Aluminum Strip Ceiling Panel Machine

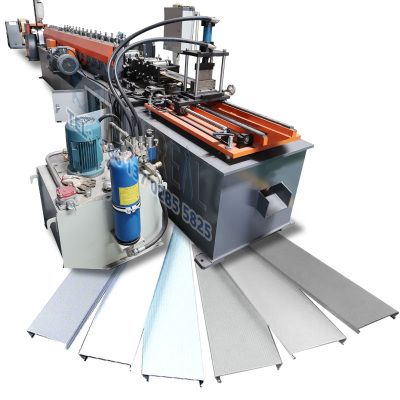

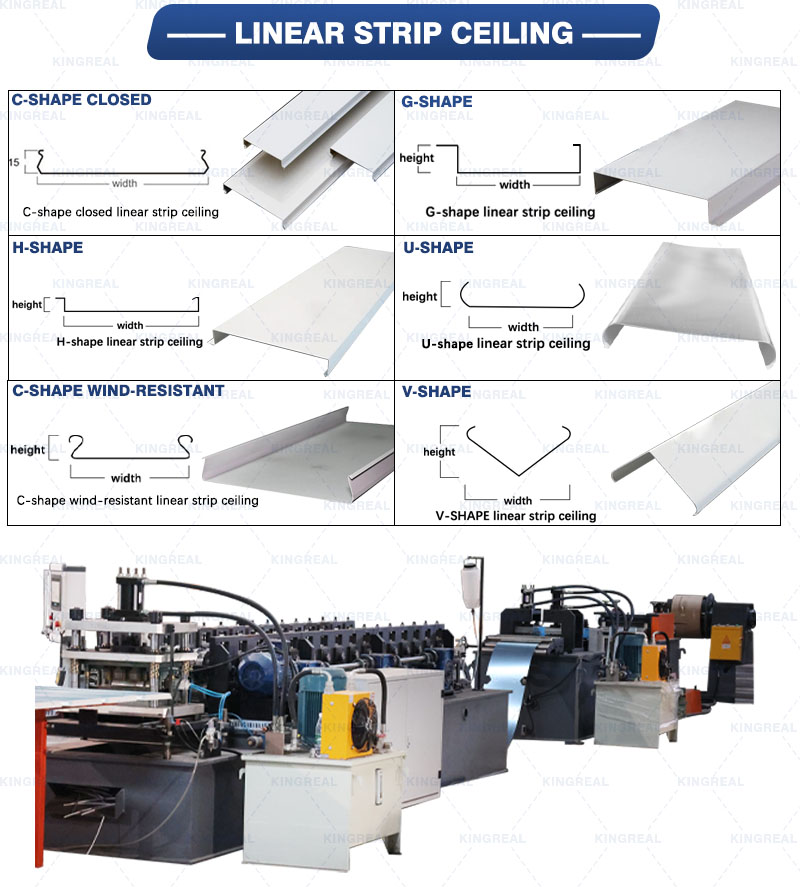

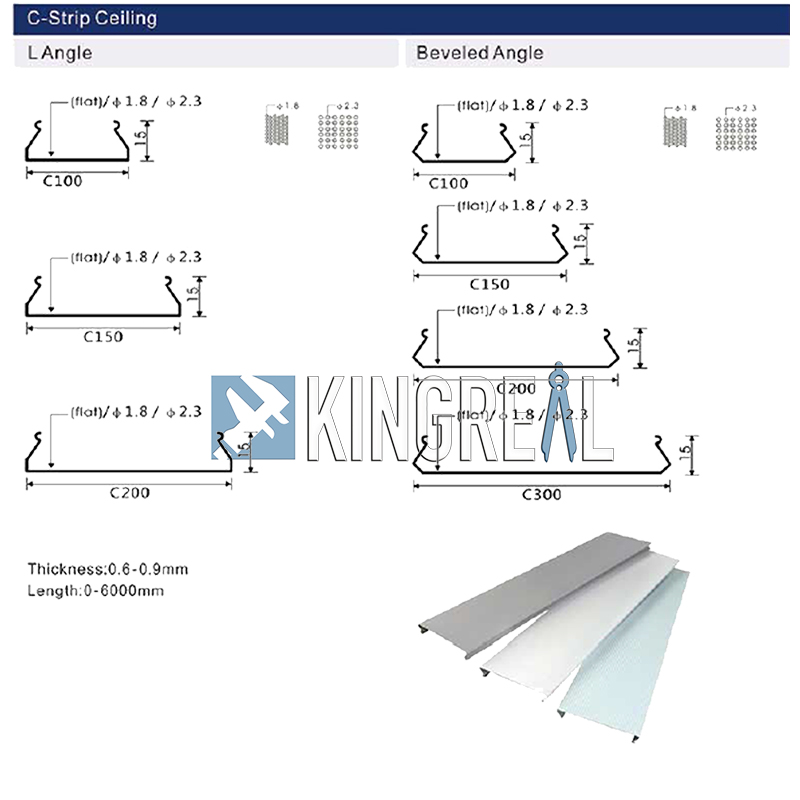

KINGREAL CEILING MACHINERY aluminum strip ceiling panel machine is designed for producing precise, high-strength, and wind-resistant linear strip ceilings. This suspended strip ceiling panel machine allows for the flexible production of linear strip ceilings in varying widths (100-300 mm) on the same production line to meet diverse customer needs.

- KINGREAL CEILING MACHINERY

Details

Video About Aluminum Strip Ceiling Panel Machine

Description of Aluminum Strip Ceiling Panel Machine

In modern construction, linear linear strip ceilings are widely used due to their superior performance and aesthetic appeal. The KINGREAL CEILING MACHINERY suspended strip ceiling panel machine is specifically designed to produce precise, high-strength, wind-resistant linear strip ceilings. Aluminum strip ceiling panel machine efficiently processes aluminum sheets or roll-coated