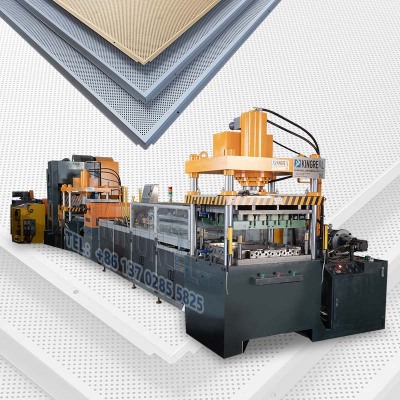

Metal Ceiling Tile Production Line

KINGREAL CEILING MACHINERY fully automated metal ceiling tile production line is primarily designed for producing various sizes and types of metal ceiling panels and it can produce metal ceiling panels of varying thicknesses, widths, and materials.

KINGREAL CEILING MACHINERY drop ceiling panel making machine can be customized to meet your specific perforation pattern or metal ceiling type. Customization is welcome based on samples or drawings.

- KINGREAL CEILING MACHINERY

Details

Video About Metal Ceiling Tile Production Line

Description of Metal Ceiling Tile Production Line

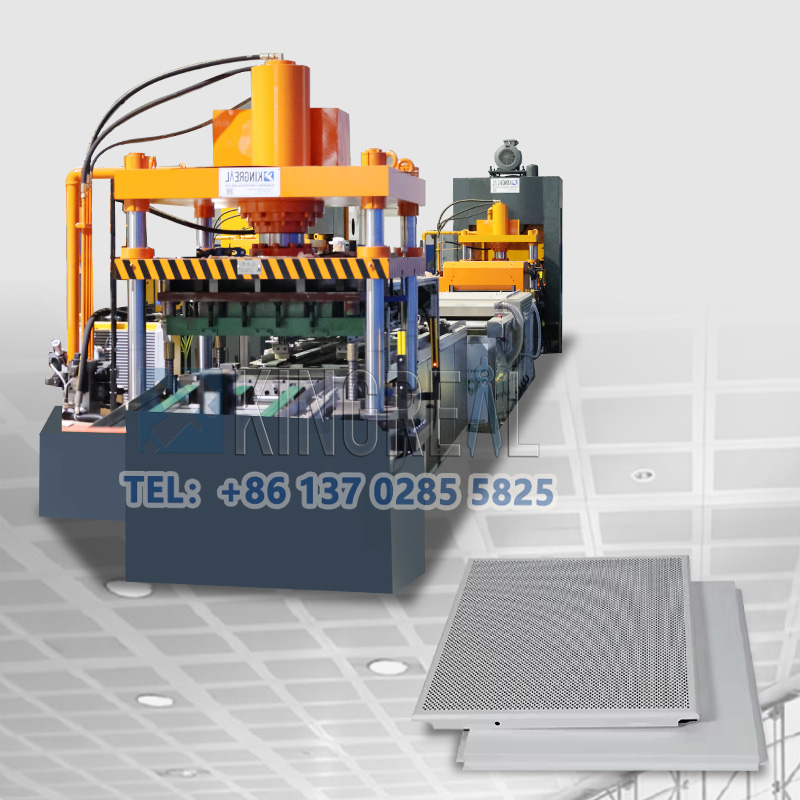

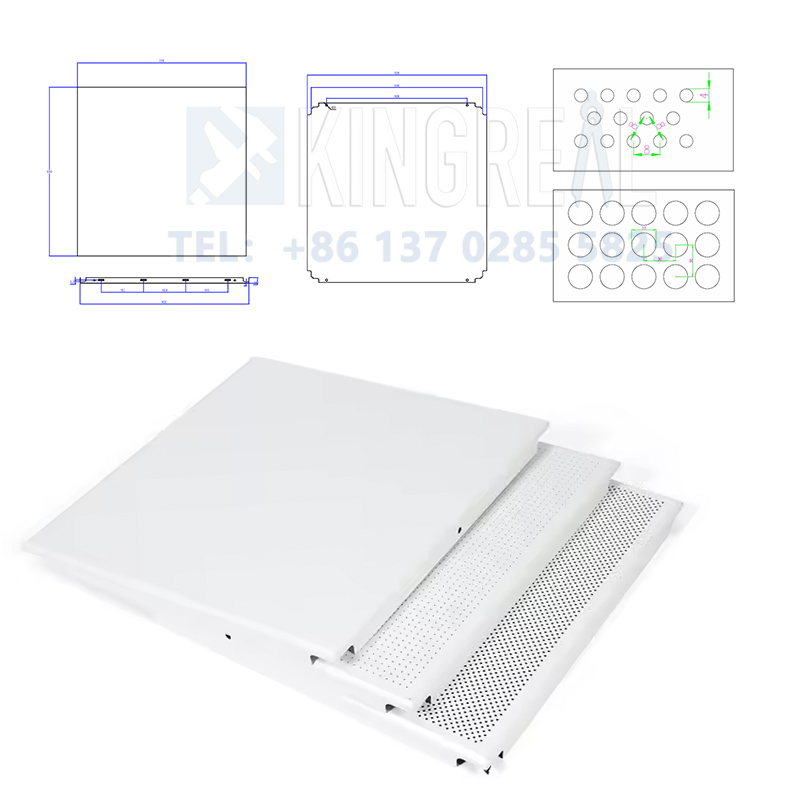

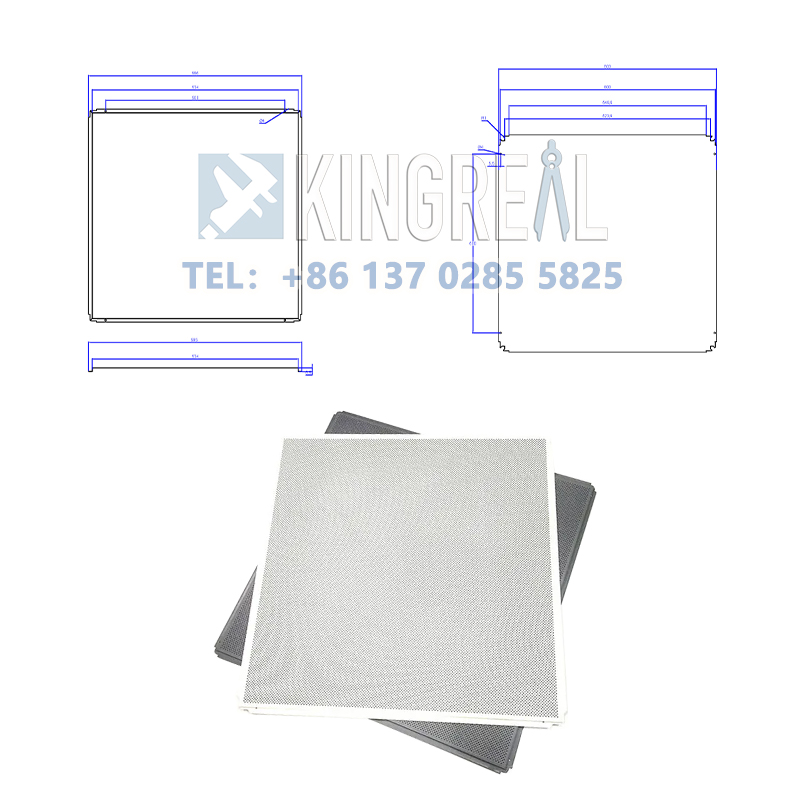

The KINGREAL CEILING MACHINERY fully automated metal ceiling tile production line is primarily designed for producing various sizes and types of metal ceiling panels, including clip in ceiling tile, lay in ceiling tile, etc. Both types can be produced on the same drop ceiling panel making machine by simply changing the mold.

