Perforated Metal Ceiling Panel Machine

KINGREAL CEILING MACHINERY Perforated Metal Ceiling Panel Machine is specially designed for processing perforated metal ceiling tiles made of aluminum or GI steel. With its superior technology, this metal ceiling tile perforation line can punch holes at a speed of up to 220SPM, greatly improving production efficiency and meeting the market's demand for fast and large-scale production.

- KINGREAL CEILING MACHINERY

Details

Video About

Perforated Metal Ceiling Panel Machine

Introduction to Perforated Metal Ceiling Panel Machine

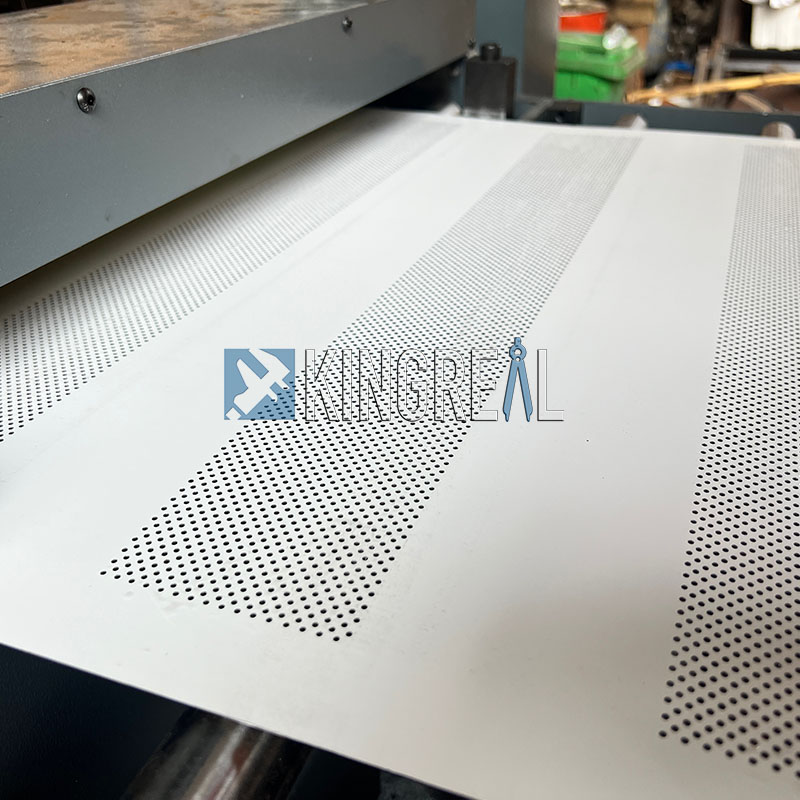

| The perforated metal ceiling panel machine is mainly used for the processing and production of perforated metal ceiling panels. It consists of multiple precision parts such as decoiler, leveling machine, punching machine, etc. It adopts a fully automatic computer control system and has significant advantages such as high manufacturing precision, fast processing speed, and less operator requirements. Compared with traditional manual operation, this automated equipment not only improves production efficiency, but also greatly reduces the possibility of human error, ensuring that the quality of each metal ceiling tile can meet customer requirements. The core of the metal ceiling tile perforation line lies in its efficient punching ability. By cooperating with the metal ceiling tile making machine, the hole diameter and hole type required by the customer are usually punched out on the metal ceiling board surface with a thickness range of 0.4-1.0mm (the production demand for ceiling hole diameters in the market is mainly 1.8 and 2.5mm), and products of various sizes are produced such as 300x300mm, 600x600mm and 600x1200mm. These metal ceiling boards not only meet functional requirements, but also add visual beauty to the space. |

Main Components of Metal Ceiling Tile Perforation Line

The workflow of the perforated metal ceiling panel machine consists of multiple links, each of which is crucial to ensure a smooth and efficient production process.

(1) Decoiler for metal ceiling tile perforation line:

This equipment is responsible for unwinding the coil to ensure that the material for subsequent processing is in good condition. The accuracy and stability of the decoiler directly affect the quality of subsequent processing, so KINGREAL CEILING MACHINERY uses high-performance decoilers to ensure that the material is flat and wrinkle-free.

