Steel Perforated Machine

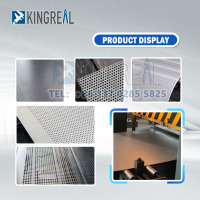

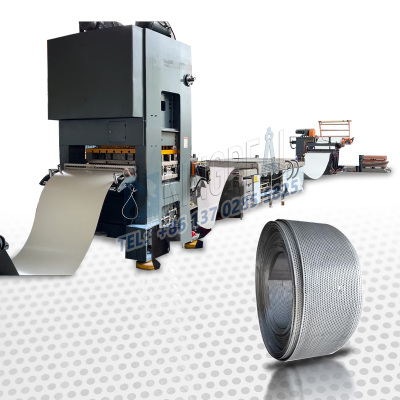

KINGREAL CEILING MACHINERY fully automated steel perforated machine can punch holes as small as 1.5mm on the surface of metal coils, and integrates a recoiler and cutting station to facilitate customers to switch production modes at any time.

- KINGREAL CEILING MACHINERY

Details

Video About S

teel Perforated Machine

KINGREAL CEILING MACHINERY Steel Perforated Machine

| In modern manufacturing, the metal perforated machine is an important equipment for efficient production. The metal sheet perforated machine launched by KINGREAL CEILING MACHINERY not only has the ability to punch out a minimum hole diameter of 1.5mm, but also combines the dual functions of a recoiler and a cutting station, providing customers with a one-stop solution. Whether you need to improve production efficiency or optimize the process, KINGREAL CEILING MACHINERY steel perforated machine is your ideal choice. Welcome to consult! Different types of steel perforated machine: |

Parameter of Steel Perforated Machine

| Thickness of material | Galvanised metal sheet 0.5 or 0.6mm; Prepainted sheet metal 0.5, 0.6, or 0.7 mm |

| Inner diameter | Φ 500 |

| Outer diameter | Φ 1200 |

| Maximum load | 5 tons |

| Expansion | Hydraulic expansion |

| Electric motor | Three-phase asynchronous motor,3KW |

| Speed adjustment | Adjusted by transducer (Optional extra) |

Main Components of Metal Sheet Perforated Machine

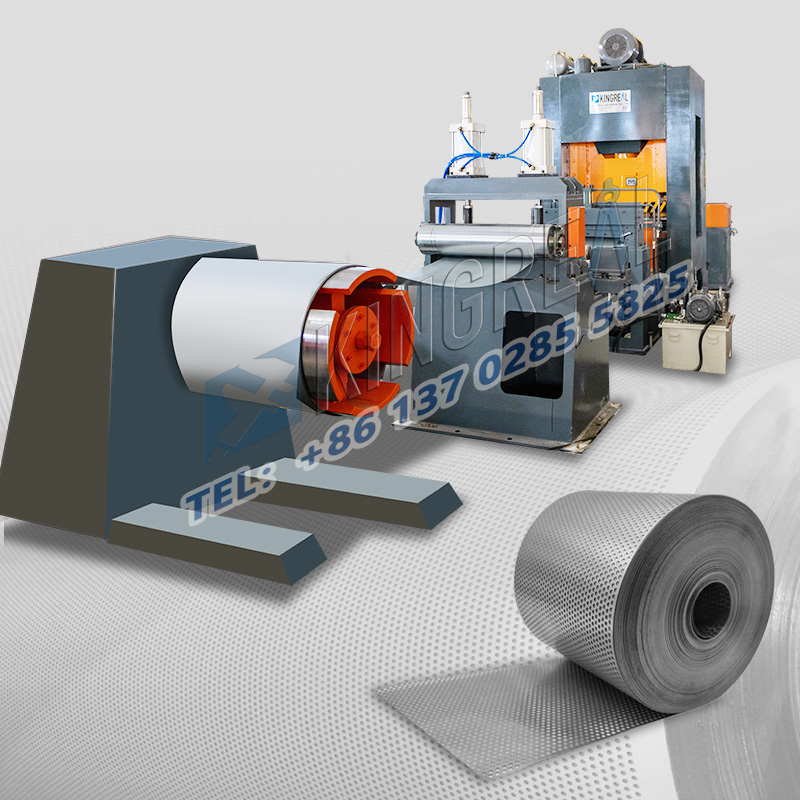

The KINGREAL CEILING MACHINERY steel perforated machine consists of several core components to ensure the efficient operation and modular design of the equipment. These components include:

