Ceiling Channel Roll Forming Machine

KINGREAL CEILING MACHINERY has been deeply involved in the false ceiling channel machine manufacturing industry for over twenty years, specializing in the production of various types of metal ceiling channel machines. These include ceiling T bar machines, u channel machines, furring channel machine, wall angle machine and metal ceiling carrier machines.

These false ceiling channel machines have been exported worldwide, and KINGREAL CEILING MACHINERY has established close connections with many brands, receiving widespread acclaim from customers. For any special production needs, please provide your drawings to KINGREAL CEILING MACHINERY, and our engineers will communicate with you to customize a complete false ceiling channel system solution.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About Metal Ceiling Channel Machine

The following are the types of false ceiling channel machines that KINGREAL CEILING MACHINERY can provide:

- U channel roll forming machine

- Silhouette ceiling t grid roll forming machine

- FUT ceiling T bar roll forming machine

- Flat ceiling T bar roll forming machine

- Black groove ceiling T bar roll forming machine

- Baffle ceiling carrier forming machine

- Linear strip ceiling carrier forming machine

- Spring tee carrier forming machine

Metal Ceiling Channel Machine

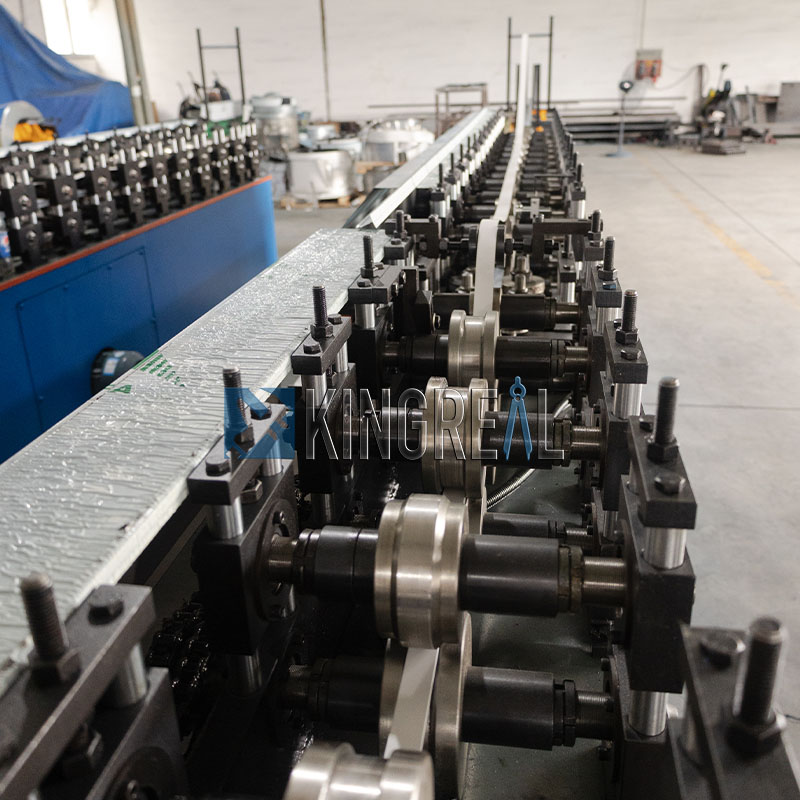

| The false ceiling channel machine is one of KINGREAL CEILING MACHINERY featured machines, designed to meet customers' diverse needs in metal ceiling channel production. KINGREAL CEILING MACHINERY offer a variety of machine models, including u channel roll forming machines, drywall wall angle profile machines and furring channel machines to accommodate the production of profiles of different types and sizes. KINGREAL CEILING MACHINERY metal ceiling channel machine has fully automatic operation, easy operation, and is equipped with a friendly human-machine interface (HMI) panel, which allows users to easily set up and monitor. Its main advantages include: ● Exquisite custom design: The machine structure is carefully designed to ensure both efficiency and beauty. ● Sturdy frame: The use of high-strength materials ensures the durability and stability of the false ceiling channel machine, and it can maintain good performance even in high-intensity production environments. ● Stable and efficient production: The whole machine runs smoothly and can achieve high-speed production to meet the needs of large-volume orders. In order to meet customers' needs for the uniqueness of the finished product, KINGREAL CEILING MACHINERY has equipped the metal ceiling channel machine with an advanced inkjet system, so that customers can print their own logos and other personalized logos on the surface of the finished product. This innovative design allows a machine to not only achieve fast production, but also provide unique customization services. These are processed from metal raw materials through a series of bending, cutting, and forming processes using KINGREAL CEILING MACHINERY's false ceiling channel forming machine. The production speed of the machine is 120 m/min, allowing for significantly improved production efficiency. |

