Application of Ceiling T Bar Machine

2025-12-19 17:49

In the modern construction industry, the aesthetics and functionality of ceiling systems are becoming increasingly important. The ceiling t bar, as the core support component of the ceiling structure, plays a crucial role. The ceiling t bar machine is specifically designed to manufacture the ceiling t bars that support ceiling panels, including main t and cross t. KINGREAL CEILING MACHINERY offers various versions of ceiling t bar roll forming machines, allowing customers to choose based on the required profile type, production volume, and level of automation to meet different production needs.

What is a Ceiling T Bar Machine?

A ceiling t bar roll forming machine mainly consists of several key components, including a hydraulic decoiler, a main roll forming machine, a punching and shearing station, and a product table. This ceiling t bar machine processes galvanized steel (Gi) and pre-painted galvanized steel materials to produce four main types of ceiling t bars: flat ceiling t bar, center black line ceiling t bar, FUT ceiling t bar, and silhouette groove ceiling t grid.

During the production process, the various components of the ceiling t bar roll forming machine work together efficiently, resulting in a highly automated production process and guaranteed product quality. The efficiency and precision of this machine have led to its widespread application in the market.

What are the Applications of Ceiling T Bar Machine?

Ceiling t bar roll forming machines are crucial in construction, especially in commercial and residential building sectors. They are used to produce the ceiling t bar and wall angle required for suspended ceilings, which support ceiling tiles and lighting fixtures. Ceiling t bar machines are not only suitable for home renovations but are also widely used in the construction of offices, schools, and hospitals, helping to build durable and fire-resistant ceiling systems.

With the increasing demands for material and structural safety in the construction industry, the importance of ceiling t bar roll forming machines is becoming even more pronounced. Through mass production, these machines are ideal for manufacturers supplying large-scale projects, enabling them to quickly respond to market demands and provide customers with large quantities of consistent and high-precision products.