sheets into a variety of strip types. This suspended strip ceiling panel machine can flexibly produce linear strip ceilings in varying widths (100-300mm) on the same production line to meet diverse customer needs. Linear strip ceilings play a vital role in many large-scale public projects, particularly in offices, schools, hospitals, commercial centers, sports centers, airport terminals, banks, and hotels. They are highly valued for their fast installation, precise tolerances, and excellent sound absorption, all of which can be achieved with KINGREAL CEILING MACHINERY aluminum strip ceiling panel machines. Whether meeting design or functional requirements, the KINGREAL CEILING MACHINERY suspended strip ceiling panel machine provides customers with the perfect solution. |  |

Working Process of Aluminum Strip Ceiling Panel Machine

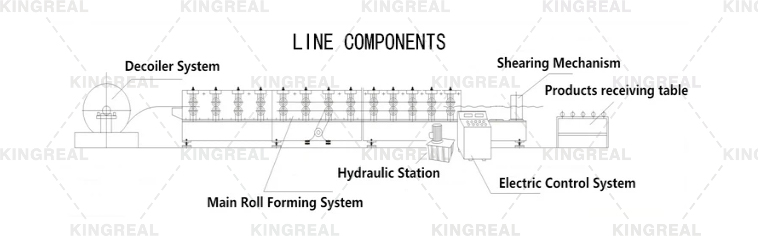

Hydraulic Decoiler -- Precision Straightener -- Hydraulic Punching Station(Optional) -- Main Roll Forming Machine -- Cutting Station -- Product Table