This metal ceiling tile production line includes precision processes such as automatic unwinding, primary leveling, CNC feeding and perforation, corner cutting, secondary leveling, robotic arming, and bending. It boasts high precision, fast production speed, and high capacity. The KINGREAL CEILING MACHINERY drop ceiling panel making machine can produce metal ceiling panels of varying thicknesses, widths, and materials. Common metal ceiling tile production lines can process stainless steel, aluminum, iron, galvanized steel, cold-rolled steel, hot-rolled steel, copper, brass, etc. The KINGREAL CEILING MACHINERY drop ceiling panel making machine can be customized to meet your specific perforation pattern or metal ceiling type. Customization is welcome based on samples or drawings. |  |

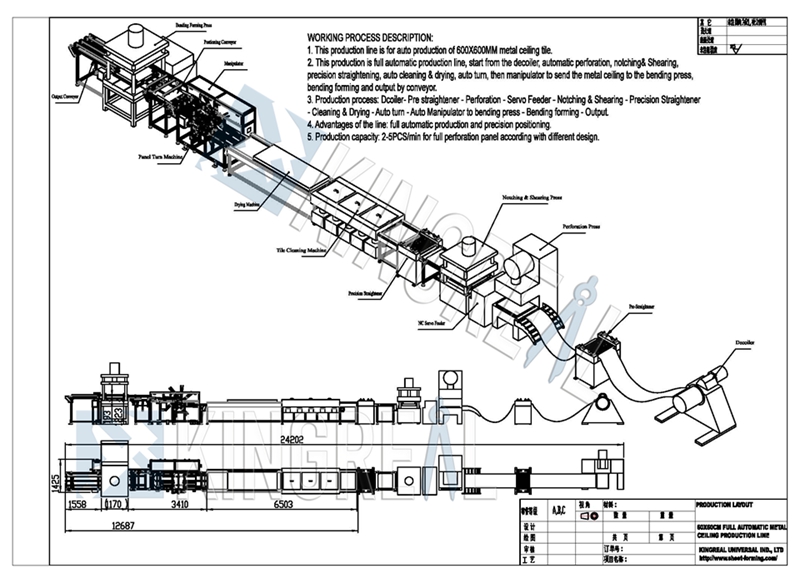

Workflow of Metal Ceiling Tile Production Line

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching and Shearing Press -- 2nd Precision Straightener -- Flipping Machine -- Automatic Tile Feeding Machine -- Auto Bending Forming Machine

