Types of Metal Stamping Making Machine

2025-10-18 17:00

Metal stamping making machines are essential for manufacturing precision parts in industries like automotive and aerospace. Their efficient production and precise punching capabilities have earned them widespread demand from manufacturers worldwide. Whether for large-scale production or small-batch customization, metal stamping presses play a vital role in modern industry.

KINGREAL CEILING MACHINERY is a professional metal stamping making machine manufacturer, capable of bending, plastic deformation, and punching metal materials of varying thicknesses and materials. These finished products are widely used in a variety of industries. This article will introduce various types of metal stamping presses. Whether you prioritize speed, precision, or affordability, these recommendations will help you select the metal stamping making machine manufacturing solution that meets your needs.

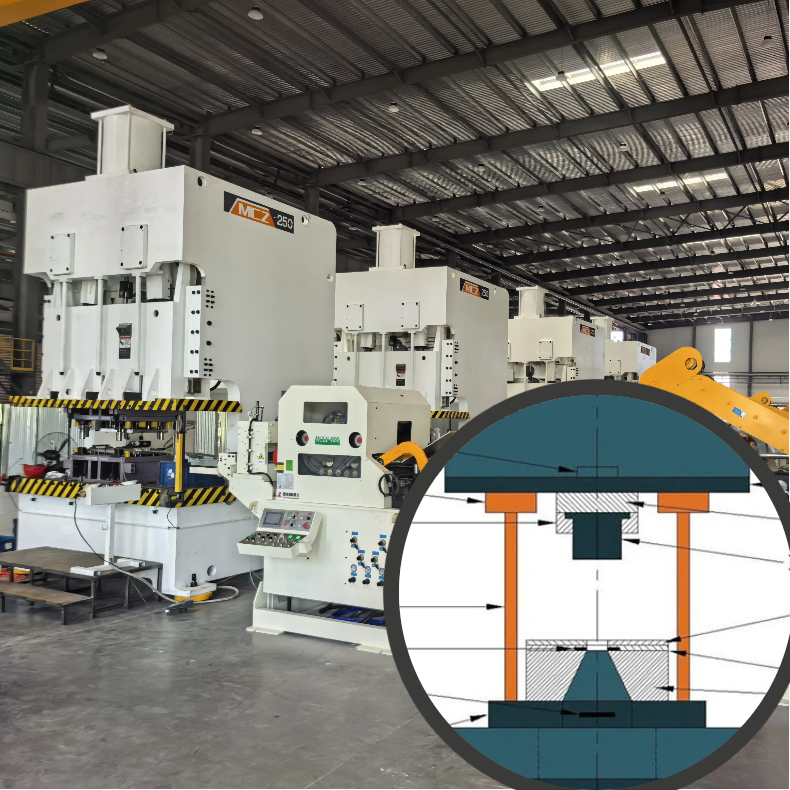

1. Mechanical Metal Stamping Press

Mechanical metal stamping making machines offer the advantages of high-speed processing and are relatively easy to maintain. With the advancement of automated processing, they have become an indispensable tool for mass production of metal parts. Mechanical metal stamping presses can be categorized into the following types based on machine type:

1.1 Flywheel-driven mechanical metal stamping press

Flywheel-driven mechanical metal stamping making machines use a flywheel to store energy, enabling efficient impact force during the stamping process. This design allows metal stamping presses to perform well when processing thicker metals. Flywheel-driven mechanical metal stamping making machines are well-suited for high-volume production because they can complete multiple stamping cycles in a short period of time.

1.2 Single-gear mechanical metal stamping press

Single-gear mechanical metal stamping making machines are typically used for smaller stamping applications, featuring a simple design and relatively low cost. This type of metal stamping press is suitable for low- to medium-volume production needs.

1.3 Dual-gear mechanical metal stamping press

Dual-gear mechanical metal stamping making machines are more complex in design, capable of greater impact force and higher production efficiency. This type of metal stamping press is often used for stamping applications requiring high precision and strength.

1.4 Eccentric gear mechanical metal stamping press

Eccentric gear mechanical metal stamping making machines utilize an eccentric design to achieve a wide variation in impact force throughout the stroke. This type of metal stamping press is suitable for processing metals of various thicknesses and materials, meeting diverse production needs.

