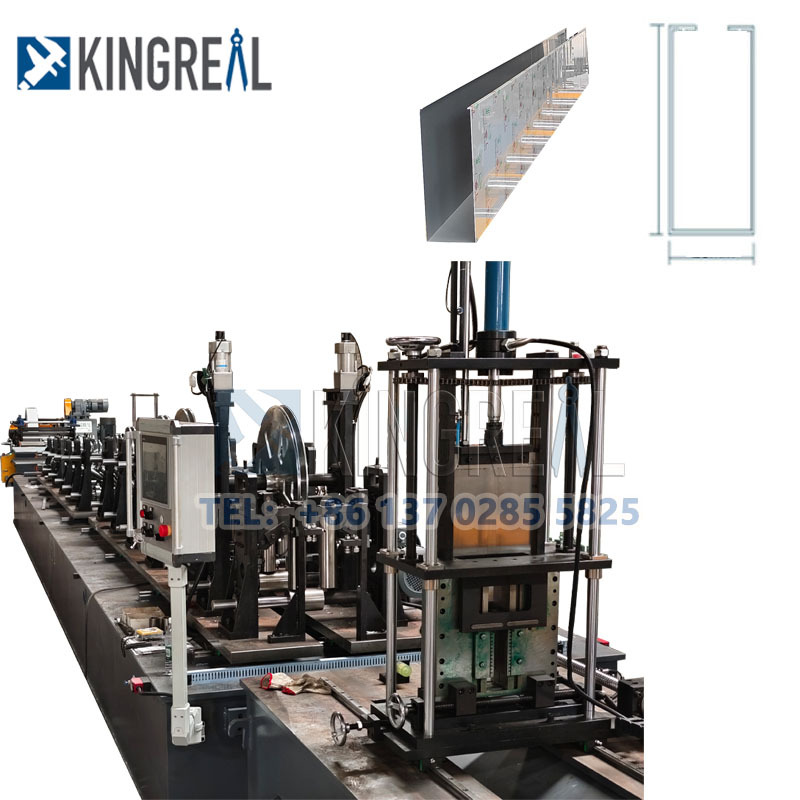

Baffle Ceiling Making Machine

KINGREAL CEILING MACHINERY provides customers with a variety of baffle ceiling making machine manufacturing solutions, with a variety of configurations to choose from to meet different needs. Currently, KINGREAL CEILING MACHINERY baffle ceiling machine has been successfully exported to India, Italy, the Netherlands, Russia, Mexico, Turkey and Saudi Arabia and other countries.

