Metal Stamping Machine: Everything You Need to Know

2025-07-31 17:00

Metal stamping machines can form sheet metal into various shapes. As highly efficient metalworking equipment, sheet metal stamping press plays a vital role in industrial production. They not only bend, plastically deform, and punch metal sheets, but also create ribs, meeting the needs of various industries.

This article will comprehensively explore the metal stamping machine's workflow, advantages, applications, and importance in modern manufacturing.

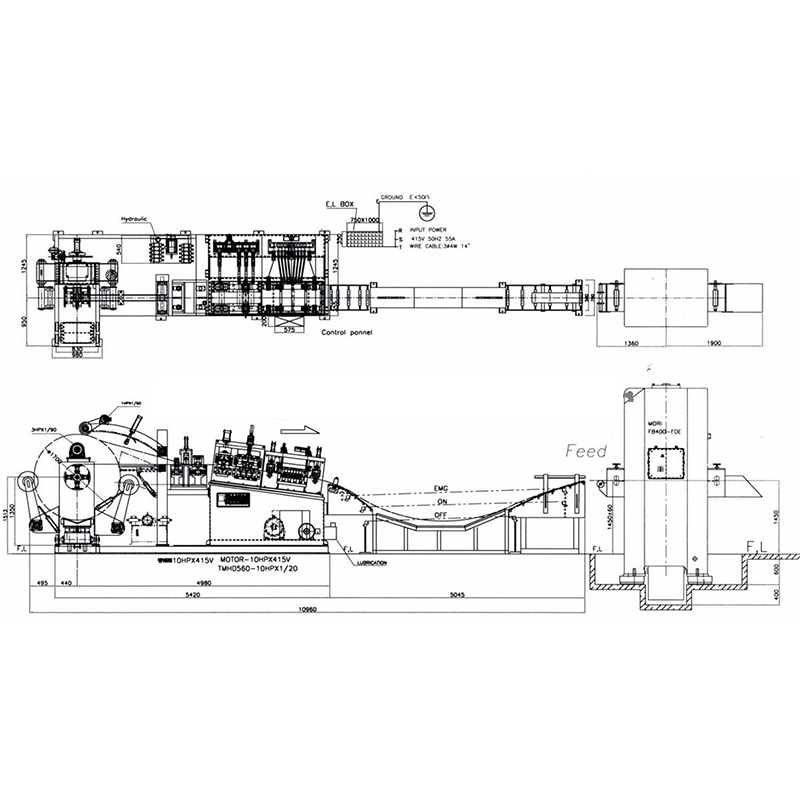

Workflow of Metal Stamping Machine

Decoiler ↓ Leveling Machine ↓ Punching Machine |  |

1. Decoiler for metal stamping machine

The uncoiling process is performed by a specialized material rack, which unwinds the cylindrical coil from its outer periphery and feeds it to the subsequent leveling machine.

At this stage, the decoiler typically uses a heavy-duty material rack or a flat electronic feeder. These devices can handle heavy coils and feature vertical expansion and contraction loading to ensure smooth material feeding.

2. Leveling machine for sheet metal stamping press

The leveling machine is a crucial step in preparing the coil for subsequent punching. Leveling improves the coil's shape and surface quality, thereby enhancing punching accuracy. Flattened coils are better suited for stamping, ensuring product consistency and quality.

3. Punching machine for sheet metal stamping press

Stamping is the core process of a metal stamping machine. It is performed by specialized punching presses, which, equipped with progressive dies, apply powerful force to the incoming sheet metal, achieving deformation.

Depending on the characteristics of the stamping process and efficiency requirements, different types of punching presses can be selected, including open-type high-power precision punching presses, single-point semi-closed-type precision punching presses, and closed-type double-crank precision punching presses.

These presses provide efficient and precise processing capabilities for metal sheets of varying thicknesses and materials.

Parameters of Metal Stamping Machine

The technical parameters of a sheet metal stamping press are crucial to its performance and application range. The following are some key parameters:

| Tonnage: | 315 tons |

| Capacity threshold: | 7 mm |

| Stroke length: | 300 mm |

| Stroke rate: | 20-35 strokes/minute |

| Maximum die height: | 550 mm |

| Slide adjustment: | 120 mm |

| Lower table dimensions: | 2800 x 1000 x 190 mm |

| Upper table dimensions: | 2200 x 900 x 95 mm |

| Main motor power: | 30 kW |

| Air supply pressure: | 5 kg/cm² |

| Die pad type: | Two-platen dual-cylinder |

| Capacity: | 14 x 2 tons |

Air pressure: | 9 kg/cm² |

| Stroke: | 100 mm |

| Die pad top plate area: | 640 x 470 x 2 sets |

Advantages of Metal Stamping Machines

1. Simple operation for sheet metal stamping press

The sheet metal stamping press is designed with the user experience in mind. Operators simply adjust production parameters on the PLC control panel, and the machine automatically operates. This streamlined operation allows even novice operators to quickly learn the basics, significantly reducing training costs.