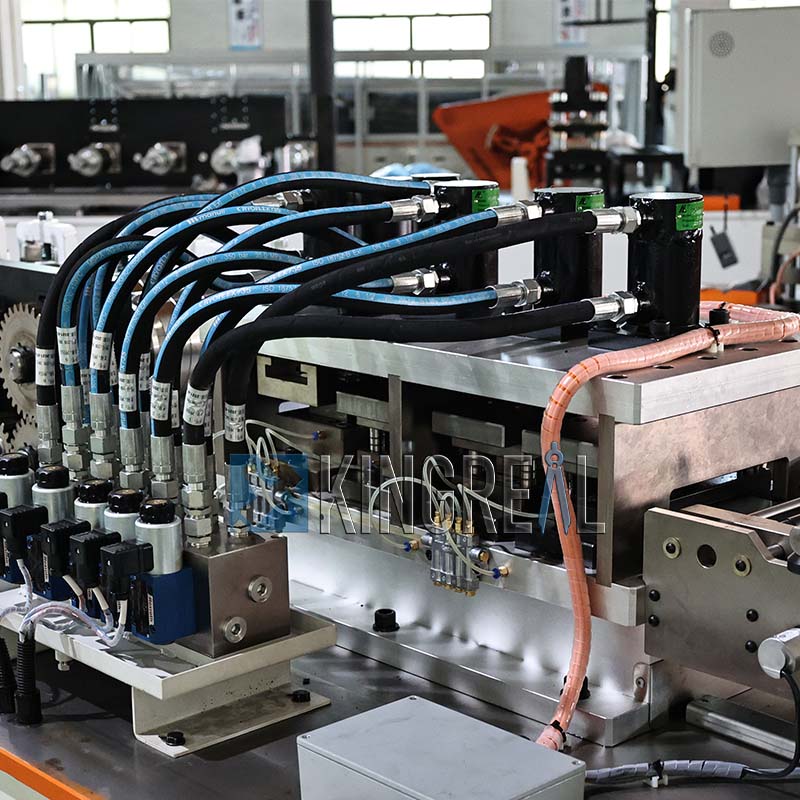

2. Hydraulic Metal Stamping Making Machine

Hydraulic metal stamping presses use a pump to deliver oil or water to a cylinder, utilizing the pressure generated in this process to perform the work. Their characteristic is the ability to flexibly control the hydraulic pressure to perform plastic working. This type of metal stamping making machine is particularly suitable for deep drawing applications because it can apply the full tonnage across the entire stroke length.

2.1 Flexible Control System

Customers of hydraulic metal stamping making machines can program the speed at which the ram closes the die. The return stroke can be programmed for rapid retraction, and the stroke distance can be adjusted as needed to achieve the maximum strokes per minute achievable by the pump design. Furthermore, hydraulic metal stamping presses feature preset pressures; once the set value is reached, a valve activates pressure reversal to prevent overloading.

2.2 Die Guiding System

The design of hydraulic metal stamping making machine allows the die to better guide the press, eliminating the need for a precise guiding system like that of mechanical presses with progressive stamping. This flexibility enables hydraulic metal stamping making machines to deliver superior results when processing complex metal shapes.

2.3 Production Speed

Although hydraulic metal stamping presses generally have lower production speeds than mechanical presses, their flexibility and adaptability make them the preferred choice for many applications. Hydraulic metal stamping making machines offer significant advantages, particularly when high punching forces and complex shapes are required.