- KINGREAL CEILING MACHINERY

Details

Video About Baffle Ceiling Making Machine

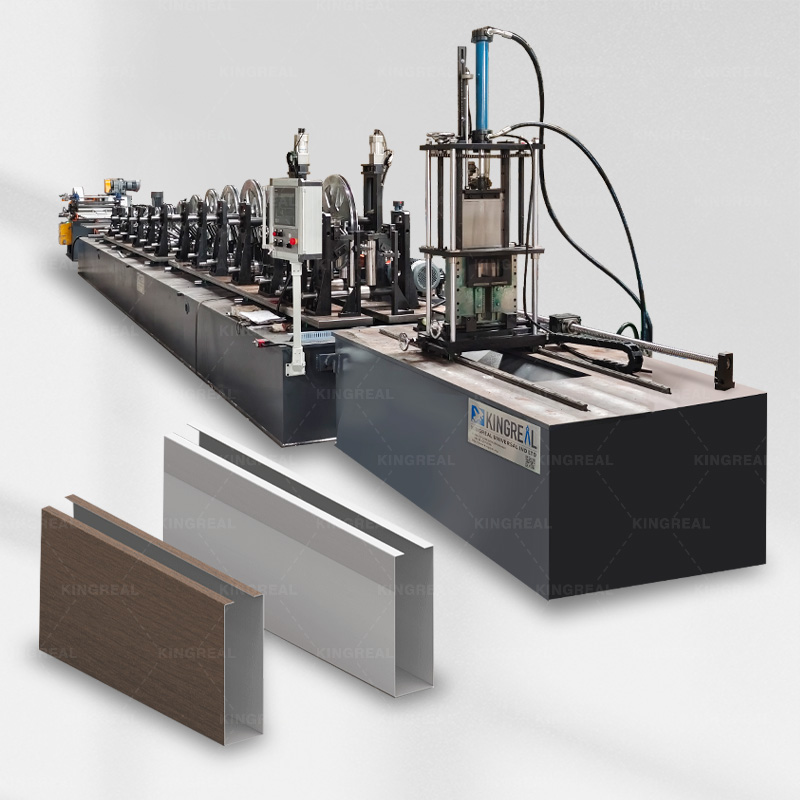

Introduction to Baffle Ceiling Making Machine

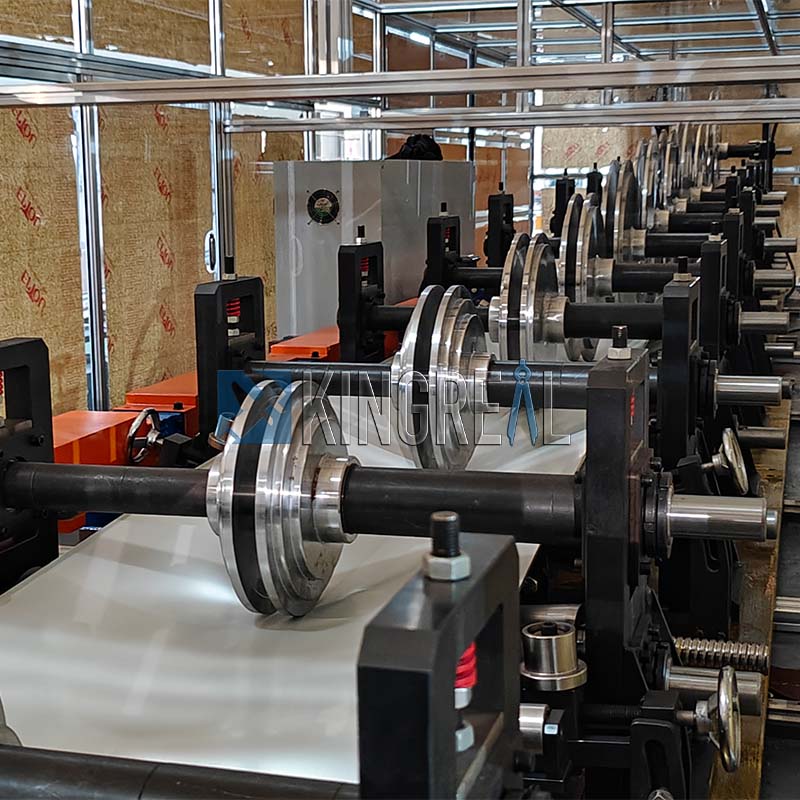

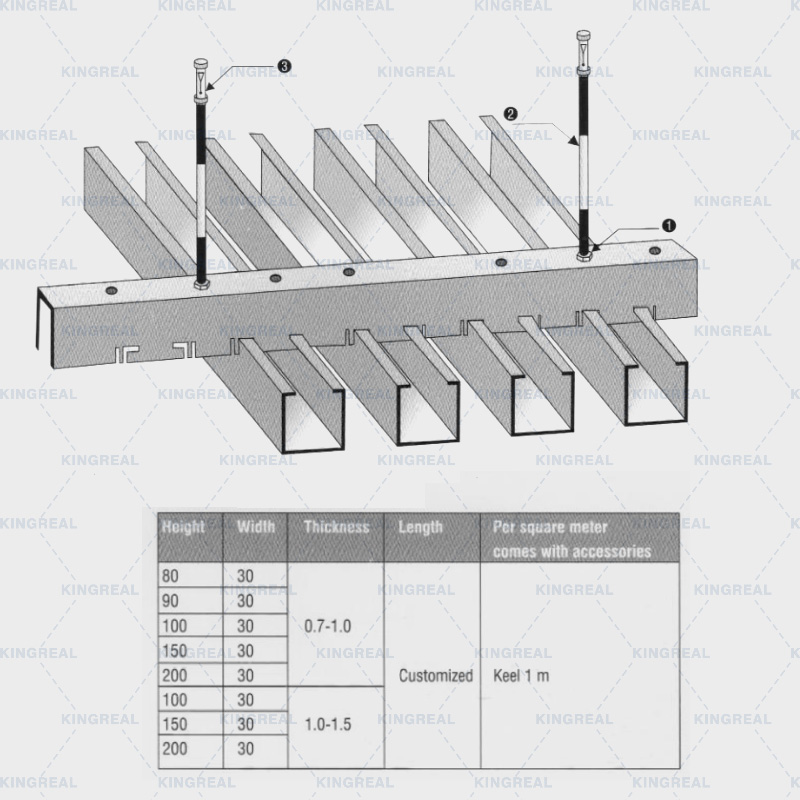

KINGREAL CEILING MACHINERY baffle ceiling making machine produces baffle ceilings of various types and sizes by passing Gi steel or aluminum metal coils through components such as decoiler, precision leveling machine, roll forming machine and cutting station. The baffle ceiling machine can reach a speed of 30m/min and can provide 150mm height baffle ceiling machine, 200mm height baffle ceiling making machine and 300mm height baffle ceiling machines to meet customers' needs for 25-100mm width and 75-300mm height. In addition, KINGREAL CEILING MACHINERY can also provide baffle ceiling carrier machine, which can be used with baffle ceiling to perfectly assemble into a complete baffle ceiling system. |  |

Parameters of Baffle Ceiling Machine

| Material | Gi steel or aluminum coils |

| Material thickness | 0.4-0.7mm for Gi steel coils, 0.4-1.1mm for aluminum coils |

| Length | 1-8m |

| Length tolerance | ±1mm |

| Production speed | 0-30m/min (adjustable) |

Optional Baffle Ceiling Machine with Different Configurations

(1) Diverse choices for decoilers

The decoiler is an important part of the baffle ceiling making machine, and its performance directly affects the efficiency of the subsequent production process. In order to achieve maximum customization, KINGREAL CEILING MACHINERY baffle ceiling machine provides a variety of decoiler configurations to adapt to different production environments and needs:

Manual decoiler

Manual decoiler is the most basic decoiler equipment, suitable for small-scale production or customers with limited budgets. It is easy to operate and does not require a complex control system. It is suitable for occasions where the decoiler speed is not required. The advantages of this decoiler are its low cost and easy maintenance, which is particularly suitable for start-ups or small processing plants.

Hydraulic decoiler

The hydraulic decoiler is suitable for large-scale production and has higher efficiency and stability. This decoiler uses a hydraulic system that can automatically control the decoiler speed and tension to ensure the stability of the material during the decoiler process. The hydraulic decoiler has a high degree of automation, which can not only effectively save manpower, but also improve production efficiency.