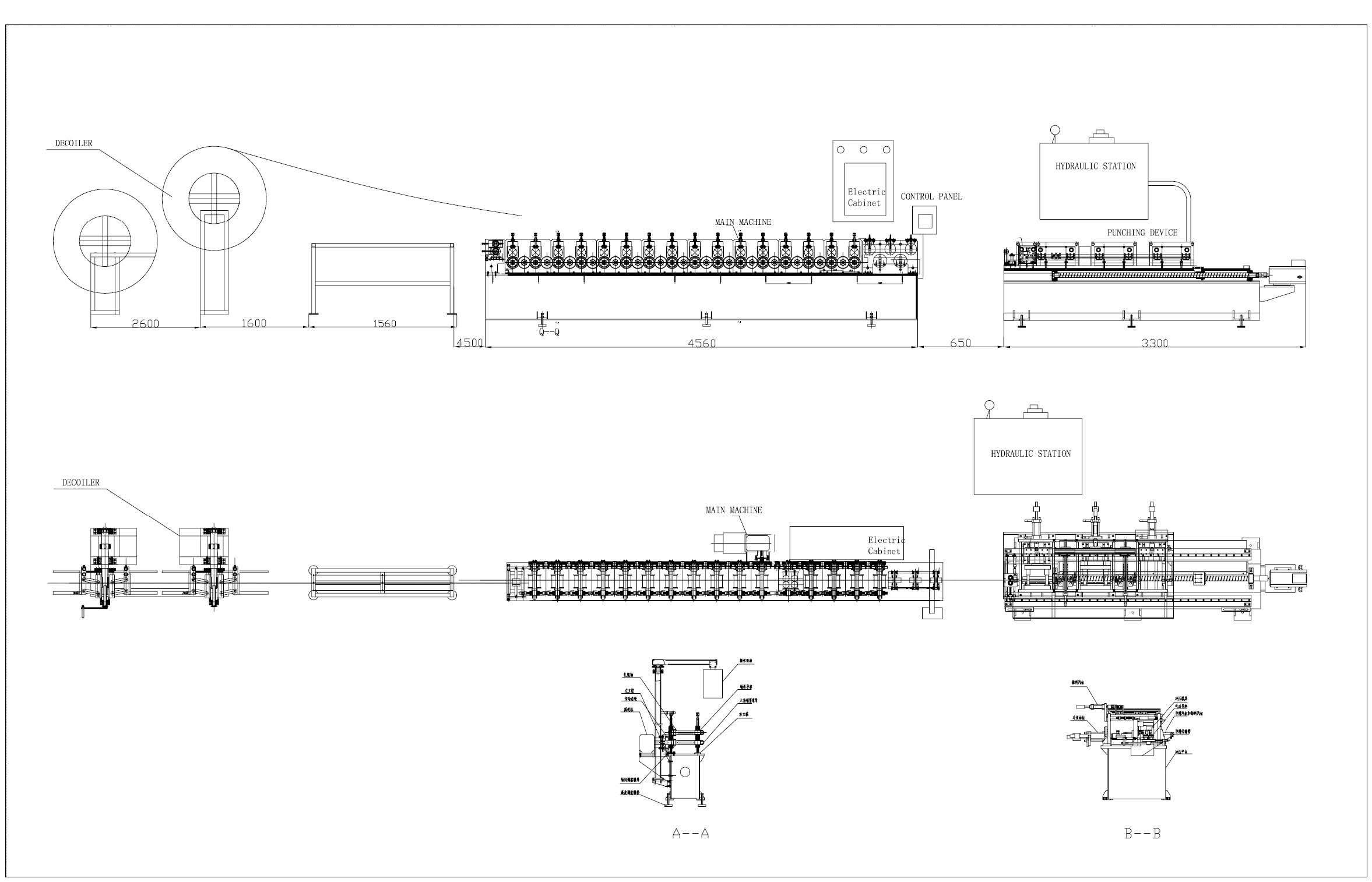

Specification of Metal Ceiling Channel Machine

Raw material | Gi steel, pre-painted gi steel |

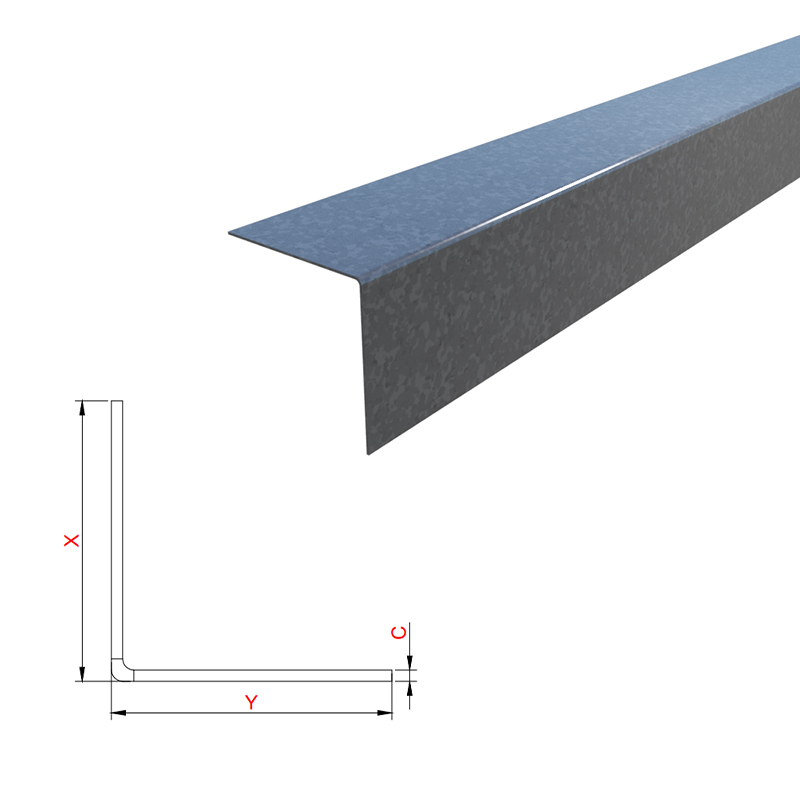

| Product shape | Wall angle, u channel, hat channel |

Production capacity | 120m/min |

| Electricity requirement | 380v 50 Hz 3 Phases |

| Power consumption | 30KW |

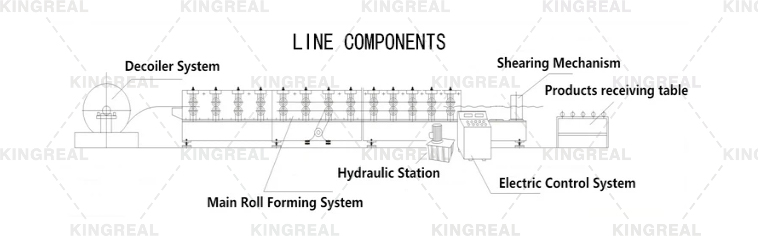

Working Process of False Ceiling Channel Machine

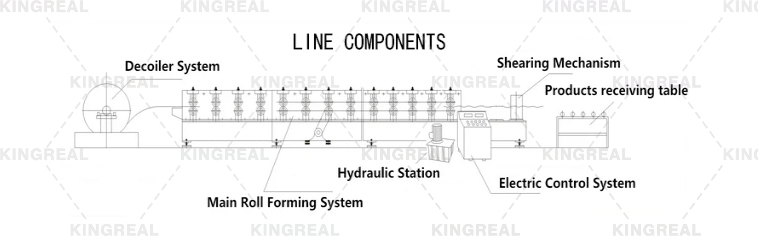

| Decoiler ↓ Main Roll Forming Machine ↓ Cutting Station ↓ Output Table |

Advantages of False Ceiling Channel Machine

(1)False Ceiling Channel Machine Help Produce Customized Products KINGREAL CEILING MACHINERY offers two flexible ways to produce finished products with customer logos to meet personalized needs. ●Roller engraving: The first way is to engrave the customer's logo on the forming roller. As the metal coil is rolled through the roll forming machine, the logo will be accurately printed on the finished product. This method is suitable for mass production, ensuring that each finished product has a consistent logo and enhances the brand image. ●Inkjet system: The second way is to equip the metal ceiling channel machine with an inkjet system. After the finished product is formed, the customer's required logo can be flexibly sprayed out through the inkjet system. The biggest advantage of this method is its flexibility. Customers can change different logos according to their needs, and they can easily achieve it by simply entering commands on the control panel. This is especially applicable to customers who need diversified products or small batch customization. Through these two methods, KINGREAL CEILING MACHINERY ensures that it can meet customers' unique and personalized needs for finished products. Whether it is mass production or customized orders, KINGREAL CEILING MACHINERY false ceiling channel machines can provide customers with efficient and accurate solutions to help brand promotion and market expansion. |  |

