How to Make a Perforated Sheet?

2025-11-22 17:00

The manufacturing process of perforated metal sheets has evolved over centuries. From the initial hand-drilling to modern, high-speed metal perforated making machine punching, technological advancements have made perforated metal sheets not only more aesthetically pleasing but also more functional. This article will detail how to manufacture high-precision and versatile perforated metal sheets using modern metal sheet perforated machines.

1. Definition and Applications of Perforated Metal Sheets

Made with a sequence of holes utilizing methods including laser cutting, punching, and drilling, perforated metal sheets are metal objects. This substance is used extensively in audio, ornament, construction, engineering, and industries where its special features and design help it to be especially effective.

Application Areas:

-Architectural Decoration: Perforated metal sheets are often used in facade design, providing ventilation, increasing natural light, and offering aesthetic decorative effects.

-Acoustic Control: In auditoriums and concert halls, perforated metal sheets help control sound propagation and reduce echoes.

-Mechanical Components: Used for ventilation and heat dissipation, improving the cooling efficiency of machinery.

-Drainage Systems: Commonly found in outdoor furniture and flooring to prevent water accumulation.

2. Manufacturing Process of Perforated Sheets

2.1 Material Preparation

Generally speaking, the production of perforated metal sheets depends on large coils of metal. Weighing up to 50,000 pounds and measuring as much as 72 inches wide, these coils are acquired from dedicated steel mills. Common substances are composite materials, aluminum, carbon steel, stainless steel, galvanized steel, and copper.

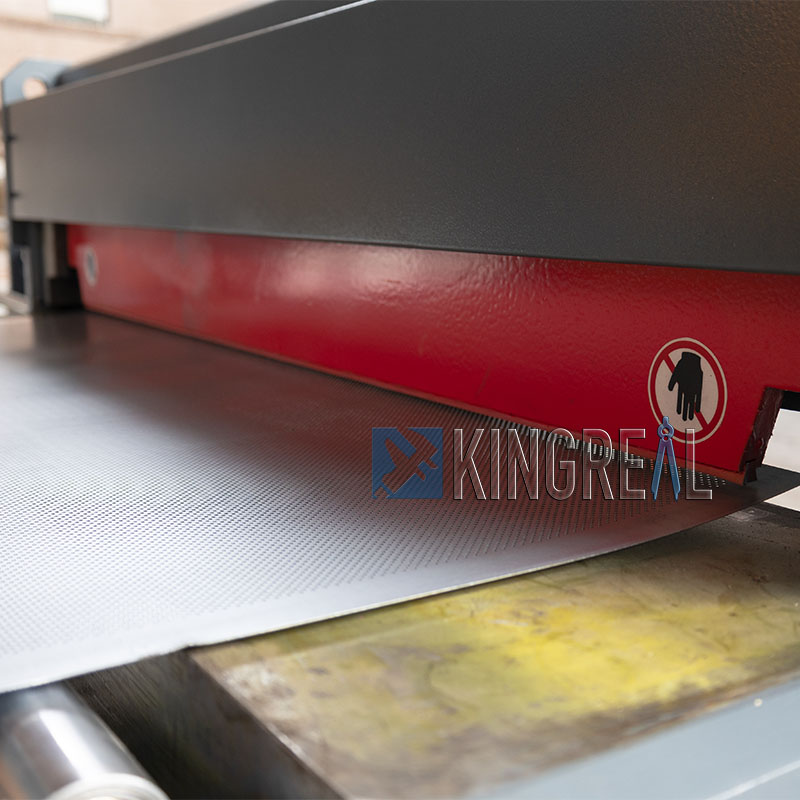

2.2 Use of Metal Sheet Perforated Machine

The primary method for modern manufacturing of perforated metal sheets is the use of metal perforated making machines. Uncoils and levelers unwind and level the metal coils, ensuring their stability during the perforation process. A metal punching machine quickly punches certain hole shapes onto the metallic surface. The punch falls quickly as the metal coil goes through the metal punching machine, producing numerous rows of precisely spaced holes in one pass.

2.3 Cutting and Cleaning

After punching, the metal sheet perforated machine is equipped with a cutting station to cut the perforated metal coils into perforated sheets of specified lengths. To ensure the cleanliness of the perforated sheet surface, the metal perforated making machine is usually equipped with an automatic metal sheet cleaning machine to remove oil and other impurities during the production process.