In large-scale production, hydraulic decoilers can quickly and continuously feed materials into the baffle ceiling making machine, reducing errors caused by manual operation. Its efficient performance enables customers to complete mass production in a short time, greatly improving production capacity.

Decoiler equipped with a feeding trolley

In order to further improve the automation level of the baffle ceiling machine, KINGREAL CEILING MACHINERY also provides the option of decoilers equipped with a feeding trolley. This configuration can quickly feed materials to the next process, reduce manual operation, and improve overall production efficiency.

The design of the feeding trolley makes the material transmission more convenient, and the operator can focus more on other links in the production process. This configuration is particularly suitable for companies that require efficient and continuous production, and can significantly improve production efficiency and product quality.

(2)Choice of leveling machine

Leveling machine is an indispensable part of the baffle ceiling making machine. KINGREAL CEILING MACHINERY provides two different leveling machine configurations to meet the needs of different customers:

Precision Leveling machine

Precision leveling machine is equipped with more rollers, which can achieve better leveling effect and is suitable for customers with higher requirements for leveling. The design of this leveling machine can ensure the consistency of materials during processing and improve the quality of the final product. In many applications, the flatness directly affects the appearance and performance of the baffle ceiling. With the precision leveling machine, customers can produce higher quality baffle ceilings to meet the market demand for high-standard products.

Leveling machine

For customers who do not have high requirements for flatness, the leveling machine is an economical and practical choice. It can meet basic leveling needs while reducing equipment costs. This leveling machine is suitable for some production occasions that do not require high appearance, and can effectively control production costs.

