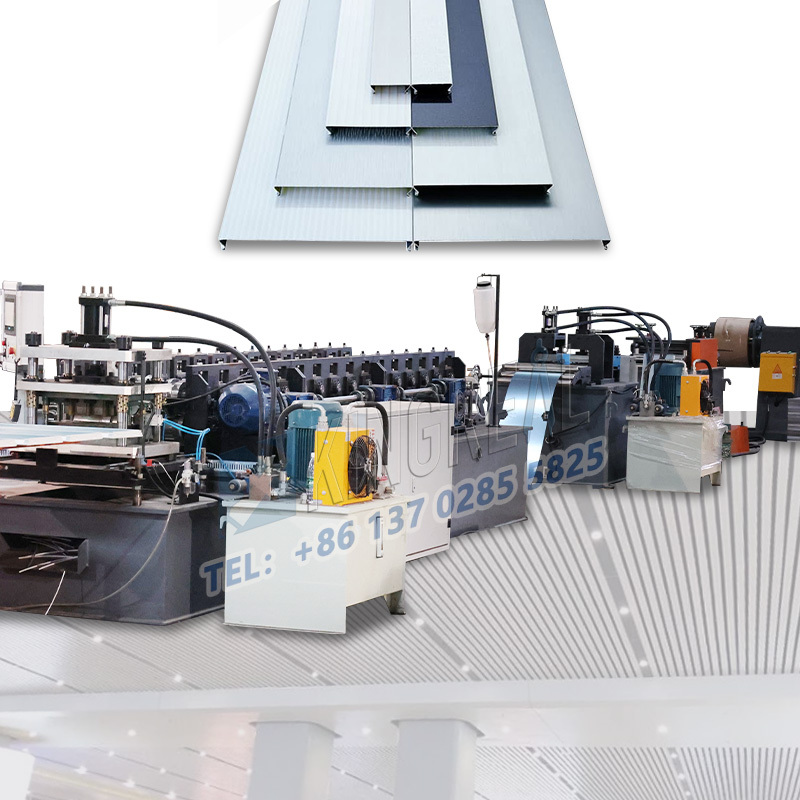

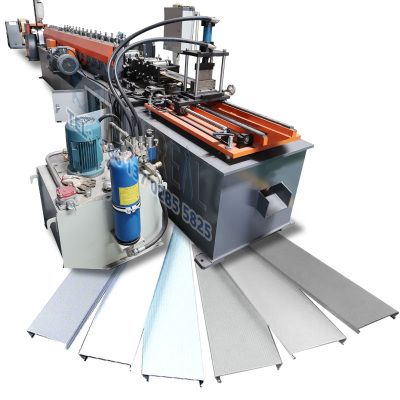

Linear Strip Ceiling Machine

KINGREAL CEILING MACHINERY can provide a variety of linear strip ceiling machine manufacturing solutions according to the different production needs of customers. This linear strip ceiling machine can produce high-precision, burr-free linear strip ceilings at a speed of 30m/min.