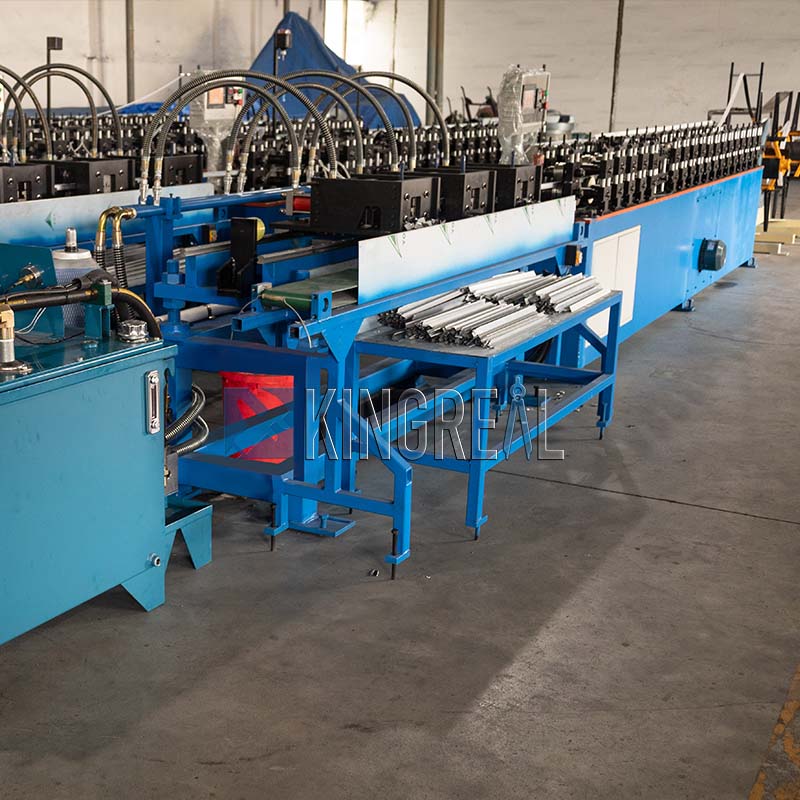

(2)Double-Head Decoiler of Metal Ceiling Channel Machine The double-head decoiler is designed for high-speed roll forming, allowing two rolls of material to be processed simultaneously. This reduces changeover time and enhances production efficiency, enabling continuous material supply and minimizing downtime to improve overall output. |  |

