Perforated Sheet: Fabrication, Application and Patterns

2025-12-06 17:00

Perforated sheets have wide applications in modern industry and construction. This article will delve into the diverse uses of perforated sheets, covering a detailed analysis from manufacturing processes to applications.

We will focus on the following topics:

1/What are perforated sheets?

2/How are perforated sheets manufactured?

3/Grades of materials used,

4/The perforation designs and patterns,

5/Perforated sheets applications in different fields.

1/What are Perforated Sheets?

Perforated sheets are created by punching holes in the surface of metal materials using stamping technology. They are commonly used in the manufacture of perforated wall panels, motorcycle mufflers, and other components. Perforated sheets not only play an important role in structural support and sound insulation, but also regulate light, enhance the stability of railings, and provide filtration functions. Their great flexibility lets perforated sheets be readily modified with different patterns and designs as needed while still keeping strength, stability, and durability. Thus, widely employed in several structures and installations, perforated sheets have become an essential component of contemporary architectural design and industrial manufacture.

2/How are Perforated Sheets Manufactured?

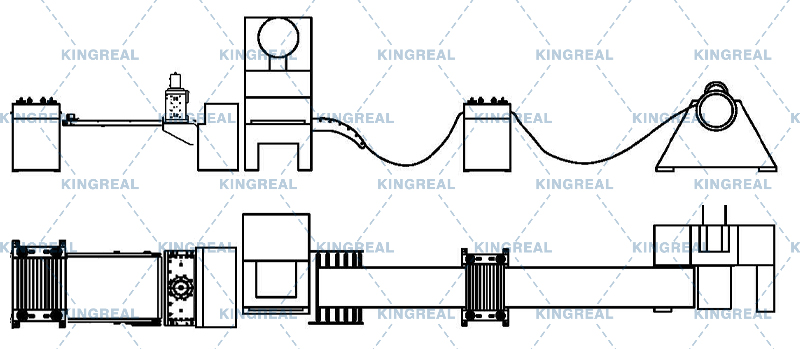

The production of perforated sheets is typically carried out using advanced metal perforated making machines. The production process includes uncoiling, leveling, punching, and post-processing.

-Uncoiling and Leveling: First, the metal coil is processed by the combined action of a decoiler and a leveler to ensure a smooth surface.

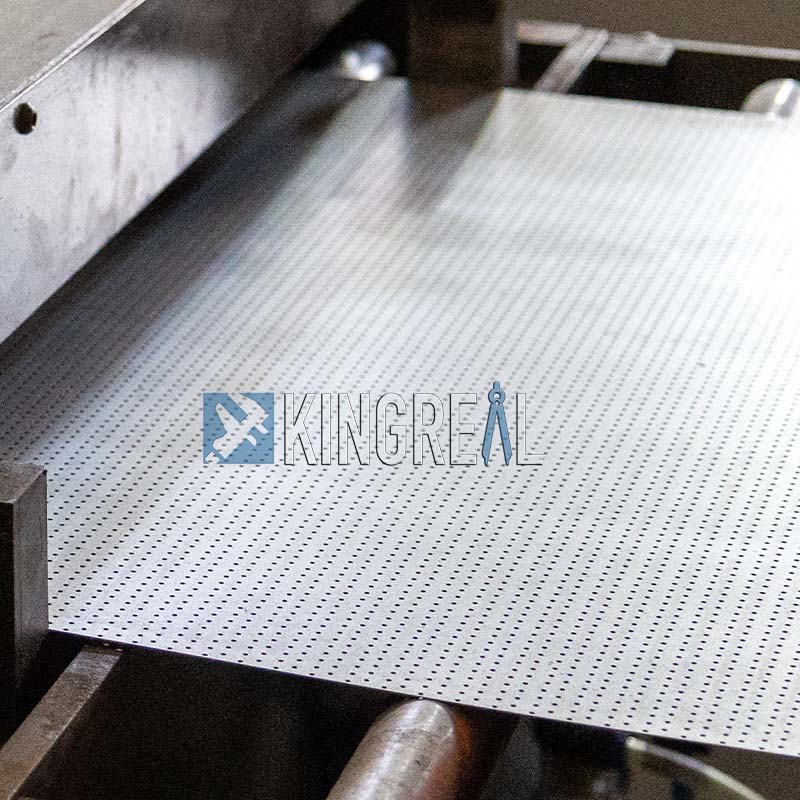

-Punching: Punching is the core step in perforated sheet manufacturing. This process uses metal sheet perforated machines and specialized dies, custom-made according to customer-provided drawings. The precision of the punching dies determines the quality of the finished product; typically, high-precision dies ensure the consistency of the pattern on each perforated sheet.

-Automated Control: Modern metal perforated making machines are equipped with PLC control panel. After parameters are set on the control panel, the metal sheet perforated machine automatically executes the operation, achieving efficient large-scale production.

-Versatility: Given the demands for load-bearing capacity and perforated sheet thickness in several application situations, KINGREAL CEILING MACHINERY metal sheet perforated machine can process many different metal materials and provide various thickness choices. To allow for more design freedom, for instance, ornamental perforated sheets are often composed of thinner sheets; while heavier, more strong materials are needed to guarantee sufficient load-bearing capability and longevity in steel mesh and railings utilized for structural support.

3/Grades of Materials Used

Perforated sheets are typically produced from a variety of materials. Depending on the application requirements, they can be classified into the following grades and their characteristics:

●Stainless Steel:

Grades: 304 (06Cr19Ni10), 316 (06Cr17Ni12Mo2), 430 (10Cr17).

Characteristics: Corrosion resistant and high-temperature resistant, suitable for chemical, marine, and decorative applications.