- KINGREAL CEILING MACHINERY

- China

- 90 Days

- 9999

Details

Video About Linear Strip Ceiling Machine

Introduction to Linear Strip Ceiling Machine

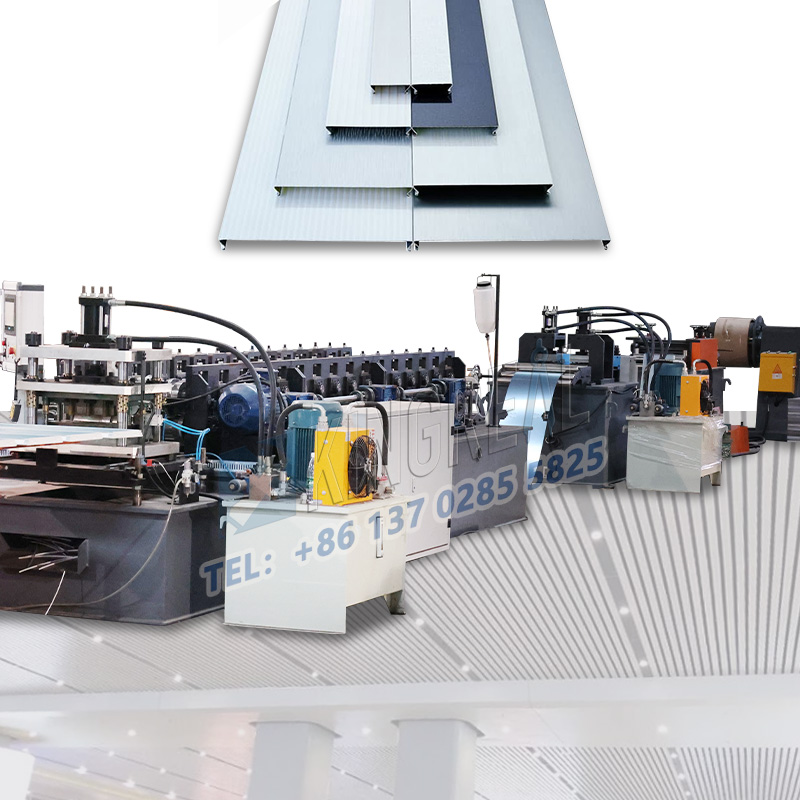

| KINGREAL CEILING MACHINERY linear strip ceiling machine can efficiently produce linear strip ceilings of various sizes and types with a production speed of up to 30 m/min, including G-type, F-type, H-type, S-type, R-type, C-type, B-type, V-type and other designs. In order to better meet the different production needs of customers, KINGREAL CEILING MACHINERY also provides a variety of linear strip ceiling making machine manufacturing solutions, including: single-specification linear strip ceiling machine, multi-specification linear strip ceiling making machine, linear strip ceiling machine with punching station, etc. Through these rich options, KINGREAL CEILING MACHINERY ensures that every customer can find the linear strip ceiling making machine manufacturing solution that best suits their needs, helping them maintain their advantages in the highly competitive market. Whether it is mass production or personalized customization, KINGREAL CEILING MACHINERY linear strip ceiling machine can provide customers with excellent performance and reliable support. |  |

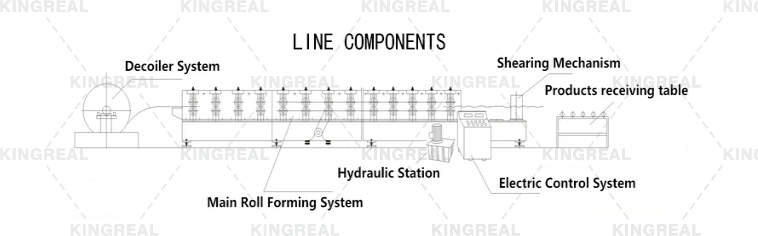

Workflow of Linear Strip Ceiling Making Machine

Hydraulic Decoiler ↓ Precision Straightener ↓ Hydraulic Punching Station ↓ Main Roll Forming Machine ↓ Product Table |  |

Features of Linear Strip Ceiling Machine

√Can produce different types of linear strip ceilings (including 84R, B-type, C-type, V-type, G-type, H-type, U-type, etc.)

√High-speed production, stable operation (up to 30m/min)

√Fully automatic linear strip ceiling machine

√High precision of finished products, no burrs on the surface

√Can be equipped with punching station

√Personalized linear strip ceiling making machine manufacturing solution (designed completely according to customer drawings and actual conditions)