(3)Flexible selection for main roll forming machines

The configuration of the main roll forming machine directly affects the production efficiency and finished product quality of the baffle ceiling. KINGREAL CEILING MACHINERY baffle ceiling machine has the following flexible main roll forming machine options:

Automatically adjust the width and narrowness of the roller group

This design allows customers to quickly adjust the width of the roller according to actual production needs, facilitating the production of baffle ceilings of different sizes. This flexibility allows customers to quickly adjust production strategies according to market demand and improve production efficiency. KINGREAL CEILING MACHINERY baffle ceiling machine helps customers quickly adapt to market changes and meet the needs of different customers through the roller set that automatically adjusts the width and narrowness.

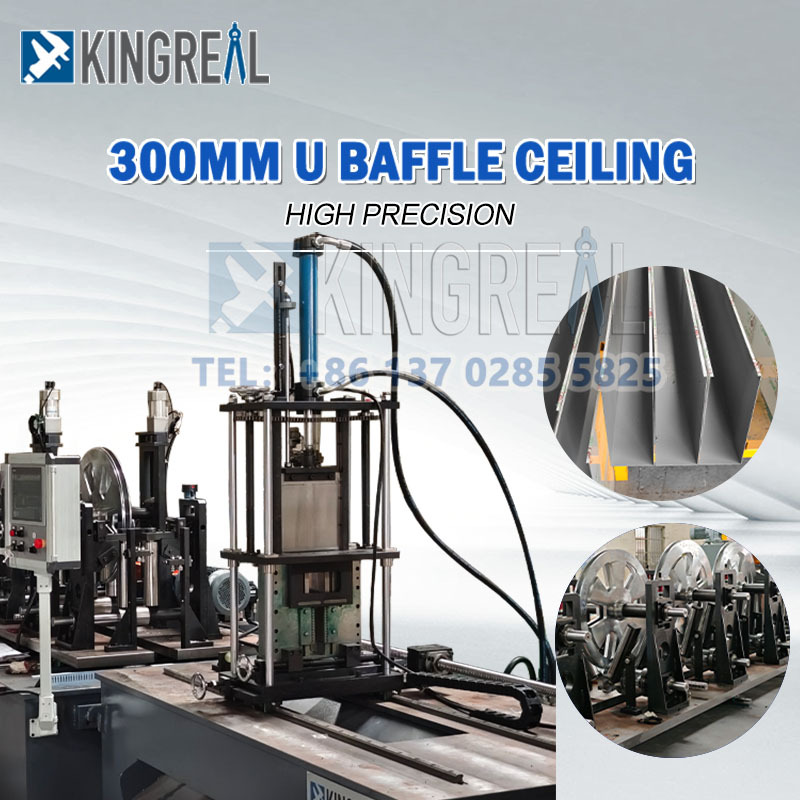

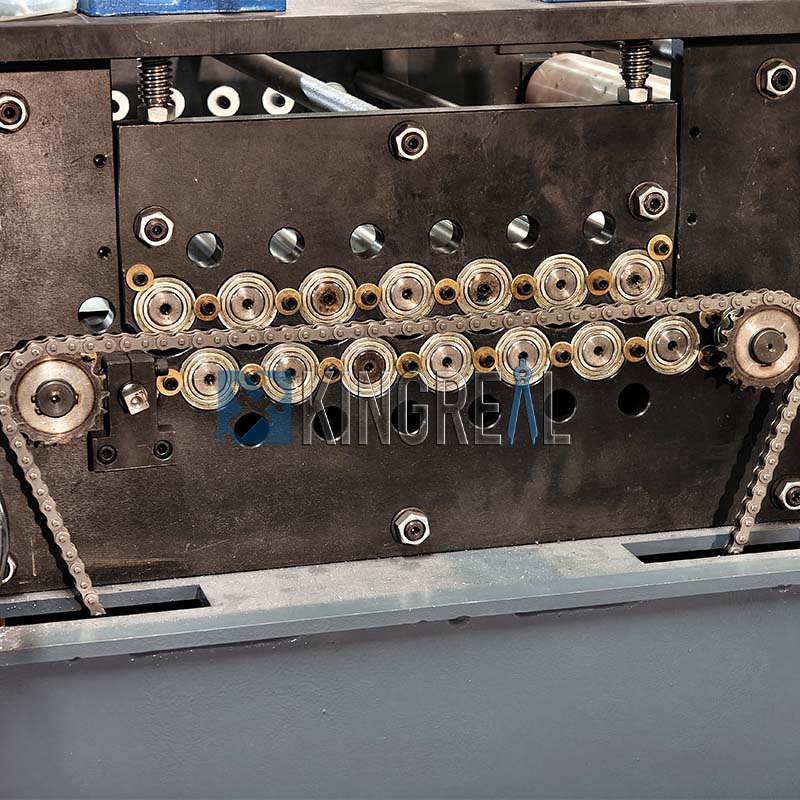

Hollow rollers

For the production of oversized baffle ceilings, such as 300mm height baffle ceilings, hollow rollers are indispensable. The hollow design not only reduces the weight of the roller, but also improves the forming accuracy of the material, ensuring that there will be no deformation or damage to the material during the production process. The design of the hollow roller greatly improves the production efficiency of baffle ceilings, which can speed up the production while ensuring quality. When using baffle ceiling machines with hollow rollers, customers can not only achieve higher production efficiency, but also ensure the accuracy and consistency of the final product.

(4)Flexibility for cutting devices