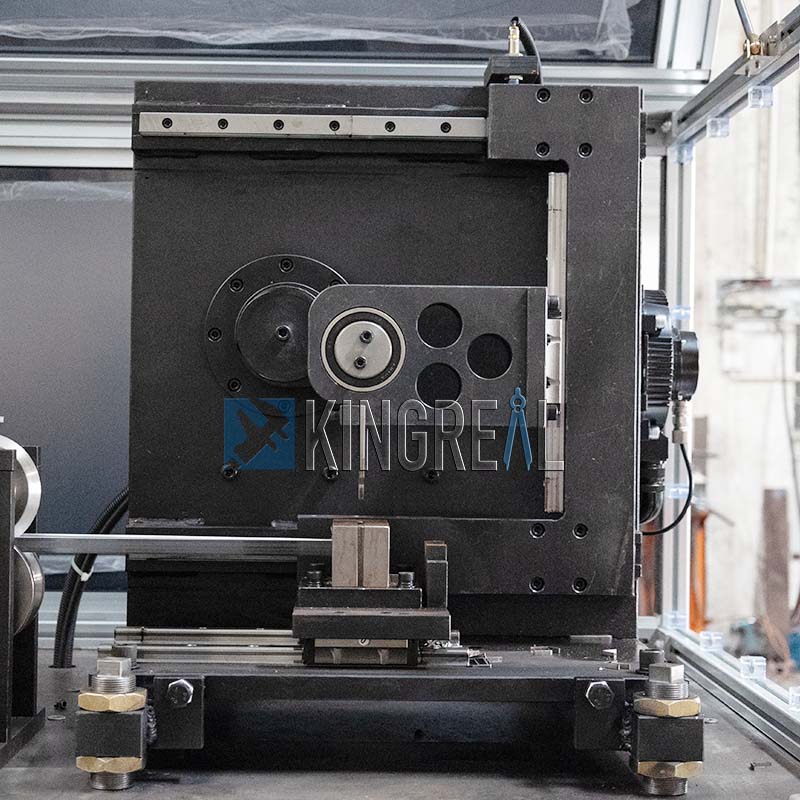

(3)Two Cutting Models about False Ceiling Channel Machine The KINGREAL CEILING MACHINERY false ceiling channel machine offers two cutting models—flying shear and swing shear to meet customers' different production needs. Usually, the wall angle profile machines provided by KINGREAL CEILING MACHINERY adopt the swing shear system. If you have special requirements for the shear system of the false ceiling channel machine, please feel free to consult KINGREAL CEILING MACHINERY. |  |

(4)Multi-specification False Ceiling Channel Machine This metal ceiling channel machine is designed for customers with multiple false ceiling channel production requirements. By simply changing the rollers and cutting molds, you can produce wall angle, u channel and omega channel. |  |

Additional Options About False Ceiling Channel Machine

(1) Protective Shield for Metal Ceiling Channel Machine: You can equip the KINGREAL CEILING MACHINERY false ceiling channel machine with a protective shield to prevent dust, debris, and other external materials from entering the machine, thereby reducing equipment wear and extending its lifespan. It also effectively protects operators from contact with moving parts, reducing the risk of accidental injury. |  |

(2)Automatic Packing Machine for False Ceiling Channel Machine: KINGREAL CEILING MACHINERY can provide an automatic packing machine for an automated packing solution for profiles. The packing machine can quickly complete packing tasks, significantly enhancing production efficiency. |  |