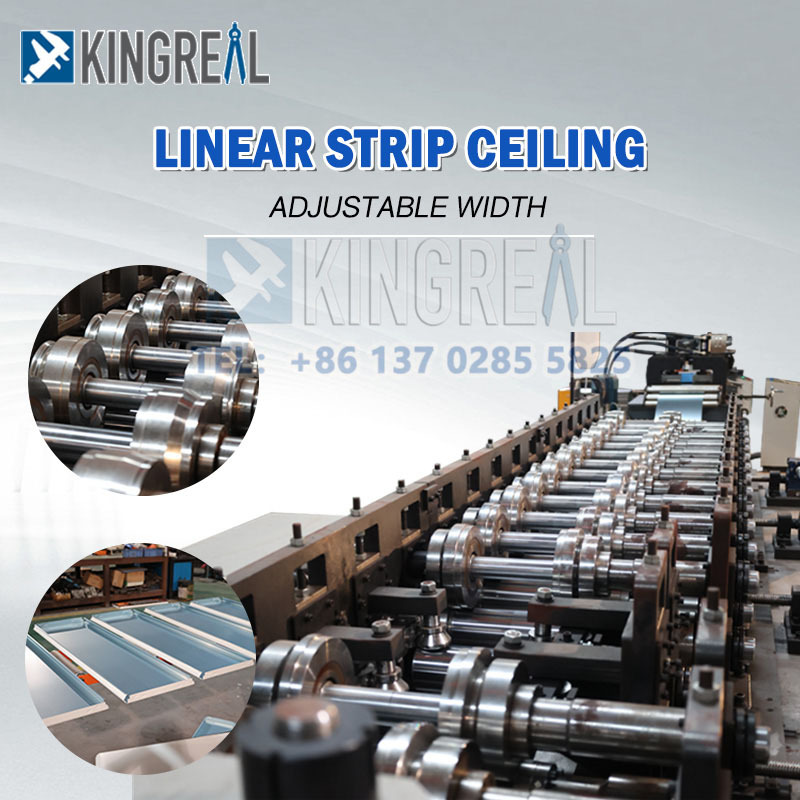

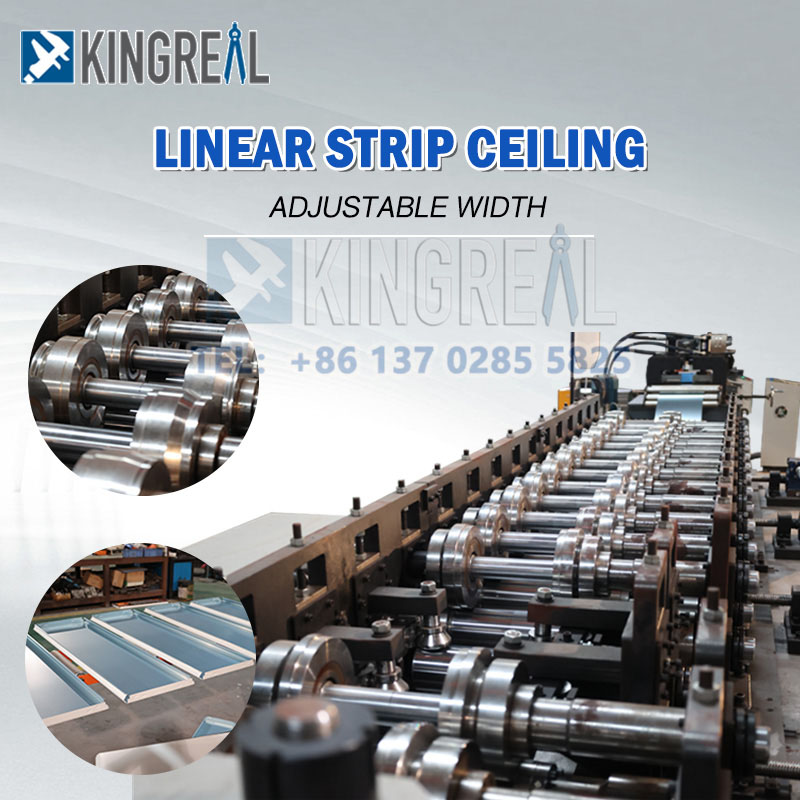

KINGREAL CEILING MACHINERY New Design: Linear Strip Ceiling Machine with Adjustable

After investigation, KINGREAL CEILING MACHINERY engineers found that customers who usually buy linear strip ceiling making machines have production requirements for multiple linear strip ceiling sizes. After many experiments, KINGREAL CEILING MACHINERY successfully designed a multi-specification linear strip ceiling machine. This machine can adjust parameters in real time through the control panel to quickly change the production of linear strip ceilings of different sizes. In addition, the width and narrow switching speed of the roll forming machine is very fast. In order to improve production efficiency for customers and suit customers who need diversified production, KINGREAL CEILING MACHINERY linear strip ceiling making machine with both flexibility and customization can well meet customers' actual production needs. |  |