The cutting device is another key component of the baffle ceiling making machine. KINGREAL CEILING MACHINERY provides adjustable blade configurations to meet the needs of different customers:

Interchangeable blades

This design allows customers to replace and adjust the blades according to different sizes of baffle ceilings. Whether it is small or large baffle ceilings, customers can easily adapt to production needs and ensure the accuracy of cutting. The replaceable blade design greatly improves the flexibility of production, and customers can quickly adjust according to the actual production situation. This flexibility allows customers to cope with diverse production needs and ensure the efficient operation of the baffle ceiling making machine.

(5)Optional other configurations

In order to further enhance the function of the baffle ceiling making machine, KINGREAL CEILING MACHINERY also provides a variety of other optional configurations to ensure that customers get more comprehensive production support:

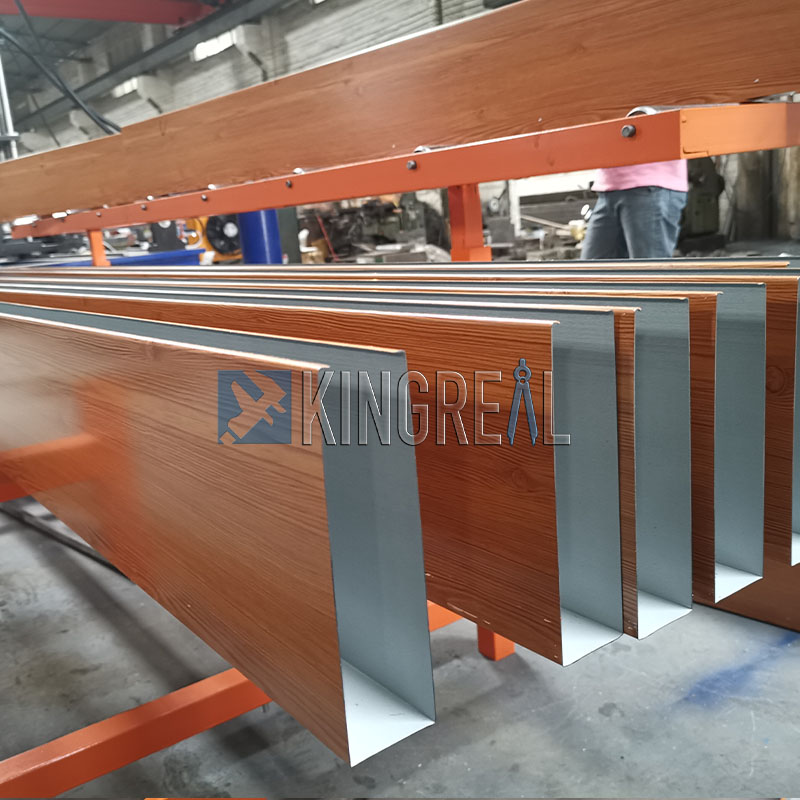

Laminating device

The laminating device can laminar the baffle ceiling during the production process, with the aim of reducing the scratches on the surface of the baffle ceiling during the production process and improving the appearance quality and durability of the product. Laminating treatment can not only enhance the aesthetics, but also improve the moisture and anti-fouling ability of the baffle ceiling. The introduction of this device enables the square tube to not only meet customer requirements in terms of function, but also maintain high standards in appearance and enhance market competitiveness. After using the laminating device, customers can significantly improve the market appeal of the produced baffle ceiling.