Parameters of Metal Ceiling Tile Production Line

| Raw Materials | Galvanized iron coil, aluminum coil, roll-coated coil, etc. |

| Material Thickness | Iron 0.4-0.5mm, Aluminum 0.5-0.6mm |

| Product Types | Lay-in (T24, T15), Lay-on, Clip-in, Tegular |

| Product Dimensions | 600*600mm, 300*300mm, 300*600mm, 300*1200mm, 600*1200mm |

| Common Apertures | 1.8mm, 2.5mm |

Main Components of Metal Ceiling Tile Production Line

| NO. | Equipment | Specification | Qty. |

| 1 | Hydraulic Decoiler | With Coil Car (Optional) | 1 Unit |

| 2 | 1# Leveler | Including Integrated Film Applicator | 1 Unit |

| 3 | Perforation (Power Press) | With Servo Feeder | 1 Unit |

| 4 | Corner Cut (Hydraulic Press) | 40T (600×600) / 80T (1200×600)(Optional) | 1 Unit |

| 5 | Conveyors | 1# - Between Cutting Unit And 2# Leveler. 2# - After Bending | 2 Units In Total |

| 6 | 2# Leveler | 21 Leveling Rolls | 1 Unit |

| 7 | Turnover Unit | Integrated In Conveyor | 1 Unit |

| 8 | Manipulator | Transfer Material After Turnover Into Bending Tool | 1 Unit |

| 9 | Bending Press | 120T For 600×600 Forming (Clip-In / Lay-In) (Optional) | 1 Unit |

| 10 | Control System | YASKAWA Servo Motor; PANASONIC PLC | 1 Unit |

| 11 | Tools (Customized) | Perforation, Corner Cutting And Bending Tools | 1 Set |

| 12 | Acoustic Fleece Sticking Machine(Optional) | 380 / 50 HZ / 3 PHASE | 1 Unit |

| 13 | Metal Sheet Cleaning Machine(Optional) | 440V 50Hz 3-Phases, 30KW typical | 1 Unit |

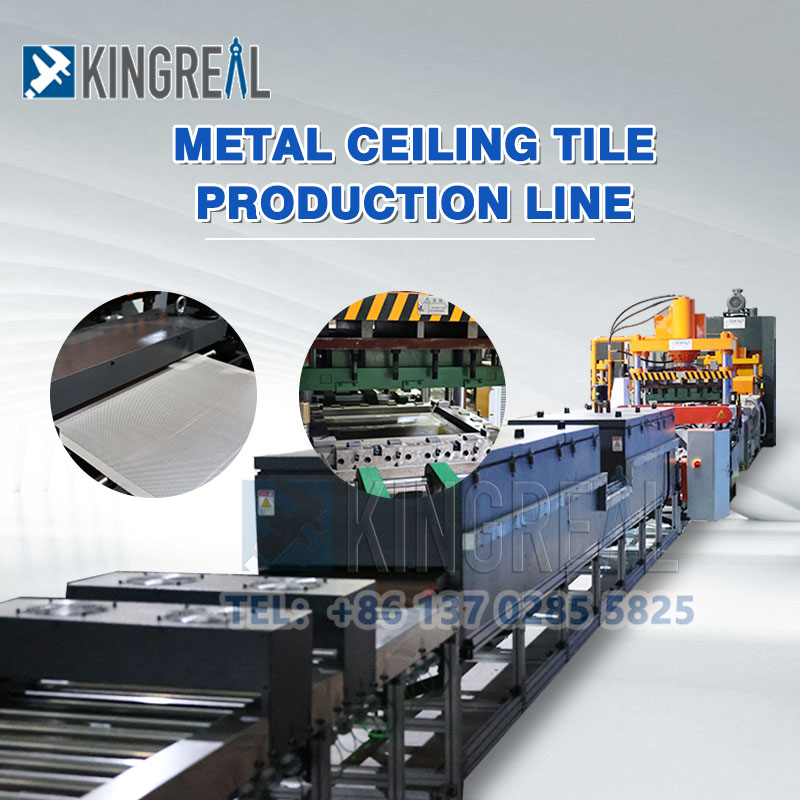

Fully Automatic Drop Ceiling Panel Making Machine Solution

KINGREAL CEILING MACHINERY specializes in designing customized manufacturing solutions for our clients, excelling in tailoring to their specific needs. This metal ceiling tile production line was custom-built to meet the requirements of a South American customer. This customer had high requirements for ceiling cleanliness and sound insulation. They also wanted a single drop ceiling panel making machine that could handle the entire production, cleaning, and tile application process, all within one machine.