Product Display

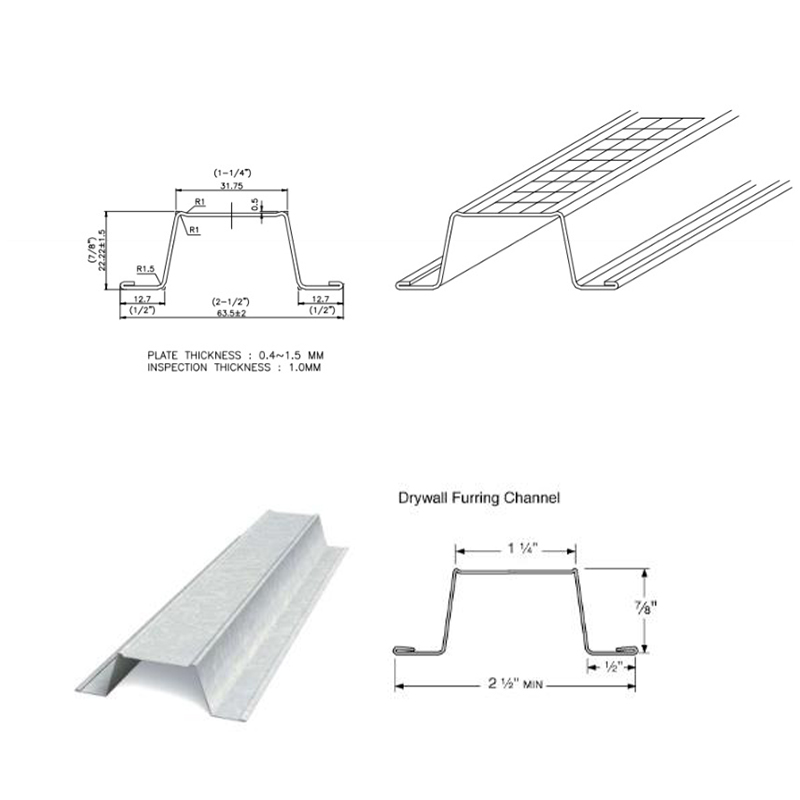

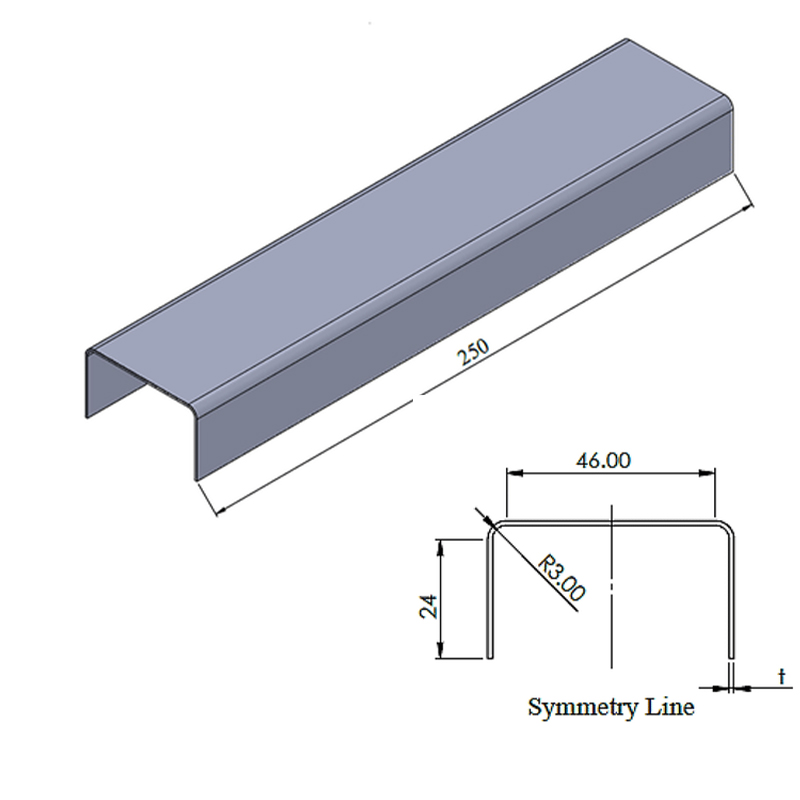

Drawing of False Ceiling Channel Product

Ceiling T Bar Machine

Ceiling t bar machines usually use galvanized steel and pre-coated galvanized steel as the main metal raw materials, and can produce ceiling t grids of different sizes and types. KINGREAL CEILING MACHINERY is committed to providing customers with diversified solutions, including Flat ceiling t grid machine, Black line ceiling t bar machine, Silhouette ceiling t bar machine, FUT ceiling t bar machine and other equipment to meet different needs.

KINGREAL CEILING MACHINERY ceiling t bar machines are well received by customers for their stable operation, excellent forming accuracy and production speed of up to 30 m/min. KINGREAL CEILING MACHINERY ceiling t grid machines not only excel in performance, but also ensure the high standards and consistency of each ceiling t bar through strict quality control.

In addition, the ceiling t grids produced by KINGREAL CEILING MACHINERY ceiling t bar machine can be combined with the open cell ceilings produced by the grilyato ceiling machine to form a complete open cell ceiling system with a surround.

Specification of Ceiling T Grid Machine

| Roller Stands | 18sets, 2sets of rollers for alignment(main t) 18sets, 1sets of rollers for alignment(main t) |

| Roller Material | CR12 Mold steel, average hardness HRC55 |

| Production Speed | 0-33m/min |

| Machine Frame | 20mm thickness base panel, 6mm side panel,45# steel |

Working Process of Ceiling T Bar Machine

| Hydraulic Decoiler ↓ Main Roll Forming Machine ↓ Punching and Shearing Station ↓ Product Table |

Advantages of Ceiling T Grid Machine

(1)One Line for Different Finished Sizes: The KINGREAL CEILING MACHINERY ceiling t bar machine can produce ceiling T bar of various sizes by simply changing the roller set and cutting molds, making operation easy. |  |

(2)Punching and Cutting in One Step: The KINGREAL CEILING MACHINERY fully automatic ceiling T bar roll forming machine can perform punching and cutting simultaneously, greatly enhancing the precision of finished products and production efficiency. |  |

(3)High-Speed Ceiling T Bar Machine: The KINGREAL CEILING MACHINERY ceiling T bar machine operates at a high speed of up to 30 m/min, equipped with advanced automatic control, requiring minimal manual intervention. |  |

Additional Options About Ceiling T Grid Machine

(1)Protective Shield for Ceiling T Bar Machine: KINGREAL CEILING MACHINERY can provide a protective shield to effectively prevent material or debris from splashing, protecting workers and ceiling t bar machine. Additionally, the cover helps block dust and pollutants, extending the equipment's lifespan. |  |

(2)Hydraulic Cooling Unit for Ceiling T Bar Machine: The hydraulic cooling unit maintains the equipment at an ideal operating temperature, preventing overheating and improving machine performance and longevity. Proper temperature management reduces the risk of equipment failure and enhances production reliability. |  |

