Metal Stamping Press Machine Solution

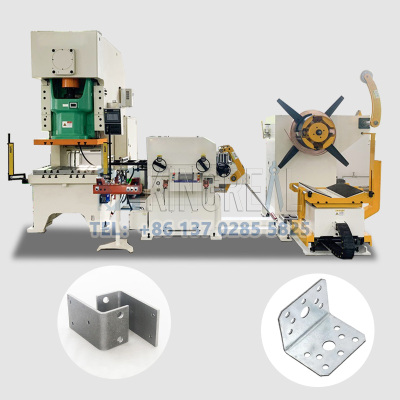

KINGREAL CEILING MACHINERY metal stamping press machine solution is specially used to process metal materials such as zinc-plated steel, stainless steel, etc. into various shapes, providing indispensable metal mounting brackets for many industries.

- KINGREAL CEILING MACHINERY

Details

Video About Metal Stamping Press Machine Solution

Description of Metal Stamping Press Machine Solution

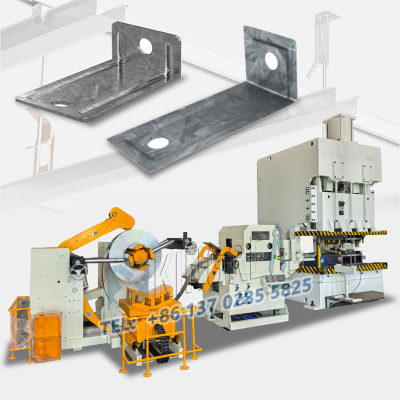

KINGREAL CEILING MACHINERY metal stamping press machine solution is specially used to process metal materials such as zinc-plated steel, stainless steel, etc. into various shapes, providing indispensable metal mounting brackets for many industries. In the process of sheet metal manufacturing, the main processes include folding and pressure. By using KINGREAL CEILING MACHINERY metal stamping press machine, customers can efficiently produce reinforced installation brackets, which are suitable for fixing the ventilation curtain wall structure system, ensuring its stability and safety in various environments.

KINGREAL CEILING MACHINERY metal stamping press machine solution has many advantages, including automatic folding, stamping, flexible adjustment of production speed, and high-precision production capacity.

Whether it is in the manufacture of wall lining brackets, or in the production of other metal mounting brackets, KINGREAL CEILING MACHINERY can provide reliable metal stamping press machine solutions to meet the different needs of customers. |  |