(2 )Precision Straightener for perforated metal ceiling panel machine:

The unrolled coil needs to be flattened to eliminate bending and deformation. The function of the flattener is to ensure that there will be no errors in the material when punching, laying the foundation for subsequent precision processing.

(3)Punching Machine for metal ceiling tile perforation line :

This is the core equipment of the perforated metal ceiling panel machine. The punching machine punches the required hole shape and hole diameter on the metal ceiling tile according to the preset mold. KINGREAL CEILING MACHINERY punching machine is driven by advanced servo motors and has fast and efficient punching capabilities to meet the needs of mass production.

(4)Notching and Shearing Press for metal ceiling tile perforation line:

After punching, the four corners of the metal ceiling panel are cut off and sheared according to the length preset by the customer.

(5)2nd Precision Straightener for perforated metal ceiling panel machine:

After punching and shearing, the metal ceiling board is straightened again to ensure that the quality of the final product meets the standard.

Through the close cooperation of the above links, the metal ceiling tile perforation line can efficiently and accurately complete the production task of the metal ceiling tile.

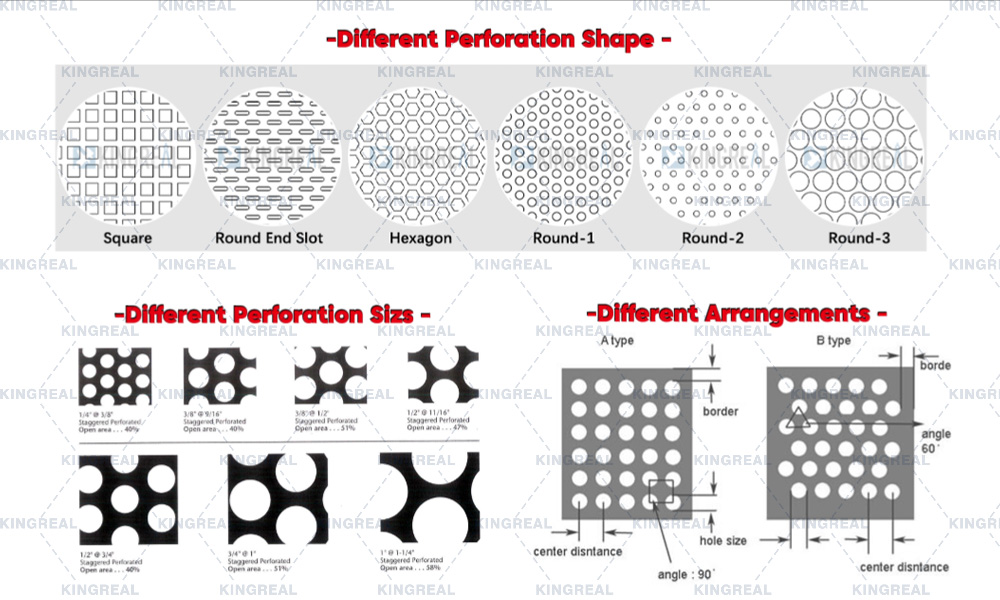

Aperture Drawings

Two Metal Ceiling Tile Perforation Line Manufacturing Solution

When choosing a perforated metal ceiling panel machine, the punching capacity of 125 tons and 160 tons is an important parameter that customers need to pay attention to. (120 ton punching machine is also available) There is a significant difference in the processing capacity of these two equipment. When choosing a metal ceiling tile perforation line, the 125-ton and 160-ton punching capacities are important parameters that customers need to pay special attention to (the 120-ton punching machine is also an option). There are significant differences in the processing capacity of these two types of equipment, which are suitable for different production needs.

