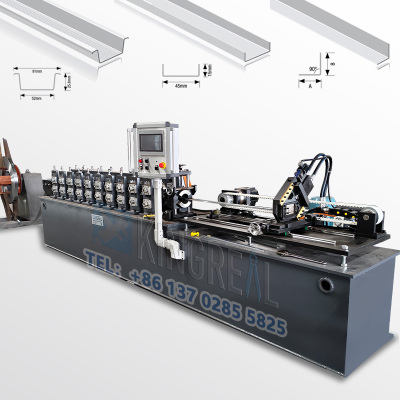

Wall Angle Making Machine

KINGREAL CEILING MACHINERY can provide a variety of gypsum wall angle making machine manufacturing solutions and design components with different parameters for gypsum board wall angle making machines according to customers' actual needs and drawings.

- KINGREAL CEILING MACHINERY

- China

Details

Video About Gypsum Wall Angle Making Machine

Introduction of Gypsum Wall Angle Making Machine

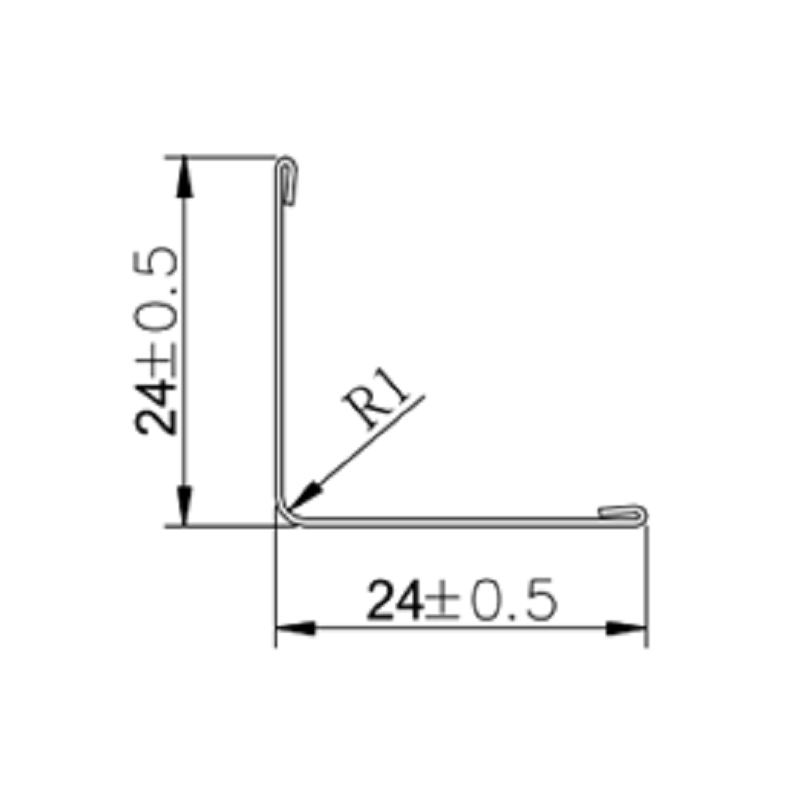

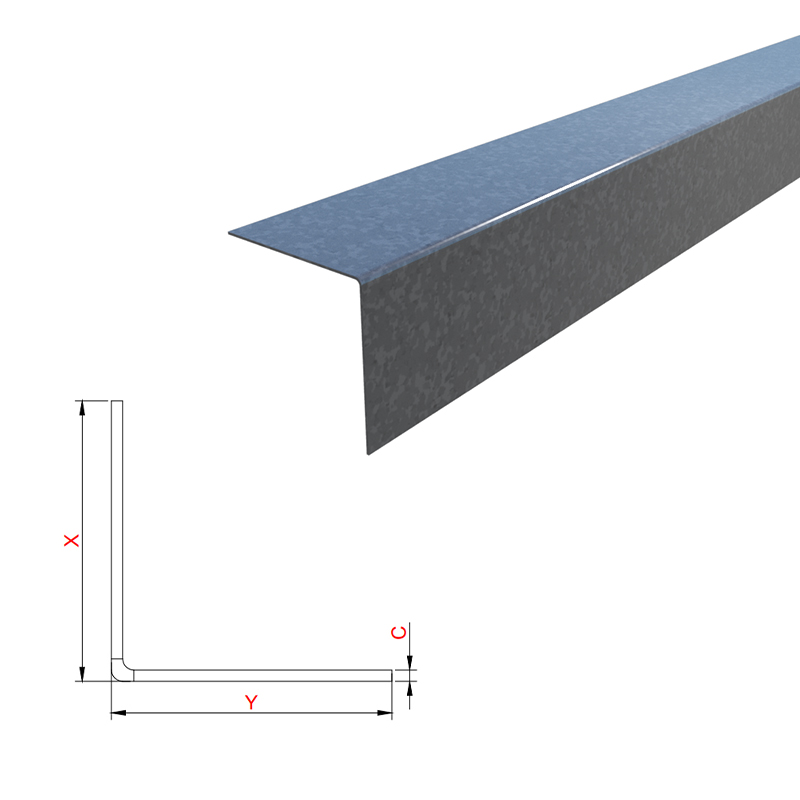

Gypsum wall angle making machines are special equipment used to make wall angles, which can produce corners of different sizes through processing and manufacturing. Among them, the gypsum wall angle making machine can produce the most common finished product size: 25mmx25mmx3000mm. Wall