Product Display

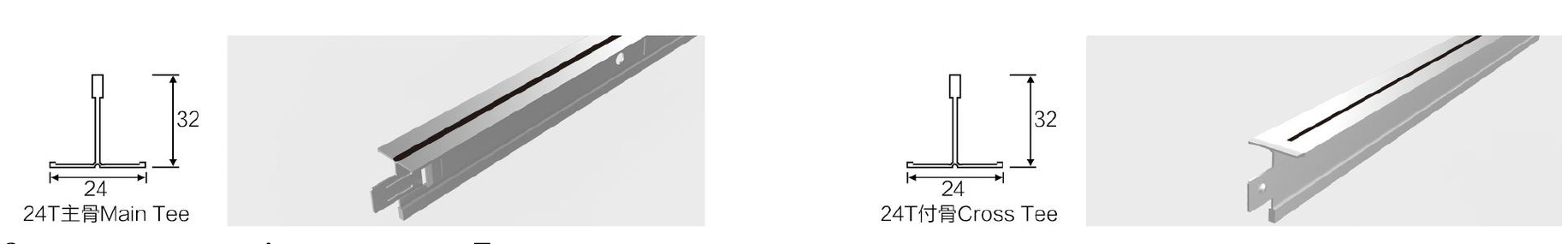

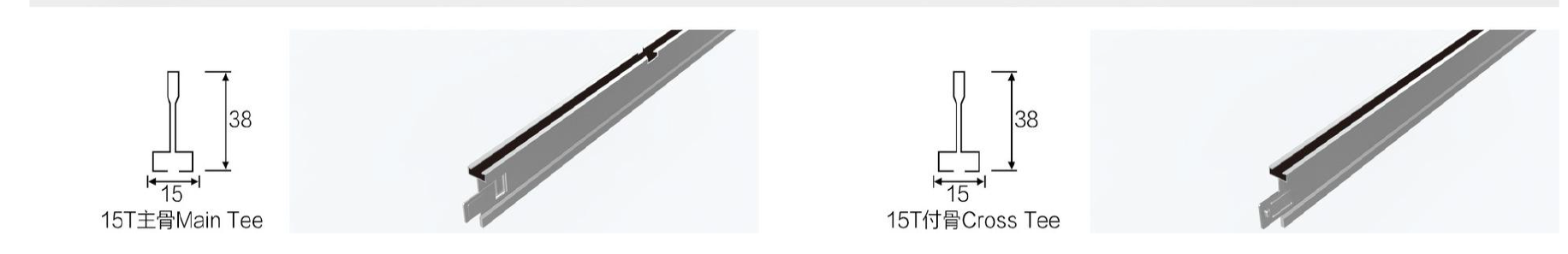

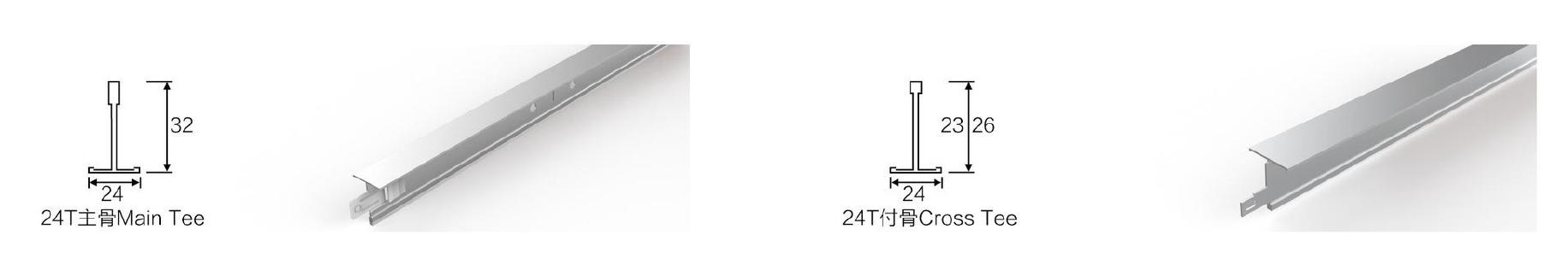

Drawing of Ceiling T Bar Product

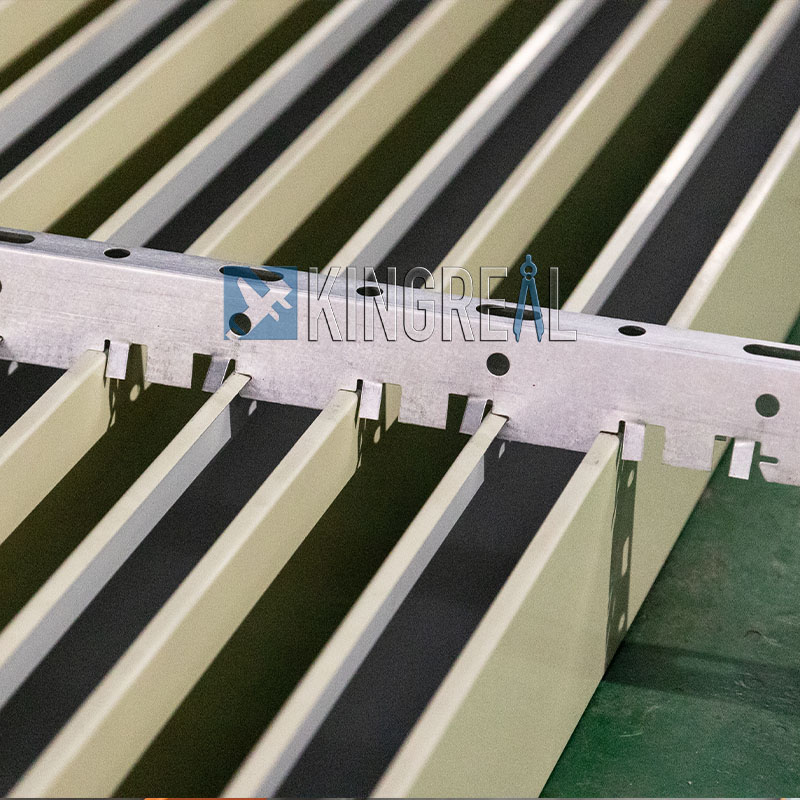

Metal Ceiling Carrier Machine

KINGREAL CEILING MACHINERY offers three metal ceiling carrier machine manufacturing solutions: linear strip ceiling carrier machine, baffle ceiling carrier machine, and spring tee roll forming machine.

These metal ceiling carrier machines are carefully designed to meet the diverse needs of different customers and has high-speed and high-precision forming capabilities to meet the needs of large-scale production and ensure the consistency and quality of each metal ceiling carrier.

It is worth mentioning that the metal ceiling carrier machines have excellent stability and can maintain good performance even in high-intensity production environments. These metal ceiling carrier machines are highly automated and easy to operate, which not only achieves rapid production, but also ensures the stability of the forming effect and product quality.

In addition, KINGREAL CEILING MACHINERY metal ceiling carrier machines are usually used in conjunction with equipment such as baffle ceiling machines, linear strip ceiling machines and clip in metal ceiling tile making machines to produce a complete suspended ceiling system. This system is not only beautiful and generous, but also has good load-bearing capacity, suitable for various ceiling designs in commercial and residential buildings.