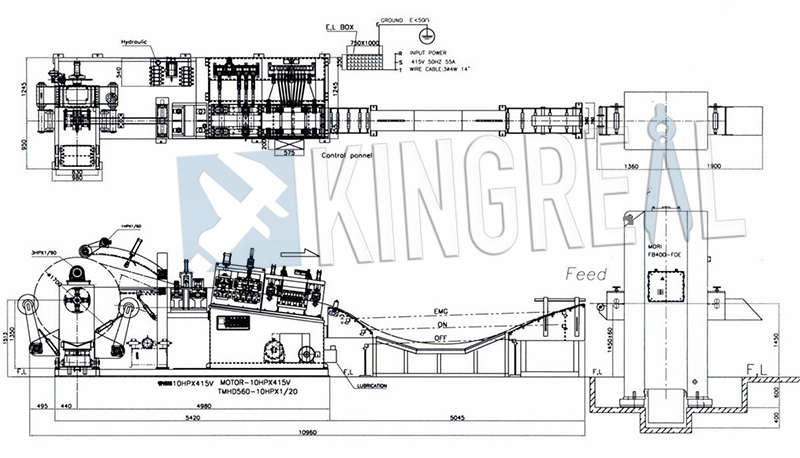

Working Process of Metal Stamping Press Machine Solution

Decoiler ↓ Straightener ↓ Metal Punching Machine |  |

Main Components of Metal Stamping Press Machine Solution

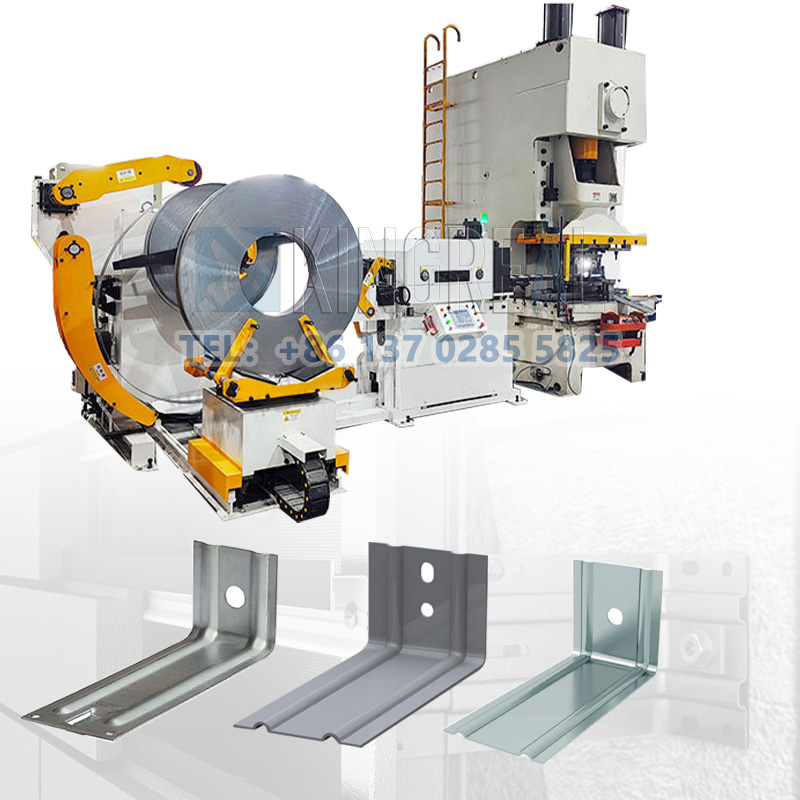

1. Decoiler for metal stamping press machine

The decoiler is the first step of the metal stamping press machine. It uses manual or hydraulic adjustment of the inner diameter, and can provide a variety of options according to the width and weight of the coil.

2. Leveling machine for metal stamping press machine

The leveling machine is equipped with a pneumatic pressure straightening roller, worm wheel adjustment, can perform precise straightening of a variety of materials, and ensure the accuracy of the material in the subsequent processing.

3. Punching machine for metal stamping press machine

Metal punching machine is KINGREAL CEILING MACHINERY The core components of the metal stamping press machine, its characteristics are as follows:

●Transmission precision: The transmission center and the machine bed center keep the same, to ensure the accuracy of pressure.

●Design stability: It adopts the symmetrical plate design of the balancer, to ensure that the machine runs smoothly.

●Mold adjustment: Mold adjustment accuracy up to 0.1mm, safe and reliable, convenient adjustment.

●Durability: the handle, gear, and linkage are all oxidized and milled, and the comprehensive mechanical performance is excellent, ensuring the long-term use of the metal stamping press machine.

●Safety function: equipped with high-level separation/brake, international advanced double solenoid valve and over-load protection device, to ensure the precision of slide block operation and stopping, to protect the machine's safety production.

Precision Progressive Stamping Die for Metal Stamping Press Machine

KINGREAL CEILING MACHINERY specializes in customizing efficient progressive stamping dies based on specific customer needs. KINGREAL CEILING MACHINERY design incorporates multiple, equidistant stations within a die, each equipped with one or more basic stamping processes, enabling the precise processing of different parts of the stamped workpiece. Through the stamping process at each station, a complete metal bracket is ultimately produced.

The progressive stamping die design enables multiple processes, including blanking, bending, drawing, and forming, to be completed continuously. This efficient operation not only improves production efficiency but also ensures part consistency and precision. Regardless of the complexity of the metal bracket's shape or the number of stamping steps, KINGREAL CEILING MACHINERY can produce high-precision metal brackets using KINGREAL CEILING MACHINERY advanced metal stamping press machines and carefully designed progressive stamping dies.