●Carbon Steel:

Grades: Q235 (ordinary carbon steel), SPCC (cold-rolled sheet), SGCC (galvanized sheet).

Characteristics: Low cost, high strength, but requires surface treatment (such as powder coating or galvanizing) to prevent rust.

●Aluminum and Aluminum Alloys:

Grades: 1060 (pure aluminum), 5052 (aluminum-magnesium alloy), 6061 (aluminum-magnesium-silicon alloy).

Properties: Lightweight, corrosion-resistant, suitable for building curtain walls, etc.

●Other Materials:

Copper (H62, T2): Excellent electrical conductivity, suitable for electromagnetic shielding.

Titanium (Gr1, Gr2): High biocompatibility, commonly used in medical equipment.

International Grade Comparison:

304 Stainless Steel → AISI 304 (American Standard), SUS304 (Japanese Standard).

6061 Aluminum Alloy → AA6061 (American Standard), EN AW-6061 (European Standard).

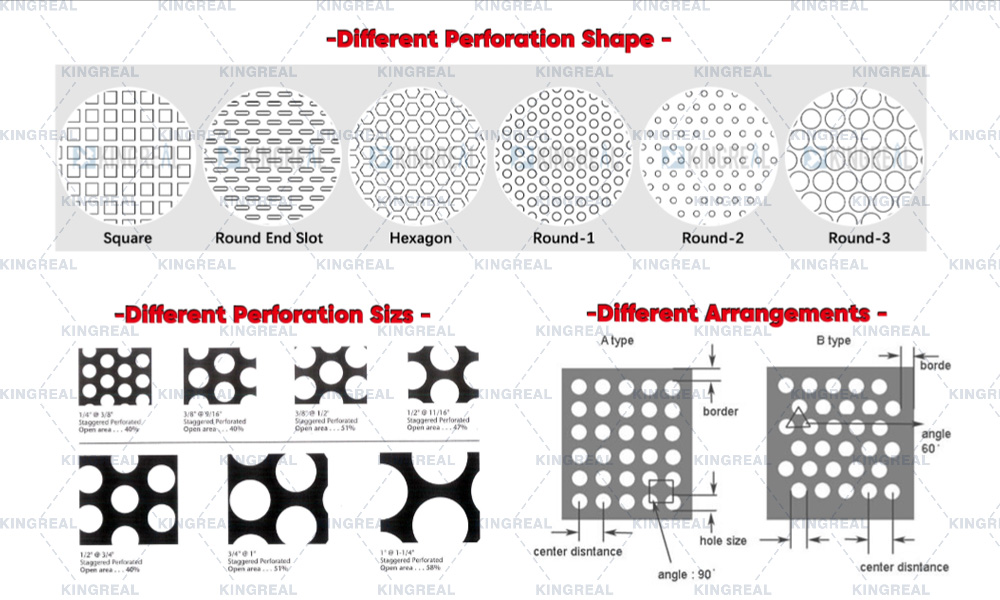

4/The Perforation Designs and Patterns

The aesthetics and functionality of perforated sheets largely depend on their pattern design. KINGREAL CEILING MACHINERY can customize various punching dies according to customer needs, meeting the requirements of different hole shapes and diameters.

●Common Hole Types

-Round Holes: Highly versatile, suitable for ventilation and screening applications, such as building facades.

-Square/Rectangular Holes: Highly decorative, suitable for mechanical protection, such as equipment fences.

-Hexagonal Holes: Achieve lightweight and high load-bearing capacity with their honeycomb structure, suitable for automotive filters.

-Irregular Hole Shapes: Includes rhomboid, quincunx, and cross-shaped holes to meet special design requirements.

●Arrangement

Straight-line: Holes are center-aligned, simple to process, and low in cost.

Staggered Arrangement (Queen Cuboid): Holes are staggered, enhancing strength and shielding effect.

5/Perforated Sheets Applications in Different Fields

1. Acoustic Applications: Noise Reduction and Sound Quality Optimization

Perforated sheets, as an important component of resonant sound-absorbing structures, can be combined with the underlying "air layer + sound-absorbing cotton" to effectively absorb sound waves of specific frequencies through the resonance effect of the holes and the air layer. For example, perforated panels improve low-frequency sound quality in speakers; in automobiles, they effectively reduce wind and road noise, improving cabin quietness; and in the casings of air conditioners and washing machines, they reduce noise generated by motor vibrations.

2. Fluid Control: Gas-Liquid Filtration and Uniform Distribution

Perforated panels utilize the "blocking + conducting" properties of their perforations to control the flow path and speed of gases or liquids. In industrial equipment and environmental systems, perforated plates can be used as primary filter layers to block large particles from entering the system, thereby enhancing equipment operating efficiency. In wastewater treatment and chemical reactions, perforated plates ensure uniform contact of reactants, improving reaction efficiency.

3. Structural Protection: Safety Isolation and Load Buffering

In the field of safety isolation, the strength of perforated plates combined with the "pressure relief/weight reduction" characteristics of their perforations allows for protection without excessive structural weight. In complex environments, such as flammable and explosive locations, perforated panels effectively relieve pressure, preventing equipment damage due to excessive internal pressure.

4. Decorative Effects: Visual Enhancement and Light and Shadow Creation

Many times utilized as decorative elements in architectural and interior design, perforated sheets create distinct light and shadow effects under illumination as well as visual interest via various patterns and arrangements. Perforated sheets may conform to several modern architectural trends thanks to their design flexibility.

KINGREAL CEILING MACHINERY, as a professional metal perforated making machine manufacturer, is committed to providing customers with high-quality, customized perforated sheet solutions. If you have further interest or needs regarding perforated sheets and their applications, please contact KINGREAL CEILING MACHINERY for more information.

Get the latest price? We'll respond as soon as possible(within 12 hours)