Advantages of Aluminum Strip Ceiling Panel Machine

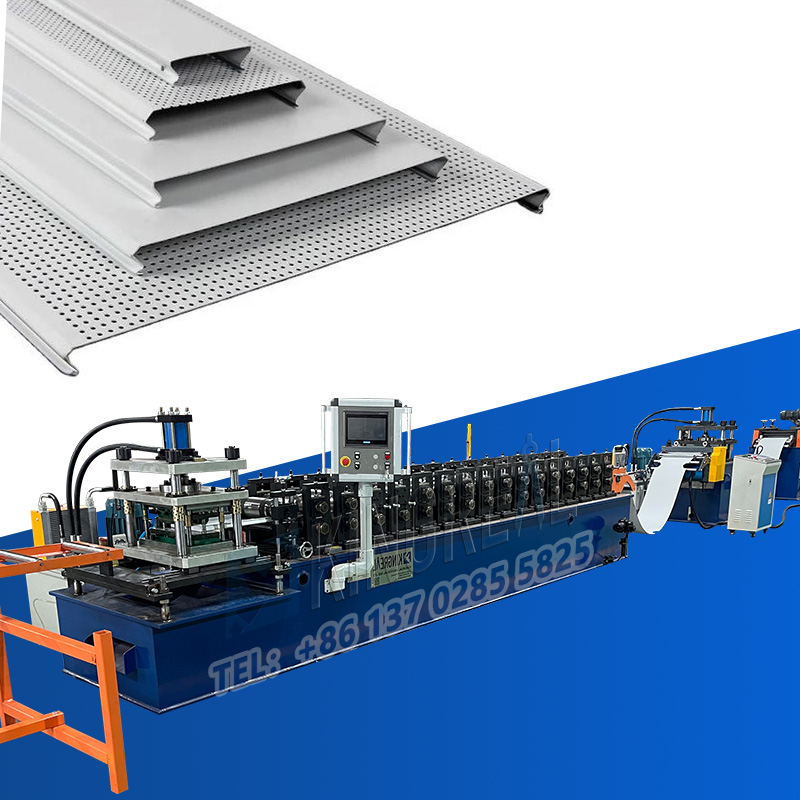

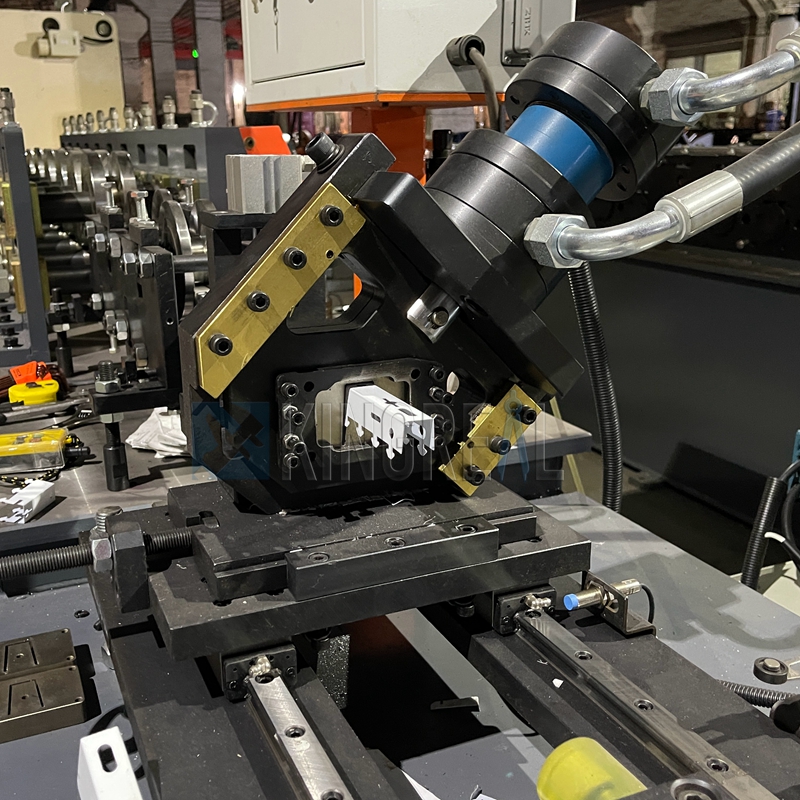

1. High precision aluminum strip ceiling panel machine The KINGREAL CEILING MACHINERY suspended strip ceiling panel machine utilizes high-quality materials and advanced processes to ensure high precision during production. First, the forming rollers are made of CR12MOV die steel, ensuring no wear or deformation during long-term operation. This material also offers excellent processing properties, enabling the creation of more complex and detailed profiles. Second, the shearing station blades utilize a D2 hardening treatment, achieving a hardness of up to HRC 60°C, ensuring sharpness and durability during the cutting process. The high-hardness of the blades enables precise cutting of metal sheets, eliminating inaccuracies caused by blade wear. This high-precision cutting capability ensures seamless installation of the linear strip ceilings, eliminating gaps and unevenness at the joints, significantly enhancing the overall aesthetics and functionality of the ceiling. |  |

