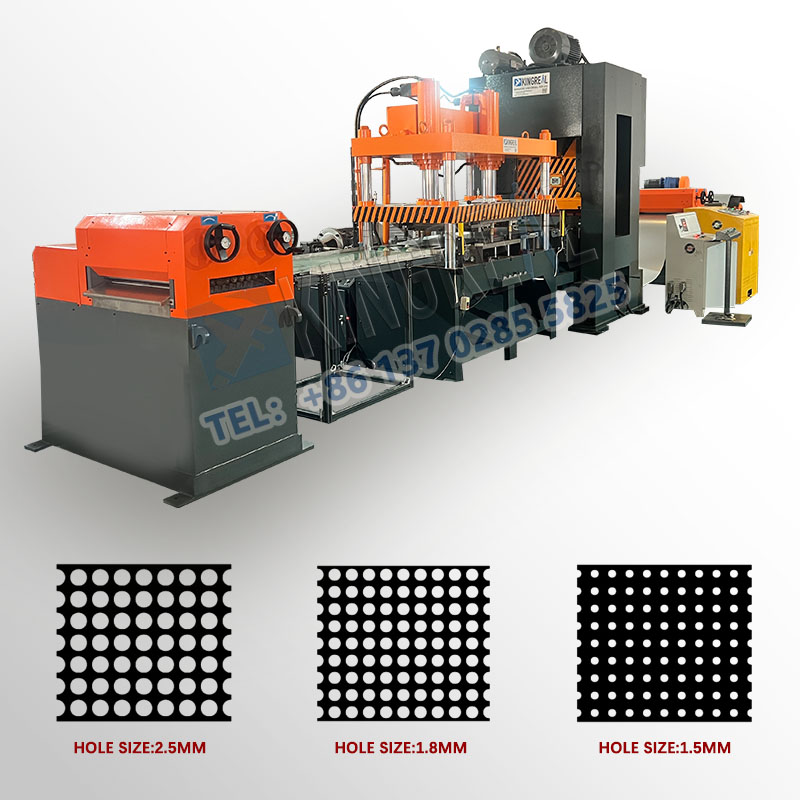

2) Different apertures designs for perforated metal machine

KINGREAL CEILING MACHINERY steel perforated machines can meet customers' punching needs for various hole diameters. KINGREAL CEILING MACHINERY perforated metal machines have no upper limit on hole diameters, capable of punching micro-holes as small as 1mm. This guarantees consistency and quality even with very small hole diameters by need of high-precision manufacture technology for both the punching dies and the steel perforated machine itself. Widely utilized in fields including medical, electronics, and high-precision machines, micro-components depend much on perforated metal machines' capacity.

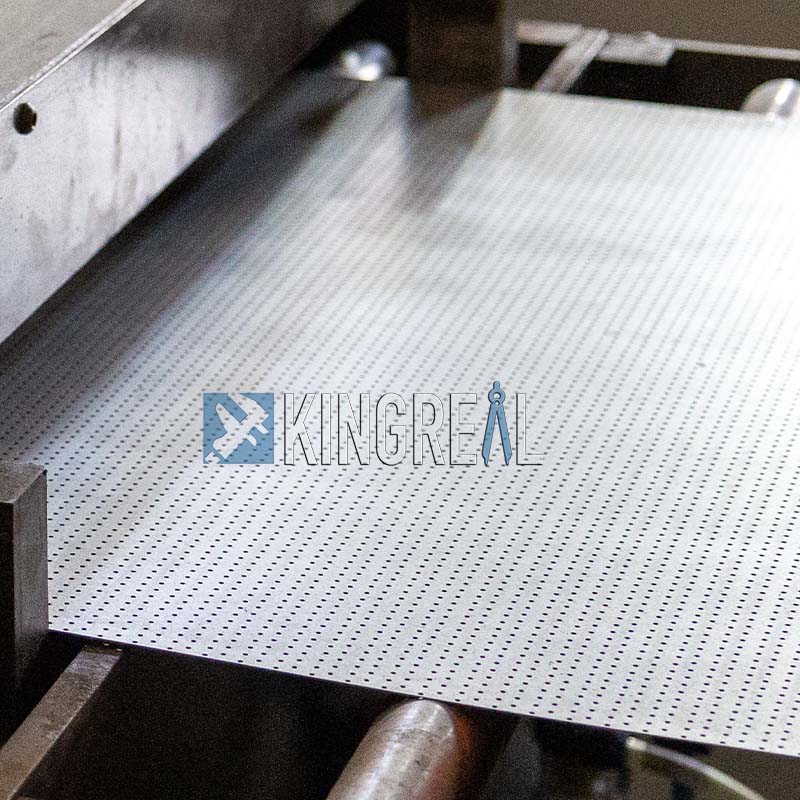

3) Various thicknesses for steel perforated machine

Metal coils with thicknesses from 0.4mm to 1.0mm may be processed by KINGREAL CEILING MACHINERY perforated metal machine. This processing capacity meets the demands of popular metal materials in the market, so enabling steel perforated machines to satisfy the demands of many consumers in realistic uses. Whether processing thin metal materials or slightly thicker metal plates, KINGREAL CEILING MACHINERY perforated metal machines can efficiently complete processing tasks, ensuring product quality and performance.