Parameters of Wall Lining Brackets

KINGREAL CEILING MACHINERY metal stamping press machine solutions are capable of producing finished products of various specifications. The main parameters are as follows:

| Depth B (mm) | Height A (mm) | Width C (mm) | Metal Thickness (mm) |

| 80 | 90 | 95 | 2.0 |

| 80 | 100 | 95 | 2.0 |

| 80 | 150 | 95 | 2.0 |

| 80 | 200 | 95 | 2.0 |

| 80 | 250 | 95 | 2.0 |

| 80 | 350 | 95 | 2.0 |

These parameters can be customized according to customer needs, ensuring that the finished product meets specific application requirements.

Application of Metal Stamping Press Machine Solution

The wall lining brackets produced by KINGREAL CEILING MACHINERY metal stamping press machines are widely used in various fields, especially in the reinforced adjustable brackets of ventilated curtain walls. These brackets are made of galvanized steel and are used to carry the heavy-duty profiles of the support frames of the ventilated curtain wall subsystems. The design of the metal mounting bracket uses two reinforcing muscles, extending along the entire length of the product, and strengthening it at the bend, ensuring its stability under high wind conditions. The bracket made of steel plate covered with a zinc-plated layer, molded by modern cold-rolling equipment, ensures high-quality physical and mechanical properties.

Metal mounting brackets are used to secure the guide profiles of ventilated curtain wall subsystems to the wall. They form a support frame that provides a secure foundation for the subsequent installation of the ventilated curtain wall system's facing materials. The design ensures a ventilated layer between the facing panels and the insulation layer. The wall lining brackets allow excess moisture to escape, preventing it from accumulating on the internal components of the ventilated curtain wall subsystem.

Made of galvanized steel, this L-shaped component features overhangs of varying lengths to meet various construction requirements. Two reinforcing ribs in the center of the component provide additional strength and resistance to bending deformation, ensuring it can withstand high loads from wind pressure and the weight of the facing materials.

FAQ About Metal Stamping Press Machine Solution

Besides producing the wall lining brackets used to secure the ventilated curtain wall structural subsystem, what else can a metal stamping press machine produce?

KINGREALCEILING MACHINERY metal stamping press machines can produce a wide variety of metal mounting brackets for use in a variety of industries.

We primarily design metal stamping press machine solutions based on customer needs.

Common products produced by KINGREALCEILING MACHINERY metal stamping press machines include connectors for suspended ceiling systems, photovoltaic mounting systems, and pallet racking systems.

Can metal stamping press machine solutions be customized?

Of course. KINGREAL CEILING MACHINERY metal stamping press machines can be customized based on part and customer requirements. KINGREAL CEILING MACHINERY will tailor a metal stamping press machine solution based on the features required for your specific production task.

Please submit your production requirements to KINGREAL CEILING MACHINERY so that our engineers can provide you with the best solution.

What safety features are included in the metal stamping press machine?

KINGREAL CEILING MACHINERY metal stamping press machine solutions are equipped with numerous safety features, such as emergency stop buttons, light curtains, safety interlocks, and enclosed operating areas, to protect operators during operation. These systems automatically stop the metal stamping press machine when hazardous conditions are detected, reducing the likelihood of accidents.

Standard safety features also reduce equipment damage and downtime, ensuring a safer working environment and continued reliable production.

Is metal stamping hard?

Using a KINGREAL CEILING MACHINERY metal stamping press machine is a convenient method for metal stamping. By choosing a metal stamping press machine with the appropriate pressure capacity, you can easily obtain high-quality finished products.

What functions can metal stamping press machines automate?

Based on your specific part requirements, KINGREAL CEILING MACHINERY metal stamping press machines can integrate multiple process steps such as punching, coining, blanking, bending, and flanging to produce high-precision plastic products.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)