With protective shield

The protective shield is designed to improve operating safety and prevent accidental injuries during the production process. It can effectively protect the operator and extend the service life of the baffle ceiling machine.

KINGREAL CEILING MACHINERY Baffle Ceiling Machine VS Other Suppliers'

| Comparison point | KINGREAL CEILING MACHINERY baffle ceiling making machine | Baffle ceiling machine from other suppliers |

| Sizes of baffle ceiling | Width:25-100mm, Height: 75-300mm | Limited size selection, insufficient flexibility |

| Cooperation experience | Well-known companies, such as Douglas | Relatively little cooperation experience |

| Project experience | Exported to India, Mexico, Italy, Turkey, Saudi Arabia, Russia, the Netherlands and other countries | Less project experience, limited international market coverage |

| Types of baffle ceilings | U-shaped/V-shaped/folded/perforated baffle ceilings | U-shaped baffle ceilings only |

| After-sales service | Machine installation,operation training, machine commissioning,machine maintenance,parts maintenance | After-sales service is not perfect |

| Product quality assurance | Raw material selection, machine manufacturing, machine testing, and machine commissioning | Quality control process is not strict enough |

Drawing About Baffle Ceiling

Product Display

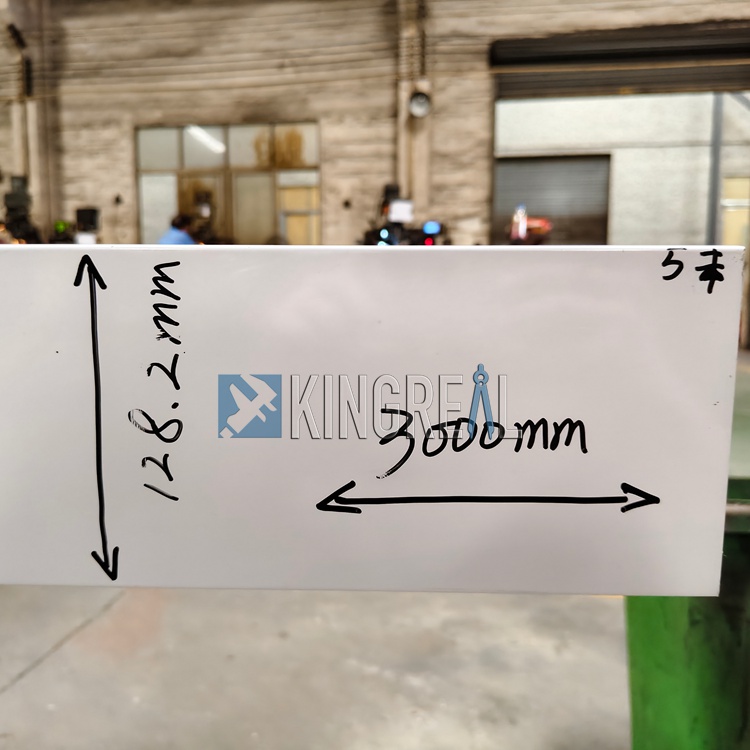

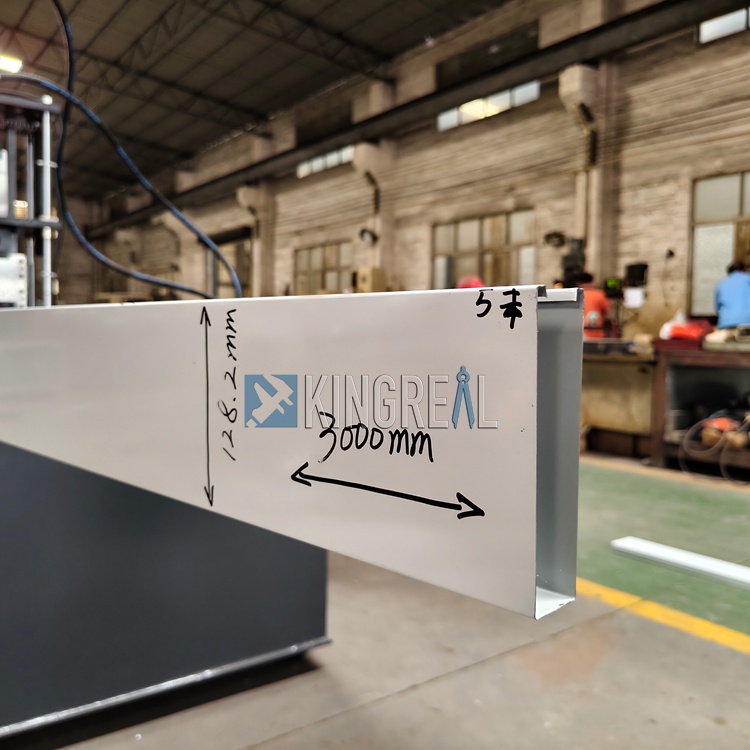

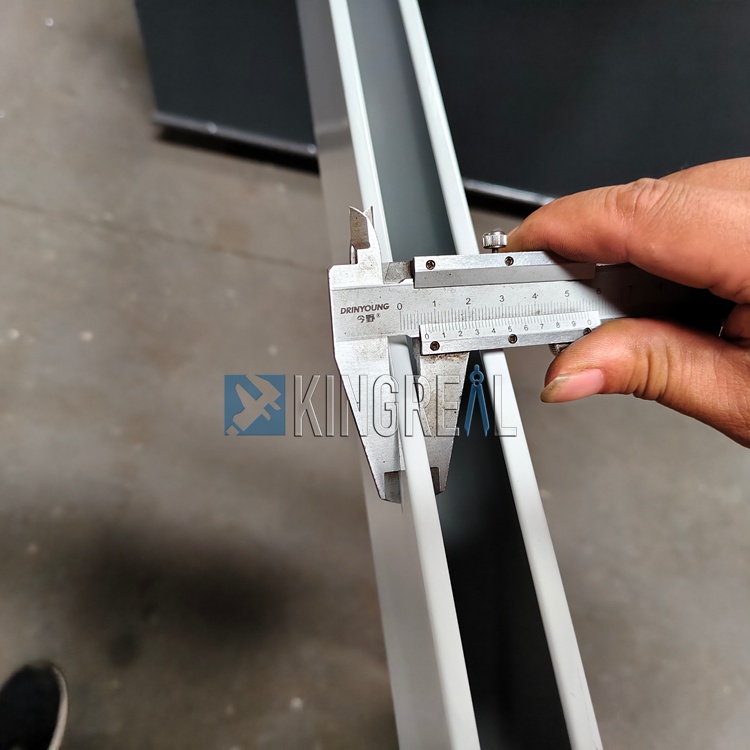

