Steel Strip CNC Hydraulic Punching Machine

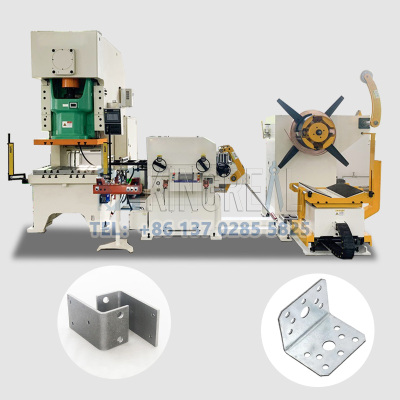

The steel strip cnc hydraulic punching machine is driven by a high-performance hydraulic station and is specifically designed for punching metal strips, especially steel strips.

- KINGREAL CEILING MACHINERY

Details

Steel Strip CNC Hydraulic Punching Machine

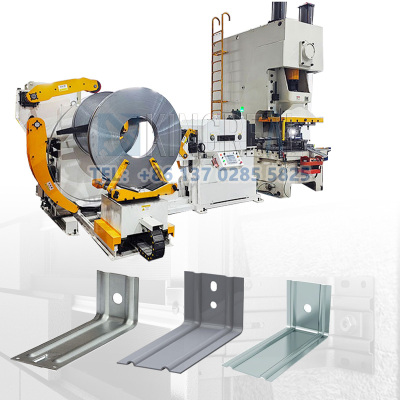

The steel strip cnc hydraulic punching machine is driven by a high-performance hydraulic station and is specifically designed for punching metal strips, especially steel strips. This metal strip cnc hydraulic punching machine can punch holes of various shapes to meet the needs of different customers. This flexibility allows customers to achieve great process freedom in their manufacturing. To better serve our customers, KINGREAL CEILING MACHINERY can provide customized steel strip cnc hydraulic punching machine manufacturing solutions.

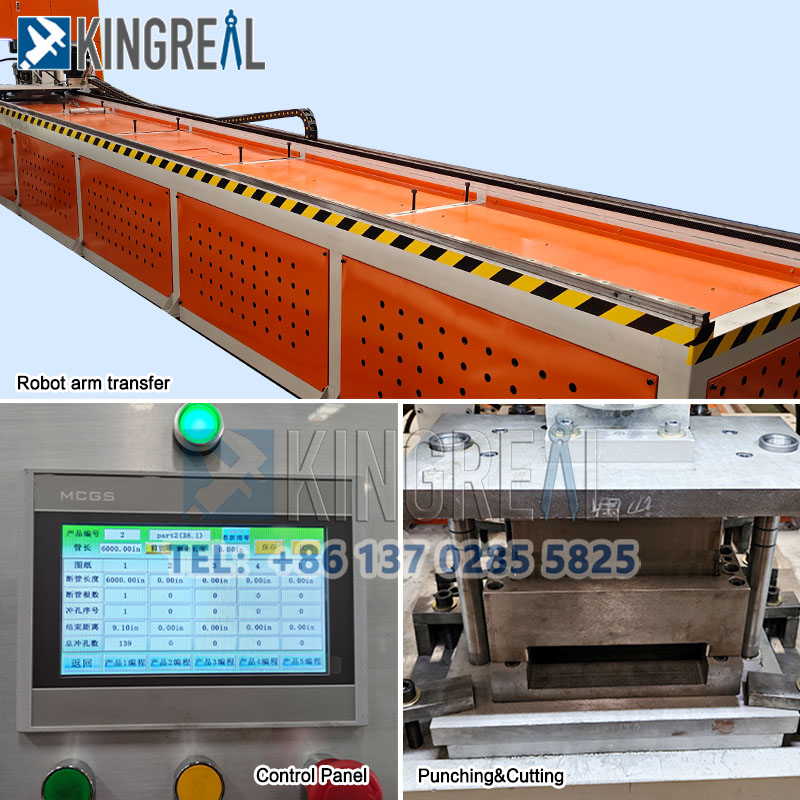

After the worker places the steel strip into the punching die, the metal strip cnc hydraulic punching machine automatically feeds the strip according to the set distance and quickly completes the punching process. It is worth noting that all punching parameters, including the length of the steel strip, the number of holes, and the hole spacing, can be set through the advanced PLC control system. In addition, the touchscreen interface supports multiple languages, greatly facilitating operation for operators with different language backgrounds.