| Decoiler | Used to unfold the metal coil to ensure the smooth progress of subsequent processing. |

| Precision leveler | By leveling the metal material, eliminating the waves and unevenness of the material, ensuring the accuracy of the punching process. |

| Metal punching machine | The core part is responsible for punching the required hole diameter on the metal material. |

| Cutting station | Used to cut the punched metal material into a specific length (note that the shearing station and the recoiler will not work at the same time). |

| Recoiler | Used to roll back the punched metal material for subsequent storage and transportation. |

KINGREAL CEILING MACHINERY Innovation in Steel Perforated Machine

1. Micro aperture for metal sheet perforated machine

KINGREAL CEILING MACHINERY metal sheet perforated machine can punch holes with a minimum aperture of 1.5mm on the metal surface. This feature makes the metal sheet perforated machine have great application potential in many industries.

1.1 Application field of steel perforated machine

Ultra-small aperture punched metal sheets or coils play an important role in many fields, such as:

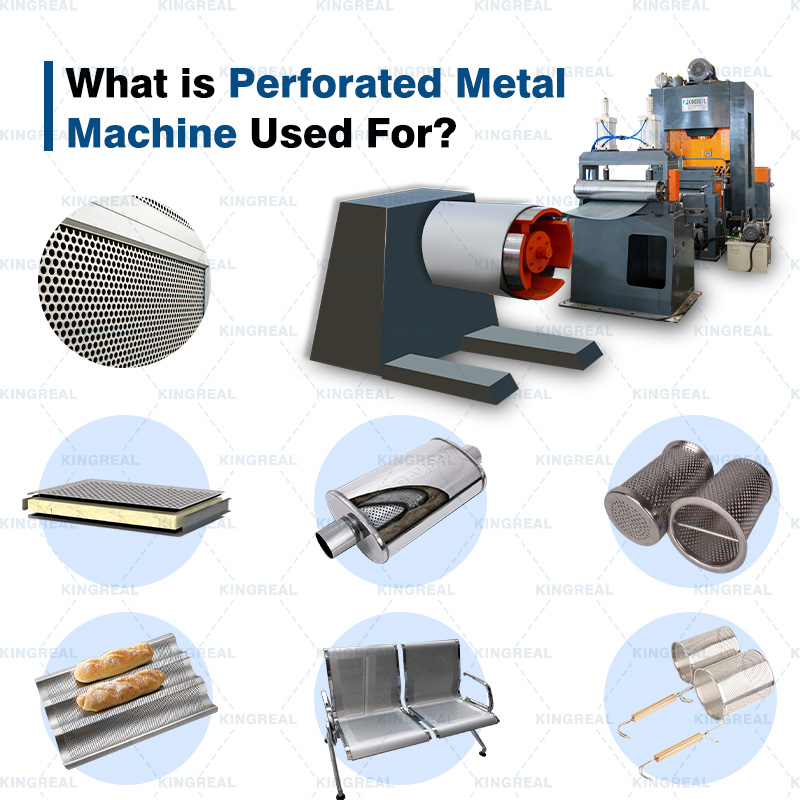

-Electronic industry: In the manufacturing process of circuit boards and various electronic components, ultra-small aperture metal materials are widely used for heat dissipation, shielding and connection. The application of steel perforated machine in this field ensures the high efficiency and reliability of the product.

-Filter production: In the manufacture of air and liquid filters, metal materials with micro-pores can effectively block unnecessary particles while allowing fluids to pass smoothly. The precise performance of the metal sheet perforated machine greatly improves the performance of the filter.

-Construction industry: The microporous metal sheets produced by the steel perforated machine can be used for ceilings, partitions and exterior wall decoration, which are both beautiful and functional, meeting the needs of modern architectural design.

-Automobile manufacturing: In automobile parts, metal materials with ultra-small apertures can be used to reduce weight and enhance structural strength, improving the overall performance of the car. The use of metal sheet perforated machines can effectively improve production efficiency and reduce production costs.