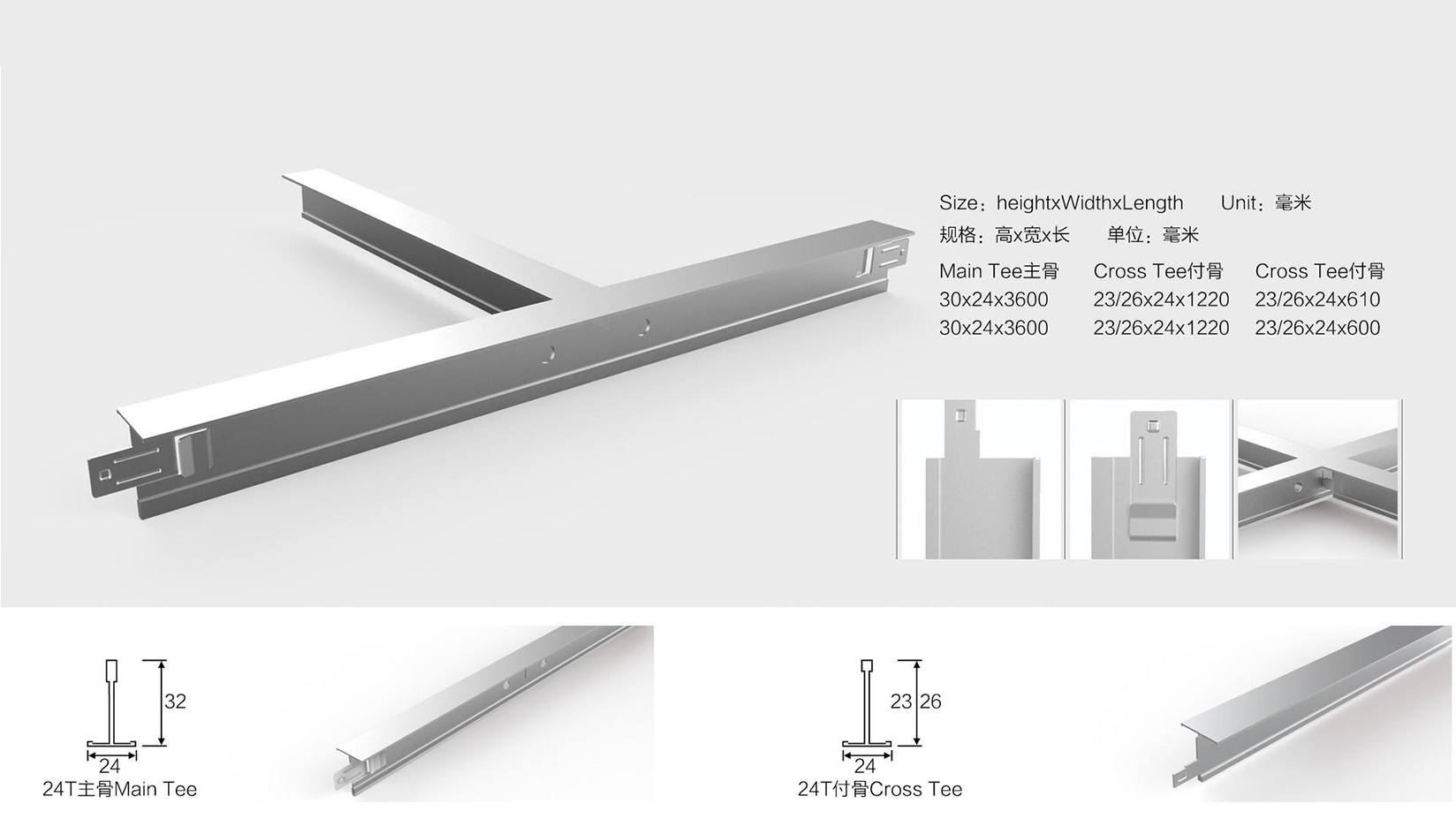

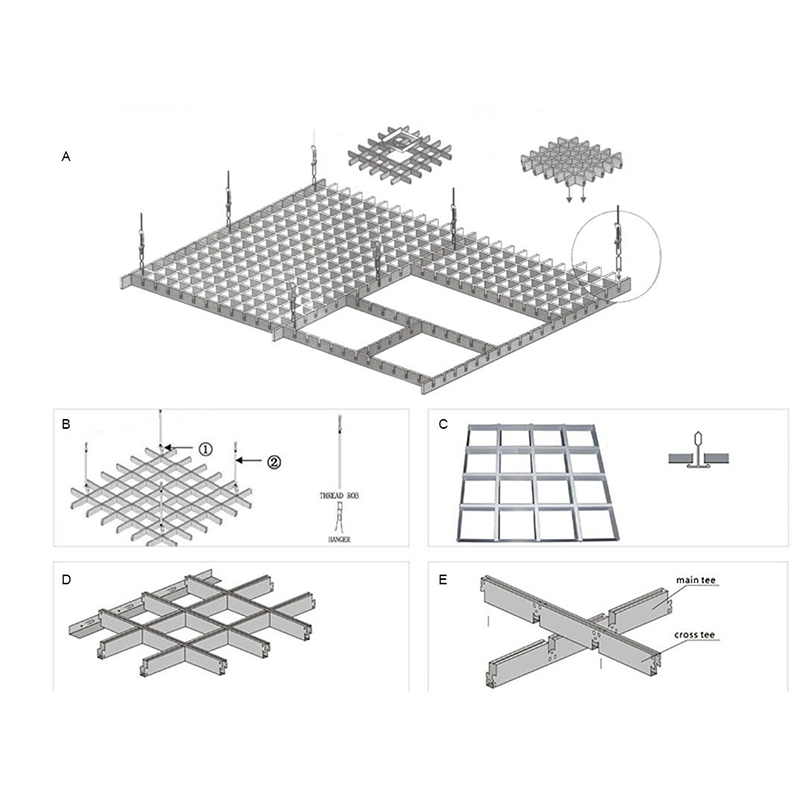

●Applications of ceiling t bar machine in grilyato ceiling systems

The ceiling t bar produced by ceiling t bar roll forming machines can be used with grilyato ceilings and are widely applied in open cell ceiling systems. When installing open cell ceilings, it is usually necessary to first install the perimeter wall angle, then suspend and level the main t, add cross t to form a grid structure, and finally insert the open cell ceilings, using special clamps for easy maintenance. This ceiling design is not only simple and aesthetically pleasing but also facilitates the integration of lighting and ventilation systems, improving the overall comfort of the environment. Key steps in the installation process include precise layout, using suspension wires to fix the main t, and connecting the cross t to build a modular grid, ultimately achieving a smooth architectural aesthetic. |  |

KINGREAL CEILING MACHINERY can provide complete grilyato ceiling systems tailored to customer needs, producing equipment including ceiling t bar machine, open cell ceiling machine, and ceiling t grid wall angle machine, ensuring that customers receive the highest quality solutions for their construction projects.

●Applications of ceiling t bar machine in metal ceiling systems

The ceiling t bar produced by ceiling t bar roll forming machines, combined with lay in ceiling panels produced by metal ceiling tile production lines, form a complete metal ceiling system. This system is widely used in many commercial environments, and its advantages lie in its aesthetics and practicality. During the installation of metal ceilings, it is necessary to first determine the perimeter outline using a laser level, then suspend the main t from the structure using suspension wires, and then connect the cross t to form a grid. To ensure the flatness and stability of the ceiling, the spacing of the main t (usually 4 feet apart) and the suspension wires (minimum 12 gauge wire) should meet the requirements during installation. |  |

In addition to providing high-quality ceiling t bar machines, KINGREAL CEILING MACHINERY offers customized metal ceiling tile production lines to meet customers' needs for personalized metal ceilings, providing a variety of sizes, finishes, and perforation patterns. This not only enhances aesthetics but also improves acoustic performance. By providing modular design machines, KINGREAL CEILING MACHINERY makes the installation process more convenient and efficient, matching the customer's actual production projects. Furthermore, KINGREAL CEILING MACHINERY also offers various acoustic treatment solutions to improve sound absorption and reduce noise levels.

The ceiling t bar roll forming machine is not only a crucial piece of equipment in modern building construction but also key to achieving aesthetically pleasing, efficient, and versatile ceiling systems. Whether in commercial, residential, educational, or healthcare settings, the supporting function of ceiling t bar and the efficiency of the ceiling t bar roll forming machine in the manufacturing process significantly improve construction quality and speed.

KINGREAL CEILING MACHINERY is committed to providing customers with high-performance ceiling t bar machines and continuously adapts and innovates based on market demands. KINGREAL CEILING MACHINERY welcomes customers from all sectors to contact KINGREAL CEILING MACHINERY to discuss further applications and solutions for ceiling t bar roll forming machines.

Get the latest price? We'll respond as soon as possible(within 12 hours)