How to perforate sheet metal by perforated metal machine?

2025-07-29 17:00

In this article, KINGREAL CEILING MACHINERY will reveal the exquisite craftsmanship behind the production of perforated sheet. Perforated sheet is an indispensable component in many industries such as construction and environmental protection.

Here, KINGREAL CEILING MACHINERY will witness how the perforated metal machine produces perforated sheet. How are these extraordinary structures born? Let's take a deeper look.

1/ Preliminary Design and Requirements Analysis for Perforated Metal Machine

Our journey began in KINGREAL CEILING MACHINERY design and engineering department.

Here, customer consultations and estimates for complex orders are carried out. Customer needs are at the core of KINGREAL CEILING MACHINERY work, including coil thickness, processing materials, output, and coil width. Through careful communication with customers, KINGREAL CEILING MACHINERY is able to provide fully customized solutions based on actual conditions.

This personalized service ensures that every customer gets a metal perforated making machine that meets their specific needs.

2/ How a Perforated Metal Machine Works?

One of the most common ways to manufacture perforated metal sheets is to use a metal perforated making machine. Most perforated metal sheets are produced in this way.

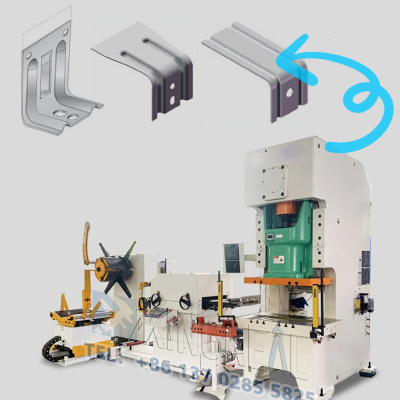

The perforated metal machine is equipped with a punching die that can be customized according to the required hole size and shape.

In the manufacturing process of perforated sheet, accurate die design is crucial. The quality of the die largely determines the overall quality of the perforated sheet product.

Therefore, KINGREAL CEILING MACHINERY has invested a lot of money and energy in punching dies, significantly improved the design and production capabilities of dies, and accumulated a wealth of die patterns.

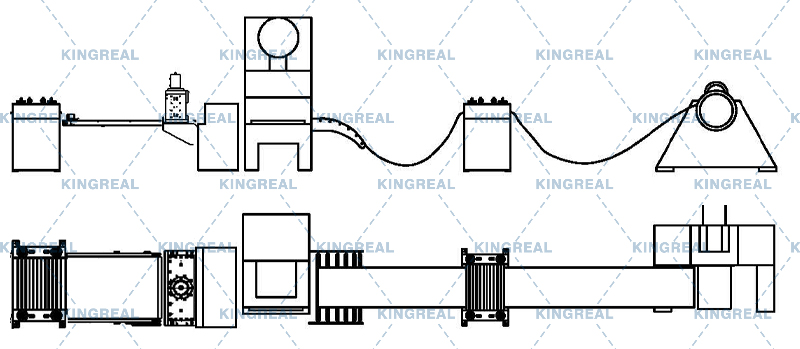

3/ Components of Metal Perforated Making Machine

Decoiler: used to unwind the coil and prepare for subsequent processing. Leveling Machine: ensures that the coil reaches the original flat state before punching, usually suitable for steel plates with a thickness of 0.4mm to 1mm. Metal Punching Machine: It is the core part of the entire perforated metal machine and is responsible for the actual punching operation. Cutting station: used to cut the punched metal sheet into the required size. |  |

4/ Metal Perforated Making Machine: Key Steps and Details in Manufacture of Perforated Sheets

Before punching, we first need to use a leveling machine to restore the coil to a flat state. This process is crucial to ensure the accuracy of subsequent punching. After leveling, the metal sheet will be fixed on the workbench of the punching machine.

Before the metal perforated making machine is opened, select the appropriate punching die according to the required hole shape and hole diameter, and install it in the punching machine.

Through the control system, the punching machine begins to perform the corresponding operation. During the perforation process, the maintenance of the punching die is an important factor in ensuring a stable perforation effect. Compared with traditional perforation methods, the perforated metal machine has higher perforation speed and accuracy, and can meet the perforation requirements of various complex shapes and sizes.

In addition, the metal perforated making machine also has the characteristics of energy saving, environmental protection, and safety, so perforated metal machine is widely used and well received in the metal processing industry.

After the punching is completed, the next step is to cut the whole roll of sheet into the size required by the customer.

There may be some processing residues on the cut metal sheet, so if the customer has requirements for the surface cleanliness of the sheet, KINGREAL CEILING MACHINERY will equip the metal perforated making machine with a metal sheet cleaning machine. The cleaning process includes removing oil and other stains on the surface to make the perforated sheet appear cleaner.

5/ Wide Application of Perforated Metal Machine

Metal perforated making machine in architecture and decoration: Perforated metal panels and screens add a unique beauty to the space, combining practicality and beauty.

Perforated metal machine in Industry and manufacturing: Widely used to manufacture filters, grilles and vents to meet the specific requirements of different industries.

Metal perforated making machine in acoustic application: Effectively absorbs and diffuses sound waves, playing an important role in architectural acoustic design.

Perforated metal machine in agriculture and food processing: Used in the production of sieves and sorting equipment to ensure processing efficiency and reliability.

Metal perforated making machine in transportation and automotive: Used in air filters, radiator grilles and exhaust components to ensure performance and safety. |  |

Perforated metal machinesplay an indispensable role in the process of perforated metal sheets. KINGREAL CEILING MACHINERY provides customers with advanced designs, precise molds and efficient metal perforated making machines, enabling customers to produce high-quality perforated metal sheets that meet their needs. From architectural decoration to industrial applications, the diversity and customizability of perforated metal sheets make them an indispensable material for all walks of life.

Whether it is the precision of design or the efficiency of production, every link of the perforated metal machine demonstrates the technological charm of modern manufacturing.

Get the latest price? We'll respond as soon as possible(within 12 hours)