By using the KINGREAL CEILING MACHINERY baffle ceiling machine, customers can produce high-precision, burr-free baffle ceilings. This baffle ceiling making machine uses advanced manufacturing technology and high-quality materials to ensure that every production link meets strict quality standards. In practical applications, high-precision, burr-free baffle ceilings not only enhance the beauty of the overall design, but also enhance its applicability in various environments. Whether it is commercial buildings, residential or public spaces, KINGREAL baffle ceiling machines can provide customers with excellent solutions to help them achieve higher standards of construction and design requirements.

Quality Assurance

The baffle ceiling machine provided by KINGREAL CEILING MACHINERY can well meet your production needs. It can produce baffle ceilings with a width range of 25-100mm and a height range of 75-300mm. KINGREAL CEILING MACHINERY baffle ceiling making machine has been well received by customers from many countries because of its outstanding performance in production capacity and the high quality and high precision of the finished products produced. Through advanced technology and strict quality control, KINGREAL CEILING MACHINERY baffle ceiling machine ensures that every product meets industry standards and helps customers improve production efficiency and product competitiveness. At the same time, KINGREAL CEILING MACHINERY baffle ceiling machine can provide customers with flexible solutions to meet different production needs.

Customers in KINGREAL CEILING MACHINERY Factory

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)