Compared with the single-specification linear strip ceiling productional line, the manufacturing difficulty of this multi-specification linear strip ceiling machine lies in:

① Complex control system: KINGREAL CEILING MACHINERY engineers need to develop a precise automatic adjustment system, including sensors, servo motors and control software, to ensure the accuracy of width and narrow adjustment. ② Mechanical structure: KINGREAL CEILING MACHINERY engineers need to design a stable and flexible mechanical structure to support rapid adjustment without affecting the stability and accuracy of the linear strip ceiling making machine. ③ Adjustment mechanism: KINGREAL CEILING MACHINERY engineers need to design an efficient adjustment mechanism to ensure that the width and narrow switching can be completed in a short time while maintaining production efficiency. ④ User interface: KINGREAL CEILING MACHINERY engineers need to develop a friendly operation interface to facilitate customers to quickly set and adjust parameters. |  |

Combination of Linear Strip Ceiling Machine & Linear Strip Ceiling Carrier Machine

| In addition to the linear strip ceiling making machine, KINGREAL CEILING MACHINERY can also provide linear strip ceiling carrier machines so that customers can get a variety of equipment only at KINGREAL CEILING MACHINERY, saving procurement time and cost, and also facilitating unified technical support and after-sales service. The combination of linear strip ceiling machine and linear strip ceiling carrier machine can provide customers with a complete linear strip ceiling solution, improve the overall efficiency of the production line, and ensure good coordination between equipment. It is worth mentioning that the linear strip ceiling carriers produced by KINGREAL CEILING MACHINERY linear strip ceiling carrier machine can be matched with linear strip ceilings of different specifications. |  |

Different Types of Linear Strip Ceiling Making Machines

KINGREAL CEILING MACHINERY is a professional linear strip ceiling machine manufacturer, which can provide customers with different types of linear strip ceiling machines according to the actual production needs of customers and combined with drawings. For example, a linear strip ceiling machine that can produce 84R, a linear strip ceiling machine that can produce B-types, a linear strip ceiling making machine that can produce C-type, a single-specification linear strip ceiling making machine, a linear strip ceiling making machine with a punching station, etc. KINGREAL CEILING MACHINERY engineers will adjust parameters, add components, etc. for the linear strip ceiling making machine according to customer needs.

