Types of Metal Processing Equipment And Their Uses

2025-12-16 17:00

Metal processing equipment refers to various types of machinery used for processing and manufacturing metal materials. With the development of modern industry, the types of metal processing lines have become increasingly diverse, and their application fields have become wider. KINGREAL CEILING MACHINERY offers a variety of metal processing equipment, covering metal perforated machine, metal stamping making machine, sheet metal leveling machine, and NC servo feeder. These metal processing equipment are indispensable in industries such as automotive, construction, and electronics. KINGREAL CEILING MACHINERY will now discuss these metal processing lines in detail.

Important Metal Processing Line--Metal Perforated Machine

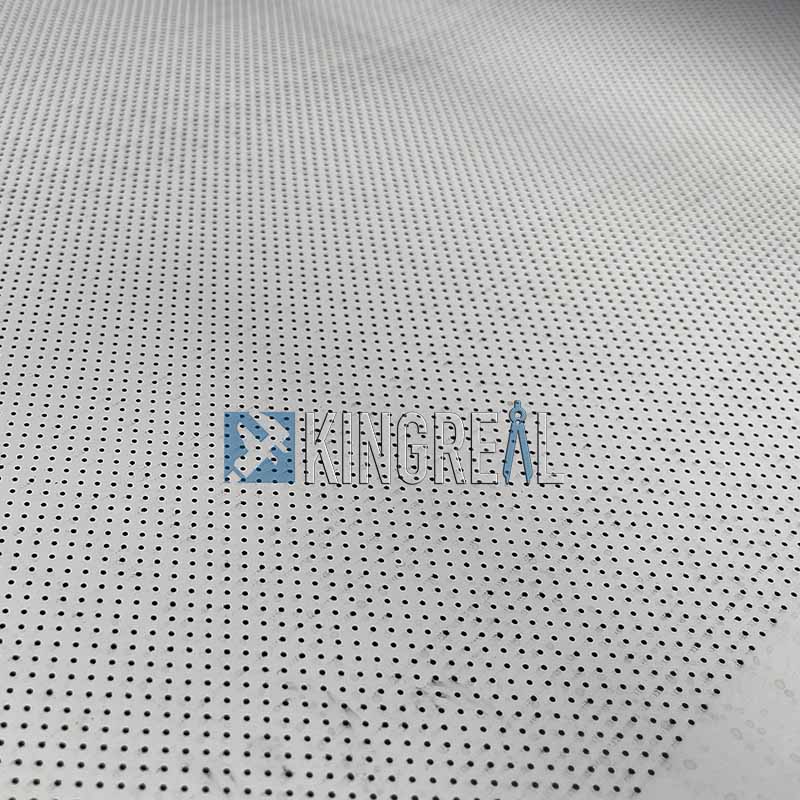

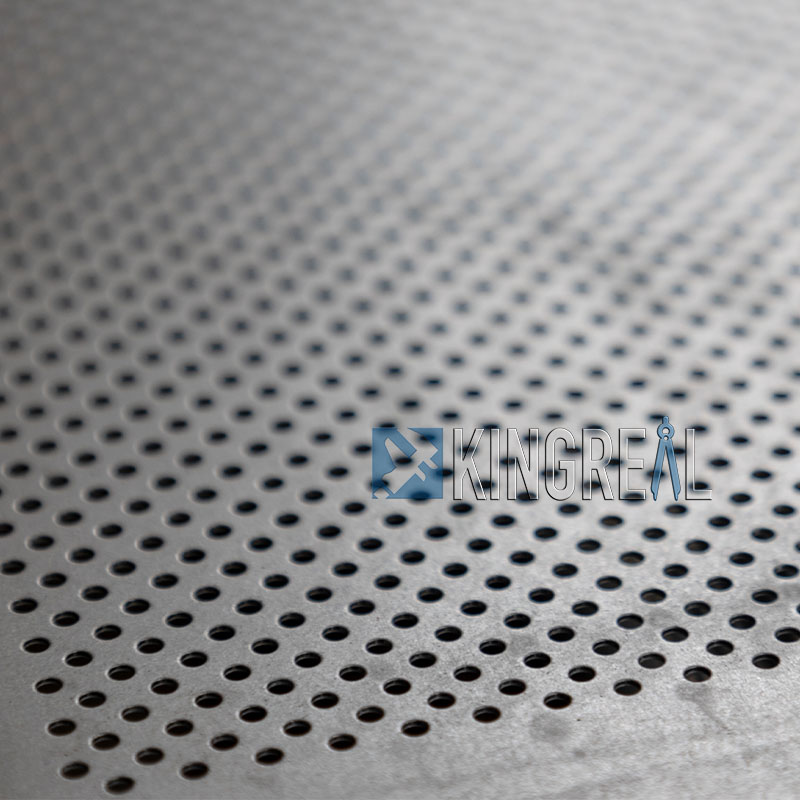

| Metal perforated machines are equipment specifically designed to punch holes of different specifications and diameters on the surface of metal materials. Through metal perforated machines, perforated sheets or coils suitable for subsequent processing can be produced, widely used in the automotive, construction, and other industries. For example, in automotive manufacturing, perforated materials are often used in the production of air conditioning radiators and exhaust pipes, while in the construction industry, perforated materials are used for ceiling and wall decoration. KINGREAL CEILING MACHINERY metal perforated machines support the precise design and manufacturing of punching dies according to customer drawings, enabling the production of various hole types, including round holes, oval holes, square holes, triangular holes, rhombic holes, hexagonal holes, and cross holes, meeting the needs of different industries. At the same time, changing the punching dies is very simple; users only need to replace the dies to produce materials with different hole types. Notably, KINGREAL CEILING MACHINERY has developed a metal perforated machine capable of punching micro-holes (1.0mm and 1.5mm). This presents higher technical challenges in punching die design and metal perforated machine manufacturing, but KINGREAL CEILING MACHINERY has successfully overcome this challenge through continuous innovation and technological advancement, providing customers with more diversified processing solutions. |