angles are essential parts in the construction industry and are widely used in the construction industry. They specifically play the role of bearing weight and hanging suspended ceilings . These Gypsum wall angle roll forming machines are designed to produce high-quality and precise wall angles using metal materials such as Gi Steel or PPGI with a thickness range of 0.4-1.0mm. |  |

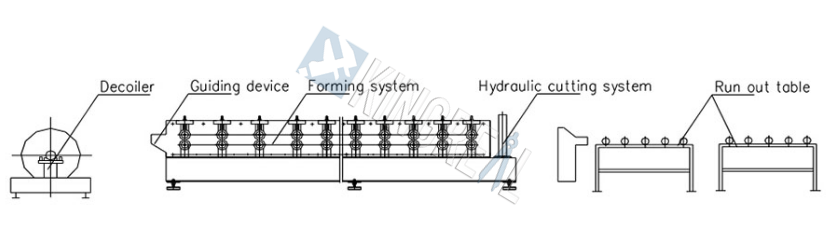

Working Process of Gypsum Wall Angle Making Machine

Hydraulic Decoiler ↓ Main Roll Forming Machine ↓ Fly Shearing System ↓ Product Table |  |

Parameters of Gypsum Wall Angle Making Machine

Specification | A. Uncoiler x one unit. 1. Loading capacity : 1,100 Kgs 2. Coil specification : O.D.: 1,200 mm. / I.D.:480 – 510 mm. Strip width : 100 mm. 3. Manual coil tightening 4. Driven by forming machine. |