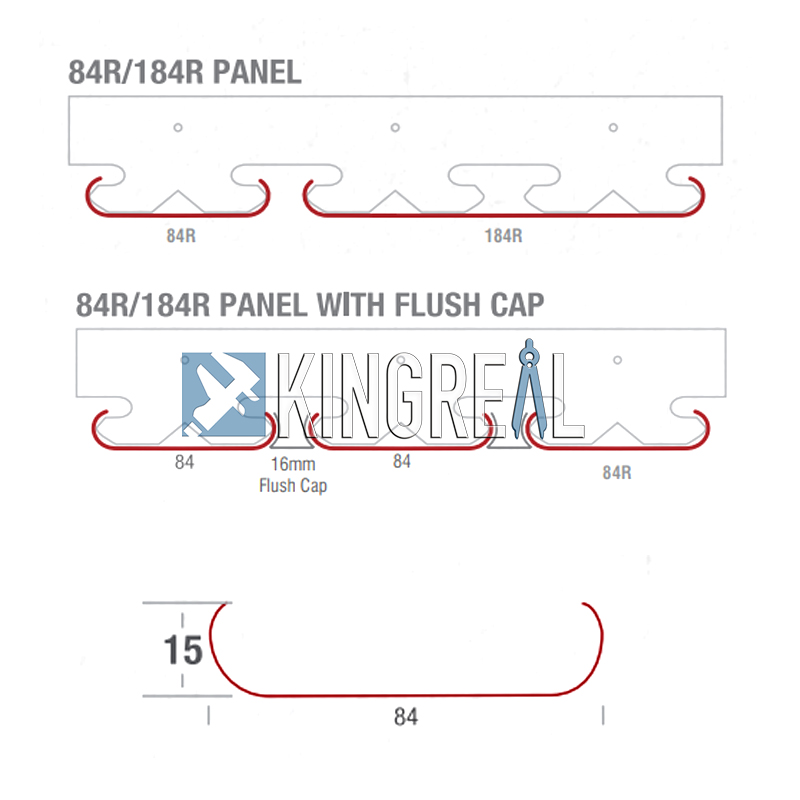

(1)A linear strip ceiling making machine that can produce 84R. This linear strip ceiling machine can produce 84R linear strip ceilings and has the characteristics of smooth operation. The 84R linear strip ceiling gives a strong sense of guidance to the space design, and can create rich, vivid and directional indoor and outdoor spaces. The joints between the boards can not only connect the board surface along the longitudinal direction to extend the sense of lines, but also can be combined with a variety of widths or heights of boards in the width direction to create a staggered and layered effect. |  |

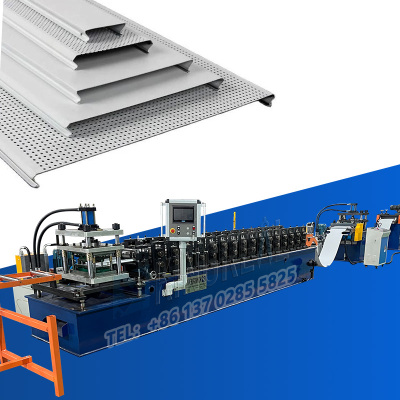

(2)Linear strip ceiling making machine that can produce B-type. This linear strip ceiling machine can produce B-type linear strip ceilings. It is composed of fully automated components such as decoilers, precision leveling machines, roll forming machines, and cutting stations, and does not require excessive human intervention. As long as the parameters are set and clicked to start, the linear strip ceiling making machine will run automatically. B-type linear strip ceilings are a common building material with a B-type groove shape. They can realize large panels and are used for indoor and outdoor decoration. They can play a role in beautification and shielding. |  |

(3)Linear strip ceiling machine that can produce C-type. This linear strip ceiling making machine can produce C-shaped linear strip ceilings, and the cutting station uses a high-hardness blade, which can achieve precise shearing. The cross-section of the produced C-shaped linear strip ceiling is flat and uniform in size. KINGREAL CEILING MACHINERY linear strip ceiling machine can guarantee the quality of each finished product for customers. |  |

(4)Single specification linear strip ceiling making machine. This single specification linear strip ceiling machine can only produce one size of linear strip ceiling per machine. According to customer needs, KINGREAL CEILING MACHINERY can customize single specification linear strip ceiling making machines suitable for different styles of linear strip ceilings such as S-type, V-type, G-type, etc. This machine is particularly suitable for customers who need to mass-produce linear strip ceilings of a specific size, for example: Focusing on a single product line: Those companies that only need to produce one specification of linear strip ceilings can achieve efficient and stable production through this linear strip ceiling machine. Or customers with less customization needs: If the customer's production needs are relatively fixed and the size of the linear strip ceiling does not change much, this linear strip ceiling making machine will be an ideal choice. |  |