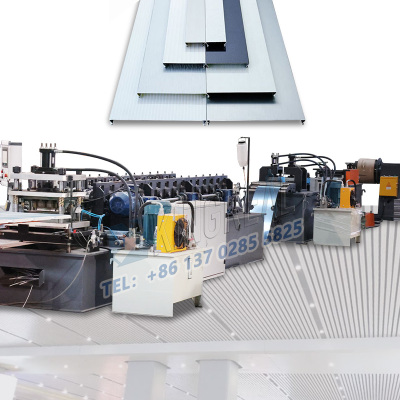

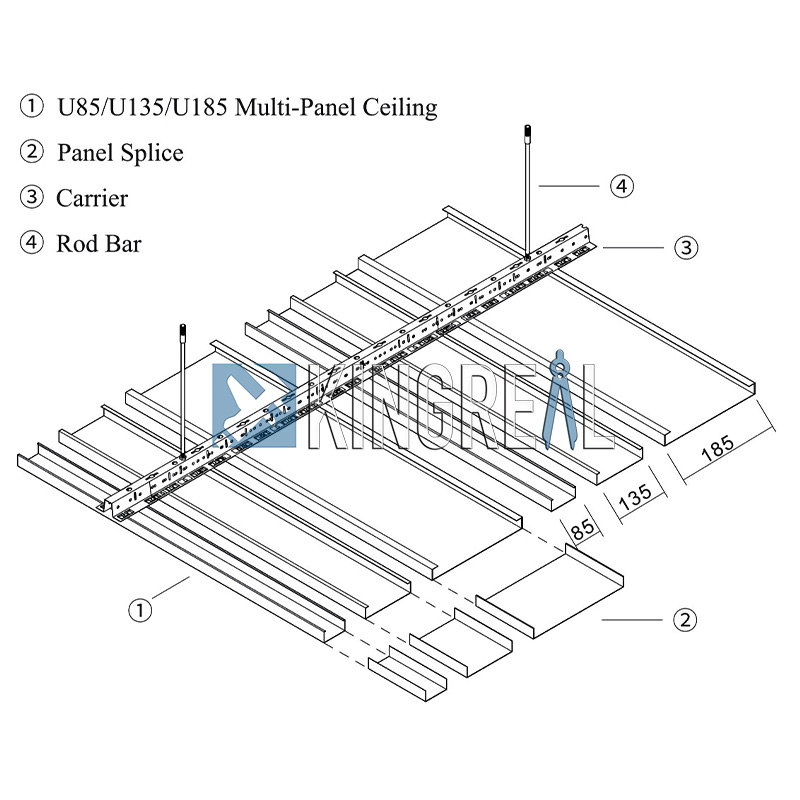

2. Complete linear strip ceiling solution In addition to high-quality aluminum strip ceiling panel machines, KINGREAL CEILING MACHINERY also develops linear strip ceiling carrier machines. These linear strip ceiling carrier machines work perfectly with the suspended strip ceiling panel machines, producing linear strip ceiling carrier that securely connect to the linear strip ceilings, forming a complete linear strip ceiling system. This integrated system ensures a simple and secure installation process, avoiding installation difficulties caused by mismatched equipment. |  |