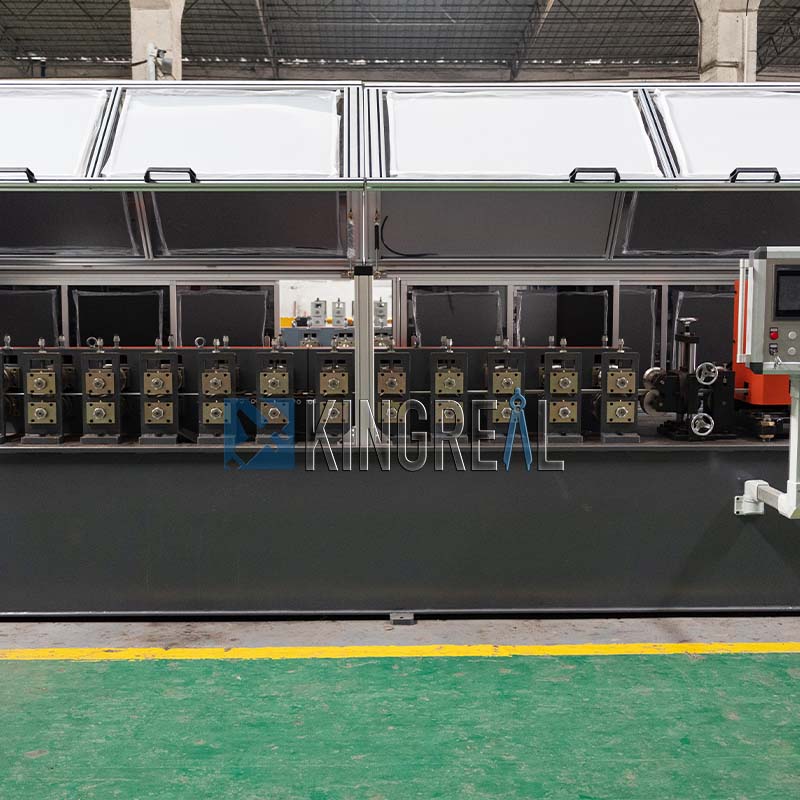

| B. Cold roll forming machine x one unit. 1. Model: G-240-CL type. (Changeable type) 2. Roll Forming Stands: 10 stands with entry guide stand. 3. The machine base is made of high-strength steel with precise welding, stress relief treatment. Each stand will have an individual worm gear reduction, and common drive shaft to make all rollers are running simultaneously. 4. Main driven motor: 7.5 HP motor with 7.5HP inverter. 5. Forming rollers: one full set. 6. Roll shaft: Ø40mm, in S45C material. 7. Rolls: use the material SKD11 with vacuum heat treatment, Hardness is HRC 58-61, wear-resistant and durable. | |

| C. Hydraulic automatic cut-off device x one unit 1. Cut-off blade is in material of SKD11 with vacuum heat treatment, Hardness HRC 58 – 61, wear-resistant, steel structure, long life. 2. Unique design gives trouble-free operation. 3. Cut-off length: 1M – 4.0M, Length is adjustable. Length tolerance within ±3.0mm. 4. Hydraulic pack (3 HP): 1 set. 5. Cut-off blade: 3 sets. | |

| D. Product run-out table (3.5 Meter) x one unit. Material run-out table for finished parts collection. | |

| E. PLC electric control system x one unit. 1. Mitsubishi PLC controller x 1 set 2. HMI control panel x 1 set. 3. Electric voltage will be confirmed before placing order. |

Selection of Different Production Options --Gypsum Wall Angle Making Machine

(1) Decoiler for Gypsum wall angle making machine In the selection of decoiler, users can choose between single-head decoiler and double-head decoiler. The double-head decoiler design allows decoiler on the left and material loading on the right, ensuring that the gypsum board wall angle making machine always has sufficient raw materials during operation. This configuration effectively avoids downtime caused by raw material shortage, thereby significantly improving overall production efficiency. For example, in the case of high production demand, double-head decoiler can achieve seamless connection to ensure the continuity and stability of the gypsum board wall angle machine. Such a design not only increases the production volume per unit time, but also reduces the time waste caused by changing coils during the production process, thereby further improving economic benefits and production capacity. |  |

| (2) Roll forming machine for gypsum board wall angle making machine The roll forming machine is one of the most critical equipment in the production process of gypsum board wall angle machine. The diversity and flexibility of its configuration directly affect the quality, appearance and function of the finished product. | |

① Roller for gypsum wall angle making machine The roller of the roll forming machine can be configured in various ways according to customer needs. For example, it can be equipped with an embossing roller. The role of the embossing roller is not only to produce a beautiful pattern on the surface of the finished product, but also to significantly enhance the anti-slip effect. This design is crucial in many application scenarios, especially in areas where anti-slip performance is required, which can effectively improve user experience and product safety. In addition, the roller can be engraved with the logo required by the customer. By rolling, the logo is directly printed on the surface of the finished product. Such personalized customization not only enhances the brand value, but also enhances market competitiveness. |  |