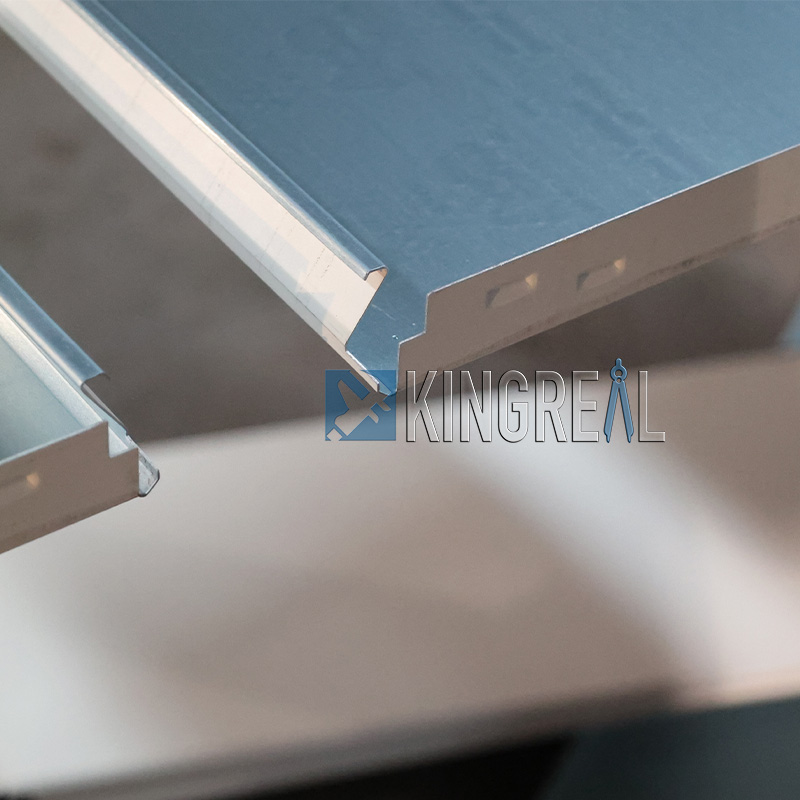

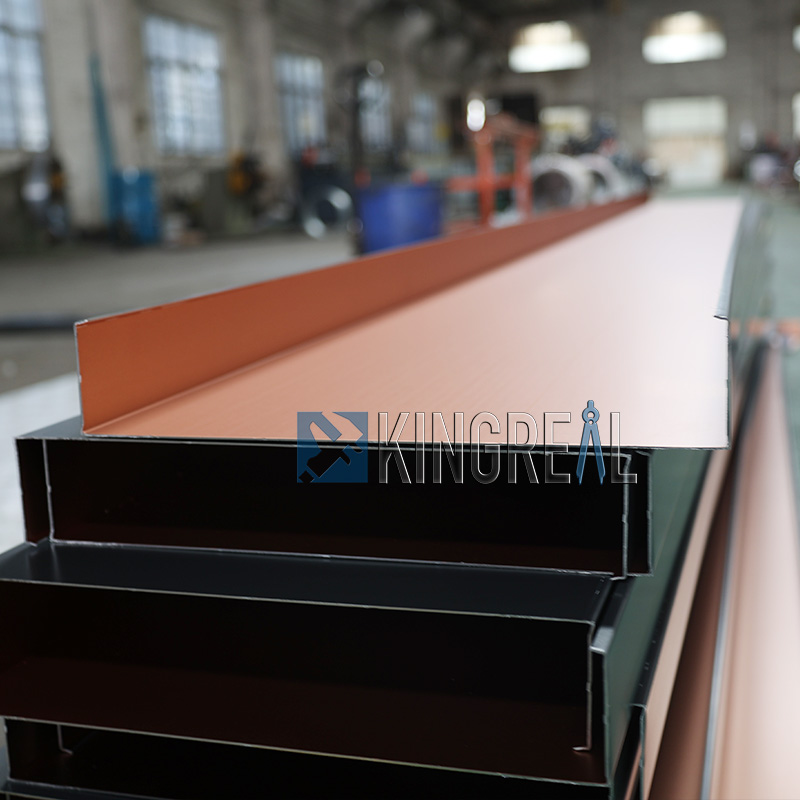

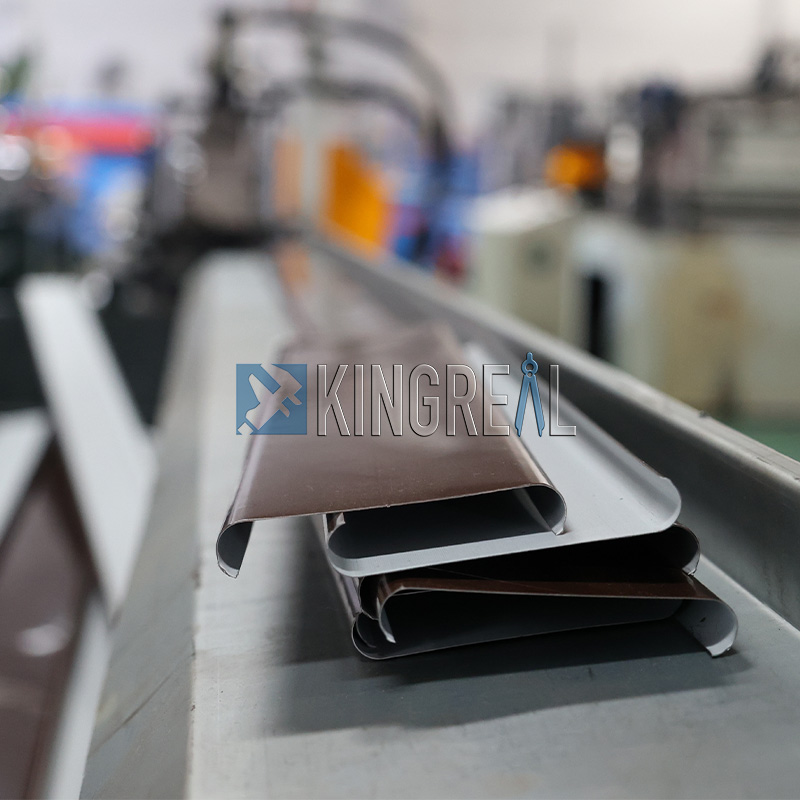

Product Display

The finished products produced by the KINGREAL CEILING MACHINERY linear strip ceiling machine have been well received by customers. They said that the KINGREAL CEILING MACHINERY linear strip ceiling making machine is of good quality, and the linear strip ceilings produced are of high precision and consistency, ensuring that each finished product can meet strict standards.

And this linear strip ceiling machine adopts advanced manufacturing technology and high-precision control system, which can strictly control every detail in the production process. Customers reflect that the surface of the linear strip ceiling is smooth and burr-free, which avoids the trouble of subsequent processing and greatly improves production efficiency.