●Types of metal perforated machines

According to different customer process requirements, metal perforated machines are usually divided into three main types:

Metal sheet perforated machine

The main function of this type of metal sheet perforated machine is to punch and then immediately shear the metal material. This metal sheet perforated machine is equipped with a shearing station. After the metal material is punched, it automatically enters the shearing station for fixed-length cutting, producing the required perforated sheets. This is suitable for customers requiring specific dimensions.

This type of coil to coil perforation line rewinds the metal material after punching. This coil to coil perforation line is equipped with a recoiler that automatically winds up the material after punching is completed. Even more advanced, the coil to coil perforation line can be optionally equipped with a metal sheet cleaning machine and an unloading trolley. The former cleans the material surface, removing oil stains and ensuring the material is dry before the next process, while the latter provides automatic transportation to reduce labor costs.

Metal ceiling tile perforation line

This type of metal ceiling tile perforation line is usually used in conjunction with a metal ceiling tile production line and can produce perforated ceilings of various sizes and types, such as 300mm x 300mm, 600mm x 600mm, 1200mm x 600mm, and many other specifications. In addition, it can produce ceilings of types such as clip-in, lay-in, and tegular. To improve the sound insulation effect of the finished product, KINGREAL CEILING MACHINERY can equip the metal ceiling tile perforation line with an acoustical ceiling tile textile stick machine, ensuring better performance in residential and commercial buildings.

●Applications of metal perforated machine

Using these different types of metal perforated machines, the products produced include bread trays, filter screens, motorcycle mufflers, perforated wall panels, perforated chairs, etc. These finished products often have advantages such as lightweight, high strength, easy installation, and aesthetics, playing an important role in various applications.

Other Metal Processing Equipment

In addition to metal perforated machines, KINGREAL CEILING MACHINERY also provides a variety of other metal processing line to support different metal processing needs.