2. Highly automated metal stamping machine

With sensor-controlled start and stop capabilities, the metal stamping machine offers a great level of automation, automatically changing its working state according to production demands.

This computerized design not only boosts manufacturing efficiency but also lowers human error, therefore guaranteeing product consistency.

This automated design not only improves production efficiency but also reduces human error, ensuring product consistency.

3. Wide range of applications

With sensor-controlled start and stop capabilities, the metal stamping machine offers a great level of automation, automatically changing its working state according to production demands.

This computerized design not only boosts manufacturing efficiency but also lowers human error, therefore guaranteeing product consistency.

Up to 1600mm, the metal stamping machine fits a broad variety of material widths to satisfy various manufacturing requirements. This freedom lets the sheet metal stamping press be used in a great number of industrial situations.

4. Precision die adjustment

The metal stamping machine guarantees high-precision processing throughout the stamping operation with a die change accuracy of up to 0.1mm. Producing premium metal connectors and satisfying consumers' demanding quality standards depends on this feature.

5. Safety design for sheet metal stamping press

To guarantee safe and accurate operation, the sheet metal stamping press employs highly sensitive and dependable clutch and braking systems together with internationally recognized double solenoid valves and overload protection. These safety components not only shield operators but also lengthen the sheet metal stamping press’s lifespan.

6. High-rigidity frame design for metal stamping machine

High-quality steel plates are welded to create the frame of the metal stamping machine, which is then treated to get rid of internal stress, hence providing very strong rigidity and stability.

This design greatly enhances product processing accuracy and guarantees steady functioning during high-intensity stamping processes.

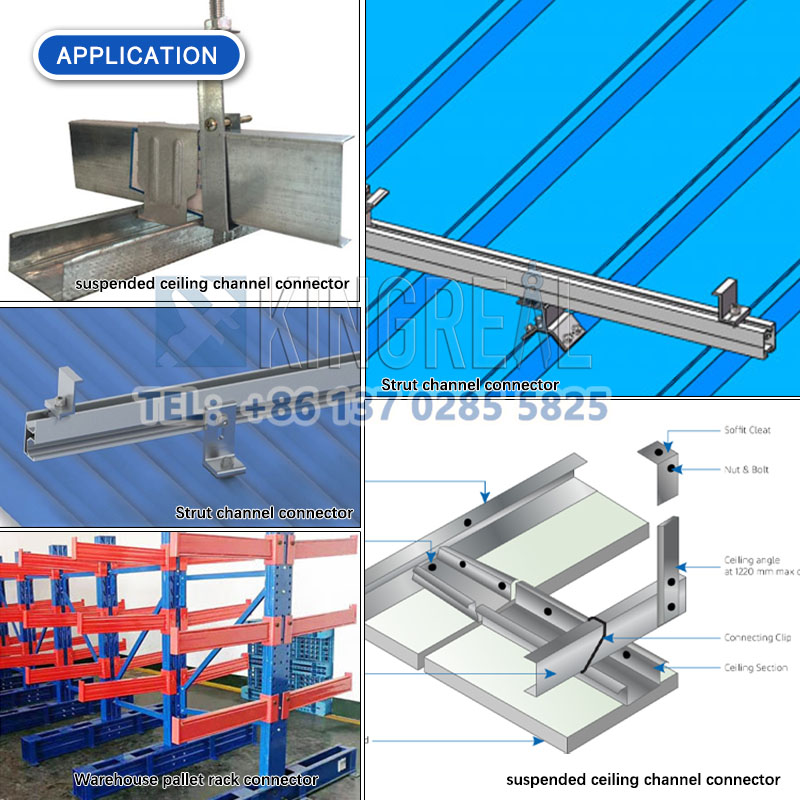

Applications of Metal Stamping Machines

Sheet metal stamping presses are widely used to produce various metal connectors, such as:

Angle Brackets: Used for architectural and structural support to ensure structural stability.

Heavy-Duty Metal Brackets: Widely used in racking and ceiling systems, capable of carrying heavy loads.

U-Shaped Carbon Steel Small Brackets: Suitable for various support needs in the construction industry.

Small Stamping and Bending Brackets: Used to support lightweight structures and equipment.

Among other industrial uses, metal ceiling systems, pallet racking systems, and photovoltaic mounting systems all benefit from these metal connectors. By means of the effective manufacture of sheet metal stamping presses, these parts can meet market demand with high quality at a low cost. |  |

Strong metalworking tools, metal stamping machines have several benefits including high speed, automated operation, and high precision processing. Meeting the varied demands of the building and industrial sectors, they are increasingly employed in metal connector manufacture.

With the continuous development of technology, sheet metal stamping presses will remain quite important in the manufacturing sector, offering businesses dependable and effective production answers.

Readers should get a thorough grasp and learn how to better use sheet metal stamping press to raise product quality and boost output efficiency by reading this post.

Get the latest price? We'll respond as soon as possible(within 12 hours)