Specification of Metal Ceiling Carrier Machine

| Metal Ceiling Carrier Machine | ||

Raw Material | Type | GI Steel Strip |

| Material Thickness | 0.5-0.7mm for metal ceiling carrier | |

| Yield Strength | G300-G45 Comply with international standard | |

| Production Speed | 15m/min | |

Products Accuracy | Shearing Accuracy | ±1.0mm |

| Straightness | Bending is less than 1‰/m, twist is less than 1.3%/m | |

Working Process of Metal Ceiling Carrier Machine

| Decoiler ↓ Leveling Machine ↓ Punching Machine ↓ Roll Forming Machine ↓ Cutting Station |

Advantages of Metal Ceiling Carrier Machine

(1)High-Precision Punching Machine for Metal Ceiling Carrier Machine: The KINGREAL CEILING MACHINERY metal ceiling carrier machine is equipped with a high-speed punching machine that can punch 300 mm lengths in one go, improving production speed while ensuring product precision with each punch. |  |

(2)2-in-1 Uncoiler and Leveling Machine of Metal Ceiling Carrier Machine: This machine integrates uncoiling and leveling functions into one device, reducing space requirements and optimizing the production line layout. By combining these two functions, it minimizes changeover time and enhances overall production efficiency. |  |

Product Display

Customers in KINGREAL CEILING MACHINERY Factory

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)