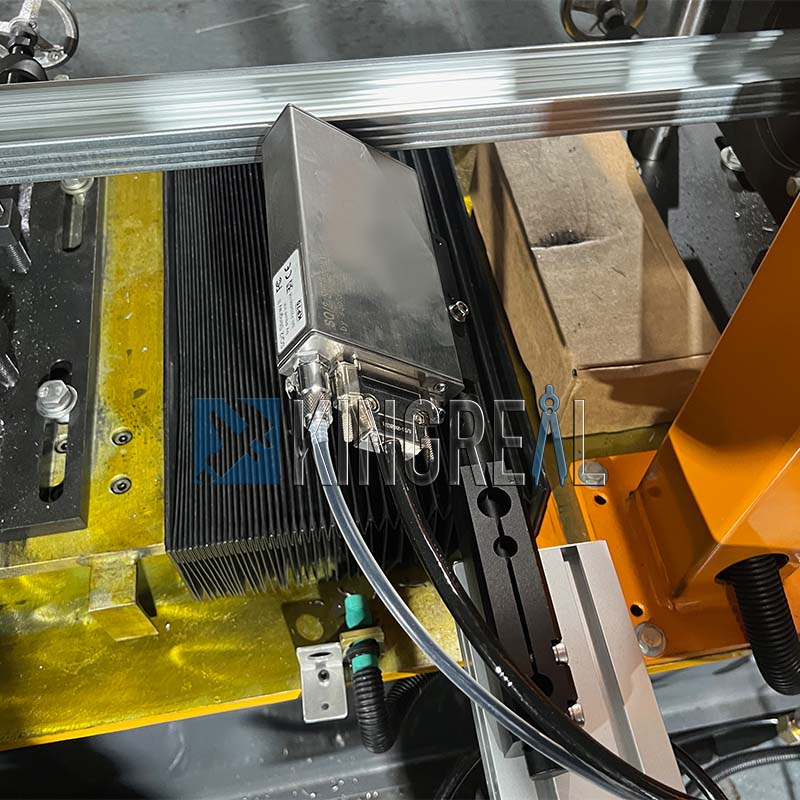

② Inkjet device for gypsum wall angle roll forming machine In order to further enhance the personalized production capacity of the roll forming machine, customers can choose to install an inkjet device. Through the inkjet system, the logo required by the customer can be sprayed on the surface of the finished product during the forming process. This flexibility allows customers to adjust the logo design in real time on the control panel according to their needs, truly realizing personalized production. |  |

③ Protective shield for gypsum wall angle making machine To improve operational safety, the gypsum board wall angle machine can be equipped with a protective shield. When the gypsum wall angle making machine is running, the protective shield can effectively isolate the operator from the contact with the mechanical parts, reducing the risk of accidents. This design not only protects the safety of workers, but also meets the high safety standards of modern production. |  |

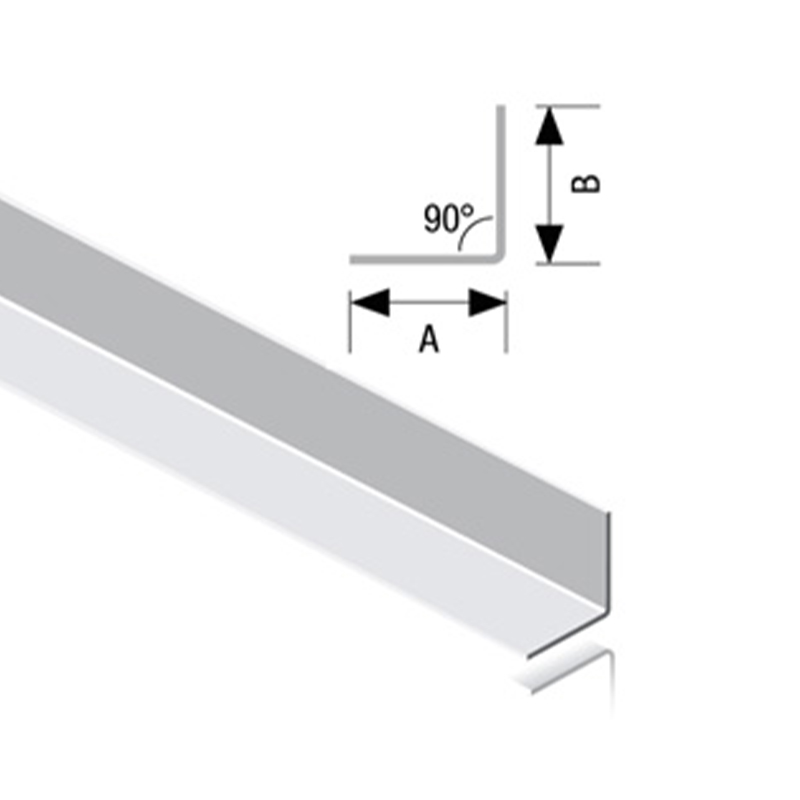

④ Single-specification & multi-specification gypsum wall angle making machines Gypsum wall angle making machines can be divided into two types: single-specification and multi-specification. Single-specification gypsum wall angle making machines are suitable for producing products of fixed sizes, while multi-specification gypsum wall angle making machines are highly flexible. Multi-specification gypsum board wall angle machines can easily produce finished products of different sizes by automatically adjusting the width and narrowness. This flexible size adjustment capability enables the gypsum wall angle making machine to meet diverse market needs. |  |

(3) Shearing system for gypsum wall angle making machine The shearing system is also indispensable in the production process of the gypsum board wall angle machine. The high-speed gypsum wall angle making machine is equipped with a swing shear. This design can not only maintain good shearing accuracy during high-speed production, but also effectively respond to the shearing needs of different materials. The advantages of the swing shear are its fast cutting speed and high cutting quality, which can ensure that the edges of the finished product are neat and smooth, improving the overall product's visual effect and performance. Other configurations of the gypsum board wall angle machine are equipped with flying shears, whose flexibility and efficiency provide guarantee for production. The flying shear system can perform precise shearing at high speed, which is suitable for mass production. This efficient shearing method enables enterprises to respond quickly and efficiently to large-scale orders. |  |