3. Specifications and Design of Perforated Metal Sheets

3.1 Size Specifications

Standard sizes for perforated metal sheets typically depend on application requirements. Some common sizes on the market include:48 inches x 96 inches,

60 inches x 120 inches,36 inches x 96 inches,48 inches x 144 inches

3.2 Perforation Patterns

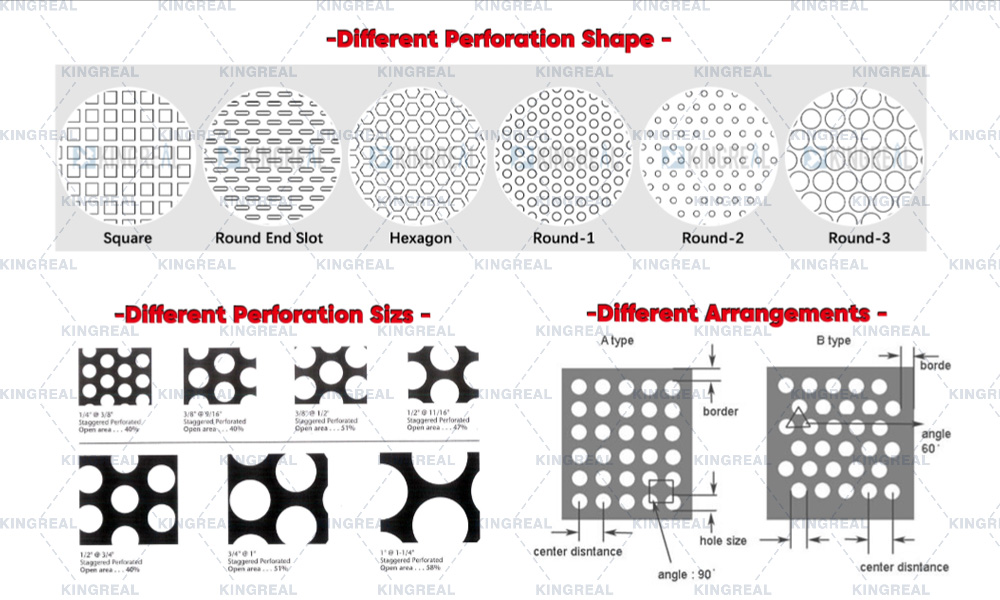

The shapes of the holes in perforated metal sheets vary. Common hole types include: round holes, oblong holes, square holes, triangular holes, diamond holes, hexagonal holes, and intersecting holes. The choice of these hole types depends on specific project requirements to achieve the best visual and functional effect.

3.3 Specifications and Materials

Perforated metal sheets are typically available in sizes 11 to 26 based on their thickness. The choice of base material depends on the application requirements: aluminum alloys (e.g., 3003, 5052, 6061), galvanized steel (e.g., G30, G60, G90), carbon steel (e.g., pickled and oiled, cold-rolled, or hot-rolled), stainless steel (e.g., 304, 316, 409), brass and copper, and nico alloys.

4. Specific Applications of Perforated Sheets

4.1 Architectural Decoration Particularly in façade construction, perforated metal sheets are somewhat often employed in the building sector. Perforated metal sheets are included in the exterior design of many well-known structures; these perforations serve practical sun shading during times of strong sunlight as well as improve the building's look.

4.2 Acoustic Improvement Perforated metal sheets are often used on ceilings and walls in concert halls and conference centers to regulate the acoustic environment and improve sound quality. By maximizing sound transmission, this design lowers echo and so enhances the interactive experience between the artists and the audience.

4.3 Industrial Applications Perforated metal sheets are frequently utilized in industrial settings in enclosures and protective covers to help with heat dissipation and keep equipment working at safe temperatures. Using perforated sheets on the casings of motors and generators, for instance, guarantees enough ventilation and helps to prevent overheating. |  |

KINGREAL CEILING MACHINERY offers advanced metal sheet perforated machines for producing perforated sheets and can manufacture customized perforation dies according to customer drawings. It can also equip the metal perforated making machines with accessories such as feeding trolleys, unloading trolleys, and metal sheet cleaning machines. For more information, please contact KINGREAL CEILING MACHINERY. You can also click this link to learn more about different types of metal perforated making machines.

Get the latest price? We'll respond as soon as possible(within 12 hours)