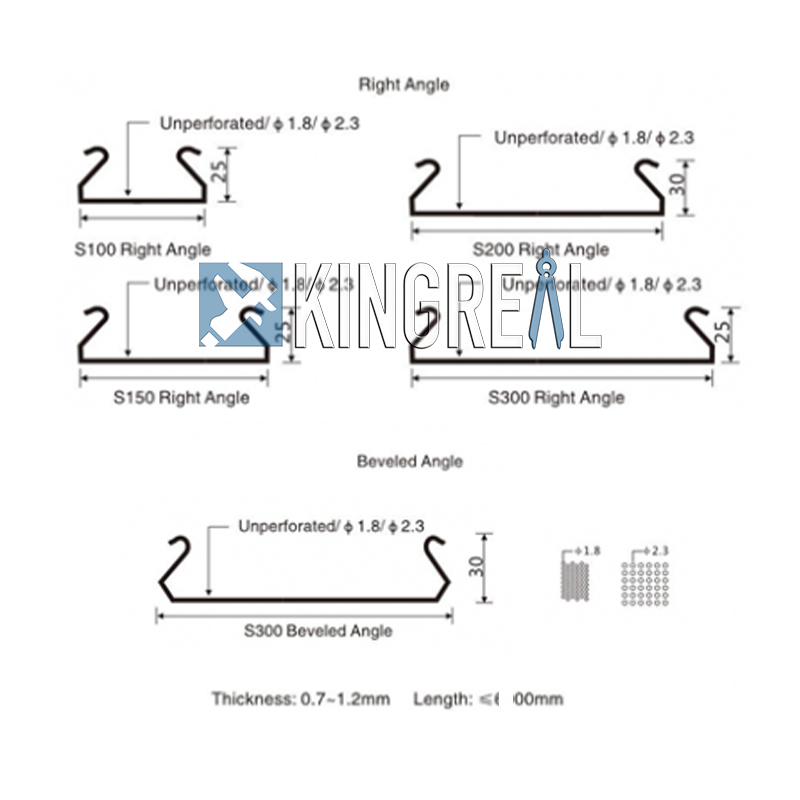

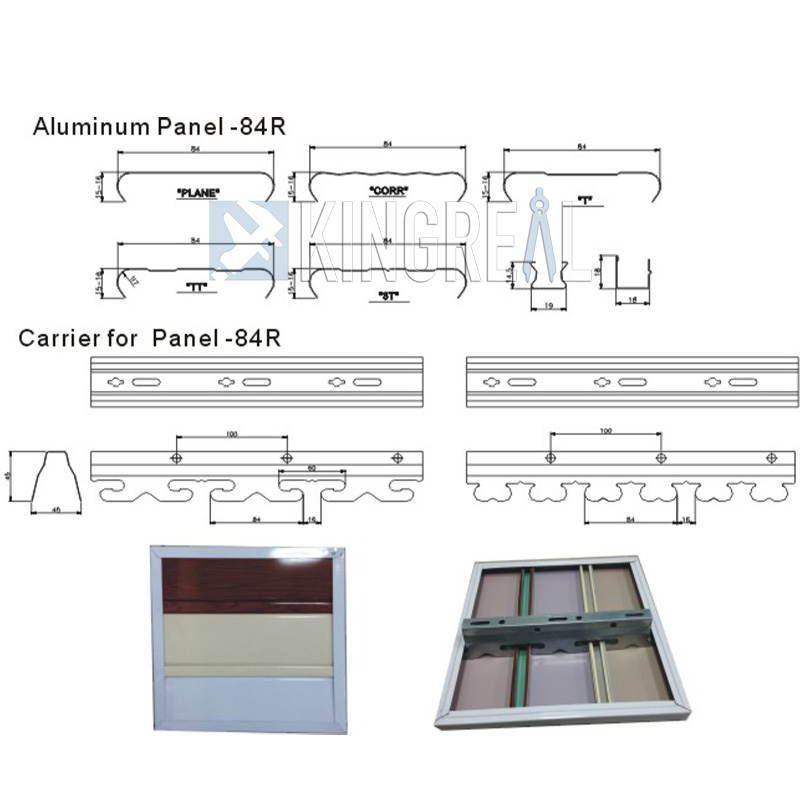

3. Multiple finished product types from aluminum strip ceiling panel machine To meet increasingly diverse market demands, KINGREAL CEILING MACHINERY suspended strip ceiling panel machines can produce a variety of strip ceiling types, including 84R, 84G, 84B, 84C, S300, 300C, 180B, and 130B. These strip ceiling sizes include both plain and perforated options, meeting the design needs of diverse environments. For customers who prefer to directly produce perforated strip ceilings, KINGREAL CEILING MACHINERY offers a punching station for aluminum strip ceiling panel machine. This design allows customers to form and punch the strip ceilings on the same machine, significantly improving production efficiency and reducing subsequent secondary processing. This integrated production process not only saves customers time but also reduces production costs. |  |

4. Single-specification & multi-specification suspended strip ceiling panel machine When producing linear strip ceilings, different customers often have varying needs. To address this, KINGREAL CEILING MACHINERY offers both single-specification and multi-specification aluminum strip ceiling panel machines, allowing customers to choose based on their specific production needs. If a customer's production needs are relatively simple, a single-specification suspended strip ceiling panel machine is a wise choice. This aluminum strip ceiling panel machine is dedicated to producing a single strip ceiling specification, avoiding unnecessary resource waste. For customers who need to produce multiple specifications, a multi-specification suspended strip ceiling panel machine offers greater flexibility. Easily adjusted via a PLC control panel, this aluminum strip ceiling panel machine can automatically produce strip ceilings of varying widths and types. Customers simply enter the desired specifications on the control panel, and the suspended strip ceiling panel machine quickly adjusts to the appropriate production mode, eliminating the hassle of purchasing multiple aluminum strip ceiling panel machines. |  |