Drawing About Linear Strip Ceiling

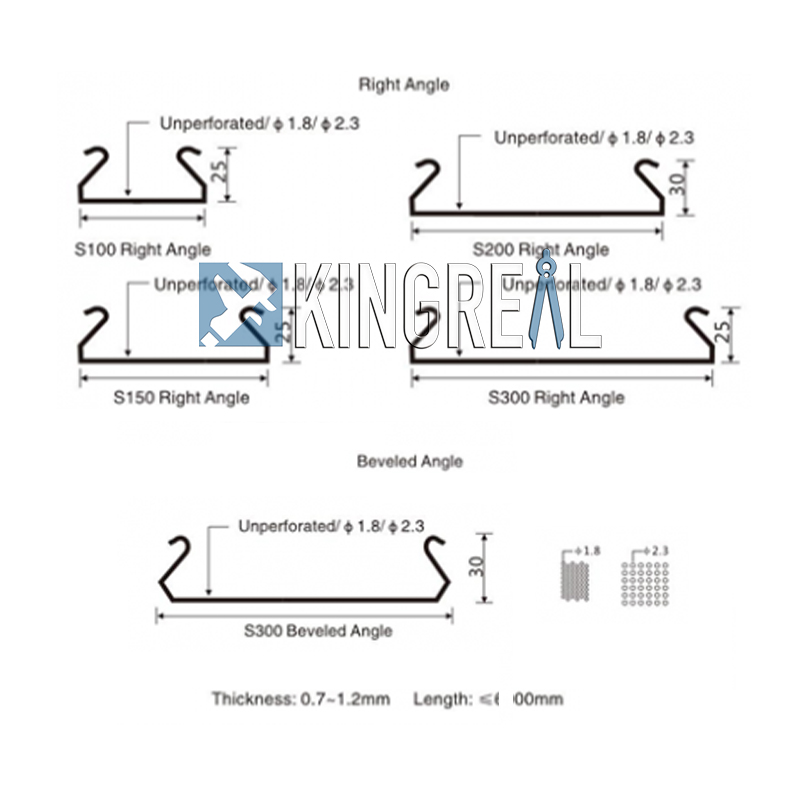

84R Linear Strip Ceiling

S-Type Linear Strip Ceiling

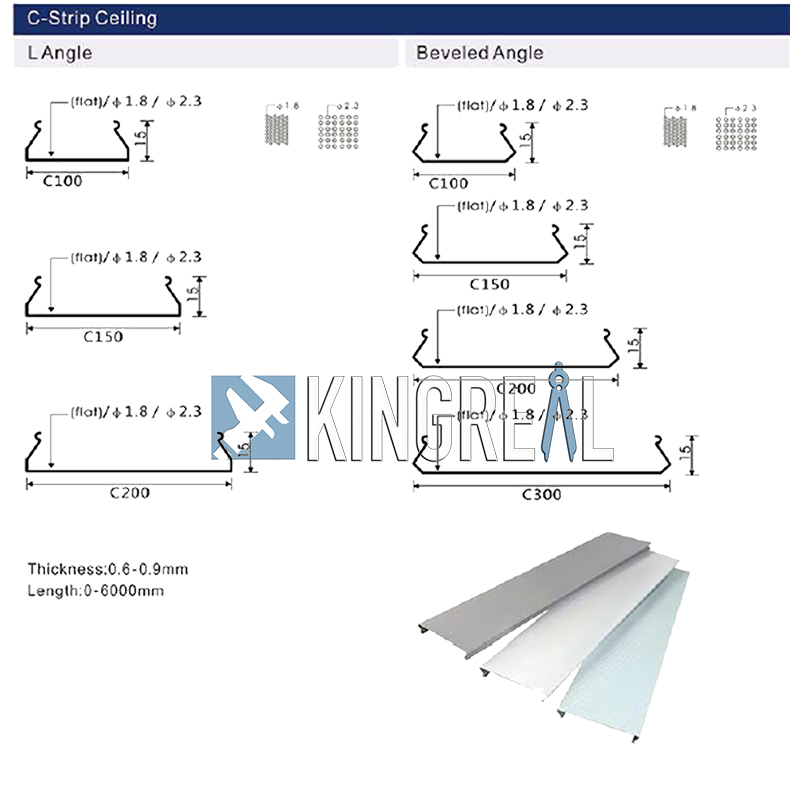

C Type Linear Strip Ceiling

Application of Linear Strip Ceiling Making Machine

| The linear strip ceilings of different types and sizes produced by KINGREAL CEILING MACHINERY linear strip ceiling machines are widely used in commercial buildings, gymnasiums, gas stations, office buildings, hotels, hospitals, schools, airports, subway stations and other public places. It has the characteristics of light weight, corrosion resistance, fire resistance, waterproof, dustproof and easy to clean, and can be disassembled and assembled separately, which is convenient for future maintenance and equipment maintenance. |  |

After-sales Service about Linear Strip Ceiling Making Machine

KINGREAL CEILING MACHINERY linear strip ceiling machines have been sold to many countries such as the United Kingdom, Canada, Greece, Turkey, Russia, Vietnam, India, etc., and KINGREAL CEILING MACHINERY engineers went to the customer's factory to install the linear strip ceiling machine and provide machine operation training for the workers.

(1)Machine installation process

Site survey: The engineer first conducts a detailed survey of the customer's factory to ensure that the installation location meets the requirements of linear strip ceiling making machine operation and takes into account the overall layout of the production line.

Equipment installation: After confirming the site conditions, the engineer will quickly install the linear strip ceiling machine, including fixing the equipment, connecting the power supply and debugging the mechanical parts to ensure that all functions are functioning normally.

System debugging: After the installation is completed, the engineer will conduct a comprehensive system debugging of the linear strip ceiling making machine to ensure that the parameters of the strip buckle machine are set correctly and the operation is smooth.

(2)Machine training

While the machine is being installed, KINGREAL CEILING MACHINERY will also provide workers with comprehensive operation training:

Operation demonstration: The engineer will demonstrate in detail how to operate the linear strip ceiling machine, including starting, stopping, adjusting parameters and daily maintenance.

Practical training: The workers will perform actual operations under the guidance of the engineer to ensure that they can master the use of the linear strip ceiling machine.

Question answering: During the training, workers can ask any questions, and the engineer will answer them one by one to ensure that each operator can understand clearly.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)