Applications of Steel Perforated Machine

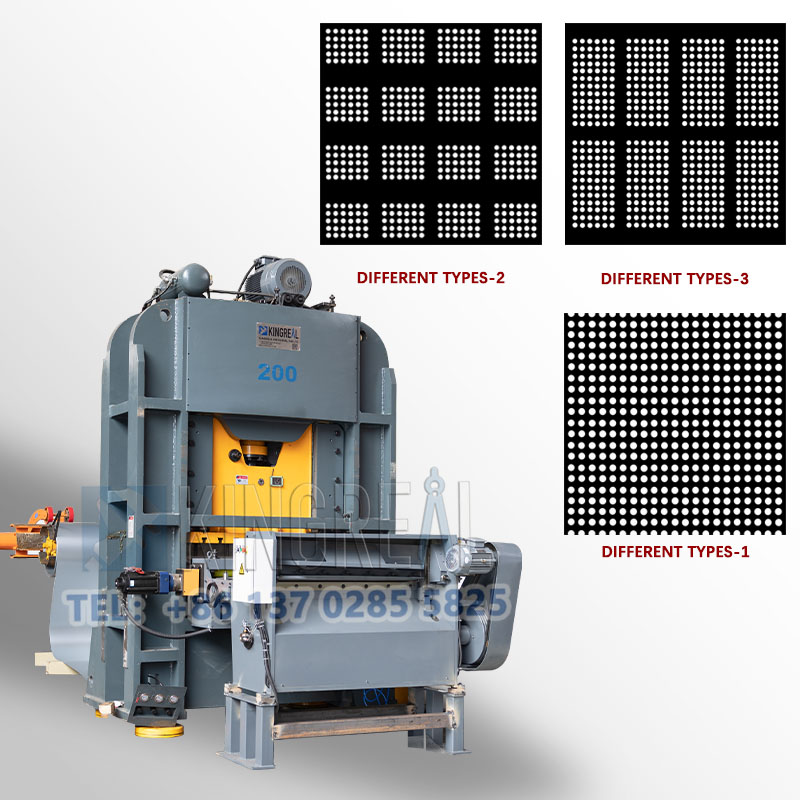

Different types of perforated metal machines are used in different applications to produce different finished or semi-finished products. The following is a detailed introduction to the three main types of steel perforated machines:

1. Coil to coil perforation line Coil to coil perforation lines are equipped with a high-efficiency recoiler. This kind of coil to coil perforation line punching punctures holes in the metal coil and then rewinds it, therefore enabling long-distance travel and next treatment. Commonly used to create perforated baffle ceilings and bread trays, this coil to coil perforation line also has applications in other goods. The coil to coil perforation line punches holes at great speed during this process, therefore guaranteeing exact control of the precision and spacing of every hole. guaranteeing the quality of the ultimate product. By helping with material transit and storage, the rewinding mechanism boosts production efficiency. |  |

2. Metal sheet perforated machine The metal sheet perforated machine combines punching and cutting functions, enabling precise cutting of perforated coils to customer-specified lengths. Especially appropriate for the manufacturing of items like automotive mufflers and perforated wall panels, this metal sheet perforation machine is also excellent. By combining the punching and cutting operations on this metal sheet perforated machine without a hitch, production efficiency is much enhanced. Customers just establish the appropriate criteria; then, the metal sheet perforated machine automates the whole process, therefore lowering production expenses and greatly minimizing human involvement. |  |

3. Metal ceiling tile perforation line Especially for the production of different perforated ceiling panels, the metal ceiling tile perforation line is intended. It can generate a range of sizes and forms, including 300x300mm, 600x600mm, and 1200x600mm, as well as many installation styles like as clip in ceiling tile, tegular ceiling tile, lay in ceiling tile, etc. Designed to fully meet the varied demand for perforated ceiling panels, this metal ceiling tile perforation line improves production flexibility and efficiency. Moreover, the metal ceiling tile perforation line guarantees the quality of every perforated ceiling panel, satisfying the construction industries stringent expectations for appearance and utility. |  |

Advantages of Steel Perforated Machine

1) High efficient perforated metal machine

One of the greatest advantages of steel perforated machines is their high efficiency. Traditional manual punching is not only time-consuming but can also result in inconsistent hole shapes and diameters, impacting product quality. However, through automated production, perforated metal machines can complete large volumes of punching work in a short period of time, significantly increasing production capacity. This high efficiency enables companies to quickly respond to market demand, shorten lead times, and enhance competitiveness.

2) High-precision steel perforated machine

Perforated metal machines utilize advanced control systems and high-quality punching dies to ensure the precision of every hole. This high precision not only improves product consistency but also reduces errors in subsequent processing, providing reliable quality assurance for the metalworking industry.

3) High flexible steel perforated machine

KINGREAL CEILING MACHINERY perforated metal machines offer exceptional flexibility, adapting to diverse production requirements and accommodating a wide range of specifications and materials. Whether small-batch customization or large-scale production, the steel perforated machines can quickly adapt to meet diverse customer needs.

Tags: perforated metal machine, steel perforated machine, metal sheet perforated machine, sheet metal perforation machine, coil to coil perforation line, metal ceiling tile perforation line

Get the latest price? We'll respond as soon as possible(within 12 hours)