Introduction to Linear Strip Ceiling

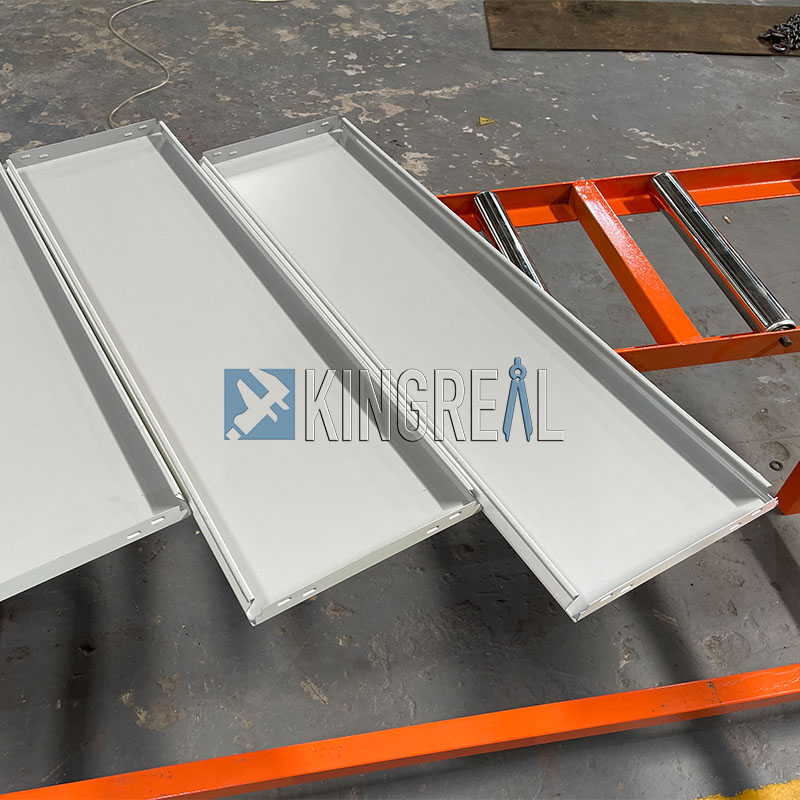

linear strip ceilings produced by KINGREAL CEILING MACHINERY suspended strip ceiling panel machines are not only beautiful and practical, but also easily disassembled for maintenance and installation. These linear strip ceilings can be mixed and matched in various sizes and heights to create the desired look. KINGREAL CEILING MACHINERY aluminum strip ceiling panel machines offer a variety of common models, including 30BD-30BXD, 75C-150C-225C, 84B, 84C, 84R, and 70U. For special production requirements, customers are welcome to provide KINGREAL CEILING MACHINERY with their drawings and will be happy to assist. |  |

Applications of Aluminum Strip Ceiling Panel Machine

The strip ceilings produced by KINGREAL CEILING MACHINERY suspended strip ceiling panel machines are widely used in a variety of applications, including office buildings, schools, hospitals, commercial centers, sports centers, airport terminals, banks, and hotels. These strip ceilings are also widely used in gas stations. The use of high-quality aluminum and the high-precision aluminum strip ceiling panel machines ensure the smoothness and stability of strip ceilings. Strip ceilings are widely used due to their excellent fire resistance, lightweight design, and stable mounting system, meeting the stringent fire and wind resistance requirements of gas stations. |  |

Drawing About Linear Strip Ceiling

S-Type Linear Strip Ceiling

84R Linear Strip Ceiling

C-Type Linear Strip Ceiling

B-Type Linear Strip Ceiling

2025 Suspended Strip Ceiling Panel Machine Project

In 2025, KINGREAL CEILING MACHINERY engineers traveled to Vietnam and the UK to install aluminum strip ceiling panel machines for customers and provide training on machine operation. After inspecting the customers factory, KINGREAL CEILING MACHINERY engineers discussed the suspended strip ceiling panel machine's installation location and provided professional recommendations. They then began connecting the aluminum strip ceiling panel machine's precision components, including the decoiler, leveling machine, punching station, roll forming machine, and shearing station, to form a complete production line.

After the suspended strip ceiling panel machine was installed, KINGREAL CEILING MACHINERY engineers loaded the metal coils for a test run, setting various parameters to ensure the KINGREAL CEILING MACHINERY aluminum strip ceiling panel machine performs optimally under varying conditions. During the training, KINGREAL CEILING MACHINERY engineers explained the suspended strip ceiling panel machine's operating procedures in detail to ensure workers could operate the aluminum strip ceiling panel machine independently. They also provided guidance on routine maintenance and helped them resolve any potential issues.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)