Parameters of Steel Strip CNC Hydraulic Punching Machine

| Name | Specification | |

Machine | Main motor | 380v-18.5kw |

| Hydraulic power | High-pressure plunger pump | |

| Reducer | 120# | |

Mold | Punch | W6 |

| Cutting blade | DC53 | |

| Die insert | DC53 | |

| Bottom die blade | W6MO5CR4V2 | |

Features of Metal Strip CNC Hydraulic Punching Machine

1. Surface protection and precision design

KINGREAL CEILING MACHINERY metal strip cnc hydraulic punching machine is equipped with a well-designed punching die and an automatic wiping system, ensuring that the steel strip surface remains scratch-free during the punching process. High-quality mold manufacturing and processing technology prevent potential surface damage, further enhancing the overall product quality.

2. High-precision performance

The mold base, precisely machined by a gantry milling machine, ensures the high-precision performance of the steel strip cnc hydraulic punching machine. KINGREAL CEILING MACHINERY metal strip cnc hydraulic punching machines utilize high-quality guide rails and transmission gears, ensuring the stability and reliability of the steel strip cnc hydraulic punching machine during long-term operation. Both punching spacing and punching position can be precisely set via the touchscreen, significantly saving time and labor costs.

3. Hydraulic drive and stepless pressure adjustment

The metal strip cnc hydraulic punching machine uses a hydraulic drive system and features stepless pressure adjustment, allowing for flexible pressure adjustment according to different processing needs, ensuring optimal results for every punch. This technology significantly improves the operating efficiency of the equipment and effectively controls resource waste.

4. Flexible mold replacement

The steel strip cnc hydraulic punching machine is equipped with a convenient mold replacement function. Users can easily adapt to various punching shapes by simply replacing the customized punching dies, ensuring the versatility and long-term value of the metal strip cnc hydraulic punching machine.

5. Automatic cutting function

In addition to the punching function, the steel strip cnc hydraulic punching machine is also equipped with a hydraulic cutting unit. This unit enables efficient automatic cutting, making the entire metal strip cnc hydraulic punching machine more efficient, reducing material waste, and achieving optimal production scheduling.

6. Advanced PLC control system

KINGREAL CEILING MACHINERY metal strip cnc hydraulic punching machine selected PLC control system features comprehensive time setting and pressure adjustment functions. Through the touchscreen's visual digital display, users can monitor metal strip cnc hydraulic punching machine performance throughout the process. In addition, the system's built-in automatic fault detection and visual alarm functions make maintenance simpler and more efficient, significantly reducing downtime.

Advantages of Steel Strip CNC Hydraulic Punching Machine

1. Intelligent operating system

The metal strip cnc hydraulic punching machine is equipped with an industry-leading intelligent operating system. The steel strip cnc hydraulic punching machine's main controller uses a PLC from a well-known Japanese brand, and the servo system used for precise feeding is also from the same brand. During actual operation, if a circuit problem occurs, KINGREAL CEILING MACHINERY can immediately view the fault information through the operating screen, quickly locate and resolve the problem. This design facilitates future system upgrades and maintenance, enhancing the customer experience.

2. High-performance linear guide rails

The KINGREAL CEILING MACHINERY metal strip cnc hydraulic punching machine utilizes TBR40 linear guide rails, ensuring parallelism between the reference surfaces and significantly improving the steel strip cnc hydraulic punching machine's motion accuracy. The high-quality guide rails support stable operation over long periods, reducing equipment failure rates and comprehensively improving production efficiency.