KINGREAL CEILING MACHINERY engineers designed this metal ceiling tile production line based on these customer's needs. In addition to fully automated components ensuring high-speed operation and guaranteed production, it also features an acoustic fleece sticking machine and a metal sheet cleaning machine.

| Metal sheet cleaning machine The metal sheet cleaning machine is a crucial component of any drop ceiling panel making machine. The metal sheet cleaning machine consists of the following key components:

-Cleaning Unit: Equipped with brushes, a water tank, and a drain pipe, it effectively cleans the ceiling surface. The cleaning unit supports the addition of cleaning agents and features a recyclable function, making it both environmentally friendly and economical. -Drying Unit: Utilizing a high-efficiency drying oven, it quickly dries the ceiling panels on both sides, ensuring production efficiency and product quality. -Oiler (Optional): To further enhance the performance of the ceiling panels, customers can opt for an oiler. This unit provides rapid oiling on both sides and also features a recyclable function. -Electrical Cabinet: Integrated electrical components and control systems ensure stable operation and intelligent control of the entire metal sheet cleaning machine.

These carefully designed components enable the metal sheet cleaning machine to seamlessly integrate with other processes in the drop ceiling panel making machine, significantly improving production efficiency. |  |

Acoustic fleece sticking machine At the end of the drop ceiling panel making machine, KINGREAL CEILING MACHINERY has installed a highly efficient acoustic fleece sticking machine. Designed with performance and efficiency in mind, its key components include:

-Fleece Sticking Section: Precisely applies the applicator patches to the ceiling, ensuring the aesthetic and consistency of each ceiling panel. -Drying Section: This efficient drying system further ensures the adhesive adhesion of the patch and prevents it from falling off due to moisture. -Air-Fan Cooling Section: After production is complete, the Air-Fan Cooling Section quickly removes any residual moisture from the ceiling surface, improving product yield.

This acoustic fleece sticking machine is directly connected to the drop ceiling panel making machine, achieving a fully automated production process and significantly reducing labor costs and production time. |  |

Various Metal Ceiling Tile Production Line Solutions

1) Various speed solutions for metal ceiling tile production line

KINGREAL CEILING MACHINERY can design drop ceiling panel making machine solutions with various speeds based on the customer's production scale and speed requirements. For example, for large-scale manufacturers, KINGREAL CEILING MACHINERY can provide high-speed metal ceiling tile production lines to meet their high-volume needs. For smaller businesses or those in emerging markets, a slower but more stable drop ceiling panel making machine can also meet their production requirements. This flexible configuration allows every customer to find a metal ceiling tile production line that's right for them.

2) Various pricing solutions for metal ceiling tile production line

KINGREAL CEILING MACHINERY understands that customers' budgets and needs vary, so we offer drop ceiling panel making machines in various price ranges to meet their needs. Typically, machines at different price points differ in performance parameters, additional components, and degree of automation. For example, fully automatic metal ceiling tile production lines are typically more expensive than semi-automatic ones, but they offer significant advantages in production efficiency and product quality. Through this pricing strategy, KINGREAL CEILING MACHINERY ensures that every customer can find a drop ceiling panel making machine solution that's right for them.

3) Various material solutions for metal ceiling tile production line

KINGREAL CEILING MACHINERY drop ceiling panel making machines are designed to be compatible with a variety of materials, processing ceiling materials of varying widths and thicknesses, and even different types of metal. This flexibility gives customers more choices when selecting raw materials, allowing them to adjust their production strategies based on market demand and their own circumstances.

Highly Flexible Metal Ceiling Tile Production Line

KINGREAL CEILING MACHINERY fully automated drop ceiling panel making machine also demonstrates exceptional flexibility in terms of metal ceiling production types. KINGREAL CEILING MACHINERY metal ceiling tile production line can produce a variety of metal ceiling types, including clip in ceiling tile, lay in ceiling tile, and tegular ceiling tile. Clip in ceiling tile and Lay in ceiling tiles are two of the most popular types in the market. To meet customer demand for these two types, KINGREAL CEILING MACHINERY has specially designed a drop ceiling panel making machine that can produce different metal ceiling types by changing molds.

This design not only enhances metal ceiling tile production line flexibility but also significantly reduces customer production costs. With a simple mold change, customers can produce different metal ceiling types on the same line, significantly improving production efficiency and cost-effectiveness.

Relevant Products

A-Type Carrier Roll Forming Machine

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)