Choosing the right tonnage punching machine mainly depends on factors such as hole type, material width, material type and material thickness. Generally speaking, if customers need to produce 600x600mm ceiling tiles, using a 120-ton or 125-ton punching machine can usually meet the needs, especially when production speed is a key consideration. If large width and thickness materials are involved, a 160-ton punching machine is more suitable and can handle more complex hole types. KINGREAL CEILING MACHINERY engineers have rich experience in metal ceiling tile perforation line manufacturing and can provide the most reasonable suggestions based on the formula and the actual production needs of customers to help customers choose the most suitable metal punching machine to ensure the best balance between production efficiency and product quality.

|  |

Material width:700mm Punching speed: 150-180SPM Material thickness:GI:0.5-0.6mm,Al:0.7-0.8mm | Material width: 1200mm Punching speed: 160-220SPM Material thickness: GI:0.6-0.7mm,Al:0.7-0.9mm |

Advantages of Metal Ceiling Tile Perforation Lines

1. Different hole types for metal ceiling tile perforation line

In order to meet the diverse needs of customers, KINGREAL CEILING MACHINERY customizes the design and manufacture of punching dies according to the drawings provided by customers. By replacing different punching dies, the perforated metal ceiling panel machine can realize the production of perforated ceiling tiles with various hole types. Whether it is a standard hole type or a special design, KINGREAL CEILING MACHINERY can provide flexible solutions to ensure that the personalized needs of customers are met.

2.High-speed punching for metal ceiling tile perforation line

The punching speed of the metal ceiling tile perforation line can reach 160-220SPM, and the punched holes are burr-free, the hole size is highly consistent, and there will be no skew. This efficient punching capacity can not only significantly improve production efficiency, but also ensure that the quality of each finished product meets customer expectations, reducing subsequent rework and material waste.

3.Highly automated metal ceiling tile perforation line

KINGREAL CEILING MACHINERY perforated metal ceiling panel machine uses an intelligent control panel. Operators only need to enter instructions to automatically produce. The system will automatically adjust the punching speed and pressure according to the set parameters, greatly reducing labor costs and improving production efficiency. This highly automated design adapts to the needs of modern production and allows customers to gain an advantage in the fierce market competition.

Precision Machining and Quality Control of Metal Ceiling Tile Perforation Line

KINGREAL CEILING MACHINERY strictly controls the processing of the perforated metal ceiling panel machine. Starting from the selection of raw materials, KINGREAL CEILING MACHINERY pays attention to quality to ensure that every roll of material used meets the standards.

After production is completed, KINGREAL CEILING MACHINERY will conduct strict machine testing and parameter adjustments to ensure that each finished product meets customer requirements. Through precise measurement and trialing, KINGREAL CEILING MACHINERY can ensure that the accuracy and quality of the final product meet industry standards.

Successful Case about Metal Ceiling Tile Perforation Line

Perforated Metal Ceiling Panel Machine in UAE

Demand: metal ceiling tile perforation line for producing 600x600mm metal ceiling boards.

Additional requirements: high cleanliness and improved production efficiency.

Solution: Equip the perforated metal ceiling panel machine with a metal sheet cleaning machine and an automatic flipping machine to achieve 180-degree flipping of the sheet material and reduce manual handling. After the improvement, the production efficiency increased by 30%, and more high-quality metal ceiling tiles can be manufactured per hour.

Metal Ceiling Tile Perforation Line In India

Demand: perforated metal ceiling panel machine for 300x300mm lay-in metal ceiling tile.

Additional demand: Reduce manual handling and reduce safety hazards.

Solution: Introduce a feeding trolley for the metal ceiling tile perforation line to automatically deliver the coil to the decoiler, significantly reducing the burden of workers' handling and improving safety. After the transformation, the production efficiency increased by 25%, and the working environment of workers became safer.

Perforated metal ceiling panel machine in Turkey

Demand: metal ceiling tile perforation line for 300x300mm metal ceiling board.

Additional demand: Attach sound-absorbing cloth during the production process.

Solution: Equip the perforated metal ceiling panel machine with an acoustical ceiling tile textile stick machine to achieve the complete finished product production of the perforated metal ceiling tile, eliminate secondary processing, improve production efficiency and significantly reduce labor costs.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)