1.2 Difficulties in the design and manufacture of micro-punching dies

The manufacturing difficulty of this steel perforated machine is mainly reflected in the following aspects. KINGREAL CEILING MACHINERY engineers have successfully overcome these challenges and developed efficient and durable micro-punching dies, which significantly improves production efficiency and product quality.

-High precision requirements: Micro-punching dies require extremely high precision to ensure that the size and position of each aperture meet the design standards. Any slight error may result in unqualified products.

-Material selection: Punching materials usually need to have good plasticity and strength, so choosing the right material for mold manufacturing is a complex process.

-Mold durability: Micro-aperture punching dies are subject to greater pressure during use, so the durability and life of the mold become factors that must be considered in the design process.

2. One machine completes the production of two processes

In in-depth exchanges with customers from all over the world, KINGREAL CEILING MACHINERY engineers found that many users usually put forward the demand for two processes (cutting or winding) when purchasing metal sheet perforated machines. For this reason, KINGREAL CEILING MACHINERY designed this steel perforated machine equipped with both a recoiler and a cutting station, which greatly facilitates the customer's production process.

2.1 Time-saving and money-saving solution

By integrating the recoiler and the cutting station into one metal sheet perforated machine, customers no longer need to purchase multiple steel perforated machines, which not only saves money but also effectively utilizes factory space. Specific advantages include:

-Reduced equipment investment: Customers do not need to invest in multiple metal sheet perforated machines, thereby reducing initial capital investment and improving overall production efficiency.

-Space saving: In the factory, the layout of steel perforated machine is often limited by space. KINGREAL CEILING MACHINERY metal sheet perforated machine design allows customers to implement multiple processes in a limited space and optimize the layout of the production line.

-Simplified operation: The operation of the steel perforated machine is easier, and workers only need to learn how to operate one metal sheet perforated machine, reducing training costs and human resource investment.

2.2 Flexible production mode

The design of the metal sheet perforated machine allows customers to flexibly switch working modes according to production needs. When the metal material needs to be cut, just turn on the cutting station; when it needs to be reeled, just turn on the reel. The specific working principle is as follows:

-Reeling mode: In reeling mode, the perforated metal coil will not be cut when passing through the equipment, but will pass through the cutting station smoothly in the form of a conveyor belt. This design ensures the continuity of the production process and improves production efficiency.

-Cutting mode: When the perforated metal material needs to be cut into a specific length, just switch the equipment to cutting mode. At this time, the metal material will be accurately cut at the cutting station to ensure that the size of each finished product is accurate.

Different Application Areas of Steel Perforated Machine

KINGREAL CEILING MACHINERY metal sheet perforated machine has friendly cooperation with customers from Brazil, Greece, UAE, Turkey, India, Saudi Arabia and other countries, and each customer has different industry fields.

Up to now, KINGREAL CEILING MACHINERY steel perforated machine has successfully solved various demands of global customers such as punching filter elements, punching wall panels, punching silencers, punching bread trays, punching filter screens, etc., and can punch out holes of different shapes and apertures.

Customer Visit-- Steel Perforated Machine

KINGREAL CEILING MACHINERY has its own factory in Foshan, and warmly welcomes customers from all over the world to visit KINGREAL CEILING MACHINERY steel perforated machines. After fully communicating with KINGREAL CEILING MACHINERY staff, many customers want to personally experience operating the metal sheet perforated machine, inspecting the finished products, and visiting the manufacturing workshop to confirm whether KINGREAL CEILING MACHINERY steel perforated machines meet their production needs. So far, KINGREAL CEILING MACHINERY has received customers from countries such as Canada, Algeria, Qatar, Iran and the UK, and visited a variety of steel perforated machines including metal sheet perforated machine, coil to coil perforation line and metal ceiling tile perforation line. The transaction rate of visiting customers is very high, which fully proves that the excellent quality and high-quality service of KINGREAL CEILING MACHINERY steel perforated machines have been widely recognized and satisfied by customers. KINGREAL CEILING MACHINERY looks forward to the visit of all customers!

Packaging & Shipping

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)