3. Precision rack and pinion system

The high-precision rack and pinion system used in KINGREAL CEILING MACHINERY metal strip cnc hydraulic punching machines meets DIN 5, ISO 5, and GB 4 standards. Compared to the commonly used 8-9 grade rack and pinion systems on the market, KINGREAL CEILING MACHINERY steel strip cnc hydraulic punching machine offers higher precision and a better overlap coefficient, ensuring smooth and reliable operation.

How Does the Metal Strip CNC Hydraulic Punching Machine Ensure Quality?

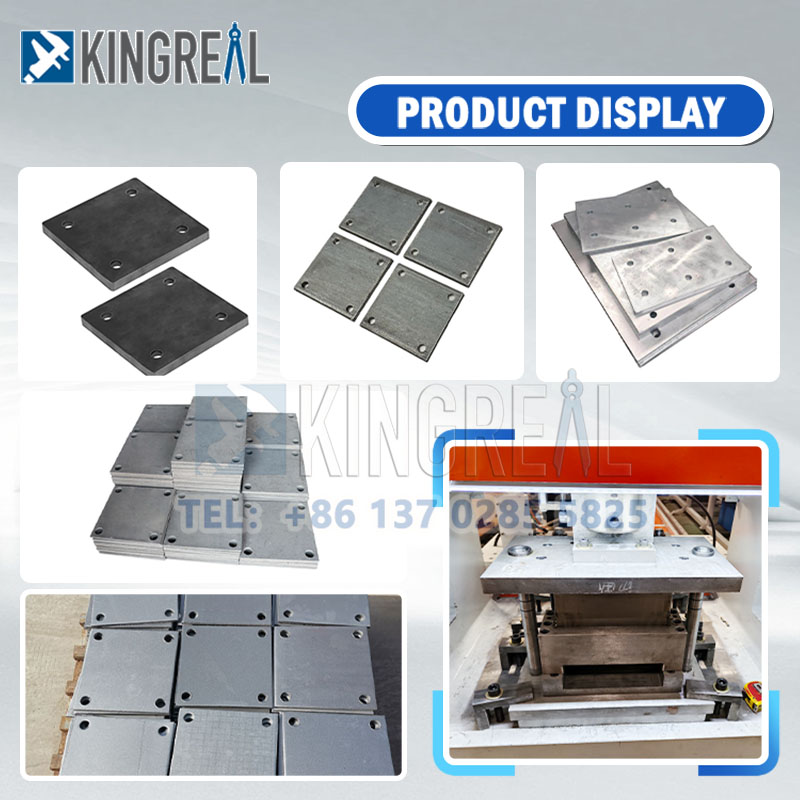

In the process of the steel strip cnc hydraulic punching machine, punching and shearing are the most critical steps. For punching, high-performance tungsten steel No. 6 blades and lower dies made of DC53 material are used, ensuring precise and durable punching. KINGREAL CEILING MACHINERY has also incorporated roller bearing positioning in the design, which effectively reduces friction and further improves punching quality and efficiency.

For shearing, the metal strip cnc hydraulic punching machine uses an automatic robotic arm to clamp the material, ensuring material stability during the process. The automatic cutting of excess waste and the automatic feeding system simplify the production process, ensuring accurate punching and shearing every time.

What Is the Metal Strip CNC Hydraulic Punching Machine Used For?

This steel strip cnc hydraulic punching machine utilizes the latest precision machining and mold manufacturing technologies to produce high-quality embedded parts. These parts are typically pre-installed during the structural casting process, providing great convenience for subsequent engineering metal strip cnc hydraulic punching machine installation. The metal strip cnc hydraulic punching machine is widely used in various fields, especially in large construction companies. By embedding bolts in the structure and leaving threads for fixing components, the steel strip cnc hydraulic punching machine provides a more efficient and reliable solution for the construction industry, helping customers significantly improve engineering efficiency and safety. |  |

Ready to Get an Advanced Steel Strip CNC Hydraulic Punching Machine?

Please contact KINGREAL CEILING MACHINERY immediately to get the latest quotes and more information about our metal strip cnc hydraulic punching machines!

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)