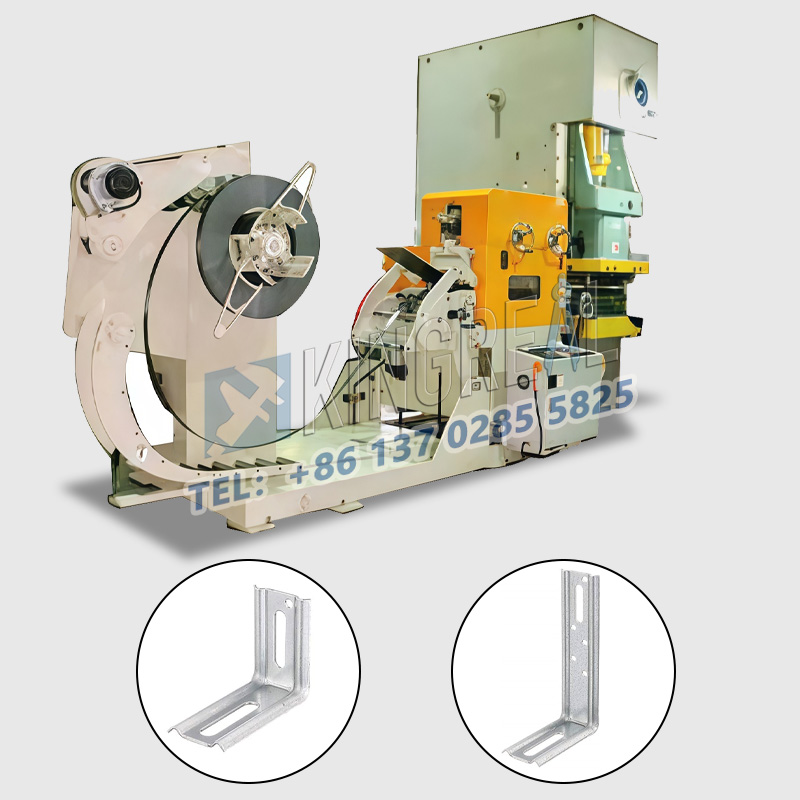

The metal stamping making machine is a device that processes materials using progressive dies, covering processes such as cutting, punching, blanking, bending, and flanging. It is widely used in various industries, such as the installation of suspended ceilings, partition wall systems, shelving systems, and photovoltaic brackets. The production of these specific metal parts is crucial for supporting and fixing various building materials.

The metal sheet leveling machine can be used to level various metal materials such as aluminum, iron, stainless steel, steel, silicon steel, PPGI, and copper. KINGREAL CEILING MACHINERY metal sheet leveling machines use rollers to level different materials such as metal sheets, perforated mesh, metal rods, and metal parts, ensuring subsequent processing accuracy. This significantly improves overall production efficiency and product qualification rate in practical applications.

KINGREAL CEILING MACHINERY NC servo feeder uses power drive to continuously and incrementally transport materials to the metal processing equipment. These NC servo feeders achieve automated directional conveying through mechanical actions (such as the rotation of rollers or the clamping of plates) and are widely used in metal processing, automotive manufacturing, precision engineering, and the electronics industry. NC servo feeders are typically used in conjunction with equipment such as punch presses, roll forming machines, or hydraulic presses, greatly promoting the continuity and automation of production lines.

Conclusion

In summary, metal processing equipment plays a crucial role in modern industry. Metal perforated machines, in particular, are a vital link in the metal processing chain. In various industries such as automotive, construction, and electronics, the existence of metal perforated machines and other metal processing line not only improves production efficiency and reduces labor costs but also provides reliable assurance for the quality improvement of modern products. KINGREAL CEILING MACHINERY continuously promotes innovation and technological advancements in metal processing equipment, striving to provide customers with efficient, precise, and flexible metal processing solutions to meet the needs of different industries.

Get the latest price? We'll respond as soon as possible(within 12 hours)