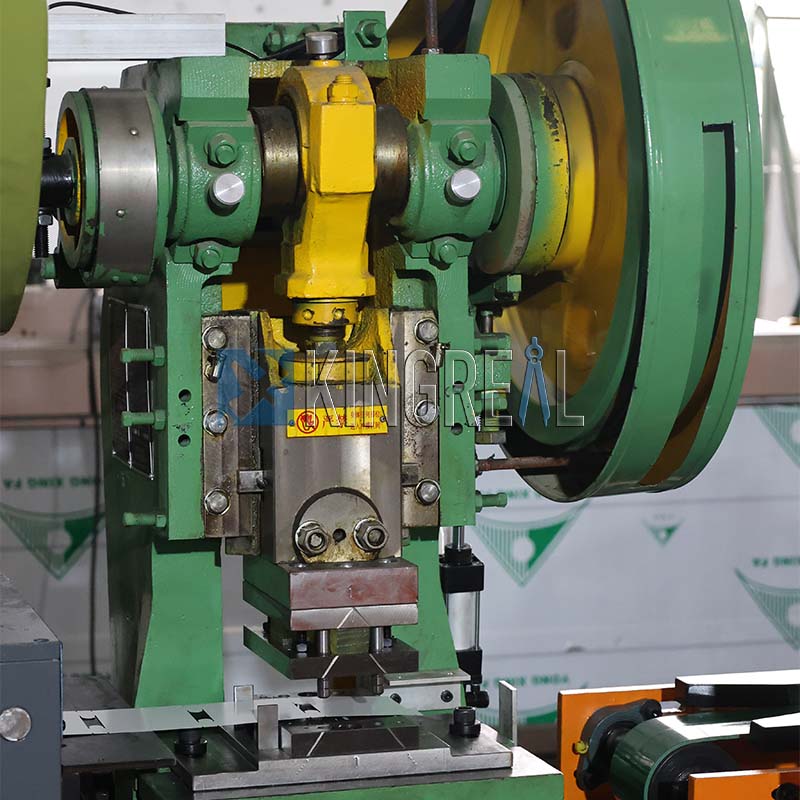

3. Pneumatic Metal Stamping Press

Pneumatic metal stamping press primarily rely on a pneumatic clutch and a motor to drive a flywheel to generate the impact force. This type of metal stamping making machine uses a pneumatic control system and is suitable for lighter metal stamping operations.

3.1 Traditional Stamping Process

A pneumatic metal stamping press is a relatively traditional metal stamping press, operating on a similar principle to a mechanical metal stamping making machine. The primary punching force in a pneumatic press comes from a motor driving a flywheel, which generates the impact force through a crankshaft. Compared to other types of metal stamping making machines, pneumatic metal stamping presss typically offer lower production speeds and punching force, but they are relatively affordable, making them suitable for businesses with limited budgets.

3.2 Machine Features

Pneumatic metal stamping making machines have the following features:

The metal stamping press body is welded from high-quality steel plates, resulting in superior rigidity compared to standard machine tools.

An overload protection device is equipped for quick and reliable operation, protecting the mold and machine, and enabling quick restoration of the metal stamping making machine.

A PLC electrical control system is used for stability and reliability.

Enclosed gear transmission with oil-immersion lubrication ensures smooth operation and low noise.

A combined pneumatic clutch-brake, using imported friction material, offers a long service life.

An optional frequency converter supports speed regulation.

A balancer adjusts clearance to ensure precise operation.

Optional features include air cushions, automatic die adjustment, photoelectric protection, automatic feeders, quick die changers, and unwinders and straighteners.

Servo metal stamping making machines operate at high speeds near the midpoint of the stroke and decelerate near bottom dead center (the lowest point of pressurization). This balances yield and productivity. The advent of servo metal stamping presses marks a significant advancement in stamping technology.

4.1 Freely Configurable Pressing Methods

Servo metal stamping making machines offer the ability to freely configure the pressing method. In addition to offering advantages in quality and efficiency, they can also process difficult-to-process materials that are difficult to process with conventional presses. Servo metal stamping presses are becoming indispensable for processing high-tensile-strength steel, which has become increasingly popular in automotive body parts due to recent trends in lightweighting, as well as various aluminum, titanium, magnesium alloys, and carbon fiber-reinforced plastics.

4.2 High-Precision Processing

The high-precision processing capabilities of servo metal stamping making machines make them excellent for manufacturing precision components. Whether for automotive, aerospace, or electronic equipment, servo metal stamping presses can meet stringent production standards. Furthermore, the noise reduction and energy-saving features of servo presses have made them increasingly popular in modern industry.

4.3 Continuous Upgrades

With the continuous advancement of technology, the application scope of servo metal stamping making machines is expanding, and the upgrade from traditional presses to servo metal stamping making machines is progressing steadily. More and more companies are investing in servo metal stamping presses to improve production efficiency and product quality.

Get the latest price? We'll respond as soon as possible(within 12 hours)