(4) Punching station for gypsum wall angle making machine(optional) The configuration of the punching station depends on the specific needs of the customer. If the customer has production needs for perforated wall angles, the punching mold can be customized according to their requirements to meet the needs of different hole diameters and hole types. For example, the customer may need to produce different types of perforated wall angles. KINGREAL CEILING MACHINERY has equipped the gypsum wall angle making machine with a highly flexible punching station, which can quickly switch different molds on the same production line, greatly improving the flexibility and efficiency of production. |  |

(5) Auto packaging unit for gypsum wall angle making machine (optional) The choice of auto packaging unit also depends on the customer's demand for automation. The equipment is designed with a knurling pattern on the conveyor roller to increase friction and improve the stability of the material. The automatic packaging function not only saves labor costs, but also improves overall production efficiency. The automatic packaging machine can quickly package the finished products after production, reducing manual intervention and improving the continuity of production. This efficient packaging method not only improves work efficiency, but also ensures the safety of finished products during transportation and reduces losses caused by human errors. |  |

Advantages of Gypsum Board Wall Angle Machine

| ① High-speed gypsum wall angle making machine The production speed of the gypsum board wall angle machine can reach 120m/min. Such efficient production capacity enables enterprises to take the initiative in market competition. The fast production capacity not only increases the output per unit time, but also brings greater economic benefits to the enterprise, especially when facing urgent orders, it can quickly meet customer needs. |

| ② Finished products of various sizes Through the PLC control panel, users can directly input parameters, and the roller of the roll forming machine will automatically adjust the width to produce finished products of different sizes. Customers can easily produce wall angles of different sizes such as 30x30mm and 40x40mm. This flexibility enables the wall angle making machine to adapt to diverse market needs and improve the utilization rate of the production line. |

| ③ Different types of wall angles The market has a variety of demands for wall angles, and the change of forming rollers is particularly important. Through the design of changing the hanger, users can easily change the rollers to produce different types of wall angles. This flexibility not only improves production efficiency, but also meets customers' demand for product diversification. |

| ④ Fully automated gypsum board wall angle machine The gypsum wall angle making machine is fully automated, including unwinding, feeding, forming, punching logos, punching holes, punching scales, cutting and automatic stacking. This design not only improves production efficiency, but also reduces the possibility of human errors and ensures the stability and reliability of the production process. In the entire process, only one employee is required to perform auxiliary operations, which greatly reduces labor costs. |

| ⑤ High precision gypsum board wall angle machine The gypsum wall angle making machine has high production accuracy, and the error range of the finished product is controlled within ±1.0mm. Such high precision ensures the quality of the finished product and meets the strict requirements of customers. In many high-standard application fields, this accuracy is the key to ensuring product performance and reliability. |

Drawing About Wall Angle

Why Choose KINGREAL CEILING MACHINERY Gypsum Wall Angle Making Machine?

KINGREAL CEILING MACHINERY is a manufacturer with more than 20 years of rich experience in the false ceiling channel machine manufacturing industry. One of its featured products is the gypsum wall angle making machine. So far, KINGREAL CEILING MACHINERY gypsum board wall angle machines have been sold to Russia, the United Kingdom, Greece, Qatar, India, Vietnam and many other countries. It has accumulated rich experience in sales, design, manufacturing and installation, and also has a keen insight into market dynamics. KINGREAL CEILING MACHINERY engineers have a deep understanding of the different requirements of various countries for gypsum wall angle making machine parameters and performance, which effectively reduces unnecessary communication in the early communication.

KINGREAL CEILING MACHINERY engineers have unique insights into the design of gypsum wall angle making machines, which can well meet the actual production needs of customers and always provide customers with high-quality, high-efficiency and demand-compliant gypsum board wall angle machines. In addition to high-quality gypsum wall angle making machines, KINGREAL CEILING MACHINERY also provides customers with comprehensive services and has won wide acclaim. KINGREAL CEILING MACHINERY services cover everything from early online communication, on-site accompanying inspections, to personalized design and manufacturing plans, strict production processes, machine inspections, packaging and delivery, installation and operation training, and even troubleshooting and resolution, to ensure that customers receive all-round support.

Customers in KINGREAL CEILING MACHINERY Factory

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)